Content Menu

● Introduction to SMT and Reel SMT

>> Advantages of Reel SMT

● How Parts Reels Reduce Waste

● Challenges and Solutions in Implementing Reel SMT

>> Advanced Technologies for Enhanced Efficiency

● Case Studies and Real-World Applications

● Environmental Impact and Sustainability

● Expanded Discussion on Environmental Impact

● Advanced Technologies for Waste Reduction

● Industry Applications and Future Trends

● Future Directions and Innovations

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary benefits of using reel SMT in manufacturing?

>> 2. How does reel SMT contribute to cost efficiency in high-volume production?

>> 3. What are some common challenges in implementing reel SMT, and how can they be addressed?

>> 4. How does reel SMT support design flexibility in electronic devices?

>> 5. What role does reel SMT play in industries with space and weight constraints?

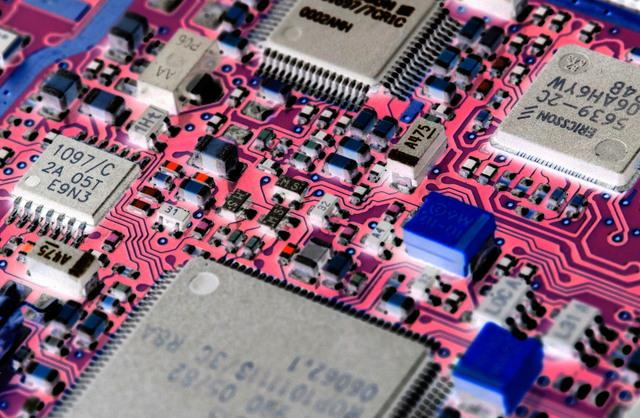

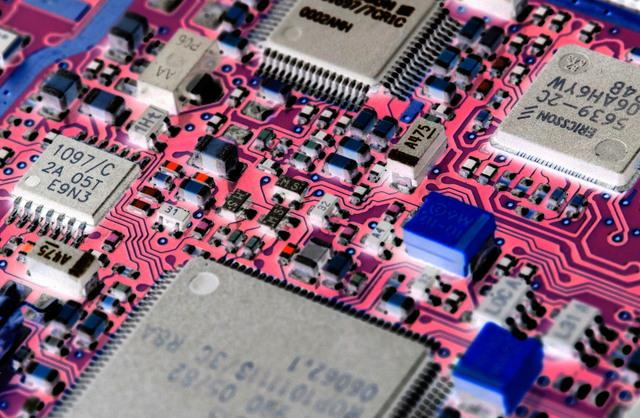

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by offering numerous advantages over traditional through-hole technology. One of the key components in SMT manufacturing is the use of reels, specifically for storing and dispensing surface mount components. These reels play a crucial role in enhancing production efficiency and reducing waste. In this article, we will explore how parts reels can help reduce waste in SMT assembly and their significance in modern electronics production.

Introduction to SMT and Reel SMT

SMT is a method of mounting electronic components directly onto the surface of a printed circuit board (PCB) without the need for holes. This technique allows for higher component density, faster assembly, and improved reliability compared to through-hole technology. SMT components are generally smaller and lighter, making them ideal for compact electronic devices. In SMT manufacturing, components are often supplied on reels, which are spools of material holding components such as resistors, capacitors, and integrated circuits. These reels are designed to be compatible with automated assembly processes, particularly pick-and-place machines, which can rapidly place components onto PCBs.

Advantages of Reel SMT

Reel SMT facilitates faster assembly by enabling continuous production without frequent line stoppages. Components are fed directly from the reel into the pick-and-place machine, reducing the need for manual handling and minimizing downtime. This automation leads to significant labor cost savings, as fewer workers are required to manage the assembly process. Additionally, reel SMT allows for higher component density on PCBs, enabling the production of smaller, more complex electronic devices. This density also provides design flexibility, as components can be placed on both sides of the PCB, enhancing the overall functionality of the device.

How Parts Reels Reduce Waste

Parts reels can significantly reduce waste in SMT assembly through several mechanisms:

1. Efficient Component Handling: By using reels, components are stored and dispensed in a way that minimizes manual handling errors and reduces the risk of component damage. This reduces the need for rework and scrap, which are major sources of waste in electronics manufacturing.

