Content Menu

● Introduction to SMT Line PCB Loaders

>> Key Features of SMT Line PCB Loaders

● Benefits of Using SMT Line PCB Loaders

>> Reduced Downtime

>> Increased Productivity

>> Improved Quality Control

>> Enhanced Efficiency

● Strategies for Optimizing SMT Line Efficiency

● Applications of SMT Line PCB Loaders

● Future Trends in SMT Line PCB Loaders

● Case Studies: Implementing SMT Line PCB Loaders

● Maintenance and Troubleshooting of SMT Line PCB Loaders

● Conclusion

● Frequently Asked Questions

>> 1. What is the primary function of an SMT line PCB loader?

>> 2. How do SMT line PCB loaders reduce production downtime?

>> 3. What are the key benefits of using SMT line PCB loaders?

>> 4. Can SMT line PCB loaders be used with different types of PCBs?

>> 5. How often should SMT line PCB loaders be maintained?

● Citations:

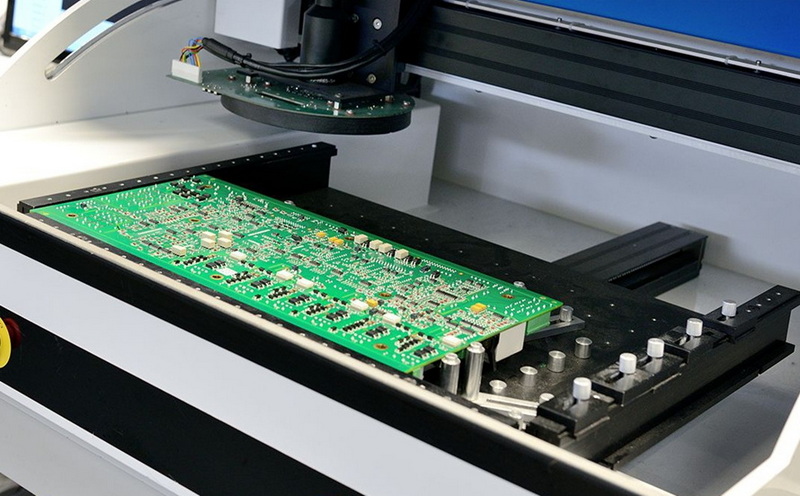

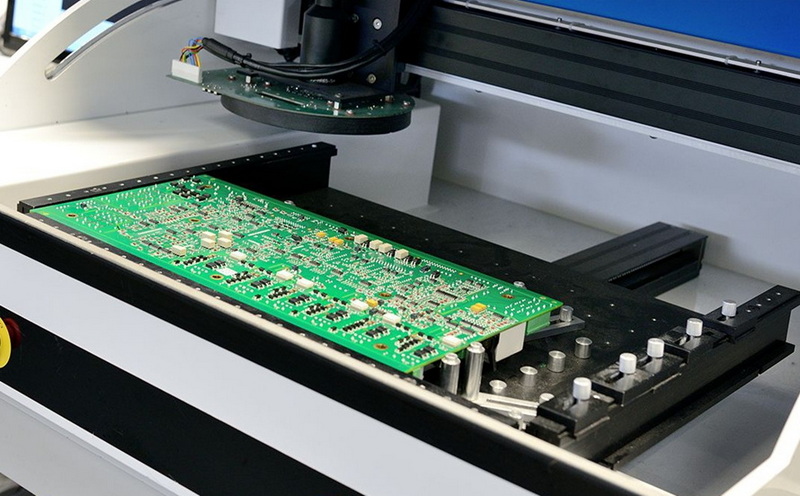

In the realm of electronics manufacturing, Surface Mount Technology (SMT) plays a pivotal role in the assembly and production of printed circuit boards (PCBs). One crucial component in this process is the SMT line PCB loader, which is designed to automate the loading of PCBs onto the production line. This automation significantly enhances efficiency, reduces manual errors, and minimizes production downtime. In this article, we will explore how an SMT line PCB loader can reduce production downtime and improve overall manufacturing productivity.

