Content Menu

● Introduction

● Understanding SMT Glue Stencils

>> Types of SMT Stencils

● Customization of SMT Glue Stencils

● Manufacturing Process

● Applications in PCB Assembly

● Challenges and Considerations

● Advanced Techniques in SMT Stencil Customization

● Case Studies: Customization in Practice

● Future Developments

● Conclusion

● FAQ

>> 1. What Materials Are Commonly Used for SMT Glue Stencils?

>> 2. How Are SMT Glue Stencils Customized for Specific PCB Designs?

>> 3. What Are the Main Differences Between Laser-Cut and Electroformed Stencils?

>> 4. How Does Stencil Thickness Affect Adhesive or Solder Paste Deposition?

>> 5. Can SMT Glue Stencils Be Used for Both Adhesive and Solder Paste Application?

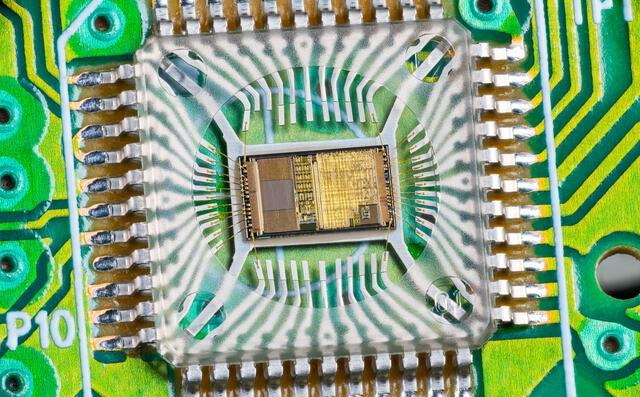

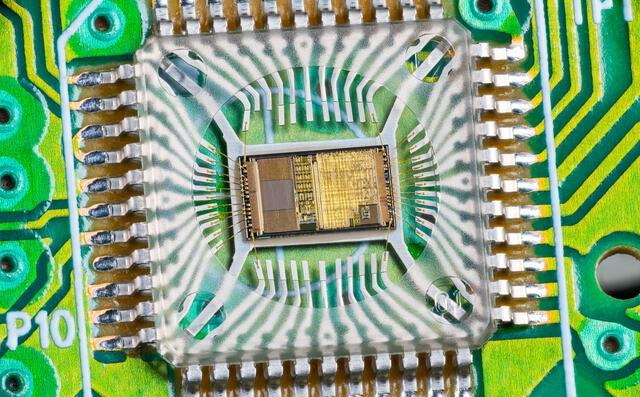

Introduction

In the realm of Surface Mount Technology (SMT), precision and customization are crucial for achieving high-quality printed circuit boards (PCBs). One key component in this process is the SMT glue stencil, which plays a vital role in applying adhesives or solder paste to PCBs. The ability to customize these stencils for specific PCB designs is essential for optimizing assembly processes, improving product reliability, and enhancing overall manufacturing efficiency. This article delves into the customization capabilities of SMT glue stencils, exploring their design, manufacturing processes, and applications in PCB assembly.

Understanding SMT Glue Stencils

SMT glue stencils are specialized templates used in the SMT assembly process to apply precise amounts of adhesive or solder paste onto PCB pads. These stencils are typically made from thin sheets of stainless steel or other materials, with precise apertures cut into them using laser cutting or electroforming techniques. The choice of material and manufacturing method depends on the specific requirements of the PCB design, including the size and complexity of the components.

Types of SMT Stencils

1. Laser-Cut Stencils: These are the most common type of SMT stencils. They are made by cutting precise holes into a stainless steel sheet using a laser. Laser-cut stencils are cost-effective and suitable for both low and high-volume production. They are commonly used for applying solder paste but can also be adapted for adhesive application.

2. Electroformed Stencils: These stencils are produced through an electroforming process, which involves depositing a thin layer of nickel onto a plastic insulator. Electroformed stencils offer higher precision and durability, making them ideal for complex PCB designs with densely packed components.

3. Frameless vs. Framed Stencils: Frameless stencils are low-cost and suitable for prototyping or low-volume production. They are not mounted on a frame and are easier to store. Framed stencils, on the other hand, are mounted on a frame with a mesh border, providing better positional accuracy and are recommended for high-volume production.

Customization of SMT Glue Stencils

Customizing SMT glue stencils for specific PCB designs involves several key considerations:

- Design Files: The process begins with CAD or Gerber files that outline the PCB layout. These files are used to create a stencil design that matches the exact specifications of the PCB, including the placement of components and the required adhesive or solder paste apertures.

- Aperture Design: The size and shape of the apertures in the stencil are critical. They must be precisely aligned with the PCB pads to ensure accurate deposition of adhesive or solder paste. The design of these apertures can be customized based on the type of components used and the desired solder joint quality.

