Content Menu

● What is an SMT Stencil and Why is it Important?

>> Key Functions of SMT Stencils:

● Challenges of Making a PCB Without an SMT Stencil

>> Manual Soldering of SMD Components

>> The Difficulty of Fine-Pitch and High-Density PCBs

>> Risk of Solder Defects Without Stencils

● SMT Stencil vs PCB Assembly Without Stencil

● How to Make a PCB Without an SMT Stencil

>> 1. Hand Soldering with Solder Paste or Wire

>> 2. Using Alternative Stencil Materials

>> 3. Advanced Printing Technologies

● Advantages and Disadvantages of SMT Stencils

>> Advantages

>> Disadvantages

● When is it Acceptable to Make a PCB Without an SMT Stencil?

● Tips for Successful PCB Assembly Without an SMT Stencil

● Conclusion

● FAQ

>> 1. Can I solder small SMD components without an SMT stencil?

>> 2. What are the main types of SMT stencils?

>> 3. How does solder paste printing without a stencil work?

>> 4. Are DIY stencils a good alternative?

>> 5. Why is solder paste application important in SMT assembly?

In the world of electronics manufacturing, the use of SMT (Surface Mount Technology) stencils is a standard practice for applying solder paste to printed circuit boards (PCBs). However, the question arises: Can you make a PCB without an SMT stencil? This article explores the possibilities, challenges, and alternatives to using SMT stencils in PCB assembly, while comparing smt stencil vs pcb processes to provide a comprehensive understanding for hobbyists, engineers, and manufacturers alike.

What is an SMT Stencil and Why is it Important?