Introduction to SMT Line PCB Loaders

SMT line PCB loaders are integral to modern electronics manufacturing, serving as the first step in the SMT assembly process. These machines automatically load bare PCBs onto the production line, ensuring that each board is correctly positioned and securely placed for subsequent processing stages. The use of SMT line PCB loaders not only streamlines the production process but also ensures that the PCBs are handled gently, reducing the risk of damage to delicate components.

Key Features of SMT Line PCB Loaders

1. Automation and Efficiency: By automating the loading process, SMT line PCB loaders significantly increase production speed and efficiency. This allows manufacturers to handle multiple PCBs simultaneously, reducing the time required for each production cycle.

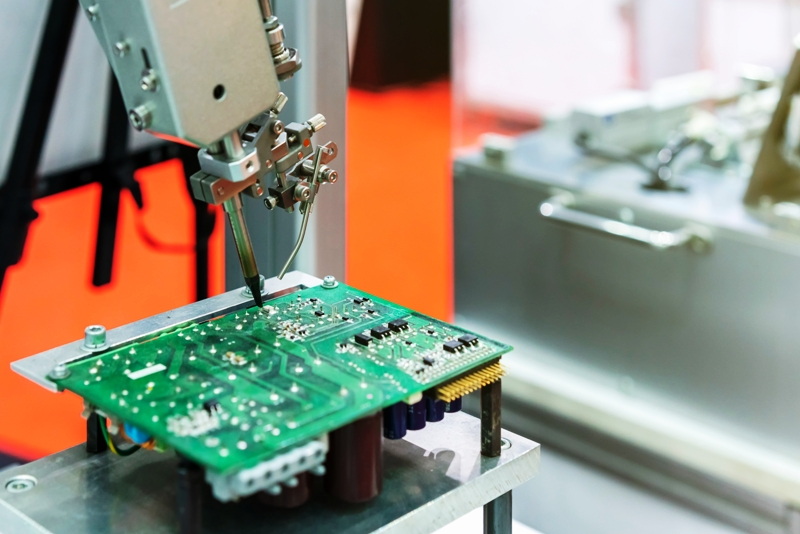

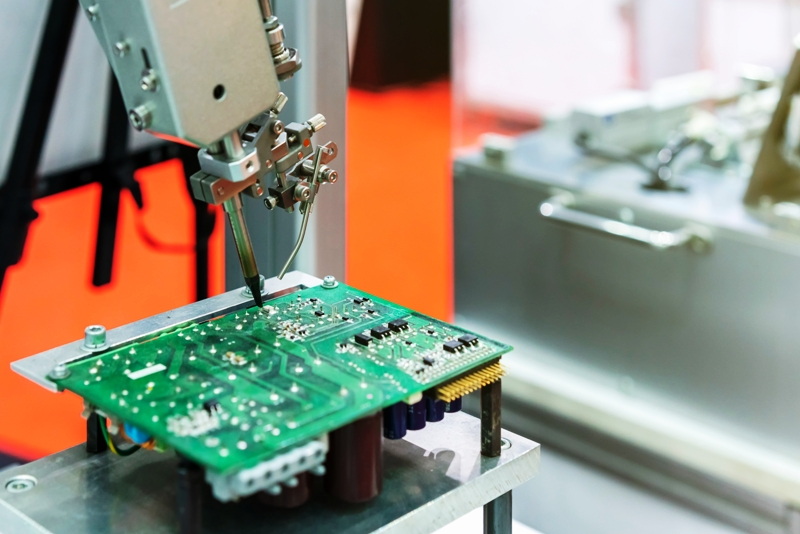

2. Precision and Accuracy: Equipped with advanced vision systems, these loaders ensure accurate detection of component positions and orientations, minimizing errors during the loading process.

3. Adaptability: SMT line PCB loaders are designed to accommodate different PCB sizes and types, making them versatile for large-scale manufacturing operations.

