Content Menu

● Introduction to LED SMD Pick and Place Machines

>> Key Features of LED SMD Pick and Place Machines

● Applications Beyond LED Components

>> Types of Components That Can Be Handled

● Benefits of Using LED SMD Pick and Place Machines for Other Components

● Challenges and Considerations

● Customization and Adaptability

>> Customization Options

● Choosing the Right Machine

● Industry Trends and Future Developments

>> Impact of Emerging Technologies

● Specific Considerations for LED Components

>> Challenges with LED Placement

● Case Studies and Applications

>> Industry Applications

● Conclusion

● Frequently Asked Questions

>> 1. What types of components can LED SMD pick and place machines handle?

>> 2. How do LED SMD pick and place machines ensure accurate component placement?

>> 3. What are the benefits of using LED SMD pick and place machines in electronics manufacturing?

>> 4. Can LED SMD pick and place machines be customized for specific manufacturing needs?

>> 5. What are common issues that may arise with LED SMD pick and place machines?

● Citations:

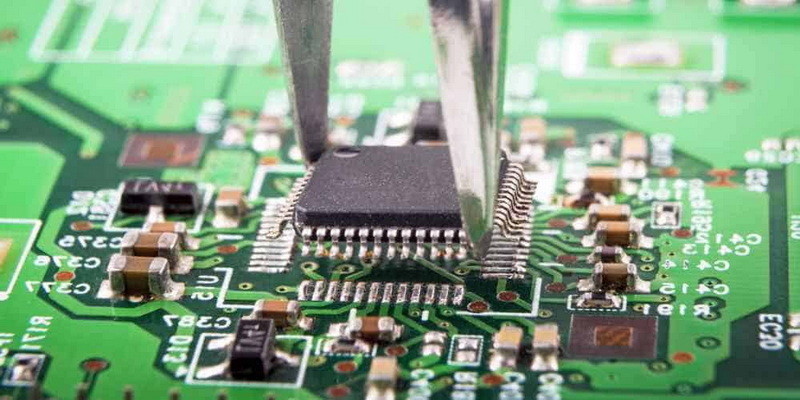

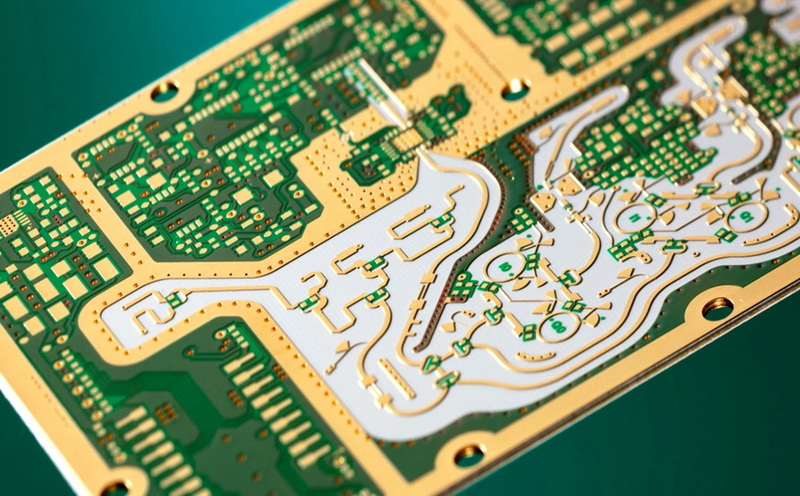

The LED SMD pick and place machine is a crucial tool in the electronics manufacturing industry, particularly for assembling LED components onto printed circuit boards (PCBs). These machines are renowned for their precision, speed, and efficiency in handling surface-mounted devices (SMDs). However, the versatility of these machines extends beyond LED components, making them suitable for a wide range of electronic components. In this article, we will explore the capabilities of LED SMD pick and place machines and their potential applications beyond LED components.

