Content Menu

● What is an SMT Small PCB Unloader?

● How Does an SMT Small PCB Unloader Work?

● Why Use an SMT Small PCB Unloader to Reduce Defect Rates?

>> 1. Minimizes Mechanical Damage

>> 2. Enhances Alignment and Placement Accuracy

>> 3. Reduces Human Error and Labor Variability

>> 4. Improves Production Efficiency and Throughput

>> 5. Enables Early Defect Detection

● Features of a High-Quality SMT Small PCB Unloader

● Practical Benefits of Using SMT Small PCB Unloaders

● Challenges and Considerations

● Integration of SMT Small PCB Unloader with Quality Control Systems

● Future Trends in SMT Small PCB Unloaders

● Conclusion

● FAQ

>> 1. What is the main function of an SMT small PCB unloader?

>> 2. How does the unloader reduce defect rates in PCB manufacturing?

>> 3. Can SMT small PCB unloaders handle different PCB sizes?

>> 4. What maintenance is required for SMT small PCB unloaders?

>> 5. Are SMT small PCB unloaders compatible with existing SMT lines?

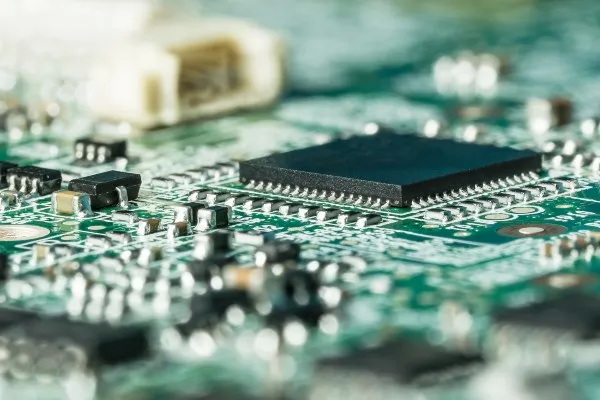

In the fast-paced world of electronics manufacturing, ensuring high-quality printed circuit boards (PCBs) while maintaining efficiency is paramount. One key technology that aids in achieving these goals is the SMT small PCB unloader. This article explores how an SMT small PCB unloader can help reduce defect rates in PCB manufacturing, its features, benefits, and practical considerations for implementation.

What is an SMT Small PCB Unloader?

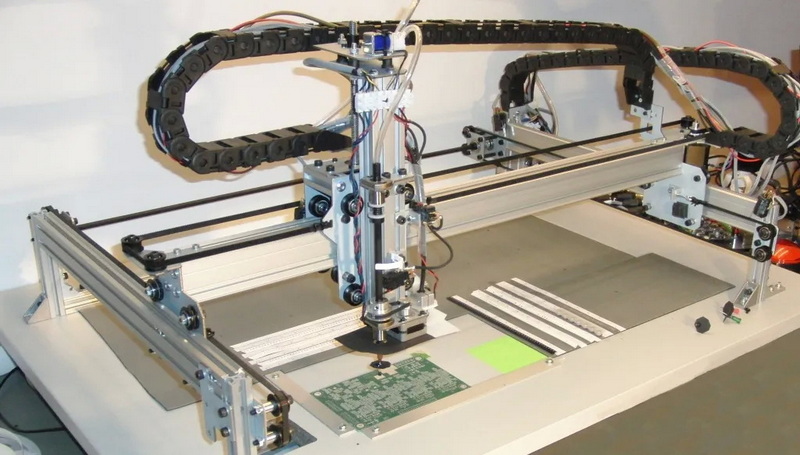

An SMT small PCB unloader is an automated machine designed to remove completed PCBs from the surface mount technology (SMT) production line. It handles small-sized PCBs with precision, ensuring smooth transfer from the assembly line to the next stage, such as inspection, packaging, or further processing.