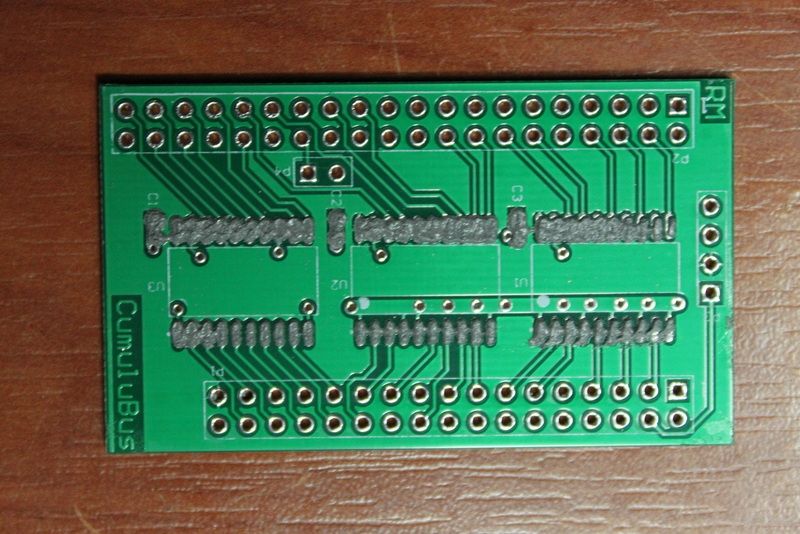

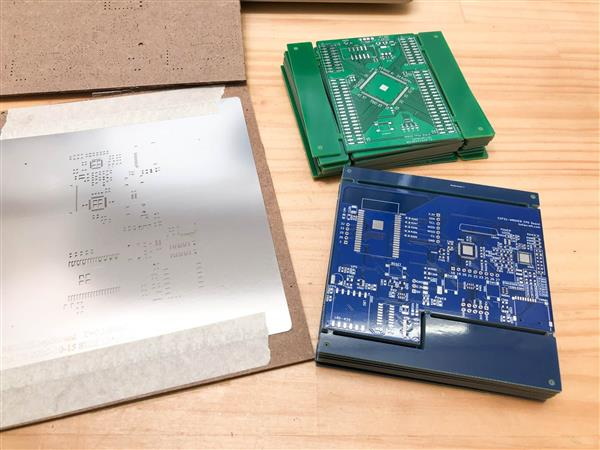

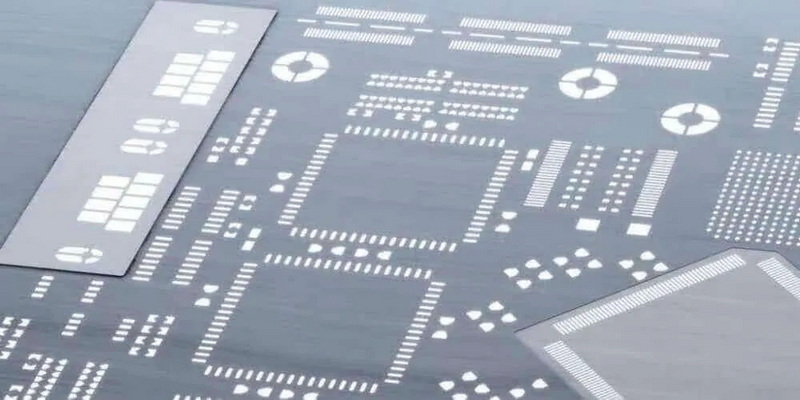

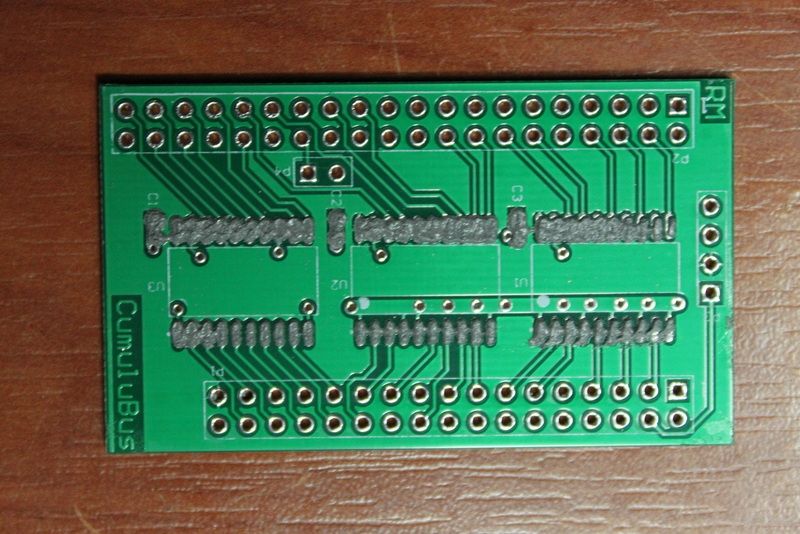

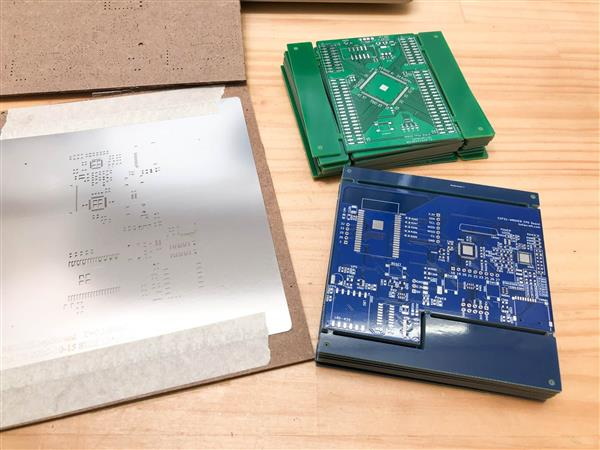

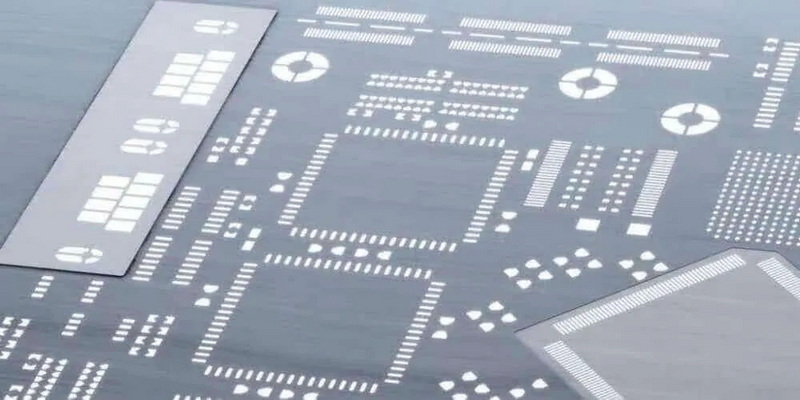

An SMT stencil, also known as a PCB stencil or circuit board stencil, is a thin sheet-usually stainless steel or nickel-with precisely cut apertures that match the layout of surface-mount components on a PCB. During assembly, solder paste is applied through these apertures onto the PCB pads, ensuring consistent and accurate solder deposition for component placement.

