Content Menu

● Introduction to SMT Reel Parts Counters

● Accuracy of SMT Reel Parts Counters

>> Factors Affecting Accuracy

● Benefits of Using SMT Reel Parts Counters

● Applications in Electronics Manufacturing

● Future Developments and Trends

>> Role of X-ray Technology

>> Impact on Production Efficiency

● Maintenance and Calibration of SMT Reel Counters

● Conclusion

● FAQs

>> 1. What is an SMT reel parts counter?

>> 2. How do X-ray SMT reel counters work?

>> 3. What are the benefits of using automated SMT reel parts counters?

>> 4. Can SMT reel counters be used for loose components?

>> 5. How do optical sensor-based SMT reel counters work?

● Citations:

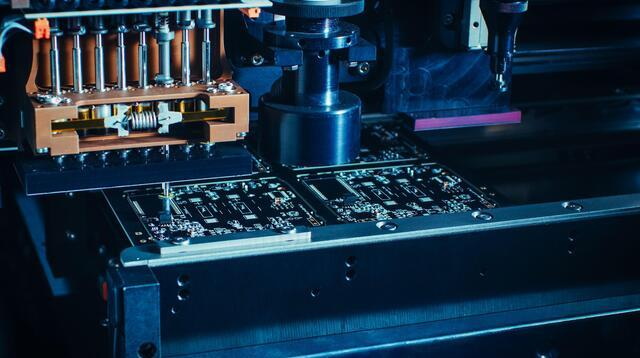

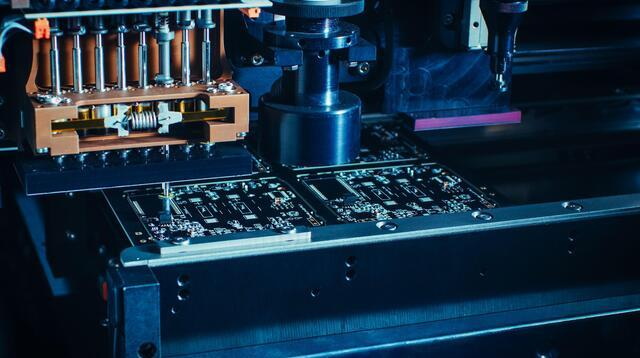

In the realm of surface mount technology (SMT), precision and accuracy are paramount. One crucial tool that ensures the reliability and efficiency of SMT assembly lines is the SMT reel parts counter. These counters are designed to accurately count the components on SMT reels, which are essential for maintaining inventory accuracy and preventing production delays. This article delves into the accuracy of SMT reel parts counters, exploring their mechanisms, benefits, and applications in modern electronics manufacturing.

Introduction to SMT Reel Parts Counters

SMT reel parts counters are specialized machines used in the electronics industry to count the number of components on a reel. These components, known as surface mount devices (SMDs), are mounted onto printed circuit boards (PCBs) using SMT. The process involves placing components onto the board, which requires precise control over the number of components used to avoid errors and ensure product quality.

SMT reel parts counters can be categorized into several types based on their counting methods:

- Manual Counters: These are mechanical devices that rely on a rotating drum or disc to measure the length of the tape on a reel. They are less accurate and more time-consuming compared to automated systems.

- Automated Counters: These use optical sensors or X-ray technology to automatically detect and count components. They offer higher accuracy and efficiency, making them ideal for large-scale production environments.

- X-ray Counters: These advanced counters use X-ray imaging to "see" inside the components, providing accurate counts even when components are densely packed or overlapping.

Accuracy of SMT Reel Parts Counters

The accuracy of SMT reel parts counters varies depending on the technology used:

- Optical Sensors: These counters detect components by analyzing the gaps between them on the reel tape. They are fast and accurate but may struggle with densely packed components.

- X-ray Technology: X-ray counters are highly accurate, with error rates typically less than 0.1%. They can handle complex component arrangements and are ideal for high-precision applications.

Factors Affecting Accuracy

Several factors can impact the accuracy of SMT reel parts counters:

- Component Density: High-density reels can pose challenges for optical counters, while X-ray counters handle these situations more effectively.

- Component Type: Different component sizes and shapes may require adjustments in counting algorithms or sensor settings.

- Machine Calibration: Regular calibration is essential to maintain accuracy over time.

Benefits of Using SMT Reel Parts Counters

The use of SMT reel parts counters offers several benefits:

- Improved Inventory Management: Accurate counts help maintain precise inventory levels, reducing stockouts and overstocking.

- Increased Efficiency: Automated counting saves time and labor, allowing for faster production cycles.

- Reduced Errors: Minimizes human error, ensuring that the correct number of components is used in production.

Applications in Electronics Manufacturing

SMT reel parts counters are widely used in various stages of electronics manufacturing:

- Production Line Optimization: They help streamline the pick-and-place process by ensuring accurate component counts.

- Inventory Management: Essential for maintaining accurate stock levels and preventing supply chain disruptions.

- Quality Control: Ensures that products meet quality standards by verifying component counts.

Future Developments and Trends

As technology advances, SMT reel parts counters are becoming more sophisticated:

- Integration with ERP Systems: Real-time inventory updates and automated stock management are becoming more common.