Unlike manual unloading, which is labor-intensive and prone to errors, the SMT small PCB unloader automates the process, reducing human handling and the associated risks of damage or misalignment. This automation is especially critical for small PCBs, which are more delicate and susceptible to damage during manual handling.

How Does an SMT Small PCB Unloader Work?

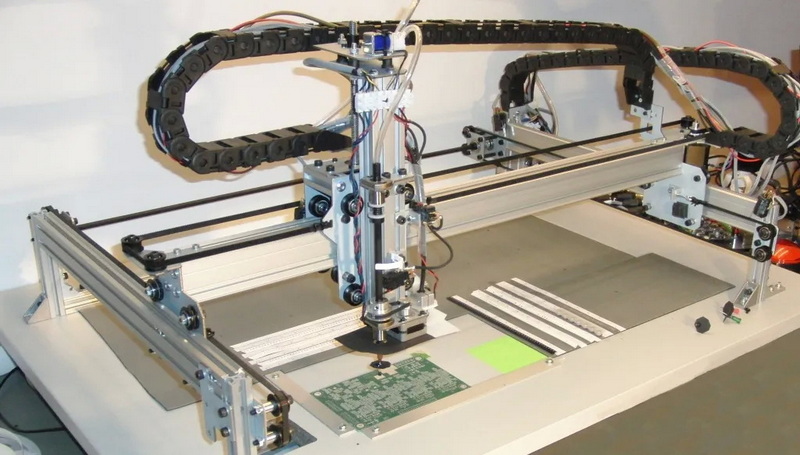

The unloader typically features:

- Conveyor System: Transports assembled PCBs from the SMT line to the unloading area.

- Vision System: Ensures precise alignment and correct orientation of PCBs, detecting defects or misplacements before unloading.

- Programmable Logic Controller (PLC): Manages the operations, including conveyor speed, stacking, and error handling.

- Stacking/Buffering Mechanism: Accumulates unloaded PCBs to maintain continuous production flow.

- User Interface: Allows operators to monitor and adjust parameters easily.

- Safety Features: Includes sensors and emergency stops to protect operators.

This combination ensures PCBs are handled gently and accurately, minimizing mechanical stress and potential damage. The integration of a vision system is particularly important in maintaining quality control, as it can identify misaligned or defective boards before they proceed further down the production line.

Why Use an SMT Small PCB Unloader to Reduce Defect Rates?

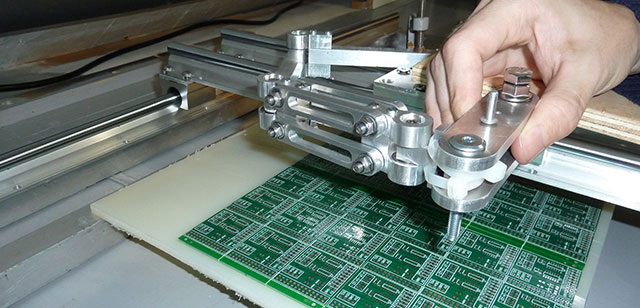

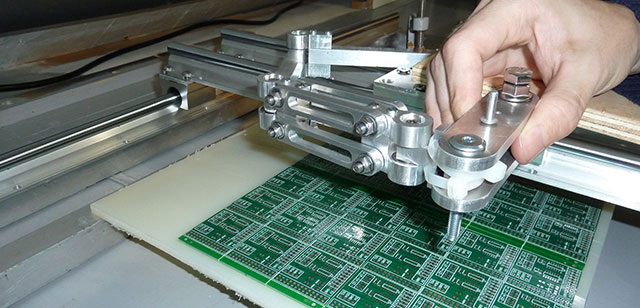

1. Minimizes Mechanical Damage

Manual unloading can cause PCB bending, scratching, or component dislodgement. The SMT small PCB unloader uses controlled pneumatic clamps and smooth conveyor belts to handle PCBs delicately, preventing physical damage that leads to defects. This gentle handling is crucial because even minor mechanical stress can cause micro-cracks in solder joints or damage sensitive components, which may not be immediately visible but can cause failures later.

