Content Menu

● Understanding the Role of Advanced SMT LED PCB Loaders

>> Key Functions of Advanced SMT LED PCB Loaders

● Benefits of Implementing Advanced SMT LED PCB Loaders

>> Enhanced Productivity

>> Improved Quality and Consistency

>> Cost Savings

>> Increased Safety

● Features of Advanced SMT LED PCB Loaders

>> PLC Control System

>> Vision Systems

>> Versatile Magazine Handling

>> Adjustable Pitch Distance

>> SMEMA Communication

● Impact on LED PCB Manufacturing

>> Precision in LED Placement

>> Handling Delicate Components

>> Supporting Miniaturization

● Choosing the Right Advanced SMT LED PCB Loader

>> Production Volume

>> PCB Specifications

>> Integration with Existing Equipment

>> Flexibility and Future-Proofing

● Case Studies: Success Stories with Advanced SMT LED PCB Loaders

>> Case Study 1: LED Lighting Manufacturer

>> Case Study 2: Consumer Electronics Company

● Future Trends in Advanced SMT LED PCB Loaders

● Conclusion

● FAQ

>> 1. What is the main advantage of using an advanced SMT LED PCB loader?

>> 2. How does an advanced SMT LED PCB loader improve product quality?

>> 3. Are advanced SMT LED PCB loaders suitable for small-scale production?

>> 4. How do advanced SMT LED PCB loaders contribute to cost savings?

>> 5. What future developments can we expect in advanced SMT LED PCB loader technology?

● Citations:

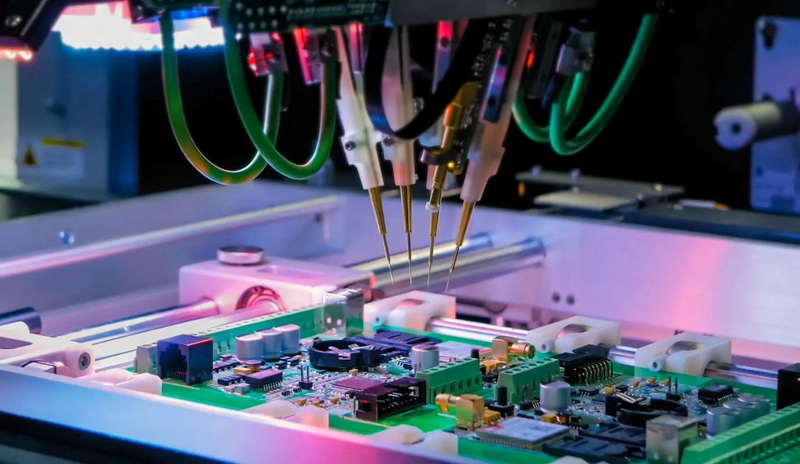

In the ever-evolving world of electronics manufacturing, efficiency and precision are paramount. One of the key components in achieving these goals is SMT LED PCB loaders. These sophisticated machines have revolutionized the way printed circuit boards (PCBs) are handled and processed, particularly in the production of LED-based products. This article will explore how an advanced SMT LED PCB loader can significantly enhance your PCB manufacturing process, offering insights into its benefits, features, and impact on overall production quality and efficiency.

