Content Menu

● Introduction to SMT Stencils

>> Types of SMT Stencils

● Using a Laser Cutter for DIY SMT Stencils

>> Materials for Laser-Cut Stencils

>> Laser Cutting Process

>> DIY Stencil Printer Setup

● Advantages of Laser-Cut SMT Stencils

● Design Considerations for SMT Stencils

>> Optimizing Stencil Design

● Maintenance and Cleaning of SMT Stencils

>> Best Practices for Stencil Maintenance

● Challenges and Limitations

>> Overcoming Challenges

● Conclusion

● FAQs

>> 1. What Materials Are Suitable for Laser-Cut SMT Stencils?

>> 2. How Do I Ensure Precision When Cutting Stencils with a Laser?

>> 3. Can I Use a DIY Laser Cutter Setup for SMT Stencil Production?

>> 4. What Are the Key Design Considerations for SMT Stencils?

>> 5. How Often Should SMT Stencils Be Replaced?

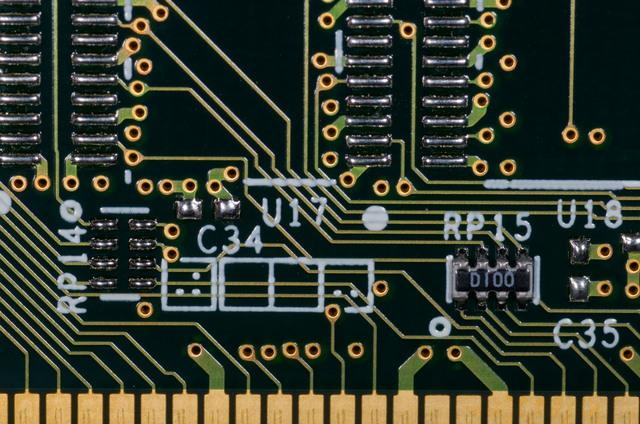

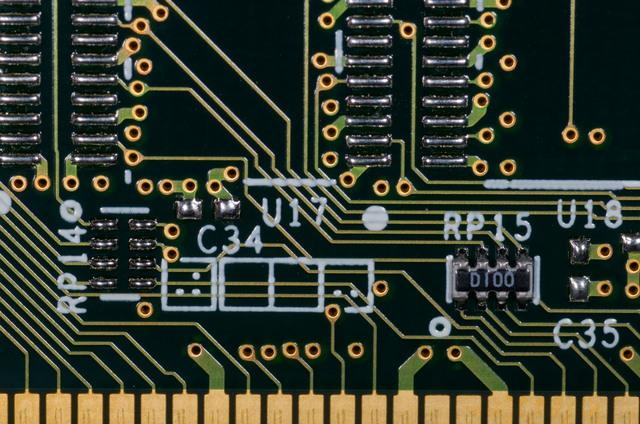

In the realm of electronics manufacturing, Surface Mount Technology (SMT) stencils play a crucial role in ensuring the precise application of solder paste onto printed circuit boards (PCBs). Traditionally, these stencils are manufactured using techniques like electroforming or chemical etching. However, with advancements in technology and the increasing availability of DIY tools, it is now feasible to create SMT stencils using a laser cutter. This approach offers several benefits, including cost-effectiveness, precision, and flexibility, making it an attractive option for both hobbyists and small-scale manufacturers.

Introduction to SMT Stencils

SMT stencils are thin sheets, typically made of materials such as stainless steel or nickel, with laser-cut apertures that correspond to the solder pad locations on a PCB. These stencils facilitate the accurate deposition of solder paste, which is essential for creating reliable solder joints between components and the PCB. The use of SMT stencils ensures consistency in solder paste volume and shape, reducing the risk of defects and improving overall product quality.

Types of SMT Stencils

There are several types of SMT stencils available, each catering to different production needs:

- Framed Stencils: These are permanently fixed within a rigid frame, ideal for high-volume production due to their high positional accuracy and stability.

- Frameless Stencils: Also known as foils, these are low-cost and suitable for low-volume stencil printing, offering cost savings and ease of storage.

- Electroformed Stencils: Created by depositing nickel onto a mandrel, these stencils offer superior paste release characteristics and are durable enough for high-volume use.

Using a Laser Cutter for DIY SMT Stencils

Creating DIY SMT stencils with a laser cutter involves several key steps and considerations:

Materials for Laser-Cut Stencils

The choice of material is crucial for the performance and durability of the stencil. Common materials include:

- Stainless Steel: Known for its durability and heat resistance, stainless steel is a popular choice for SMT stencils.

- Laser Printer Transparencies: These can be used for low-cost, DIY stencils, especially when combined with thermal management techniques to prevent melting during cutting.

- Acrylic: While not as common for SMT stencils, acrylic can be used for other types of stencils due to its rigidity and clean-cut finish.

Laser Cutting Process

Laser cutting is a subtractive process where the laser beam removes material to create the desired apertures. The precision of the cut depends on factors such as laser power, speed, and beam focus. Modern lasers can achieve tolerances as fine as 5μm, making them suitable for fine-pitch components.