2. Enhances Alignment and Placement Accuracy

The integrated vision system checks PCB orientation and alignment before unloading, reducing errors such as misfeeds or incorrect stacking. Accurate handling prevents defects related to misaligned components or improper soldering caused by board misplacement. This precise alignment also facilitates downstream processes like automated optical inspection (AOI) and functional testing.

3. Reduces Human Error and Labor Variability

Automating unloading eliminates inconsistencies from manual handling, such as improper stacking or dropping PCBs. This consistency improves overall quality control and reduces defect rates stemming from human factors. Additionally, reducing manual labor decreases fatigue-related mistakes, which are common in repetitive tasks.

4. Improves Production Efficiency and Throughput

By speeding up unloading processes without compromising quality, the SMT small PCB unloader reduces bottlenecks and idle times. Efficient unloading leads to smoother workflow and less rushed handling, which can cause defects. This efficiency is especially beneficial in high-mix, low-volume production environments where frequent changeovers occur.

5. Enables Early Defect Detection

Some unloaders integrate quality assurance (QA) systems that inspect PCBs during unloading, identifying soldering issues, component misalignments, or other faults early. Early detection prevents defective boards from advancing, reducing scrap and rework. This proactive approach saves costs and improves customer satisfaction by delivering higher quality products.

Features of a High-Quality SMT Small PCB Unloader

When selecting an SMT small PCB unloader, look for these key features:

| Feature | Benefit |

| Strong, stable frame design | Ensures machine durability and reduces vibration that can damage PCBs. |

| Touch screen and PLC control | Simplifies operation and allows precise parameter adjustments. |

| Pneumatic clamps | Securely hold PCBs without causing breakage. |

| Adjustable suction heads | Adapt to different PCB sizes and thicknesses. |

| SMEMA interface compatibility | Seamless integration with existing SMT lines. |

| Anti-jamming and foolproof functions | Prevents machine stoppages and PCB damage. |

| Multiple magazine capacity | Enables continuous production with minimal downtime. |

| Vision system integration | Enhances alignment accuracy and defect detection. |

These features collectively contribute to reducing defect rates by ensuring that the unloading process is both reliable and adaptable to different production requirements.

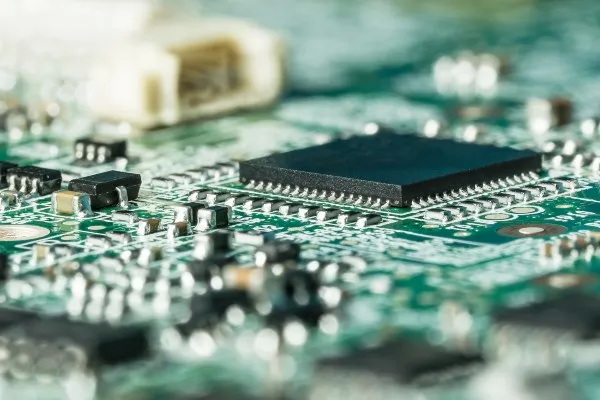

Practical Benefits of Using SMT Small PCB Unloaders

- Reduced Defect Rates: Gentle handling and precise alignment reduce soldering defects, component misplacements, and mechanical damage.

- Labor Cost Savings: Automation reduces the need for manual labor, lowering costs and minimizing human error.

- Space Efficiency: Compact designs save valuable factory floor space compared to manual unloading setups.

- Customization: Machines can be tailored to specific PCB sizes, production volumes, and line configurations.

- Increased Throughput: Faster unloading speeds keep production lines running smoothly without bottlenecks.

- Improved Workplace Safety: Automation reduces the risk of repetitive strain injuries and accidents associated with manual PCB handling.

A well-implemented SMT small PCB unloader can become a critical part of the SMT line, ensuring consistent quality and enabling manufacturers to meet tight delivery schedules without compromising product integrity.