Understanding the Role of Advanced SMT LED PCB Loaders

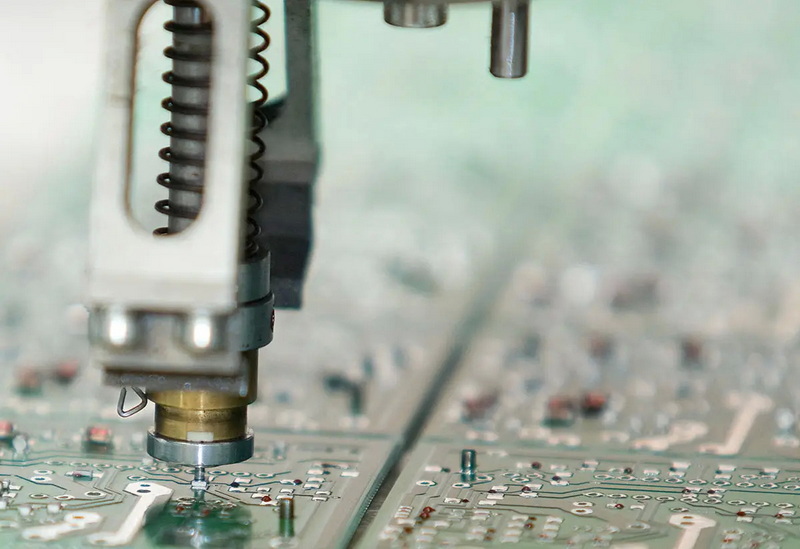

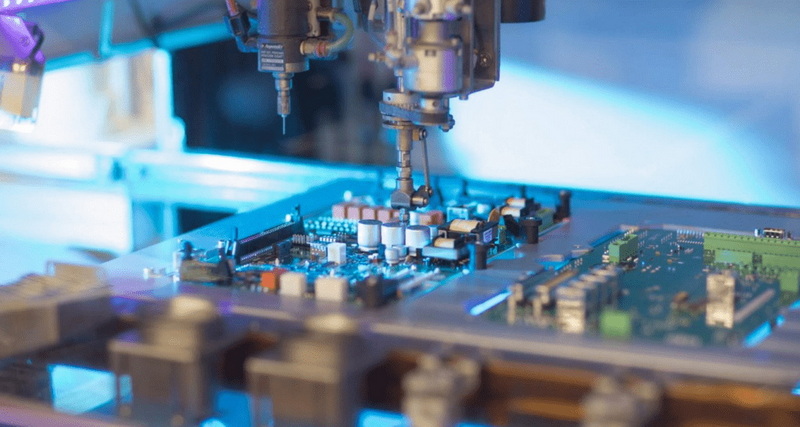

Advanced SMT LED PCB loaders are specialized machines designed to automate the loading of PCBs into surface mount technology (SMT) assembly lines[1]. These loaders play a crucial role in the manufacturing process by ensuring that PCBs are handled with care and precision, minimizing the risk of damage and improving overall production efficiency.

Key Functions of Advanced SMT LED PCB Loaders

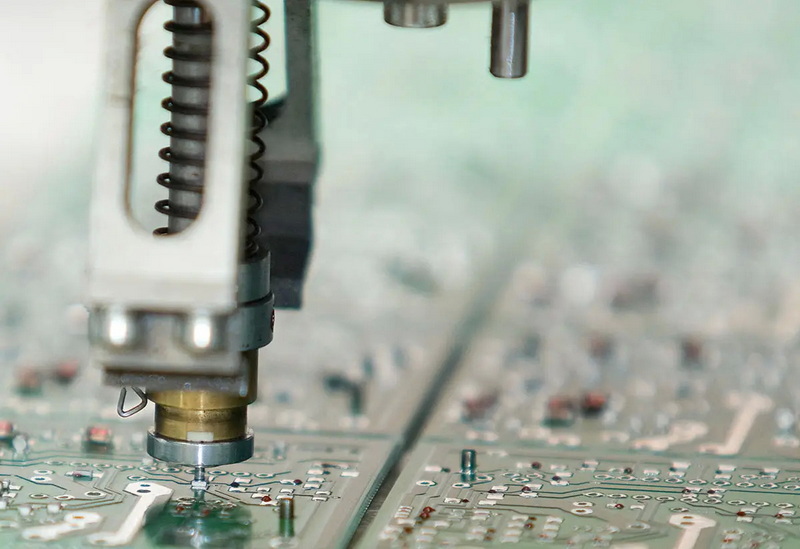

1. Automated Loading: The primary function of an advanced SMT LED PCB loader is to automate the PCB loading process. This automation significantly reduces the need for manual handling, which in turn minimizes the risk of damage to delicate components and increases production speed[1].

2. Accurate Positioning: These loaders are equipped with high-precision mechanisms that ensure each PCB is accurately positioned on the conveyor. This precise alignment is crucial for subsequent processes such as component placement and soldering[1].

3. Versatility: Advanced SMT LED PCB loaders are designed to handle a wide range of PCB sizes and thicknesses. This versatility makes them suitable for various manufacturing requirements, from small-scale production to high-volume operations[1].

