Content Menu

>> I. Understanding PCB Handling Conveyors

>> II. Key Components of a PCB Handling Conveyor System

>>> 1. Conveyor Belts

>>> 2. Workstations

>>> 3. Automated Component Placement

>>> 4. Soldering and Reflow Stations

>>> 5. Testing and Inspection Stations

>>> 6. Buffer Zones

>>> 7. Control Systems

>> III. Types of PCB Handling Conveyors

>> IV. Benefits of Implementing a PCB Handling Conveyor System

>> V. Factors to Consider Before Investing in a PCB Handling Conveyor

>> VI. Choosing the Right PCB Handling Conveyor Manufacturer

>> VII. Cost Considerations

>> VIII. Conclusion: Is a PCB Handling Conveyor Right for You?

● FAQ: Frequently Asked Questions About PCB Handling Conveyors

>>> Q1: What is the primary purpose of a PCB handling conveyor?

>>> Q2: What are the key components of a PCB handling conveyor system?

>>> Q3: What types of PCB handling conveyors are available?

>>> Q4: What are the benefits of using a PCB handling conveyor system?

>>> Q5: How do I choose the right PCB handling conveyor manufacturer?

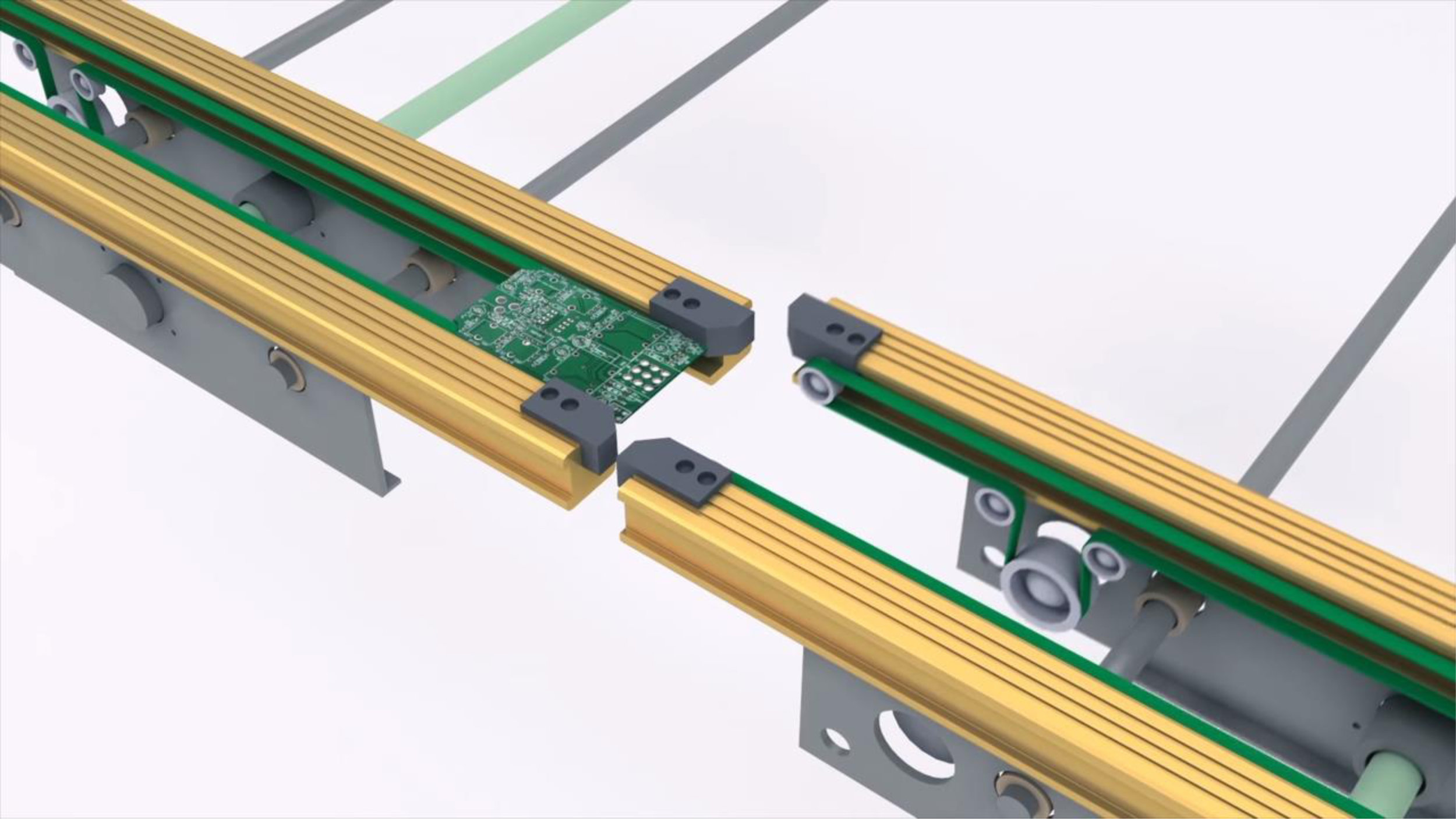

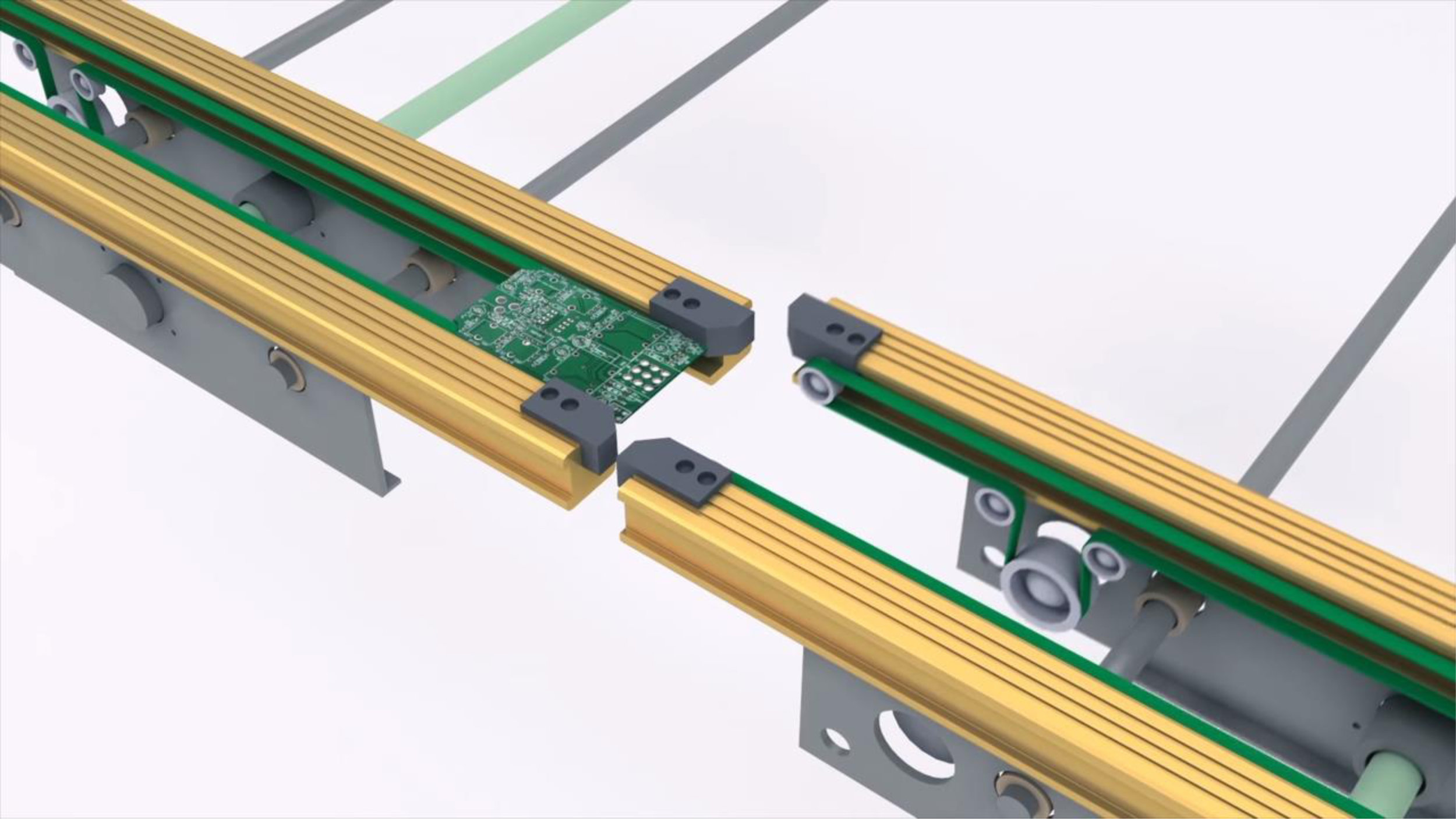

PCB handling conveyors are automated systems designed to transport PCBs safely and efficiently through different stages of the manufacturing process[1]. They play a crucial role in optimizing production, minimizing errors, improving quality, and increasing throughput[1]. These conveyors reduce manual handling, which can be prone to errors and slower than automated processes.

II. Key Components of a PCB Handling Conveyor System

A typical PCB handling conveyor system comprises several essential components[1]:

1. Conveyor Belts