Key Functions of SMT Stencils:

- Control the amount and location of solder paste: The stencil apertures correspond exactly to the PCB pads, which ensures the right amount of solder paste is deposited precisely where needed.

- Ensure uniform solder application: Uniform solder paste thickness reduces defects such as solder bridges or insufficient solder joints.

- Improve solder joint reliability: Consistent solder joints improve electrical and mechanical connections, critical for product longevity.

- Speed up the assembly process: Automated solder paste printing using stencils is much faster than manual application.

The stencil is aligned using fiducial marks on the PCB, and a metal squeegee spreads the solder paste evenly across the stencil openings. This process is critical for high-quality SMT assembly, especially for fine-pitch and complex PCB designs.

Challenges of Making a PCB Without an SMT Stencil

Manual Soldering of SMD Components

It is possible to solder surface-mount devices (SMDs) manually without a stencil, especially for simple or low-volume projects. Hobbyists and DIY enthusiasts often use soldering irons, flux, and fine tips to hand-solder components. For example, small SMD packages like 0805 resistors or capacitors can be placed and soldered by hand with some practice.

However, this method has several drawbacks:

- Inconsistent solder paste application: Without a stencil, controlling the amount of solder paste is difficult, leading to solder bridges or insufficient solder joints.

- Time-consuming: Hand soldering is slower and less efficient for large or complex boards.

- Higher risk of defects: Fine-pitch components (e.g., 0.5 mm pitch ICs) are challenging to solder accurately by hand.

- Not scalable: Manual methods are impractical for mass production.

The Difficulty of Fine-Pitch and High-Density PCBs

Modern PCBs often feature components with very fine pitch (the distance between adjacent pins), such as QFPs (Quad Flat Packages), BGAs (Ball Grid Arrays), and CSPs (Chip Scale Packages). These require extremely precise solder paste deposition to avoid bridging or open joints. Without a stencil, achieving the necessary precision is nearly impossible, making stencilless assembly unsuitable for advanced electronics manufacturing.

Risk of Solder Defects Without Stencils

The absence of an SMT stencil increases the risk of common soldering defects such as:

- Solder bridges: Excess solder connecting adjacent pins, causing shorts.

- Insufficient solder: Too little solder leading to weak or intermittent connections.

- Tombstoning: Uneven solder surface tension causes one end of a component to lift off the pad.

- Solder balls: Small solder spheres that can cause shorts or reliability issues.

These defects reduce the reliability and performance of the final PCB assembly.

SMT Stencil vs PCB Assembly Without Stencil

| Aspect | SMT Stencil Assembly | Assembly Without SMT Stencil |

| Solder Paste Accuracy | High precision and uniform paste application | Variable, depends on manual skill or printing technology |

| Production Speed | Fast and repeatable for large volumes | Slow, especially for complex boards |

| Cost | Initial cost for stencil fabrication, but cost-effective for volume | Lower upfront cost, but higher labor cost and risk of rework |

| Suitability | Ideal for fine-pitch, complex PCBs | Suitable for prototypes, simple boards, or hobbyists |

| Defect Rate | Low, due to consistent paste application | Higher, due to inconsistent soldering |

How to Make a PCB Without an SMT Stencil

Despite the challenges, there are several practical methods to assemble PCBs without using a traditional SMT stencil. These approaches vary in complexity, cost, and quality outcomes.

1. Hand Soldering with Solder Paste or Wire

This is the most straightforward method for stencilless PCB assembly, widely used by hobbyists and small-scale prototypers.

Steps:

- Prepare the PCB: Clean the PCB pads and apply flux to improve solder wetting.

- Apply solder paste: Using a syringe or toothpick, carefully deposit small amounts of solder paste on each pad.

- Place components: Use tweezers to position SMD components accurately on the paste.

- Tack solder: Heat one corner of the component with a fine-tip soldering iron to tack it in place.

- Solder remaining pins: Carefully solder the remaining pins, adding solder wire as needed.

- Inspect and rework: Use magnification to check for bridges or cold joints and fix defects with solder wick or additional solder.

Pros:

- Low cost and no need for stencil fabrication.

- Good for quick prototyping or repairs.

Cons:

- Time-consuming and requires skill.

- Difficult for fine-pitch or high pin-count components.

- Higher risk of defects.

2. Using Alternative Stencil Materials

If traditional stainless steel stencils are unavailable or too costly, some makers use alternative materials to create DIY stencils:

- Laser-cut mylar or plastic films: These can be cut with precision laser cutters or craft cutters to create stencil-like apertures.

