Content Menu

● Introduction to SMT PCB Cleaning Machines

>> Types of Flux Residues

● Capabilities of SMT PCB Cleaning Machines

>> Features of Modern SMT PCB Cleaning Machines

● Importance of Effective PCB Cleaning

● Challenges in PCB Cleaning

● Advances in SMT PCB Cleaning Technology

● Best Practices for SMT PCB Cleaning

● Conclusion

● Frequently Asked Questions

>> 1. What types of flux residues can SMT PCB cleaning machines handle?

>> 2. Why is PCB cleaning important after SMT assembly?

>> 3. What are the common methods used in SMT PCB cleaning machines?

>> 4. How do modern SMT PCB cleaning machines address environmental concerns?

>> 5. What precautions should be taken when using SMT PCB cleaning machines?

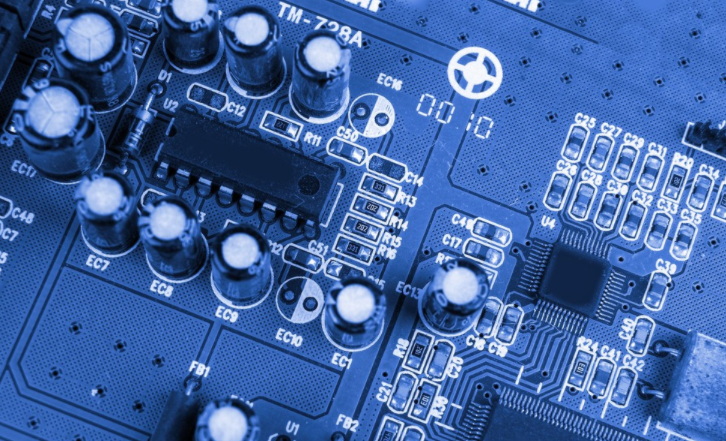

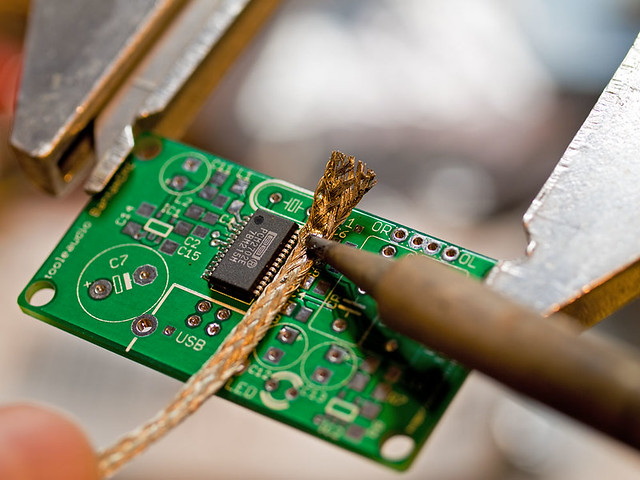

The process of cleaning printed circuit boards (PCBs) after Surface Mount Technology (SMT) assembly is crucial for ensuring the reliability and functionality of electronic devices. Flux residues, which are left behind during the soldering process, can lead to corrosion, electrical leakage, and other performance issues if not properly removed. SMT PCB cleaning machines are designed to handle various types of flux residues, including rosin-based, water-soluble, and no-clean fluxes. In this article, we will explore the capabilities of SMT PCB cleaning machines in managing different flux residues and discuss the importance of effective PCB cleaning.

Introduction to SMT PCB Cleaning Machines

SMT PCB cleaning machines are specialized equipment used to remove contaminants such as flux residues, solder paste, and other substances from printed circuit boards. These machines are essential in the electronics manufacturing industry, where cleanliness is paramount for ensuring the quality and reliability of electronic components. The primary goal of these machines is to provide a thorough cleaning process that does not damage sensitive components on the PCB.

Types of Flux Residues

Flux residues can be categorized into several types, each requiring specific cleaning methods:

- Rosin-Based Flux: This type of flux is commonly used in traditional soldering processes. It leaves behind a residue that can be difficult to remove and often requires specialized solvents or saponification cleaning methods.

- Water-Soluble Flux: Designed to be easily removable with water, this flux is more environmentally friendly. However, it may require additional cleaning agents or detergents to ensure complete removal.

