Content Menu

● Understanding SMT Stencils and Their Importance in Assembly Efficiency

● What is an SMT Stencil Frame Rack?

● How SMT Stencil Frame Racks Enhance Assembly Efficiency

>> 1. Improved Organization and Accessibility

>> 2. Protection and Longevity of Stencils

>> 3. Space Optimization on the Production Floor

>> 4. Integration with Factory Management Systems

>> 5. Reduced Setup and Changeover Time

● Best Practices for Using SMT Stencil Frame Racks

>> Regular Cleaning and Maintenance

>> Clear Labeling and Documentation

>> Controlled Storage Environment

>> Operator Training

>> Utilize Smart Storage Features

● Challenges and Considerations When Choosing an SMT Stencil Frame Rack

>> Initial Investment Cost

>> Compatibility with Stencil Frames

>> Space Availability

>> Operator Adaptation and Training

● Conclusion

● FAQ

>> 1. What is the main purpose of an SMT stencil frame rack?

>> 2. How does a stencil frame rack improve solder paste printing quality?

>> 3. Are there smart stencil frame racks available?

>> 4. Can stencil frame racks reduce setup times in SMT assembly?

>> 5. What factors should be considered when choosing an SMT stencil frame rack?

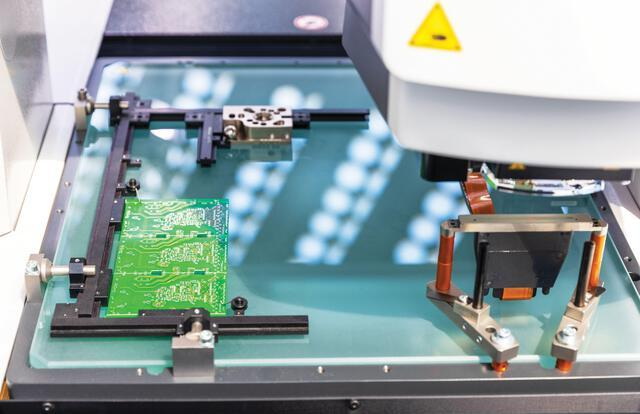

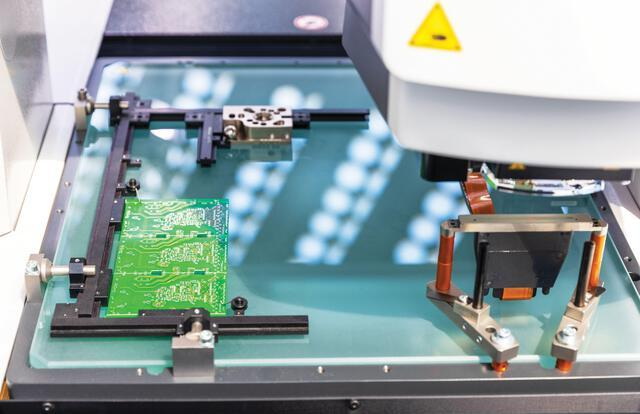

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by enabling the precise placement of miniature components onto printed circuit boards (PCBs). This technology demands exceptional accuracy and repeatability, where even the smallest deviation can lead to defects, costly rework, or product failure. Central to this process is the SMT stencil-a finely engineered metal sheet with laser-cut apertures that control the deposition of solder paste onto PCB pads. While much attention is often given to the stencil itself, the way these stencils are stored, handled, and managed plays an equally vital role in maintaining assembly efficiency and product quality.

This article explores the role of the SMT stencil frame rack in enhancing assembly efficiency. We will discuss what an SMT stencil frame rack is, how it functions within the SMT assembly line, its benefits, best practices for usage, and considerations when selecting the right rack for your manufacturing environment. By understanding and optimizing stencil storage and handling, manufacturers can reduce downtime, improve yield, and ultimately increase throughput.

Understanding SMT Stencils and Their Importance in Assembly Efficiency

Before diving into the benefits of stencil frame racks, it is essential to understand the role of SMT stencils in the assembly process. An SMT stencil is a thin sheet, typically made from stainless steel or nickel alloy, with precisely laser-cut apertures that correspond to the solder pads on a PCB. During the solder paste printing process, the stencil is placed over the PCB, and solder paste is applied using a squeegee. The paste passes through the stencil apertures and deposits onto the PCB pads, preparing the board for component placement.