DIY Stencil Printer Setup

For those interested in creating a DIY setup, repurposing existing machinery like scanners or printers can be a cost-effective approach. By mounting a laser on a one-axis stepper-motor-driven machine, you can create a simple stencil cutting device. This setup requires minimal investment and can be assembled using readily available components.

Advantages of Laser-Cut SMT Stencils

Laser-cut SMT stencils offer several advantages over traditional methods:

- Precision and Accuracy: Laser cutting provides smooth internal pad walls and high pad positional accuracy, making it ideal for fine-pitch components.

- Aperture Consistency: This reduces potential defects and ensures consistent solder paste application.

- Cost-Effectiveness: Creating stencils in-house can save time and money compared to ordering from manufacturers.

- Flexibility: Laser cutting allows for quick design changes and prototyping, which is beneficial for small-scale or custom projects.

Design Considerations for SMT Stencils

Proper stencil design is crucial for achieving high-quality solder paste prints and minimizing defects. Key factors include:

- Aperture Size and Shape: Apertures should match PCB pads while accounting for solder paste properties and desired solder joint profiles.

- Stencil Thickness: Selecting the appropriate thickness is critical for achieving optimal solder paste volume and print quality.

- Aspect Ratio and Area Ratio: These ratios affect paste release efficiency and should be optimized for the specific PCB design and component specifications.

Optimizing Stencil Design

To optimize stencil design, consider the following strategies:

- Use Design Software: Utilize specialized software to create and simulate stencil designs before cutting. This helps in identifying potential issues and optimizing aperture dimensions.

- Material Selection: Choose materials that offer good paste release characteristics and durability.

- Testing Prototypes: Always test prototype stencils to ensure they meet the required specifications and make necessary adjustments.

Maintenance and Cleaning of SMT Stencils

Regular maintenance is essential for extending the lifespan of SMT stencils:

- Cleaning: Implement a regular cleaning schedule to remove solder paste residue and prevent aperture clogging.

- Inspection: Regularly inspect stencils for damage or wear to maintain print quality.

- Storage: Store stencils in a clean, dry environment to prevent damage during handling and transportation.

Best Practices for Stencil Maintenance

Adopting best practices in maintenance can significantly extend the life of your stencils:

- Use Proper Cleaning Solutions: Avoid harsh chemicals that might damage the stencil material.

- Dry Stencils Properly: Ensure stencils are completely dry after cleaning to prevent corrosion.

- Regularly Check for Wear: Monitor stencil condition and replace them when necessary to maintain quality.

Challenges and Limitations

While laser-cut SMT stencils offer many advantages, there are also challenges and limitations to consider:

- Material Limitations: Some materials may not be suitable for laser cutting or may require special handling.

- Precision Requirements: Achieving the required precision for fine-pitch components can be challenging with lower-end laser cutters.

- Cost of Equipment: While creating stencils in-house can be cost-effective, the initial investment in a laser cutter can be significant.

Overcoming Challenges

To overcome these challenges, consider the following strategies:

- Invest in Quality Equipment: Ensure your laser cutter is capable of achieving the necessary precision.

- Optimize Material Selection: Choose materials that are well-suited for laser cutting and offer good durability.

- Develop Maintenance Routines: Regular maintenance helps extend the life of both the stencil and the laser cutter.

Conclusion

Using a laser cutter to create SMT stencils offers a viable DIY solution for electronics enthusiasts and small manufacturers. With the right materials and techniques, laser-cut stencils can provide precision, cost-effectiveness, and flexibility in PCB assembly. Whether you are prototyping or producing small batches, this approach can significantly enhance your workflow efficiency.

FAQs

1. What Materials Are Suitable for Laser-Cut SMT Stencils?

SMT stencils can be made from materials like stainless steel, nickel, and laser printer transparencies. Stainless steel is preferred for its durability and heat resistance, while transparencies offer a low-cost DIY option.

2. How Do I Ensure Precision When Cutting Stencils with a Laser?

Precision in laser cutting depends on factors such as laser power, speed, and beam focus. Modern lasers can achieve tolerances as fine as 5μm, making them suitable for fine-pitch components. Testing small samples before cutting the final stencil helps optimize these settings.

3. Can I Use a DIY Laser Cutter Setup for SMT Stencil Production?

Yes, a DIY setup using repurposed machinery like scanners or printers can be effective for creating SMT stencils. This approach requires minimal investment and can be assembled using readily available components.

4. What Are the Key Design Considerations for SMT Stencils?

Key design considerations include aperture size and shape, stencil thickness, and aspect and area ratios. These factors directly impact the quality of solder paste deposition and should be optimized based on the PCB design and component specifications.

5. How Often Should SMT Stencils Be Replaced?

The lifespan of an SMT stencil depends on factors like material, usage frequency, and maintenance practices. Generally, stainless steel stencils can last for 20,000 to 50,000 prints, while electroformed nickel stencils can last up to 100,000 prints or more.