- No-Clean Flux: As the name suggests, this type of flux is intended to leave minimal residue and does not require cleaning. However, in some cases, cleaning may still be necessary to improve appearance or ensure compatibility with conformal coatings.

Capabilities of SMT PCB Cleaning Machines

SMT PCB cleaning machines are versatile and can handle various flux residues by employing different cleaning technologies:

- Aqueous Cleaning: This method uses water-based cleaning agents, often combined with mechanical agitation or ultrasonic vibrations, to remove water-soluble flux residues. Aqueous cleaning is effective for water-soluble fluxes but may not be suitable for rosin-based or no-clean fluxes.

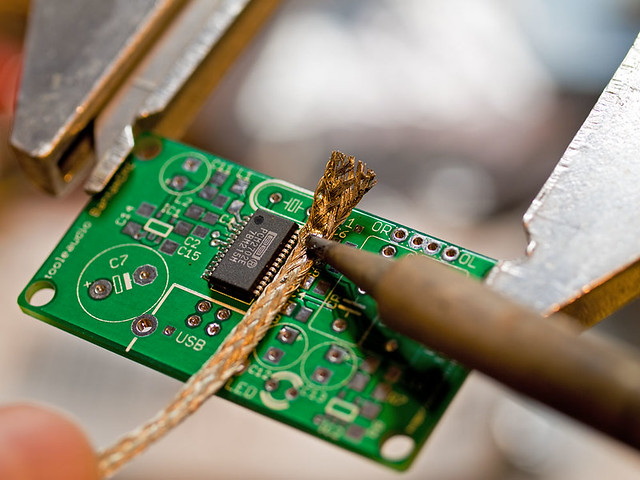

- Solvent-Based Cleaning: Organic solvents like isopropyl alcohol or acetone are used to dissolve and remove rosin-based and other stubborn flux residues. This method requires proper ventilation due to the volatile nature of the solvents.

- Ultrasonic Cleaning: This technique uses high-frequency sound waves to create bubbles that dislodge contaminants from the PCB surface. It can be combined with aqueous or solvent-based cleaning methods for enhanced effectiveness.

- Vapor Phase Cleaning: Although less common, vapor phase cleaning involves condensing a vaporized cleaning agent onto the PCB to dissolve contaminants. This method is useful for specific applications where other methods may not be suitable.

Features of Modern SMT PCB Cleaning Machines

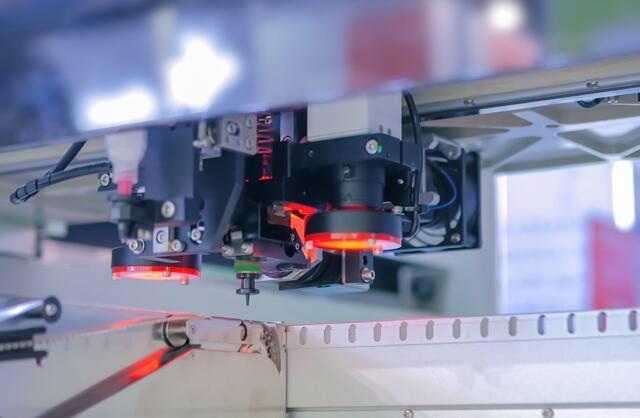

Modern SMT PCB cleaning machines are designed with efficiency and effectiveness in mind:

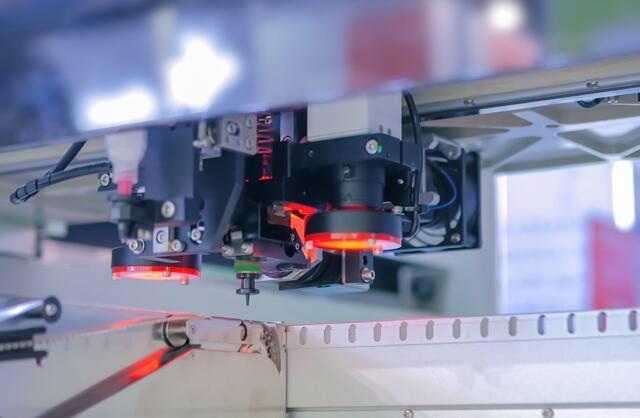

- Automatic Cleaning Modes: Many machines offer automated cleaning cycles that include washing, rinsing, and drying processes. This automation ensures consistent results and reduces manual labor.