These are the primary components, consisting of motorized belts that carry PCBs from one workstation to another[1]. Conveyor belts can be customized in width, length, and material to accommodate different sizes and types of PCBs[1]. SunzonTech's PCB Conveyor machines provide secure handling of PCBs[2].

2. Workstations

These are designated areas along the conveyor line where specific tasks are performed, such as component placement, soldering, testing, and inspection[1]. Workstations can be equipped with specialized equipment and tools for their respective tasks[1].

3. Automated Component Placement

Many modern conveyors integrate robotic arms or pick-and-place machines to automate the precise placement of electronic components onto the PCBs[1]. This reduces manual labor, speeds up the assembly process, and enhances accuracy[1].

4. Soldering and Reflow Stations

Conveyors can be equipped with reflow ovens or soldering stations to ensure proper soldering of components onto the PCB[1]. The conveyor system moves the PCBs through heating, ensuring consistent and reliable solder connections[1].

5. Testing and Inspection Stations

Inspection stations can be integrated into the conveyor line to perform quality control checks, such as visual inspection, automated optical inspection (AOI), and in-circuit testing (ICT)[1]. Defective PCBs can be identified and removed from the production line[1]. Anda Technologies offers UV inspection stations for conformal coatings[4].

6. Buffer Zones

Buffer zones are sections of the conveyor system where PCBs can accumulate temporarily[1]. These zones help prevent bottlenecks and maintain a steady production flow, especially when there are variations in processing times at different workstations[1].