4. Speed and Efficiency: By automating the loading process, these machines significantly increase the speed and efficiency of PCB assembly lines. This boost in productivity leads to higher production outputs and shorter lead times[1].

Benefits of Implementing Advanced SMT LED PCB Loaders

The integration of advanced SMT LED PCB loaders into your manufacturing process offers numerous advantages that can significantly improve your operations and bottom line.

Enhanced Productivity

One of the most significant benefits of using an advanced SMT LED PCB loader is the substantial increase in productivity. These machines can handle multiple PCBs quickly and accurately, reducing bottlenecks and downtime in the production line[1]. The automated loading process eliminates the need for manual intervention, allowing for continuous operation and higher throughput.

Improved Quality and Consistency

Manual loading of PCBs can lead to inconsistencies and potential damage. Advanced SMT LED PCB loaders ensure that each board is handled with utmost care and precision[1]. This level of consistency in handling translates to improved overall product quality, reduced defect rates, and enhanced customer satisfaction.

Cost Savings

While the initial investment in an advanced SMT LED PCB loader may seem significant, the long-term cost savings are substantial. These savings are realized through:

- Reduced labor costs due to automation

- Lower defect rates, resulting in less waste and rework

- Higher production efficiency, leading to increased output with the same resources[1]

Increased Safety

Automating the PCB loading process with an advanced SMT LED PCB loader enhances workplace safety by reducing the need for manual handling. This minimizes the risk of injuries associated with repetitive tasks and the handling of delicate electronic components[1].

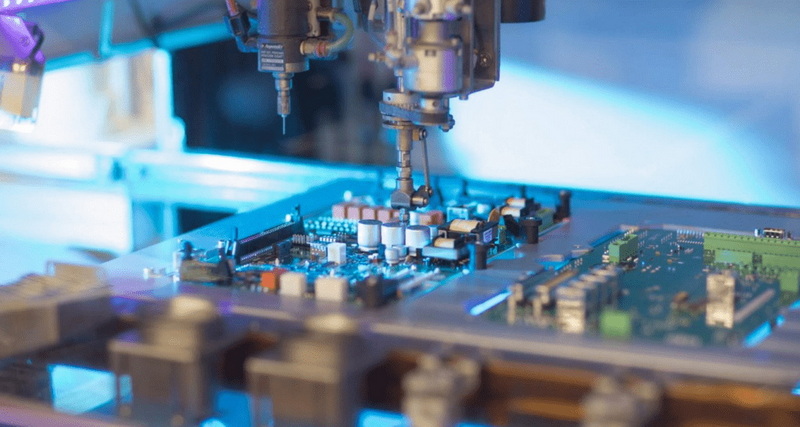

Features of Advanced SMT LED PCB Loaders

To fully appreciate the impact of these machines on PCB manufacturing, it's essential to understand their key features:

PLC Control System

Advanced SMT LED PCB loaders are typically equipped with a Programmable Logic Controller (PLC) system. This sophisticated control system offers precise control over the loading process, making the machines easy to operate and maintain[2].

Vision Systems

Many advanced SMT LED PCB loaders incorporate advanced vision systems. These systems enable accurate detection of component positions and orientations, ensuring precise placement on the PCB[3].

Versatile Magazine Handling

These loaders often feature versatile magazine handling capabilities. For instance, some models can handle dual magazines simultaneously, allowing for higher throughput and greater efficiency[2].

Adjustable Pitch Distance

Advanced SMT LED PCB loaders often offer adjustable pitch distances, typically ranging from 10 to 40mm. This feature allows the machine to accommodate various PCB sizes and configurations[2].

SMEMA Communication

Standard SMEMA (Surface Mount Equipment Manufacturers Association) communication interfaces are a common feature in advanced SMT LED PCB loaders. This allows for seamless integration with other equipment in the SMT assembly line[2].

Impact on LED PCB Manufacturing

The use of advanced SMT LED PCB loaders has a particularly significant impact on the manufacturing of LED PCBs. LED technology has become increasingly prevalent in various applications, from lighting to displays, and the demand for high-quality, efficient LED PCB production has grown accordingly.