Introduction to LED SMD Pick and Place Machines

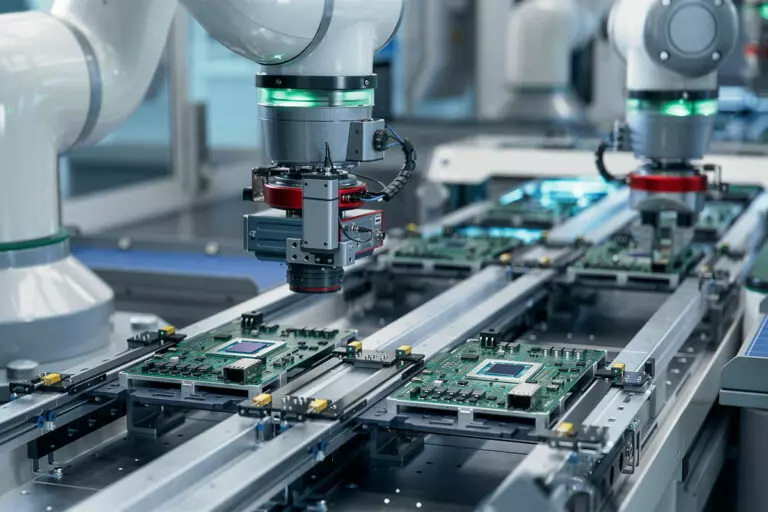

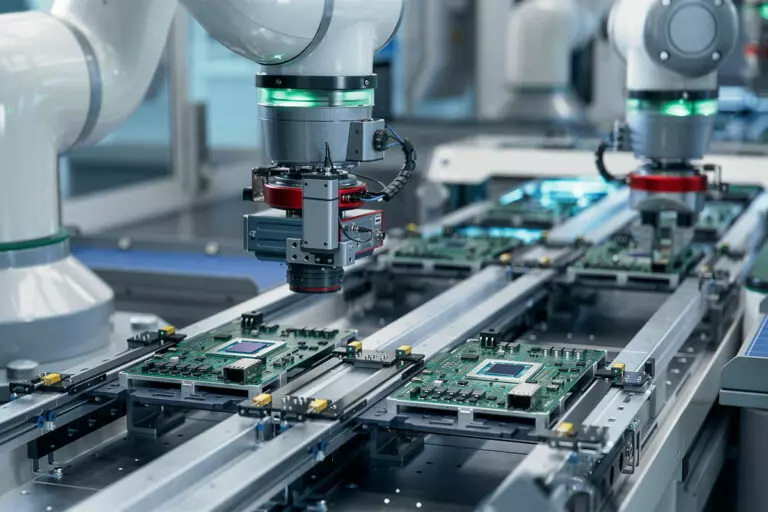

LED SMD pick and place machines are automated systems designed to pick up components from feeders and place them onto PCBs with high accuracy. They utilize advanced technologies such as vision systems, robotic arms, and vacuum nozzles to ensure precise component placement. These machines are essential in modern electronics manufacturing due to their ability to enhance production efficiency, improve accuracy, and reduce costs associated with manual assembly processes.

Key Features of LED SMD Pick and Place Machines

1. Versatility: These machines can handle various types and sizes of SMD components, making them suitable for diverse product requirements.

2. User-Friendly Interface: Operators can easily program and monitor the machine's operations, reducing the learning curve and maximizing productivity.

3. Automation Capabilities: Equipped with advanced automation features, these machines allow for continuous and unmanned operation, minimizing human errors and downtime.

Applications Beyond LED Components

While LED SMD pick and place machines are primarily used for LED components, their versatility allows them to be used for other types of components as well. This includes resistors, capacitors, ICs, SOPs, QFPs, QFNs, and SOTs, among others. The ability to handle a wide range of components makes these machines invaluable for manufacturers who produce a variety of electronic products.

Types of Components That Can Be Handled

1. Resistors and Capacitors: These are common SMD components used in electronic circuits. They are small and require precise placement, making them ideal candidates for automated assembly by LED SMD pick and place machines.

2. ICs (Integrated Circuits): These components are crucial in modern electronics and come in various packages such as SOP, QFP, and QFN. LED SMD pick and place machines can accurately place these components onto PCBs.

3. SOT (Small Outline Transistor) Components: These are used in a variety of electronic devices and can be efficiently placed using LED SMD pick and place machines.

Benefits of Using LED SMD Pick and Place Machines for Other Components

Using LED SMD pick and place machines for other types of components offers several benefits:

1. Enhanced Efficiency: Automation significantly reduces assembly time compared to manual processes, allowing for faster production cycles and increased output.

2. Improved Accuracy: The precision of these machines ensures that components are placed accurately, minimizing errors and improving product quality.