4. Reliability and Maintenance: Constructed with robust materials and designed for minimal wear, these machines are highly reliable and require less maintenance compared to manual loading systems.

5. Cost Savings: By reducing the need for manual labor, SMT line PCB loaders lead to substantial cost savings on wages and related expenses.

Benefits of Using SMT Line PCB Loaders

Reduced Downtime

One of the primary benefits of SMT line PCB loaders is their ability to reduce production downtime. By automating the loading process, these machines ensure that PCBs are consistently fed into the production line without interruptions. This consistency is crucial for maintaining continuous production flow and minimizing idle time.

Increased Productivity

The automation provided by SMT line PCB loaders allows for higher production volumes in less time. This increased productivity is due to the machines' ability to handle multiple PCBs simultaneously and their precision in placing components, which reduces the need for rework and repair.

Improved Quality Control

SMT line PCB loaders enhance quality control by minimizing errors during the loading process. This ensures that each PCB is correctly positioned and securely placed, leading to improved customer satisfaction and fewer returns or warranty claims.

Enhanced Efficiency

These loaders improve work efficiency by allowing operators to focus on other tasks while the machine handles the loading process. This not only saves labor but also enables more efficient use of human resources within the manufacturing facility.

Strategies for Optimizing SMT Line Efficiency

To maximize the benefits of SMT line PCB loaders, manufacturers should consider the following strategies:

1. Streamline Production Line Layout: Ensure that the production line is well-organized to minimize material handling and reduce the risk of errors.

2. Invest in Advanced Technology: Utilize state-of-the-art SMT line machines that offer enhanced precision and faster cycle times.

3. Regular Maintenance: Regularly maintain SMT line PCB loaders to prevent mechanical failures and ensure continuous operation.

4. Training and Support: Provide operators with comprehensive training on operating and maintaining the loaders to optimize their performance.

5. Continuous Monitoring: Continuously monitor production metrics to identify bottlenecks and optimize efficiency.

Applications of SMT Line PCB Loaders

SMT line PCB loaders are widely used in various electronic device manufacturing processes, including:

- Smartphones and Computers: These loaders are essential for the high-volume production of consumer electronics.

- Assembly Lines: They are used to speed up the manufacturing process and increase efficiency on assembly lines.

- Quality Control: Equipped with vision systems, these loaders help ensure that the correct PCBs are being loaded, maintaining quality control standards.

Future Trends in SMT Line PCB Loaders

The field of SMT manufacturing continues to evolve, with advancements in PCB loader technology on the horizon. Some key trends include:

- Enhanced Automation and AI Integration: Future SMT line PCB loaders are likely to incorporate advanced automation features and artificial intelligence (AI). These enhancements will enable loaders to adapt to varying PCB designs and production requirements dynamically.

- Improved Connectivity and IoT: Integration with the Internet of Things (IoT) will allow SMT line PCB loaders to communicate seamlessly with other equipment in the assembly line. This connectivity will facilitate real-time data sharing and process optimization.

- Eco-Friendly Designs: As sustainability becomes a priority, manufacturers will develop SMT line PCB loaders with eco-friendly features. These designs will focus on reducing energy consumption and minimizing waste.

Case Studies: Implementing SMT Line PCB Loaders

Several companies have successfully integrated SMT line PCB loaders into their production lines, achieving significant improvements in efficiency and productivity. For instance, a high-tech enterprise in Jiangsu Province, China, utilized a fully automatic PCB loader machine as part of its SMT production line. This machine automated the loading of PCBs, improving production efficiency and reducing manual errors.

Another example is the use of 90 Degree SMT Loader Unloaders, which offer robust designs and advanced features like intelligent diagnostics and seamless connectivity with other equipment via SMEMA interfaces. These loaders enhance production stability and minimize downtime by providing quick issue resolution through automatic fault code displays.