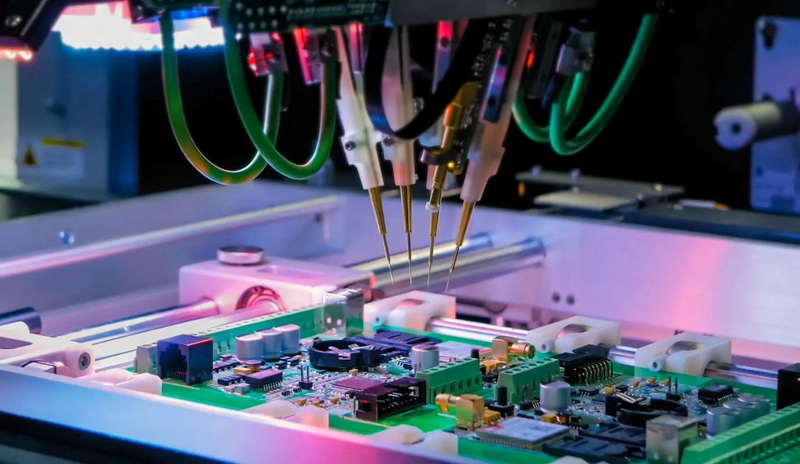

Precision in LED Placement

LED components often require extremely precise placement on the PCB. Advanced SMT LED PCB loaders contribute to this precision by ensuring that the PCBs are accurately positioned for subsequent processes[3]. This precision is crucial for the performance and reliability of LED products.

Handling Delicate Components

LED components can be delicate and sensitive to physical stress. The gentle handling provided by advanced SMT LED PCB loaders helps protect these components from damage during the manufacturing process[3].

Supporting Miniaturization

As LED technology continues to evolve, there's a growing trend towards miniaturization. Advanced SMT LED PCB loaders are capable of handling smaller PCBs and components, supporting this trend towards more compact LED products[7].

Choosing the Right Advanced SMT LED PCB Loader

Selecting the appropriate advanced SMT LED PCB loader for your manufacturing needs requires careful consideration of several factors:

Production Volume

The choice of loader should align with your production volume. For high-volume production, consider loaders with dual magazine capabilities or customized solutions designed for rapid throughput[1].

PCB Specifications

Consider the size, thickness, and weight of the PCBs you typically handle. Ensure that the loader you choose can accommodate your specific PCB specifications[1].

Integration with Existing Equipment

Look for loaders that offer standard communication interfaces (like SMEMA) to ensure seamless integration with your existing SMT assembly line[2].

Flexibility and Future-Proofing

Choose a loader that offers flexibility in terms of PCB sizes and types it can handle. This will help future-proof your investment as your production needs evolve[3].

Case Studies: Success Stories with Advanced SMT LED PCB Loaders

To illustrate the real-world impact of advanced SMT LED PCB loaders, let's look at a couple of hypothetical case studies:

Case Study 1: LED Lighting Manufacturer

A medium-sized LED lighting manufacturer implemented an advanced SMT LED PCB loader in their production line. Within six months, they reported:

- 30% increase in production output

- 50% reduction in PCB handling errors

- 20% decrease in overall production costs

These improvements allowed the company to take on larger orders and expand their market share.

Case Study 2: Consumer Electronics Company

A consumer electronics company specializing in LED-based displays integrated an advanced SMT LED PCB loader into their manufacturing process. The results after one year included:

- 40% reduction in production time for complex LED display PCBs

- 25% improvement in product quality and reliability

- Ability to produce 15% smaller LED display units due to improved precision

These enhancements enabled the company to launch a new line of compact, high-performance LED displays, significantly boosting their competitiveness in the market.

Future Trends in Advanced SMT LED PCB Loaders

As technology continues to evolve, we can expect to see further advancements in SMT LED PCB loaders. Some potential future trends include:

1. AI and Machine Learning Integration: Future loaders may incorporate AI and machine learning algorithms to optimize loading processes and predict maintenance needs.

2. Enhanced Connectivity: With the growth of Industry 4.0, we can expect to see loaders with improved connectivity features, allowing for better data collection and analysis.

3. Increased Automation: Future loaders may offer even higher levels of automation, potentially integrating with robotic systems for a fully automated PCB handling process.

4. Sustainability Features: As environmental concerns grow, future loaders may incorporate energy-saving features and use more sustainable materials in their construction.