- Multi-Flux Handling: These machines can handle a variety of flux types, including rosin, water-soluble, and no-clean fluxes, making them versatile for different manufacturing needs.

- Environmental Considerations: Many modern machines use closed-loop systems that recycle cleaning solutions, reducing waste and environmental impact.

Importance of Effective PCB Cleaning

Effective PCB cleaning is critical for several reasons:

- Reliability and Performance: Flux residues can lead to electrical failures and corrosion over time. Removing these residues ensures that the PCB operates reliably and maintains its performance.

- Aesthetic Appearance: Clean PCBs are essential for visual inspection and quality control. Residues can be mistaken for defects, affecting the perceived quality of the board.

- Conformal Coating Compatibility: Flux residues can interfere with the adhesion of conformal coatings, which are used to protect PCBs from environmental factors. Cleaning ensures a smooth coating process.

Challenges in PCB Cleaning

Despite the advancements in SMT PCB cleaning machines, there are challenges to consider:

- Flux Type Variability: Different flux types require specific cleaning methods. Incorrectly choosing a cleaning method can lead to ineffective removal or damage to components.

- Component Sensitivity: Some components on the PCB are sensitive to cleaning agents or processes. Ensuring that the cleaning method does not damage these components is crucial.

- Environmental and Safety Concerns: The use of solvents and other chemicals in cleaning processes raises environmental and safety concerns. Proper ventilation and waste management are essential.

Advances in SMT PCB Cleaning Technology

Recent advancements in SMT PCB cleaning technology have focused on improving efficiency, reducing environmental impact, and enhancing safety:

- Green Cleaning Solutions: There is a growing trend towards using environmentally friendly cleaning agents that are less harmful to the environment and safer for workers.

- Advanced Ultrasonic Systems: New ultrasonic technologies provide more precise control over cleaning parameters, allowing for more effective removal of residues without damaging components.

- Integration with Manufacturing Lines: Modern cleaning machines are often integrated into automated production lines, streamlining the manufacturing process and reducing downtime.

Best Practices for SMT PCB Cleaning

To ensure effective and safe cleaning, manufacturers should follow best practices:

- Regular Maintenance: Regularly maintaining cleaning machines ensures optimal performance and extends their lifespan.

- Training Personnel: Proper training for operators is crucial to ensure they understand the correct use of cleaning agents and machine settings.

- Quality Control: Implementing rigorous quality control measures helps identify any cleaning issues early in the process, preventing defects in final products.

Conclusion

SMT PCB cleaning machines are capable of handling different types of flux residues, offering a range of cleaning technologies to suit various manufacturing needs. Effective PCB cleaning is essential for ensuring the reliability, performance, and aesthetic appearance of electronic devices. As technology advances, these machines continue to evolve, providing more efficient, environmentally friendly, and safe cleaning solutions.

Frequently Asked Questions

1. What types of flux residues can SMT PCB cleaning machines handle?

- SMT PCB cleaning machines can handle various types of flux residues, including rosin-based, water-soluble, and no-clean fluxes. They employ different cleaning technologies such as aqueous, solvent-based, ultrasonic, and vapor phase cleaning to effectively remove these residues.

2. Why is PCB cleaning important after SMT assembly?

- PCB cleaning is important to remove flux residues and other contaminants that can lead to corrosion, electrical leakage, and performance issues. It ensures the reliability and functionality of electronic devices.

3. What are the common methods used in SMT PCB cleaning machines?

- Common methods include aqueous cleaning, solvent-based cleaning, ultrasonic cleaning, and vapor phase cleaning. These methods are chosen based on the type of flux residue and the components on the PCB.

4. How do modern SMT PCB cleaning machines address environmental concerns?

- Modern machines often use closed-loop systems that recycle cleaning solutions, reducing waste and environmental impact. This approach minimizes the need for hazardous chemical disposal and conserves resources.

5. What precautions should be taken when using SMT PCB cleaning machines?

- Precautions include ensuring proper ventilation when using solvents, handling sensitive components with care, and following safety guidelines to prevent damage to the PCB or injury to personnel.