Content Menu

● Understanding PCB SMT Spacers

● The Advantages of PCB SMT Spacers

>> Automated Assembly

>> Enhanced Reliability

>> Space Efficiency

>> Improved Signal Integrity

>> Cost-Effectiveness

● Enhancing PCB Durability and Longevity

>> Mechanical Stress Reduction

>> Vibration and Shock Protection

>> Thermal Management

>> Environmental Protection

>> Stress-Free Expansion

● Implementing PCB SMT Spacers in Your Design

>> Design Considerations

>> Material Selection

>> Assembly Process Integration

● Case Studies: SMT Spacers in Action

>> Medical Devices

>> Automotive Electronics

>> Industrial Control Systems

● The Future of PCB SMT Spacers

>> Miniaturization

>> Advanced Materials

>> Integration with Other Components

>> Customization and 3D Printing

● Conclusion

● FAQ

>> 1. What are the main advantages of using PCB SMT spacers over traditional through-hole spacers?

>> 2. How do PCB SMT spacers contribute to improved thermal management in electronic devices?

>> 3. Are there any limitations or challenges associated with using PCB SMT spacers?

>> 4. How do I choose the right PCB SMT spacer for my application?

>> 5. Can PCB SMT spacers be used in high-reliability applications like aerospace or medical devices?

● Citations:

In the ever-evolving world of electronics manufacturing, engineers and designers are constantly seeking innovative ways to improve the reliability, durability, and longevity of printed circuit boards (PCBs). One such innovation that has gained significant traction in recent years is the use of PCB SMT spacers. These small but mighty components play a crucial role in enhancing the overall performance and lifespan of PCBs, particularly in applications where stability, protection, and precise component positioning are paramount.

Understanding PCB SMT Spacers

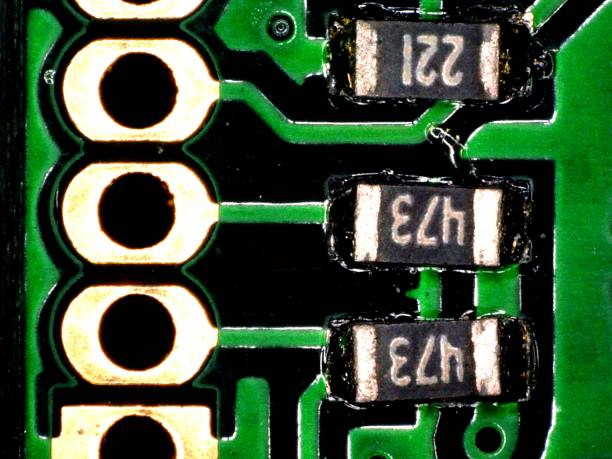

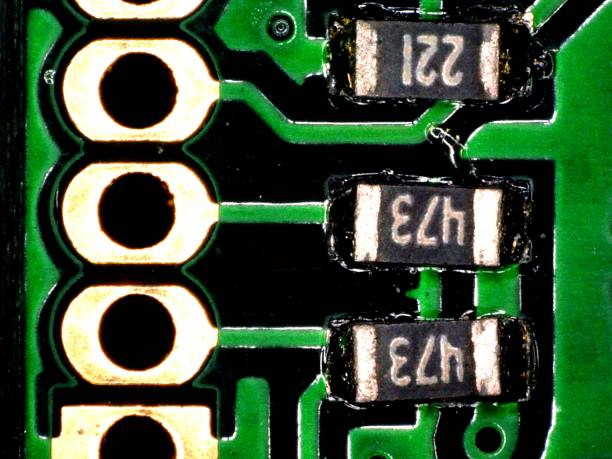

PCB SMT spacers, also known as surface mount technology spacers, are specialized components designed to be mounted directly onto the surface of a PCB using the same automated assembly processes as other SMT components. Unlike traditional through-hole spacers, which require manual insertion and soldering, SMT spacers can be placed and soldered alongside other surface mount components, streamlining the manufacturing process and improving overall efficiency[1].

These spacers serve multiple purposes in PCB design and assembly:

1. Providing structural support: SMT spacers help maintain proper spacing between PCBs or between a PCB and its enclosure, ensuring stability and preventing unwanted flexing or bending.