- Material Selection: The choice of material for the stencil depends on the application. Stainless steel is common for solder paste stencils, while other materials might be used for adhesive stencils depending on the specific adhesive properties.

- Stencil Thickness: The thickness of the stencil affects the volume of adhesive or solder paste deposited. Thicker stencils can deposit more material, but may not be suitable for all applications. Customization allows for selecting the optimal thickness based on the PCB design requirements.

Manufacturing Process

The manufacturing process for customized SMT glue stencils typically involves the following steps:

1. Design Creation: The PCB design files are converted into a format suitable for stencil production.

2. Laser Cutting or Electroforming: The stencil is created using either laser cutting for precision or electroforming for high accuracy.

3. Cleaning and Inspection: The stencil is thoroughly cleaned and inspected to ensure it meets the required specifications.

Applications in PCB Assembly

Customized SMT glue stencils are essential for efficient PCB assembly, offering several benefits:

- Improved Accuracy: Custom stencils ensure that adhesive or solder paste is applied precisely where needed, reducing errors and improving the quality of the final product.

- Increased Efficiency: By automating the application process, customized stencils can significantly reduce assembly time and labor costs.

- Flexibility: Customization allows for adapting to different PCB designs and component types, making it easier to integrate new technologies into existing production lines.

Challenges and Considerations

While customization offers many advantages, there are challenges to consider:

- Cost: Customized stencils can be more expensive than standard ones, especially for low-volume production.

- Lead Time: The process of designing and manufacturing custom stencils can take longer than using off-the-shelf solutions.

- Material Limitations: The choice of material may limit the precision or durability of the stencil.

Advanced Techniques in SMT Stencil Customization

Recent advancements in technology have enabled more sophisticated customization techniques for SMT stencils:

- Nano-Coating: Some stencils are treated with nano-coatings to improve paste release properties, reducing the risk of solder paste sticking to the stencil.

- Step Stencils: These stencils have varying thicknesses to accommodate components of different sizes on the same PCB, allowing for more efficient assembly processes.

- 3D Printing: Emerging technologies like 3D printing are being explored for creating complex stencil geometries that cannot be achieved with traditional manufacturing methods.

Case Studies: Customization in Practice

Several industries have successfully implemented customized SMT glue stencils to enhance their PCB assembly processes:

- Aerospace: High-reliability PCBs for aerospace applications require precise control over solder paste application. Customized stencils ensure that components are securely attached, meeting stringent quality standards.

- Automotive: The automotive industry benefits from customized stencils by improving the efficiency of PCB assembly for vehicle electronics, which demand high reliability and performance.

- Medical Devices: In medical device manufacturing, customized stencils help ensure the precise application of adhesives or solder paste, which is critical for the reliability and safety of medical equipment.

Future Developments

As technology continues to evolve, the customization of SMT glue stencils is expected to become even more sophisticated. Advances in materials science and manufacturing techniques will likely lead to more precise and durable stencils, further enhancing PCB assembly processes.

Conclusion

Customizing SMT glue stencils for specific PCB designs is not only possible but also highly beneficial for optimizing the SMT assembly process. By tailoring the stencil to the exact needs of the PCB, manufacturers can improve product quality, reduce assembly time, and enhance overall manufacturing efficiency. Whether using laser-cut or electroformed stencils, customization allows for precise control over adhesive or solder paste application, making it an essential tool in modern PCB manufacturing.

FAQ

1. What Materials Are Commonly Used for SMT Glue Stencils?

SMT glue stencils are commonly made from stainless steel due to its durability and precision. However, other materials may be used depending on the specific requirements of the adhesive application.

2. How Are SMT Glue Stencils Customized for Specific PCB Designs?

Customization involves using CAD or Gerber files to create a stencil design that matches the PCB layout. The stencil is then manufactured using laser cutting or electroforming techniques to ensure precise apertures for adhesive or solder paste application.

3. What Are the Main Differences Between Laser-Cut and Electroformed Stencils?

Laser-cut stencils are cost-effective and suitable for most applications, while electroformed stencils offer higher precision and durability, making them ideal for complex PCB designs with densely packed components.

4. How Does Stencil Thickness Affect Adhesive or Solder Paste Deposition?

The thickness of the stencil determines the volume of adhesive or solder paste deposited onto the PCB. Thicker stencils can deposit more material, but may not be suitable for all applications, especially those requiring precise control over the amount of material applied.

5. Can SMT Glue Stencils Be Used for Both Adhesive and Solder Paste Application?

Yes, SMT stencils can be used for both adhesive and solder paste application. However, the design and material selection may vary based on the specific requirements of the adhesive or solder paste being used.