Content Menu

● Understanding Laser Cutters

>> Types of Laser Cutters

● Traditional Wood Cutting Machines

>> Common Traditional Tools

● Advantages of Laser Cutters Over Traditional Machines

>> 1. Precision and Accuracy

>> 2. Speed

>> 3. Versatility

>> 4. Reduced Waste

>> 5. Automation

● Limitations of Laser Cutters

>> 1. Initial Cost

>> 2. Material Limitations

>> 3. Maintenance Requirements

>> 4. Safety Concerns

● Comparing Laser Cutters and Traditional Machines

● Applications in Modern Woodworking

● Environmental Impact

● Future Trends in Wood Cutting Technology

● Conclusion

● FAQ

>> 1. What is the best machine that SMD uses to cut wood?

>> 2. Can laser cutters handle all types of wood?

>> 3. Are laser cutters more cost-effective than traditional machines?

>> 4. How thick can a laser cutter cut wood?

>> 5. Is it safe to use a laser cutter at home?

The woodworking industry has undergone significant advancements in technology, and laser cutters are at the forefront of this evolution. These machines, which use concentrated beams of light to cut or engrave wood, are often touted as a replacement for traditional woodworking tools such as saws, routers, and chisels. But can laser cutters truly replace traditional wood cutting machines? This article explores the capabilities, advantages, and limitations of laser cutters compared to traditional methods, with a focus on their application in modern woodworking.