Conclusion

Advanced SMT LED PCB loaders have become an indispensable tool in modern electronics manufacturing, particularly in the production of LED-based products. These sophisticated machines offer numerous benefits, including enhanced productivity, improved quality control, cost savings, and increased safety. By automating the PCB loading process, they significantly streamline the manufacturing workflow, allowing for higher production outputs and better overall product quality.

The key features of advanced SMT LED PCB loaders, such as PLC control systems, vision systems, and versatile magazine handling, contribute to their effectiveness in handling the precise requirements of LED PCB manufacturing. As the electronics industry continues to evolve, with trends towards miniaturization and increased complexity, these loaders will play an even more crucial role in maintaining efficiency and quality in production lines.

When considering the implementation of an advanced SMT LED PCB loader, it's important to carefully evaluate your specific manufacturing needs, including production volume, PCB specifications, and integration requirements. Choosing the right loader can lead to significant improvements in your manufacturing process, as illustrated by the case studies presented.

Looking to the future, we can expect continued advancements in SMT LED PCB loader technology, with potential developments in AI integration, enhanced connectivity, and increased automation. These innovations will further enhance the capabilities of these machines, ensuring they remain at the forefront of efficient and high-quality PCB manufacturing.

In conclusion, for businesses involved in LED PCB manufacturing, investing in an advanced SMT LED PCB loader is not just a matter of keeping up with technology – it's a strategic decision that can lead to substantial improvements in productivity, quality, and overall competitiveness in the rapidly evolving electronics market.

FAQ

1. What is the main advantage of using an advanced SMT LED PCB loader?

The main advantage of using an advanced SMT LED PCB loader is the significant increase in production efficiency and quality. These machines automate the PCB loading process, reducing manual handling errors, increasing speed, and ensuring consistent placement of PCBs for subsequent manufacturing steps[1][3].

2. How does an advanced SMT LED PCB loader improve product quality?

An advanced SMT LED PCB loader improves product quality by ensuring precise and consistent handling of PCBs. This reduces the risk of damage to delicate components and ensures accurate positioning for subsequent processes like component placement and soldering. The result is fewer defects and higher overall product reliability[1][3].

3. Are advanced SMT LED PCB loaders suitable for small-scale production?

Yes, advanced SMT LED PCB loaders can be suitable for small-scale production. Many models offer flexibility in terms of PCB sizes and types they can handle. While the initial investment might be significant, the improvements in efficiency and quality can make them worthwhile even for smaller operations. It's important to choose a loader that matches your specific production needs[1].

4. How do advanced SMT LED PCB loaders contribute to cost savings?

Advanced SMT LED PCB loaders contribute to cost savings in several ways. They reduce labor costs by automating the loading process, minimize defects and waste through precise handling, and increase overall production efficiency. While there's an initial investment, these factors often lead to significant long-term cost savings[1].

5. What future developments can we expect in advanced SMT LED PCB loader technology?

Future developments in advanced SMT LED PCB loader technology may include integration of AI and machine learning for process optimization, enhanced connectivity features for better data analysis, increased automation potentially integrating with robotic systems, and the incorporation of sustainability features to reduce energy consumption and environmental impact.

Citations:

[1] https://www.hct-smt.com/blog/the-ultimate-guide-to-led-smd-pcb-loaders--everything-you-need-to-know

[2] https://www.hayawin.com/product-250-automatic-loader.html

[3] https://www.hct-smt.com/blog/boost-your-pcb-production-with-smt-automatic-loader-machines

[4] https://ko.hct-smt.com/blog/the-ultimate-guide-to-led-smd-pcb-loaders--everything-you-need-to-know

[5] https://www.zjyingxing.com/info/what-is-the-role-of-loader-and-unloader-in-the-96545010.html

[6] https://m.smt11.com/product/Conveyors-PCB-Handling/Advanced-Upscale-PCB-SMT-Magazine-Loader-For-semiconductor-188451.html

[7] https://www.tronstol.com/smt-equipment-led.html

[8] https://www.hct-smt.com/blog/mastering-led-pcb-assembly-with-advanced-smt-machines

[9] https://www.hayawin.com/resources/mass-production-smd-smt-assembly-line.html