2. Automated Processes: The use of reels in automated assembly processes minimizes the need for frequent setup changes and reduces material waste associated with manual handling. Automated systems ensure that components are placed accurately on the PCB, reducing errors and the subsequent waste generated by defective products.

3. Reduced Packaging Waste: Although SMT reels themselves are recyclable, they often end up in landfills due to the lack of a market for mixed plastic waste that doesn't weigh much. However, by optimizing reel usage and implementing efficient waste management strategies, such as crushing and compacting reels, manufacturers can reduce the volume of waste sent to landfills. For instance, Z-AXIS has developed a shredder that can reduce the volume of SMT packaging waste by about 95%, significantly reducing landfill space and the need for frequent garbage pickups.

4. Improved Production Efficiency: Reel SMT supports high automation levels, which reduce the initial setup costs for mass production. This efficiency helps in minimizing production downtime and reducing the overall production costs by minimizing manual intervention and errors during assembly.

Challenges and Solutions in Implementing Reel SMT

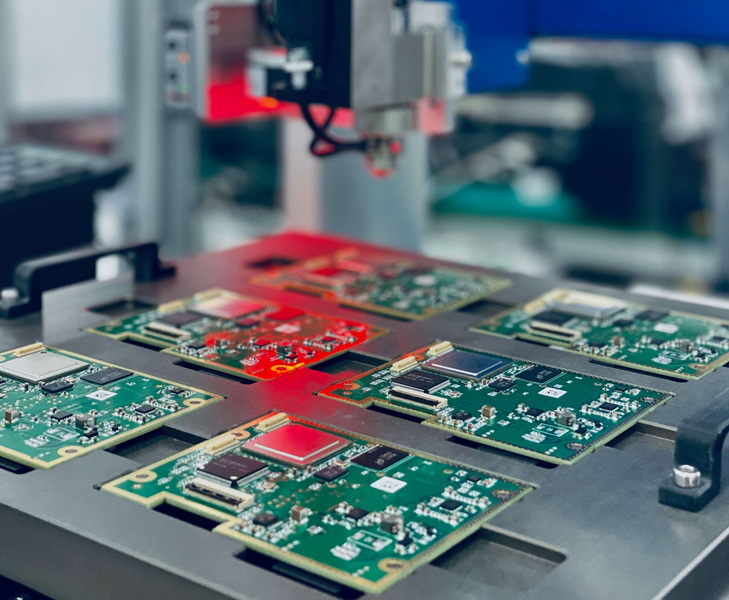

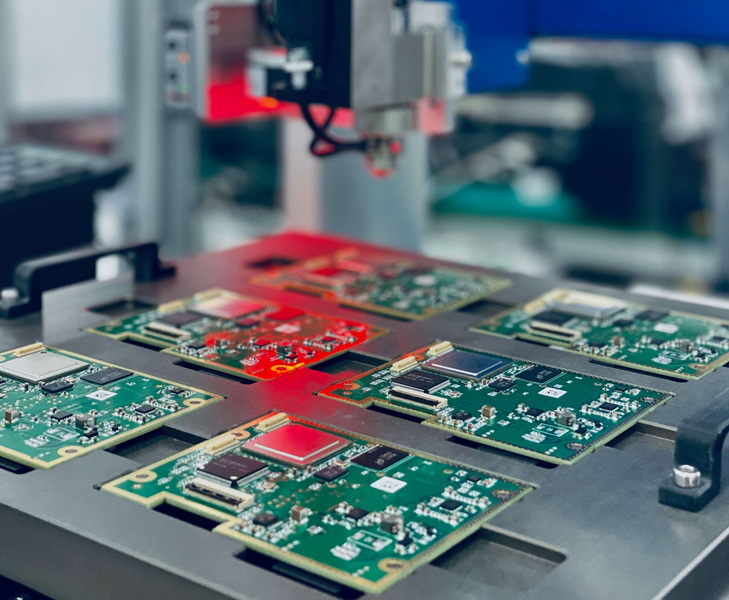

Despite the advantages, implementing reel SMT can pose challenges, such as the need for specific reel sizes and widths to match the capabilities of pick-and-place machines. Additionally, maintaining and handling reels properly is crucial to prevent component damage and ensure accurate placement on PCBs. To address these challenges, manufacturers can invest in standardized reel storage solutions that optimize space, protect components from damage, and ensure efficient retrieval. Automated storage systems offer controlled climatic conditions and complete traceability, enhancing the overall efficiency of reel management.