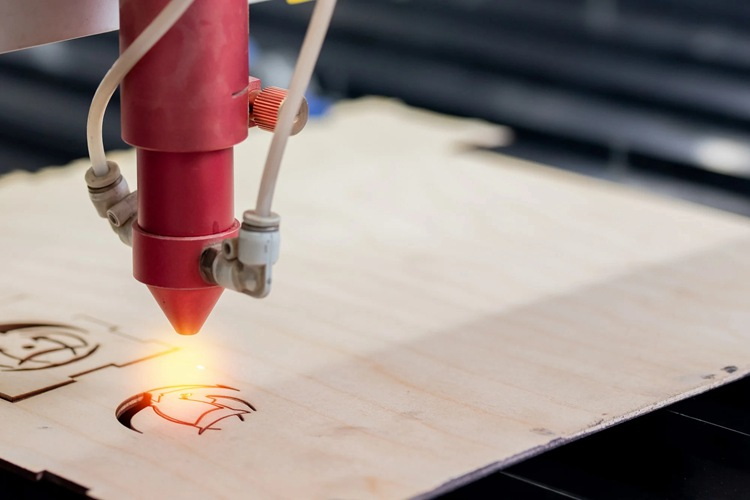

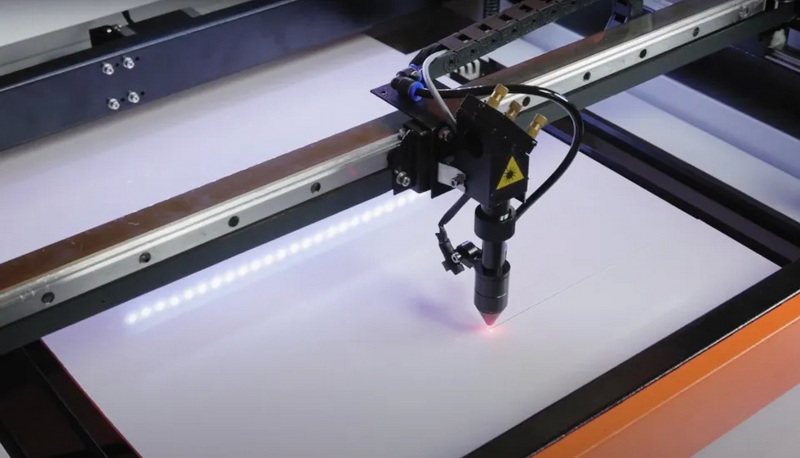

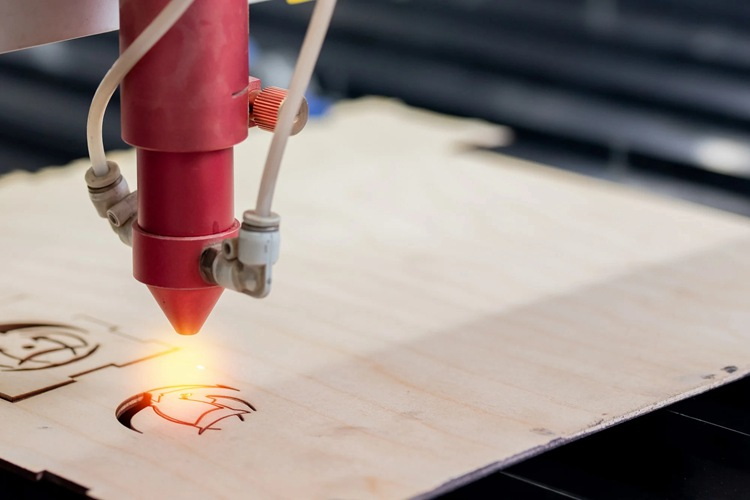

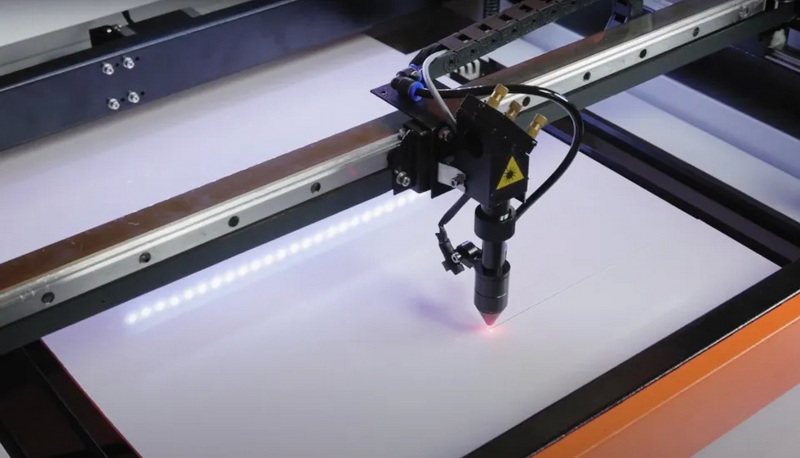

Understanding Laser Cutters

Laser cutters are precision tools that utilize a high-powered laser beam to cut or engrave materials. The machine is guided by computer numerical control (CNC) systems, ensuring accuracy and repeatability. The laser beam vaporizes the material it contacts, leaving clean and precise edges. These machines are versatile and can handle intricate designs that are difficult to achieve with traditional tools.

Types of Laser Cutters

1. CO2 Lasers: Ideal for cutting wood due to their high absorption rate in organic materials. They are commonly used for both industrial and hobbyist applications.

2. Diode Lasers: Affordable and suitable for lighter tasks like engraving or cutting thinner wood.

3. Fiber Lasers: Primarily designed for metals but can be adapted for certain types of wood.

Traditional Wood Cutting Machines

Traditional woodworking relies on tools such as saws, routers, and chisels. These tools require manual operation or mechanical assistance and are valued for their tactile feedback and craftsmanship.

Common Traditional Tools

- Band Saws: Excellent for cutting curves and irregular shapes.

- Table Saws: Used for straight cuts with high precision.

- Routers: Ideal for creating grooves or decorative edges.

- Chisels: Essential for detailed hand-carving.

While these tools offer flexibility and affordability, they often require more time and skill to achieve precise results compared to CNC-guided laser cutters.

Advantages of Laser Cutters Over Traditional Machines

Laser cutters bring several advantages to woodworking:

1. Precision and Accuracy

Laser cutters can achieve a cutting radius as small as 0.1 mm, allowing for intricate designs that are nearly impossible with traditional tools. This precision is particularly valuable in industries requiring detailed craftsmanship, such as furniture making and architectural modeling.

2. Speed

Laser cutting is significantly faster than traditional methods. For example, a high-powered CO2 laser can cut through thick wood in a fraction of the time it would take using a saw or router.