7. Control Systems

Modern conveyor systems are equipped with advanced control systems that allow for easy monitoring, adjustment, and synchronization of the production process[1]. These systems can track the progress of each PCB, adjust conveyor speed, and provide real-time data on production metrics[1].

III. Types of PCB Handling Conveyors

PCB handling conveyors come in various types to suit different needs [3, 7]:

* Link Conveyors: Ideal for a wide range of PCB handling applications and can optimize Work-In-Progress (WIP) material flow during assembly, coating, dispensing and other processes[4].

* Code-Reader Conveyors: PCB board handling with a code-reader conveyor[3].

* Work-Station Conveyors: PCB board handling with a work-station conveyor[3].

* Inspection Conveyors: PCB board handling with an inspection conveyor [3, 8].

* Elevator Conveyors: Lowers and elevates printed circuit board assemblies (PCBA) for lower return conveying[4].

* PCB Flipper Conveyors: Smoothly inverts printed circuit board assemblies (PCBA) or pallet/carriers for dual sided application requirements[4].

* Traffic Control Conveyors: Control PCB traffic flow with turn conveyors and inverter/flip conveyors[3].

IV. Benefits of Implementing a PCB Handling Conveyor System

Implementing a PCB handling conveyor system offers numerous advantages [1, 5]:

* Increased Efficiency: Automates PCB movement, reducing manual handling and speeding up production.

* Reduced Errors: Minimizes the risk of human error in handling and transporting PCBs.

* Improved Quality: Ensures consistent and reliable handling, contributing to higher quality PCBs.