Challenges and Considerations

While SMT small PCB unloaders offer many advantages, manufacturers should consider the following:

- Initial Investment: Automated unloaders require upfront capital but offer long-term savings through defect reduction and labor efficiency. The return on investment (ROI) is typically realized through lower scrap rates and increased throughput.

- Maintenance: Regular cleaning and lubrication are necessary to maintain performance and prevent breakdowns. Dust, solder paste residue, and debris must be removed to avoid sensor malfunctions or mechanical failures.

- Training: Operators need training to use and maintain the equipment effectively. Proper training ensures quick troubleshooting and reduces downtime.

- Compatibility: Ensure the unloader matches PCB sizes and integrates well with existing SMT line equipment. Compatibility with SMEMA standards and communication protocols is essential for seamless operation.

- Flexibility: In high-mix environments, the unloader should support quick changeovers to handle varying PCB dimensions without significant downtime.

By addressing these considerations, manufacturers can maximize the benefits of their SMT small PCB unloader investment.

Integration of SMT Small PCB Unloader with Quality Control Systems

Modern SMT small PCB unloaders often come equipped with or can be integrated with advanced inspection systems such as Automated Optical Inspection (AOI) and Automated X-ray Inspection (AXI). This integration allows for:

- Inline Defect Detection: Defects such as solder bridges, missing components, and tombstoning can be identified immediately after unloading.

- Data Collection and Analysis: Real-time data on defect types and frequencies help manufacturers implement corrective actions quickly.

- Traceability: Linking inspection data to specific PCBs aids in root cause analysis and quality improvement initiatives.

Such integration transforms the unloader from a simple handling device into a critical quality assurance checkpoint, further reducing defect rates and improving overall process control.

Future Trends in SMT Small PCB Unloaders

As PCB manufacturing evolves, SMT small PCB unloaders are expected to incorporate more intelligent features:

- Artificial Intelligence (AI) and Machine Learning: For predictive maintenance and smarter defect detection.

- Enhanced Robotics: For more delicate handling and adaptability to complex PCB designs.

- IoT Connectivity: Enabling remote monitoring and integration into Industry 4.0 smart factory ecosystems.

- Energy Efficiency: Improved designs to reduce power consumption and environmental impact.

Staying abreast of these trends will help manufacturers maintain competitive advantages and continue reducing defect rates effectively.

Conclusion

An SMT small PCB unloader is a valuable asset in modern PCB manufacturing, significantly contributing to reducing defect rates. By automating the unloading process, it minimizes mechanical damage, improves alignment accuracy, reduces human error, and facilitates early defect detection. These advantages translate into higher product quality, increased production efficiency, and cost savings. Investing in a reliable, feature-rich SMT small PCB unloader is a strategic move for electronics manufacturers aiming to enhance their SMT assembly lines and maintain competitive quality standards.

FAQ

1. What is the main function of an SMT small PCB unloader?

The SMT small PCB unloader automates the removal of completed PCBs from the SMT production line, ensuring gentle handling and precise alignment to reduce defects.

2. How does the unloader reduce defect rates in PCB manufacturing?

By minimizing mechanical damage, improving PCB alignment with vision systems, reducing human handling errors, and enabling early defect detection through integrated inspection systems.

3. Can SMT small PCB unloaders handle different PCB sizes?

Yes, most unloaders are customizable and equipped with adjustable clamps and suction heads to accommodate various PCB dimensions and thicknesses.

4. What maintenance is required for SMT small PCB unloaders?

Regular cleaning to prevent debris buildup, lubrication of moving parts, periodic gearbox oil changes, and motor care are essential to maintain optimal operation.

5. Are SMT small PCB unloaders compatible with existing SMT lines?

Yes, many unloaders feature standard SMEMA interfaces and programmable controls to integrate seamlessly with various SMT line equipment.