2. Protecting sensitive components: By creating a physical barrier, spacers can shield delicate components from mechanical stress, vibration, and potential damage.

3. Facilitating heat dissipation: Proper spacing between boards can improve air circulation, aiding in heat dissipation and thermal management.

4. Enabling modular design: SMT spacers allow for the creation of stackable or modular PCB designs, enhancing flexibility and ease of maintenance.

5. Ensuring precise alignment: These spacers contribute to the accurate positioning of components and boards, critical for many electronic applications.

The Advantages of PCB SMT Spacers

The adoption of PCB SMT spacers offers several significant advantages over traditional through-hole spacers or other mounting methods:

Automated Assembly

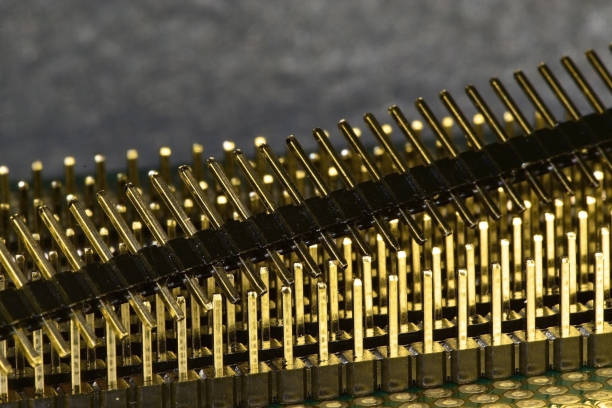

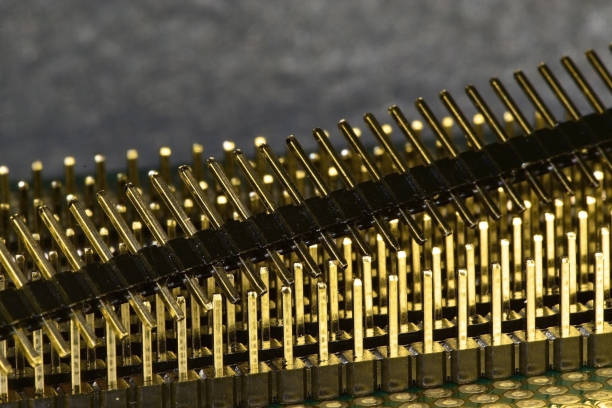

One of the primary benefits of SMT spacers is their compatibility with automated assembly processes. These spacers can be placed using the same pick-and-place machines used for other SMT components, significantly reducing assembly time and labor costs[3]. This automation not only speeds up production but also minimizes the risk of human error during assembly.

Enhanced Reliability

SMT spacers provide a more reliable and consistent mounting solution compared to manual insertion methods. The precision of automated placement ensures that spacers are positioned accurately every time, reducing the risk of misalignment or improper spacing that could lead to mechanical stress or failure over time[1].

Space Efficiency

Surface mount spacers typically have a smaller footprint compared to their through-hole counterparts. This space-saving design allows for higher component density on the PCB, which is particularly valuable in applications where miniaturization is a priority[3].

Improved Signal Integrity

By enabling shorter signal paths and reducing the need for through-hole connections, SMT spacers can contribute to improved signal integrity in high-frequency applications. The reduced inductance and resistance at connection points can lead to better overall electrical performance[3].

Cost-Effectiveness

While the initial investment in SMT equipment may be higher, the long-term cost savings associated with automated assembly, reduced labor, and improved reliability make SMT spacers a cost-effective choice for many manufacturers[1].

Enhancing PCB Durability and Longevity

The use of PCB SMT spacers can significantly contribute to the durability and longevity of PCBs in several ways:

Mechanical Stress Reduction

By providing proper support and spacing, SMT spacers help distribute mechanical stress evenly across the PCB. This reduces the risk of board warping, component stress, and solder joint fatigue, all of which can lead to premature failure[1].

Vibration and Shock Protection

In applications where PCBs are subject to vibration or shock, such as in automotive or industrial environments, SMT spacers can act as shock absorbers, protecting sensitive components and solder joints from damage[5].