3. Cost Savings: By reducing labor costs and minimizing rework, manufacturers can save on production expenses.

Challenges and Considerations

While LED SMD pick and place machines can handle a variety of components, there are challenges and considerations to keep in mind:

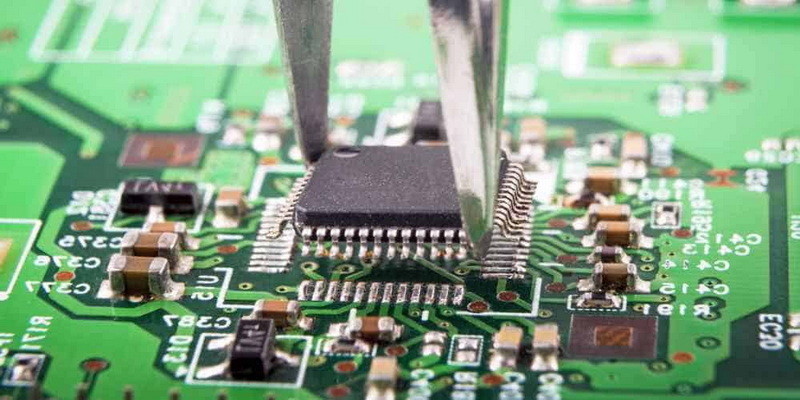

1. Component Compatibility: Ensuring that the machine is compatible with the specific components being used is crucial. Different components may require different nozzles or adjustments in placement settings.

2. Machine Calibration: Proper calibration is necessary to ensure accurate placement of components. Incorrect calibration can lead to placement errors.

3. Maintenance and Upkeep: Regular maintenance is essential to prevent issues such as component damage or inaccurate fiducial recognition.

Customization and Adaptability

One of the significant advantages of LED SMD pick and place machines is their ability to be customized and adapted to meet specific manufacturing needs. This includes modifying feeder configurations, integrating additional features, or providing tailored training and support. Such flexibility allows manufacturers to optimize their production processes for different types of components.

Customization Options

1. Feeder Customization: Manufacturers can customize the feeder setup to accommodate different component sizes and types, ensuring efficient component supply during production.

2. Software Integration: Advanced software can be integrated to enhance machine performance, improve data management, and facilitate real-time monitoring.

3. Training and Support: Suppliers often provide comprehensive training and ongoing support to ensure operators can maximize machine capabilities.

Choosing the Right Machine

When selecting a LED SMD pick and place machine for use with various components, several factors should be considered:

1. Machine Performance and Specifications: Ensure the machine aligns with your production requirements, including placement speed, accuracy, and component compatibility.

2. Reputation and Reliability: Choose a supplier known for reliability and quality products.

3. Customization Options: Opt for suppliers that offer customization to meet your specific needs.

Industry Trends and Future Developments

The electronics manufacturing industry is continuously evolving, with advancements in technology driving the development of more sophisticated LED SMD pick and place machines. Trends include the integration of AI and IoT technologies to enhance machine intelligence and connectivity, allowing for real-time monitoring and predictive maintenance. Additionally, there is a growing focus on sustainability, with manufacturers seeking machines that are energy-efficient and environmentally friendly.

Impact of Emerging Technologies

1. Artificial Intelligence (AI): AI can be used to optimize machine performance, predict maintenance needs, and improve component placement accuracy.

2. Internet of Things (IoT): IoT integration enables real-time monitoring and remote control of machines, enhancing operational efficiency and reducing downtime.

3. Sustainability Initiatives: Manufacturers are increasingly looking for machines that are designed with sustainability in mind, reducing energy consumption and environmental impact.

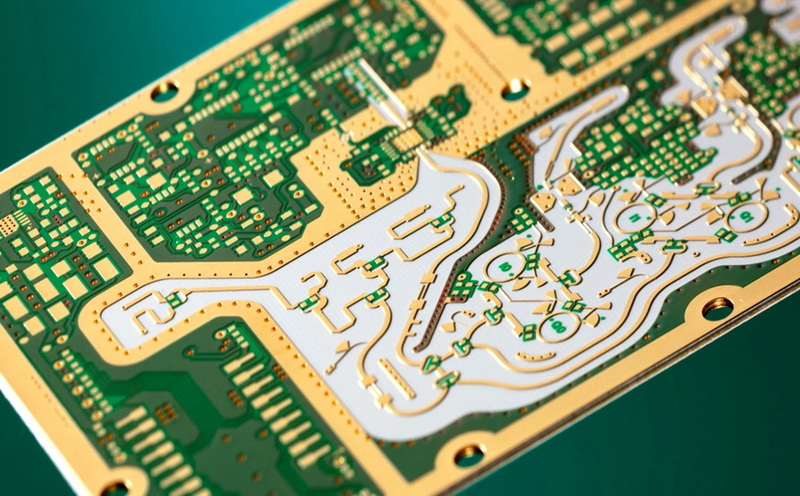

Specific Considerations for LED Components

When handling LED components, specific considerations must be taken into account. LEDs, especially high-power LEDs with soft molded silicone or glass domes, require precise nozzle setup and process parameters to ensure accurate placement without damage[5][8]. The use of custom nozzles and fine-tuning of machine settings can significantly improve the pick and place process for LEDs[7].

