Content Menu

● Introduction to SMT PCB Manufacturing Costs

● Hidden Costs in SMT PCB Manufacturing

>> Non-Recurring Engineering (NRE) Fees

>> Testing and Validation Costs

>> Shipping and Logistics Costs

>> Equipment Maintenance and Depreciation

● Strategies for Managing Hidden Costs

>> Design for Manufacturing (DFM)

>> Choose the Right Assembly Technology

>> Consolidate Components

>> Order in Volume

>> Partner with an Experienced Vendor

● SMT PCB Board Price Considerations

>> Impact of Design Complexity

>> Material Selection

>> Production Volume

● Balancing Cost and Performance

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary factors influencing SMT PCB board price?

>> 2. How can I estimate the SMT assembly cost for my project?

>> 3. What are non-recurring engineering (NRE) fees, and how do they affect SMT PCB board price?

>> 4. How does design complexity impact SMT PCB board price?

>> 5. Can ordering in volume reduce SMT PCB board price?

● Citations:

The manufacturing of Surface Mount Technology (SMT) printed circuit boards (PCBs) is a complex process that involves numerous factors influencing the final cost. While the visible costs such as material, labor, and equipment are well understood, there are often hidden costs that can significantly impact the overall SMT PCB board price. In this article, we will delve into the various components of SMT PCB manufacturing costs, explore potential hidden costs, and discuss strategies for managing these expenses effectively.

Introduction to SMT PCB Manufacturing Costs

SMT PCB manufacturing involves several key cost components:

- Material Costs: This includes the cost of the PCB itself, which varies based on factors like the number of layers, material type (e.g., FR4, Aluminum), and surface finish. Additionally, the Bill of Materials (BOM) for components such as resistors, capacitors, and integrated circuits (ICs) significantly impacts the total cost. Specialized materials, such as Rogers or Teflon, are more expensive due to their high-frequency or heat conductivity properties[1][2].

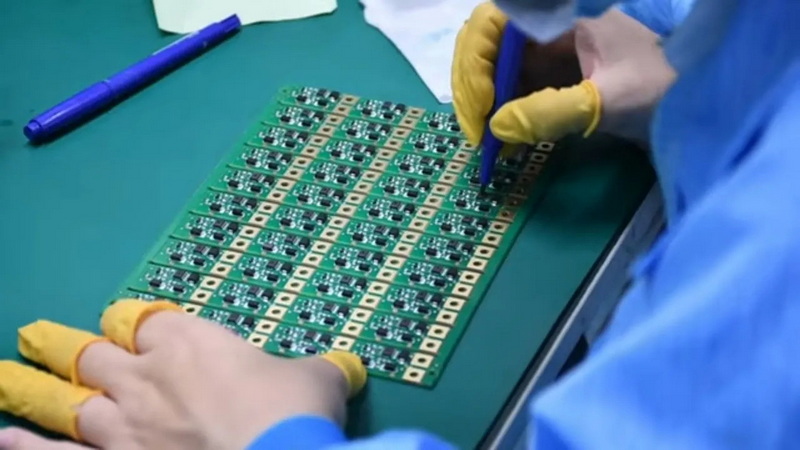

- Labor Expenses: Labor costs encompass not only assembly workers but also engineers, quality control personnel, and setup technicians. The level of automation affects these costs, with higher automation typically reducing labor expenses. For instance, using Surface Mount Devices (SMDs) allows for rapid and precise component placement, which is more cost-efficient than through-hole assembly[3][4].