Thermal Management

Proper spacing between boards and components facilitated by SMT spacers can improve air circulation, aiding in heat dissipation. This enhanced thermal management can prevent overheating and extend the lifespan of temperature-sensitive components[3].

Environmental Protection

SMT spacers can create a barrier between the PCB and its environment, offering protection against dust, moisture, and other contaminants that could potentially damage the board or its components over time.

Stress-Free Expansion

In applications where thermal expansion is a concern, the use of SMT spacers can provide the necessary clearance for boards to expand and contract without putting undue stress on components or solder joints.

Implementing PCB SMT Spacers in Your Design

To effectively incorporate SMT spacers into your PCB design and maximize their benefits, consider the following best practices:

Design Considerations

When designing your PCB layout, plan for the inclusion of SMT spacers from the outset. Consider the following factors:

- Spacer placement: Strategically position spacers to provide optimal support and protection for critical components.

- Footprint design: Ensure that the PCB layout includes appropriate footprints for the chosen SMT spacers, including solder pads and any necessary clearance areas[4].

- Height considerations: Select spacers with appropriate heights to achieve the desired board-to-board or board-to-enclosure spacing.

Material Selection

Choose SMT spacers made from materials that are compatible with your PCB's operating environment and requirements. Common materials include:

- Brass: Offers good conductivity and strength, suitable for applications requiring grounding or EMI shielding.

- Nylon: Provides electrical insulation and is lightweight, ideal for non-conductive spacing needs.

- Aluminum: Combines light weight with good heat dissipation properties.

Assembly Process Integration

Work with your PCB assembly partner to integrate SMT spacer placement into the overall assembly process:

- Pick-and-place programming: Ensure that the automated assembly equipment is properly programmed to handle the SMT spacers.

- Solder paste application: Adjust solder paste stencil designs to accommodate the spacer footprints and ensure proper solder joint formation.

- Reflow profile optimization: Fine-tune the reflow soldering profile to ensure proper attachment of SMT spacers without affecting other components.

Case Studies: SMT Spacers in Action

To illustrate the real-world benefits of PCB SMT spacers, let's examine a few case studies from different industries:

Medical Devices

In the development of a portable medical monitoring device, engineers faced the challenge of creating a compact, reliable design that could withstand frequent handling and potential drops. By incorporating SMT spacers, they were able to:

- Provide stable support for the main PCB within the device enclosure.

- Protect sensitive sensors and components from shock and vibration.

- Improve overall device durability, extending its operational lifespan in challenging clinical environments.

Automotive Electronics

An automotive ECU manufacturer implemented SMT spacers in their design to address issues with vibration-induced failures. The results included:

- Reduced warranty claims due to improved vibration resistance.

- Enhanced thermal management, allowing for more reliable operation in high-temperature engine compartments.

- Simplified assembly process, leading to faster production times and reduced costs.

Industrial Control Systems

A manufacturer of industrial control systems used SMT spacers to create a modular, stackable PCB design. This approach offered:

- Improved flexibility, allowing for easy customization and upgrades.

- Better heat dissipation between stacked boards, enhancing overall system reliability.

- Reduced assembly time and complexity compared to traditional mounting methods.

The Future of PCB SMT Spacers

As the electronics industry continues to evolve, the role of PCB SMT spacers is likely to grow in importance. Several trends are shaping the future of these components:

Miniaturization

As electronic devices become smaller and more compact, the demand for ultra-low-profile SMT spacers is increasing. Manufacturers are developing new designs that offer the same support and protection in an even smaller form factor.

Advanced Materials

Research into new materials for SMT spacers is ongoing, with a focus on improving thermal properties, electrical characteristics, and overall durability. This may lead to spacers that can withstand even more extreme environments or provide additional functionality beyond simple spacing.

Integration with Other Components

The future may see the development of multifunctional SMT spacers that combine spacing with other features such as electrical connections, thermal management, or even embedded sensors.

Customization and 3D Printing

Advancements in 3D printing technology may enable the rapid prototyping and production of custom SMT spacers tailored to specific PCB designs, offering unprecedented flexibility in board layout and assembly.