3. Versatility

Laser cutters can handle various types of wood, including hardwoods like oak and softwoods like pine. They can also engrave designs onto surfaces, adding functionality beyond cutting.

4. Reduced Waste

The precision of laser cutting minimizes material waste, making it an environmentally friendly option.

5. Automation

CNC-guided lasers allow for repeatable designs with minimal human intervention, improving efficiency in mass production settings.

Limitations of Laser Cutters

Despite their advantages, laser cutters have some drawbacks:

1. Initial Cost

High-quality laser cutters require a significant upfront investment, which may not be feasible for small businesses or hobbyists.

2. Material Limitations

Not all woods are suitable for laser cutting. Woods with high resin content may discolor or burn during the process.

3. Maintenance Requirements

Laser machines require regular maintenance, including cleaning optics and replacing components like laser tubes.

4. Safety Concerns

Although safer than some traditional tools due to their non-contact nature, laser cutters pose risks such as fire hazards from excessive heat and harmful fumes from certain woods.

Comparing Laser Cutters and Traditional Machines

| Feature | Laser Cutters | Traditional Machines |

| Precision | Extremely high (0.1 mm radius) | Moderate (depends on skill level) |

| Speed | Faster | Slower |

| Versatility | Can cut/engrave intricate designs | Limited to basic cuts |

| Cost | High initial investment | Lower upfront cost |

| Maintenance | Regular cleaning required | Minimal |

| Waste | Minimal | Higher |

| Craftsmanship | Automated | Hands-on |

Applications in Modern Woodworking

Laser cutters excel in areas where precision and speed are critical:

1. Furniture Making: Creating intricate patterns and interlocking pieces.

2. Artisanal Crafts: Engraving personalized designs on wooden surfaces.

3. Mass Production: Ensuring consistency across multiple units.

4. Architectural Modeling: Producing detailed scale models with clean edges.

5. Custom Signage: Crafting unique wooden signs with engraved lettering or logos.

However, traditional tools remain indispensable for projects requiring hands-on artistry or when working with thicker materials that lasers struggle to penetrate efficiently.

Environmental Impact

One often overlooked aspect of woodworking is its environmental footprint. Laser cutters are generally more eco-friendly than traditional machines due to their ability to minimize waste during production. The precision of these machines ensures that only the necessary amount of material is removed during cutting or engraving processes.

Additionally, many modern laser cutters incorporate energy-efficient technologies that reduce power consumption compared to older machinery used in traditional woodworking practices.

Future Trends in Wood Cutting Technology

The future of woodworking is likely to see even greater integration of advanced technologies like artificial intelligence (AI) into CNC-guided systems used by laser cutters. AI could enhance design capabilities by automating complex patterns while optimizing material usage further.

Moreover, hybrid machines that combine the strengths of traditional woodworking tools with the precision of lasers may emerge as viable solutions for artisans who value both craftsmanship and technological efficiency.

Conclusion

While laser cutters offer unparalleled precision, speed, versatility, and environmental benefits, they cannot entirely replace traditional woodworking machines. Each method has its strengths and is suited to different applications. For intricate designs and mass production, laser cutters are the ideal choice; however, traditional tools excel in hands-on craftsmanship and affordability.

Ultimately, the choice between laser cutters and traditional machines depends on the specific needs of the project—whether it's the complexity of the design, budget constraints, or production scale.

FAQ

1. What is the best machine that SMD uses to cut wood?

SMD (Surface Mount Device) manufacturers often use CNC-guided CO2 lasers due to their precision and ability to handle various wood types efficiently.

2. Can laser cutters handle all types of wood?

Not all woods are suitable for laser cutting; those with high resin or moisture content may burn or discolor during the process.

3. Are laser cutters more cost-effective than traditional machines?

While laser cutters have higher initial costs, their efficiency and reduced waste can lead to long-term savings in mass production settings.

4. How thick can a laser cutter cut wood?

The thickness depends on the machine's power; for instance, a 40W diode laser can cut up to 15 mm thick wood in one pass.

5. Is it safe to use a laser cutter at home?

Yes, but proper safety measures must be followed—such as using ventilation systems to manage fumes and wearing protective goggles.