Maintenance and Troubleshooting of SMT Line PCB Loaders

To ensure optimal performance and minimize downtime, regular maintenance of SMT line PCB loaders is crucial. This includes:

- Cleaning and Lubrication: Regularly clean the machine to prevent dust buildup and lubricate moving parts to reduce wear.

- Fault Detection: Utilize built-in diagnostic systems to quickly identify and resolve issues.

- Training Operators: Ensure that operators are well-trained in operating and troubleshooting the loaders.

Conclusion

In conclusion, SMT line PCB loaders play a critical role in reducing production downtime and enhancing overall manufacturing efficiency in the electronics industry. By automating the loading process, these machines ensure consistent production flow, minimize errors, and improve quality control. As technology continues to evolve, investing in advanced SMT line PCB loaders will remain essential for manufacturers seeking to optimize their production processes and stay competitive in the market.

Frequently Asked Questions

1. What is the primary function of an SMT line PCB loader?

An SMT line PCB loader is designed to automatically load bare PCBs onto the production line, ensuring each board is correctly positioned and securely placed for subsequent processing stages.

2. How do SMT line PCB loaders reduce production downtime?

By automating the loading process, SMT line PCB loaders ensure that PCBs are consistently fed into the production line without interruptions, minimizing idle time and maintaining continuous production flow.

3. What are the key benefits of using SMT line PCB loaders?

The key benefits include increased efficiency, improved accuracy, reduced risk of damage to components, and substantial cost savings through reduced labor needs.

4. Can SMT line PCB loaders be used with different types of PCBs?

Yes, SMT line PCB loaders are designed to accommodate different PCB sizes and types, making them versatile for large-scale manufacturing operations.

5. How often should SMT line PCB loaders be maintained?

Regular maintenance is essential to prevent mechanical failures and ensure continuous operation. This includes keeping the machines free of debris, regular lubrication of moving parts, and checking for wear and tear.

Citations:

[1] https://www.tronstol.com/smt-assembly/loader-and-unloader/

[2] https://www.hct-smt.com/blog/maximizing-efficiency-with-the-smd-pcb-loader-set--a-comprehensive-guide

[3] https://www.qhsmt.com/2025/02/21/customer-case-qm81-smt-production-line-pcb-manufacturing/

[4] https://www.hayawin.com/product-list-loader.html

[5] https://www.hayawin.com/news-how-do-you-handle-pcbs-in-smt-production-line.html

[6] https://www.smtsite.com/resources/pcb-loader-unloader-improve-efficiency-and-accuracy.html

[7] https://www.nod-pcba.com/news/830-en.html

[8] https://smtmachineline.com/i-c-t-ldd-m-90-degree-smt-loader-unloader/

[9] https://www.smtfactory.com/Future-Trends-in-SMT-Lines-Innovations-Shaping-The-Electronics-Manufacturing-Industry-id44863586.html

[10] https://www.smtfactory.com/Optimizing-Efficiency-Strategies-for-A-Smooth-SMT-Line-Production-Process-id47463586.html

[11] https://www.smtfactory.com/How-do-you-handle-PCBs-in-SMT-Production-Line-id49155647.html

[12] https://www.itechsmt.com/blogs/news/smt-equipment-list-for-your-new-smt-manufacturing

[13] https://www.pcbsmtmachine.com/quality-14523249-modular-design-smt-mini-pcb-loader-machine-smt-conveyor-systems

[14] https://smtfuture.com/the-top-five-productivity-killers-in-the-pcb-industry/

[15] https://mermarinc.com/2022/12/24/smt-line/

[16] https://www.zetwerk.com/resources/knowledge-base/electronics-manufacturing-services-ems/smt-pcb-assembly-processes-benefits-and-applications/

[17] https://minearc.com/what-is-an-smt-line/

[18] https://www.jwide-smt.com/products/smt-pcb-magazine-loader/

[19] https://www.hayawin.com/resources/smt-line-an-efficient-and-cost-effective-production-line.html

[20] https://core-emt.com/board-handling