Conclusion

PCB SMT spacers represent a significant advancement in PCB design and assembly, offering numerous benefits that contribute to enhanced durability and longevity. By providing structural support, protection against mechanical stress, improved thermal management, and compatibility with automated assembly processes, these small components play a crucial role in the overall reliability of electronic devices.

As the electronics industry continues to push the boundaries of miniaturization, performance, and reliability, the importance of PCB SMT spacers is likely to grow. Their ability to address multiple challenges in PCB design and manufacturing makes them an invaluable tool for engineers and designers seeking to create robust, long-lasting electronic products.

By carefully considering the implementation of SMT spacers in your PCB designs, you can significantly enhance the durability, reliability, and overall performance of your electronic devices. As with any design decision, it's essential to carefully evaluate your specific requirements and work closely with your PCB assembly partners to ensure optimal integration of these components into your manufacturing process.

The future of PCB design and assembly is undoubtedly intertwined with innovations like SMT spacers, and staying informed about these advancements will be crucial for engineers and manufacturers looking to stay competitive in an ever-evolving industry.

FAQ

1. What are the main advantages of using PCB SMT spacers over traditional through-hole spacers?

PCB SMT spacers offer several advantages over traditional through-hole spacers:

- Compatibility with automated assembly processes, reducing labor costs and assembly time

- Improved reliability due to precise placement and consistent soldering

- Space efficiency, allowing for higher component density on the PCB

- Better signal integrity in high-frequency applications

- Cost-effectiveness in high-volume production scenarios

2. How do PCB SMT spacers contribute to improved thermal management in electronic devices?

PCB SMT spacers contribute to improved thermal management in several ways:

- They create proper spacing between boards or components, allowing for better air circulation

- This improved air flow aids in heat dissipation, preventing localized hot spots

- Some SMT spacers are made from materials with good thermal conductivity, further assisting in heat transfer

- By reducing mechanical stress, they help maintain consistent thermal interfaces between components and heat sinks

3. Are there any limitations or challenges associated with using PCB SMT spacers?

While PCB SMT spacers offer many benefits, there are some considerations to keep in mind:

- Initial investment in SMT equipment may be higher compared to manual assembly methods

- Design complexity may increase, requiring careful planning for spacer placement and footprint design

- Some very high-stress applications may still require additional mechanical fastening methods

- Height limitations may exist compared to some through-hole spacer options

4. How do I choose the right PCB SMT spacer for my application?

Selecting the appropriate PCB SMT spacer involves considering several factors:

- Required spacing height between boards or components

- Mechanical load and stress expectations

- Thermal management needs

- Material compatibility with the operating environment

- Electrical requirements (conductive vs. non-conductive)

- Available PCB real estate for spacer footprints

- Compatibility with your SMT assembly process

Consult with spacer manufacturers and your PCB assembly partner to determine the best option for your specific application.

5. Can PCB SMT spacers be used in high-reliability applications like aerospace or medical devices?

Yes, PCB SMT spacers can be used in high-reliability applications such as aerospace and medical devices. In fact, their precision placement and consistent soldering can contribute to improved reliability in these critical applications. However, it's essential to:

- Choose spacers made from materials that meet industry-specific requirements

- Ensure that the spacer design and implementation comply with relevant standards and regulations

- Conduct thorough testing and validation of the PCB assembly with SMT spacers under expected operating conditions

- Work closely with certified manufacturers and assembly partners experienced in high-reliability applications

Always verify that the use of SMT spacers aligns with the specific requirements and standards of your industry and application.

Citations:

[1] https://www.pcbjhy.com/blog/pros-and-cons-of-smt-pcb-assembly/

[2] https://patents.google.com/patent/CN108012450A/zh

[3] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[4] https://www.we-online.com/files/pdf1/final_smarter-designs-with-smt-spacers.pdf

[5] https://www.pencomsf.com/articles-updates/tdu-surface-mount-spacers/

[6] https://www.medicaldesignbriefs.com/component/content/article/46458-surface-mount-technology-for-pcb-assembly-use-case-and-smt-in-healthcare-systems

[7] https://www.fivetk.com/e-news/pcb-standoffs/

[8] https://patents.google.com/patent/CN112040669B/zh