Advanced Technologies for Enhanced Efficiency

The integration of advanced technologies, such as SMD reel counter machines, further optimizes the SMT assembly process. These machines accurately count components on reels, reducing manual errors and enhancing inventory management. This precision ensures that production lines run smoothly without interruptions due to component shortages or excesses.

Case Studies and Real-World Applications

Reel SMT is widely used across various industries, including automotive, medical, communication, gaming, and aerospace. Its compact and efficient design makes it indispensable for producing devices with space and weight constraints. For instance, Smyczek GmbH, a German electronics manufacturer, implemented an automated storage system for SMD component reels, significantly reducing handling time and improving production efficiency.

Environmental Impact and Sustainability

The SMT industry has made significant strides in environmental sustainability. The transition to lead-free soldering has reduced toxic waste, and material recycling programs help conserve resources. Additionally, the miniaturization of components reduces raw material consumption, contributing to waste reduction and resource conservation. However, challenges remain, particularly in managing packaging waste from SMT reels. Innovative solutions like shredding and compacting reels can significantly reduce landfill waste and environmental impact.

Expanded Discussion on Environmental Impact

The environmental impact of SMT manufacturing is a critical concern. While SMT components themselves are more environmentally friendly due to their smaller size and reduced material usage, the packaging waste from reels remains a challenge. Companies like Z-AXIS have developed innovative solutions to manage this waste by shredding and compacting reels, significantly reducing landfill space and environmental impact. This approach not only benefits the environment but also enhances operational efficiency by reducing waste disposal costs.

Advanced Technologies for Waste Reduction

In addition to reel management, advanced technologies play a crucial role in reducing waste in SMT assembly. For instance, SMD reel counter machines ensure precise component counting, minimizing errors and reducing the risk of defective products. This precision also helps in maintaining accurate inventory levels, preventing overstocking and the associated waste.

Industry Applications and Future Trends

Reel SMT is widely applied across various industries, including automotive, medical devices, and consumer electronics. Its versatility and efficiency make it an essential tool for producing complex electronic devices with high reliability and performance. As technology advances, we can expect further innovations in reel design and management systems, potentially integrating AI and IoT technologies to optimize production processes and minimize waste.

Future Directions and Innovations

The future of reel SMT involves integrating it with advanced technologies such as miniaturization, high-frequency applications, and digital twin technologies. This integration will further enhance production efficiency and adaptability to evolving manufacturing needs. Data-driven scheduling algorithms can optimize reel exchange times and improve throughput by leveraging component commonality across different products. This approach aligns with lean manufacturing principles, reducing waste and enhancing operational efficiency.

Conclusion

In conclusion, parts reels play a pivotal role in reducing waste in SMT assembly by facilitating efficient component handling, automating processes, reducing packaging waste, and improving production efficiency. As technology continues to evolve, the importance of reel SMT will only grow, making it a cornerstone of modern electronics manufacturing.

Frequently Asked Questions

1. What are the primary benefits of using reel SMT in manufacturing?

- Reel SMT offers faster assembly, reduced labor costs, increased component density, and improved reliability. It also supports high automation levels, reducing setup costs and enhancing overall production efficiency.

2. How does reel SMT contribute to cost efficiency in high-volume production?

- Reel SMT is particularly cost-effective in high-volume production scenarios. The automated processes reduce material waste and assembly times, making it an ideal choice for mass-producing electronic devices.

3. What are some common challenges in implementing reel SMT, and how can they be addressed?

- Challenges include the need for specific reel sizes and proper handling to prevent component damage. These can be addressed by investing in standardized reel storage solutions and automated systems.

4. How does reel SMT support design flexibility in electronic devices?

- Reel SMT allows for higher component density on PCBs, enabling the production of smaller, more complex electronic devices. This density provides design flexibility, as components can be placed on both sides of the PCB.

5. What role does reel SMT play in industries with space and weight constraints?

- Reel SMT is indispensable for producing devices with space and weight constraints, such as those in the automotive, medical, and aerospace industries, due to its compact and efficient design.