The accuracy of solder paste deposition directly influences the quality of solder joints, which are critical for electrical connectivity and mechanical strength. Any inconsistency in the stencil's aperture size, shape, or cleanliness can cause defects such as insufficient solder, solder bridges, or tombstoning of components.

Framed SMT stencils are mounted onto rigid frames that keep the stencil foil taut and stable during printing. This rigidity prevents deformation and misalignment, ensuring consistent solder paste volume and placement. However, these framed stencils are delicate and expensive tools that require careful handling and storage to maintain their precision and longevity.

What is an SMT Stencil Frame Rack?

An SMT stencil frame rack is a specialized storage system designed to hold multiple framed SMT stencils securely and in an organized manner. Unlike makeshift or ad hoc storage methods, these racks are engineered specifically to protect the stencils from physical damage, contamination, and environmental factors that could degrade their performance.

Key features of a typical SMT stencil frame rack include:

- Secure Slots or Compartments: Each stencil frame is stored in a dedicated slot that prevents bending or scratching.

- Labeling and Identification: Clear labeling or numbering systems help operators quickly identify and retrieve the correct stencil.

- Dust and Contamination Protection: Some racks come with covers or are placed in controlled environments to minimize exposure to dust, solder paste residue, and humidity.

- Space Efficiency: Vertical or compact designs maximize the number of stencils stored within a minimal footprint.

- Smart Storage Capabilities: Advanced racks integrate with manufacturing execution systems (MES) or enterprise resource planning (ERP) software, enabling digital tracking of stencil usage, maintenance, and inventory.

By providing a structured and protective environment for stencil storage, SMT stencil frame racks play a critical role in maintaining stencil quality and streamlining the assembly workflow.

How SMT Stencil Frame Racks Enhance Assembly Efficiency

The use of an SMT stencil frame rack can contribute to assembly efficiency in multiple, interrelated ways:

1. Improved Organization and Accessibility

In modern electronics manufacturing, especially in high-mix, low-volume (HMLV) or high-mix, high-volume (HMHV) environments, multiple PCB designs require different stencils. Without a proper storage system, operators can waste valuable time searching for the correct stencil, leading to delays and potential errors.

An SMT stencil frame rack provides a systematic way to organize stencils by project, size, or usage frequency. Features such as labeled slots, color coding, or pick-by-light indicators enable quick identification and retrieval. This organizational clarity reduces downtime during stencil changeovers, allowing the assembly line to maintain a steady pace.

2. Protection and Longevity of Stencils

SMT stencils are precision tools that can be easily damaged by scratches, dents, or warping. Even minor damage can alter aperture dimensions, resulting in inconsistent solder paste application and defective solder joints.

By securely holding stencils in a dedicated rack, the risk of physical damage during storage or handling is minimized. Additionally, by protecting stencils from dust, solder paste residue, and humidity, the rack helps prevent corrosion and contamination buildup. This preservation of stencil integrity extends the stencil's usable life, reducing the frequency and cost of stencil replacement.

3. Space Optimization on the Production Floor

Factory floor space is often limited and expensive. SMT stencil frame racks are designed to maximize storage density while maintaining easy access. Vertical racks, sliding drawers, or compact modular units allow manufacturers to store dozens or even hundreds of stencils in a small footprint.

Efficient space usage not only frees up valuable floor area for other equipment and processes but also contributes to a more organized and safer working environment.

4. Integration with Factory Management Systems

Smart stencil frame racks equipped with digital tracking technologies can communicate with MES and ERP systems. This integration allows real-time monitoring of stencil inventory, usage history, cleaning schedules, and maintenance needs.

Such visibility enables proactive stencil management, preventing shortages or overstocking, scheduling timely cleaning or repairs, and ensuring compliance with quality control standards. Automated alerts and data logging reduce human errors and improve traceability, which is critical for quality assurance and regulatory compliance.