Challenges with LED Placement

1. Nozzle Compatibility: LEDs with silicone domes can form a seal with metal nozzles, making component release difficult. Using nozzles with appropriate materials can mitigate this issue[5].

2. Process Parameters: Adjusting parameters such as pick speed and vacuum settings is crucial for handling delicate LED components[7].

Case Studies and Applications

LED SMD pick and place machines are used in various industries, including automotive, consumer electronics, and industrial lighting. For instance, in the automotive sector, these machines are essential for assembling LED components in vehicle lighting systems[6]. In consumer electronics, they are used for producing LED displays and backlights[1].

Industry Applications

1. Automotive Industry: LED SMD machines are used for automotive lighting systems, ensuring high precision and reliability.

2. Consumer Electronics: These machines are crucial for assembling LED components in displays and backlights for devices like smartphones and TVs.

3. Industrial Lighting: They are used for producing high-power LED lighting fixtures, which require precise assembly to ensure durability and performance.

Conclusion

In conclusion, LED SMD pick and place machines are not limited to handling LED components alone. Their versatility and precision make them suitable for a wide range of electronic components, enhancing efficiency, accuracy, and cost-effectiveness in the manufacturing process. By understanding the capabilities and limitations of these machines, manufacturers can optimize their use across various production lines.

Frequently Asked Questions

1. What types of components can LED SMD pick and place machines handle?

- LED SMD pick and place machines can handle a variety of components including resistors, capacitors, ICs (such as SOP, QFP, QFN), and SOT components.

2. How do LED SMD pick and place machines ensure accurate component placement?

- These machines use advanced vision systems to align components with predefined coordinates on the PCB, ensuring precise placement.

3. What are the benefits of using LED SMD pick and place machines in electronics manufacturing?

- The benefits include enhanced efficiency, improved accuracy, and cost savings by reducing labor costs and minimizing rework.

4. Can LED SMD pick and place machines be customized for specific manufacturing needs?

- Yes, these machines can be customized to meet specific production requirements, including modifying feeder configurations and integrating additional features.

5. What are common issues that may arise with LED SMD pick and place machines?

- Common issues include component placement errors, component damage, and inaccurate fiducial recognition, which can be addressed through proper calibration and maintenance.

Citations:

[1] https://www.tronstol.com/smt-equipment-led.html

[2] https://www.hct-smt.com/blog/exploring-automatic-led-pick-and-place-machines%E2%80%8B

[3] https://www.ddmnovastar.com/product/ls60v-pick-and-place-machine-with-vision

[4] https://www.gssmt-parts.com/what-are-the-latest-innovations-in-automatic-smd-pick-and-place-technology.html

[5] https://www.circuitinsight.com/pdf/led_pick_place_challenge_ipc.pdf

[6] https://www.hct-smt.com/blog/automatic-8-heads-led-smd-pick---place-machine

[7] https://downloads.cree-led.com/files/da/x/XLamp-Pick-Place.pdf

[8] https://www.circuitinsight.com/programs/53505.html

[9] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[10] https://www.tronstol.com/the-three-major-development-trends-of-the-pick-and-place-machine-in-the-future.html

[11] https://it.hct-smt.com/blog/what-is-a-pick-and-place-smd-led-machine

[12] https://www.smtfactory.com/introduction-of-smt-pick-and-place-machine

[13] https://www.hct-smt.com/blog/your-guide-to-choosing-the-right-led-pick-and-place-machine-supplier

[14] https://faroadsmt.com/top-trends-in-pick-and-place-tech-2024/

[15] https://www.zjyingxing.com/info/what-are-the-common-smt-pick-and-place-machine-88387624.html

[16] https://essemtec.com/en/applications/

[17] http://www.verypixel.com/m_blog/SMD_Outdoor_LED_Displays_Advantages_Disadvantage.html

[18] https://www.pcbonline.com/blog/smd-led.html

[19] https://www.neodensmt.com/news/led-mounter-development-trend-83291295.html

[20] https://iconnect007.com/index.php/article/52613/smt-preventive-maintenance-stop-5-major-problems-with-pick-and-place-nozzles/52616