* Increased Throughput: Optimizes production flow, leading to higher throughput and faster turnaround times.

* Enhanced Safety: Reduces the risk of worker injury associated with manual handling of heavy or delicate PCBs.

* Modularity and Flexibility: PCB manufacturing conveyor systems are often designed with modularity, allowing manufacturers to customize and adapt the system to their specific production needs[1].

V. Factors to Consider Before Investing in a PCB Handling Conveyor

Before investing in a PCB handling conveyor system, carefully consider the following factors:

* Production Volume: Determine your current and projected production volumes to ensure the conveyor system can handle your throughput requirements.

* PCB Size and Weight: Ensure the conveyor system can accommodate the size and weight of your PCBs.

* Process Requirements: Analyze your specific process requirements to determine the necessary workstations and features.

* Automation Level: Choose a system with the appropriate level of automation for your needs.

* Space Constraints: Consider the available space in your facility and select a system that fits within your constraints.

* Budget: Establish a budget that includes the initial investment, installation costs, and ongoing maintenance expenses.

* SMEMA Compatibility: Ensure compatibility with other SMT equipment [2, 7].

* ESD Safe Design: Select a system with ESD safe designs [2, 7].

VI. Choosing the Right PCB Handling Conveyor Manufacturer

Selecting the right PCB handling conveyor manufacturer is a critical decision that can significantly impact your investment. Look for manufacturers with the following qualities [2, 5]:

* Experience and Expertise: A proven track record in designing and manufacturing PCB handling conveyors.

* Customization Options: Ability to customize systems to meet your specific needs.

* Reliable Products: Use high-quality materials and components to ensure durability and reliability[5].

* Strong Interfaces: Equipped with state-of-the-art interfaces that are easy to use[5].

* Service and Support: Comprehensive service and support, including installation, training, and ongoing technical assistance.

* Customer References: Positive customer reviews and testimonials.

SunzonTech is a leading PCB handling machine manufacturer in China, with design, R&D, and production capabilities[2]. CORE-emt offers a full range of NUTEK board handling conveyors[3]. AMS, Inc. offers PCB handling systems with easy-to-use interfaces and design/configuration specific to your needs[5].

VII. Cost Considerations

The cost of a PCB handling conveyor system can vary widely depending on its complexity, features, and level of automation. Factors that influence the cost include:

* System Size and Length: Longer conveyor systems with more workstations will generally cost more.

* Automation Level: Systems with automated component placement and inspection capabilities will be more expensive.

* Customization: Customized systems tailored to specific needs will likely have a higher price tag.

* Manufacturer: Different manufacturers offer varying price points.

* Installation Costs: Include costs for installation, setup, and training.

* Maintenance Costs: Factor in ongoing maintenance and repair expenses.

VIII. Conclusion: Is a PCB Handling Conveyor Right for You?

PCB handling conveyors are essential for optimizing efficiency, accuracy, and throughput in PCB manufacturing. While the initial investment may seem significant, the long-term benefits of reduced errors, increased production, and enhanced safety often outweigh the costs. By carefully evaluating your needs, considering the factors outlined above, and selecting a reliable PCB handling conveyor manufacturer, you can make an informed decision that transforms your PCB manufacturing operations.

FAQ: Frequently Asked Questions About PCB Handling Conveyors

Q1: What is the primary purpose of a PCB handling conveyor?

A: To automate the movement of PCBs through various stages of the manufacturing process, improving efficiency and reducing manual handling[1].

Q2: What are the key components of a PCB handling conveyor system?

A: Conveyor belts, workstations, automated component placement, soldering/reflow stations, testing/inspection stations, buffer zones, and control systems[1].

Q3: What types of PCB handling conveyors are available?

A: Link conveyors, code-reader conveyors, work-station conveyors, inspection conveyors, elevator conveyors, and PCB flipper conveyors [3, 4].

Q4: What are the benefits of using a PCB handling conveyor system?

A: Increased efficiency, reduced errors, improved quality, increased throughput, and enhanced safety [1, 5].

Q5: How do I choose the right PCB handling conveyor manufacturer?

A: Look for experience, customization options, reliable products, strong interfaces, and excellent service and support [2, 5].