5. Reduced Setup and Changeover Time

Quick stencil changeover is crucial in SMT assembly, particularly when switching between different PCB models or production batches. An organized stencil frame rack enables operators to locate and swap stencils rapidly, minimizing machine downtime.

Some racks include features like ergonomic access, pick-by-light systems, or barcode scanning to further accelerate stencil retrieval and placement. Faster changeovers translate directly into higher line uptime and increased throughput.

Best Practices for Using SMT Stencil Frame Racks

To maximize the benefits of an SMT stencil frame rack, manufacturers should follow these best practices:

Regular Cleaning and Maintenance

Always clean stencils thoroughly before storage to remove solder paste residues and contaminants. Dirty stencils stored in racks can transfer residues to other stencils or degrade over time. Implement a routine cleaning schedule and ensure stencils are dry before placing them in the rack.

Clear Labeling and Documentation

Label stencil frames clearly with part numbers, job codes, or other identifiers. Maintain accurate records of stencil usage, cleaning, and maintenance history. This documentation supports quick identification and helps track stencil lifecycle for quality control.

Controlled Storage Environment

Place stencil frame racks in clean, temperature- and humidity-controlled areas to prevent corrosion, warping, or contamination. Avoid exposure to direct sunlight, dust, or chemical vapors.

Operator Training

Train operators on proper stencil handling, storage, and retrieval procedures. Emphasize the importance of using the stencil frame rack to protect stencil integrity and maintain assembly efficiency.

Utilize Smart Storage Features

If possible, invest in stencil frame racks with smart features such as barcode scanning, pick-by-light indicators, or MES integration. These technologies improve inventory control, reduce errors, and support lean manufacturing initiatives.

Challenges and Considerations When Choosing an SMT Stencil Frame Rack

While the advantages of stencil frame racks are clear, manufacturers should consider the following factors before investing:

Initial Investment Cost

High-end stencil frame racks with intelligent features require a significant upfront investment. However, the long-term savings from reduced downtime, scrap, and stencil replacement often justify the cost.

Compatibility with Stencil Frames

Ensure the rack is compatible with the specific sizes and types of stencil frames used in your facility. Some racks are adjustable or modular, while others are designed for standard frame dimensions.

Space Availability

Even compact racks require dedicated floor or bench space. Plan the layout carefully to integrate the rack without disrupting existing workflows.

Operator Adaptation and Training

Introducing a new storage system requires operator buy-in and training. Allocate time and resources to ensure staff understand the benefits and proper use of the stencil frame rack.

Conclusion

In the fast-paced world of SMT assembly, every second counts. An SMT stencil frame rack is more than just a storage solution-it is a critical tool that safeguards stencil quality, streamlines workflow, and enhances overall assembly efficiency. By providing organized, secure, and accessible storage, stencil frame racks reduce setup times, minimize stencil damage, optimize factory space, and integrate with digital factory management systems.

For manufacturers aiming to improve throughput, reduce defects, and maintain consistent product quality, investing in an SMT stencil frame rack is a strategic decision that pays dividends in operational efficiency and cost savings. When combined with proper stencil handling, cleaning, and operator training, stencil frame racks become an indispensable component of a lean, high-performance SMT assembly line.

FAQ

1. What is the main purpose of an SMT stencil frame rack?

An SMT stencil frame rack is designed to store and organize framed SMT stencils securely, protecting them from damage and contamination while facilitating quick retrieval to enhance assembly line efficiency.

2. How does a stencil frame rack improve solder paste printing quality?

By protecting stencils from physical damage and contamination, the rack helps maintain stencil integrity, ensuring consistent aperture dimensions and high-quality solder paste deposition.

3. Are there smart stencil frame racks available?

Yes, intelligent stencil storage cabinets feature pick-by-light systems and connectivity with MES and ERP software, enabling real-time inventory management and error reduction.

4. Can stencil frame racks reduce setup times in SMT assembly?

Yes, by organizing stencils systematically and allowing easy access, stencil frame racks enable faster stencil changeovers, minimizing machine downtime and increasing throughput.

5. What factors should be considered when choosing an SMT stencil frame rack?

Consider compatibility with stencil frame sizes, available factory space, budget for intelligent features, and operator training requirements to ensure effective use and maximum efficiency gains.