- Adhesive vinyl sheets: Cut to shape and applied temporarily to the PCB for solder paste application.

- Repurposed materials: Thin metal sheets or even soda cans can be laser-cut or manually cut to form rudimentary stencils.

These alternatives can improve solder paste consistency compared to freehand methods but are less durable and precise than professional stencils.

3. Advanced Printing Technologies

Recent advances in PCB assembly technology have introduced stencilless solder paste printing methods:

- Jet printing: Uses inkjet-like nozzles to deposit solder paste droplets directly onto PCB pads with high accuracy.

- Micro-dispensing: Precision dispensers apply controlled volumes of solder paste to each pad.

- Laser direct structuring: Combines laser etching with solder paste deposition for selective application.

These technologies eliminate the need for physical stencils, reduce setup time, and offer flexibility for design changes. However, they require expensive equipment and are currently more common in high-end manufacturing environments.

Advantages and Disadvantages of SMT Stencils

Advantages

- Durability: Stainless steel stencils can be used repeatedly for thousands of boards.

- Precision: High accuracy in solder paste volume and placement.

- Efficiency: Enables fast, automated solder paste printing for mass production.

- Consistency: Reduces variability and improves yield.

- Compatibility: Works well with a wide range of component sizes and pitches.

Disadvantages

- Cost: Initial fabrication of stencils can be expensive, especially for complex or multi-layer boards.

- Lead time: Stencil manufacturing adds time to the production process.

- Inflexibility: Any PCB design change requires a new stencil.

- Handling: Stencils require careful cleaning and storage to maintain quality.

When is it Acceptable to Make a PCB Without an SMT Stencil?

While SMT stencils are the standard in professional PCB assembly, certain scenarios justify stencilless assembly:

- Prototyping: When testing new designs or low-volume prototypes, the cost and time of stencil fabrication may not be justified.

- Hobby projects: DIY electronics builders often hand-solder components without stencils.

- Repair and rework: Small-scale rework jobs usually do not require stencils.

- Educational purposes: Learning soldering techniques without the complexity of stencil printing.

In these cases, the trade-offs in quality and speed are acceptable given the benefits in cost and flexibility.

Tips for Successful PCB Assembly Without an SMT Stencil

- Use quality solder paste: Fresh, well-stored solder paste improves wetting and joint quality.

- Apply flux liberally: Flux helps solder flow and reduces defects.

- Work in a clean environment: Dust and contaminants can cause soldering issues.

- Use magnification: A microscope or magnifying glass helps place components accurately.

- Practice steady hand skills: Consistent hand movement and soldering technique reduce errors.

- Preheat the PCB: Using a hot plate or preheater can improve solder paste reflow and reduce thermal shock.

Conclusion

While it is technically possible to make a PCB without an SMT stencil, especially for simple or prototype boards, using a stencil remains the gold standard for consistent, high-quality SMT assembly. Manual soldering or alternative methods can work for hobbyists or small runs but come with increased risks of defects and longer production times. Emerging stencil-less solder paste printing technologies promise to revolutionize PCB assembly by combining precision with flexibility. Ultimately, the choice between smt stencil vs pcb assembly without stencil depends on the project scale, complexity, and budget.

For mass production and fine-pitch components, SMT stencils are indispensable. For prototyping and DIY projects, stencilless methods offer a viable, cost-effective alternative. Understanding the trade-offs and techniques involved helps engineers and makers choose the best approach for their needs.

FAQ

1. Can I solder small SMD components without an SMT stencil?

Yes, small SMD components can be soldered by hand with a fine-tip soldering iron and flux, but it requires practice and is challenging for very fine-pitch parts like 0.5 mm pitch ICs.

2. What are the main types of SMT stencils?

The main types are framed stencils, step stencils, and frameless stencils. Frameless stencils are cheaper and more flexible but less durable and harder to align.

3. How does solder paste printing without a stencil work?

This method uses advanced printing technology to deposit solder paste directly onto the PCB surface without a metal stencil, offering high precision and flexibility.

4. Are DIY stencils a good alternative?

DIY stencils made from laser-cut plastic films or other materials can help apply solder paste more evenly than freehand methods but are less durable and precise than professional stainless steel stencils.

5. Why is solder paste application important in SMT assembly?

Accurate solder paste application ensures reliable solder joints, reduces defects like solder bridges or cold joints, and improves overall product quality.