- Advanced Sensors and Algorithms: Improvements in sensor technology and AI-driven counting algorithms are enhancing accuracy and efficiency.

The integration of AI and machine learning into SMT processes is expected to further enhance efficiency and precision. For instance, AI can be used to predict component usage patterns, optimize inventory levels, and automate quality control checks. This integration will enable manufacturers to produce higher-quality products faster and at a lower cost.

Role of X-ray Technology

X-ray technology has revolutionized the counting process by providing high accuracy and speed. X-ray counters can inspect the internal structure of components, identifying defects such as cold solder joints and ensuring the quality of soldering. This capability not only enhances component counting but also improves overall product reliability.

In addition to counting, X-ray technology can be used for quality control, ensuring that components meet the required standards before they are mounted on PCBs. This preliminary inspection helps prevent production delays and reduces material waste by identifying issues early in the process.

Impact on Production Efficiency

The use of advanced SMT reel counters significantly impacts production efficiency:

- Reduced Labor Costs: Automated counting reduces the need for manual labor, saving time and resources.

- Improved Production Flexibility: With accurate counts, manufacturers can quickly adjust production plans based on market demands, enhancing flexibility and responsiveness.

- Enhanced Quality Control: By ensuring accurate component counts and detecting defects early, manufacturers can maintain high-quality products and reduce rework.

Maintenance and Calibration of SMT Reel Counters

To ensure the accuracy and reliability of SMT reel counters, regular maintenance and calibration are crucial:

- Cleaning and Inspection: Regular cleaning and inspection help prevent dust and debris from affecting the counting mechanism.

- Calibration: Following the manufacturer's guidelines for calibration ensures consistent accuracy.

- Proper Storage: Storing the machine in a clean, dry environment protects it from damage and maintains its performance over time.

By following these best practices, manufacturers can optimize the performance and longevity of their SMT reel counters, ensuring accurate counts and efficient production processes.

Conclusion

SMT reel parts counters play a vital role in ensuring the accuracy and efficiency of SMT assembly processes. Their ability to precisely count components on reels is crucial for maintaining inventory accuracy, reducing production errors, and enhancing overall manufacturing efficiency. As technology continues to evolve, these counters will remain essential tools in the electronics industry.

FAQs

1. What is an SMT reel parts counter?

An SMT reel parts counter is a device used to accurately count the number of components on a reel, which is essential for surface mount technology (SMT) assembly processes.

2. How do X-ray SMT reel counters work?

X-ray counters use X-ray imaging to scan components on a reel, analyzing the resulting images to accurately count the components. This method is highly accurate and can handle complex component arrangements.

3. What are the benefits of using automated SMT reel parts counters?

Automated counters offer improved accuracy, increased efficiency, and reduced labor costs compared to manual counting methods. They also help in maintaining precise inventory levels.

4. Can SMT reel counters be used for loose components?

While traditional SMT reel counters are designed for reels, some advanced systems can handle loose components by integrating with other counting technologies or using X-ray imaging. For example, X-ray counters can count scattered components using X-ray penetration technology[1].

5. How do optical sensor-based SMT reel counters work?

These counters use optical sensors to detect the gaps between components on the reel tape, allowing them to automatically count the components. They are fast and accurate but may require adjustments for different component types.

Citations:

[1] https://www.seamarkzm.com/can-smt-reel-counters-be-used-for-spot-tray-loose-material.html

[2] https://www.seamarkzm.com/maintaining-and-calibrating-an-smd-reel-counter.html

[3] https://www.seamarkzm.com/application-of-xray-smd-component-counter-in-smt-production.html

[4] https://www.linkedin.com/pulse/future-surface-mount-technology-smt-industry-key-trends-p-virkhe-zxnyf

[5] https://www.seamarkzm.com/how-smd-reel-counter-machines-optimize-smt-assembly.html

[6] https://hackaday.com/2022/04/20/smt-part-counter-aims-to-ease-taking-inventory/

[7] https://www.bagmatic.com/en/component-counter-machine-smd/

[8] https://cnsmtline.com/products/smd-counter-machine/

[9] https://www.futureatt.com/single-station-smt-component-counter-semi-automatic_p19.html

[10] https://www.dafton-smt.com/news/development-forecast-of-smt-processing-80656963.html

[11] https://www.manncorp.com/collections/component-reel-counters

[12] https://www.crowdsupply.com/great-big-factory/beancounter

[13] https://www.cognitivemarketresearch.com/articles/surface-mount-technology-smt-market-trends-and-future-opportunities

[14] https://core-emt.com/blog/smt-news-1/smart-count-your-reels-17

[15] https://global.neotel.tech/2023/01/06/5-benefits-to-use-smd-reel-counter-machine/

[16] https://smttoday.com/2024/07/29/smt-component-market-trends-and-win-sources-strategic-responses/

[17] https://global.neotel.tech/products/neo-counter-series/smt-reel-counter-x800/

[18] http://www.smtworldwide.com/pf/ch-comp-counter/

[19] https://www.rhsmt.com/news/smt-industrys-future-trends-the-impact-of-ai-and-automation/

[20] https://www.seamarkzm.com/mastering-efficiency-with-manual-smd-reel-counting-tools-and-equipment.html