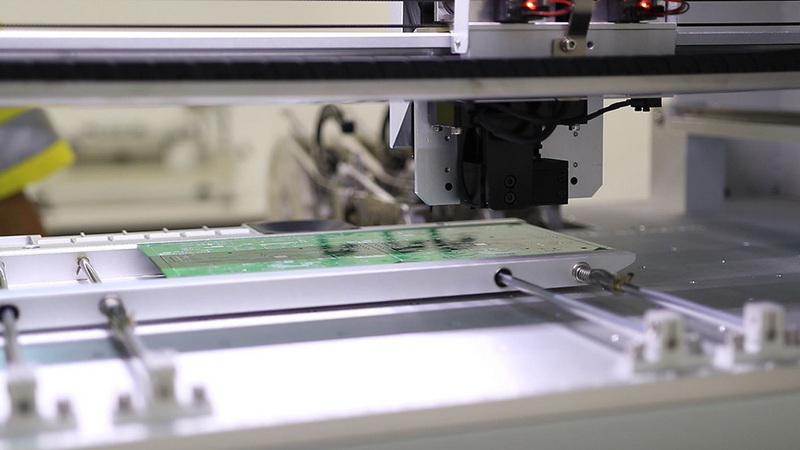

- Equipment Utilization: The type and operating costs of machinery, such as pick-and-place machines and reflow ovens, influence assembly pricing. More advanced equipment generally results in higher costs due to factors like machine depreciation and maintenance[7].

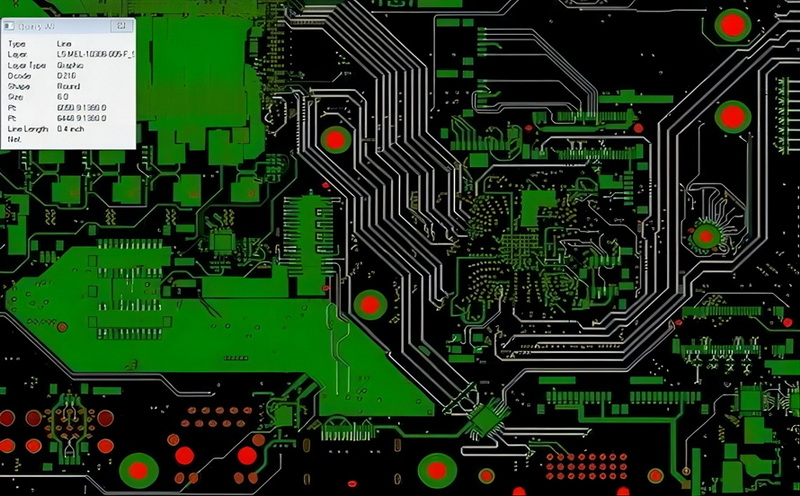

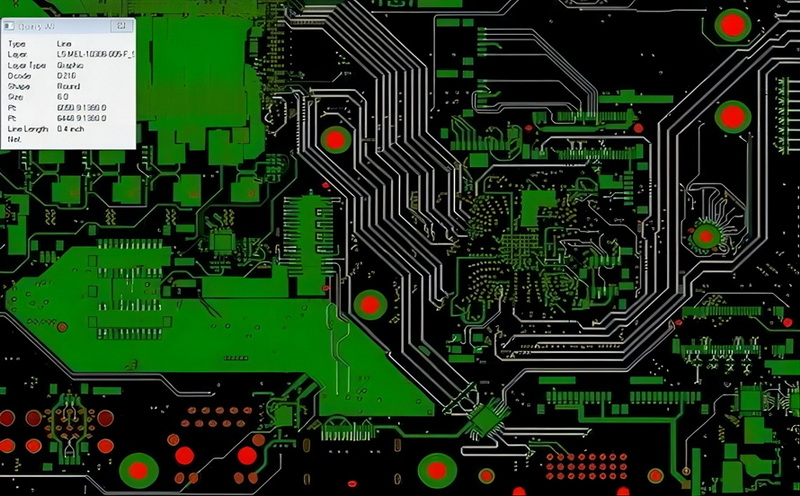

- Design Complexity: Complex board designs with dense component placement, multiple layers, and specialized features increase assembly costs due to the need for precise techniques and specialized equipment. Features like blind vias, buried vias, and controlled impedance contribute to this complexity[2][4].

Hidden Costs in SMT PCB Manufacturing

Non-Recurring Engineering (NRE) Fees

NRE fees are often overlooked but can significantly inflate initial PCB pricing quotations. These include:

- Tooling/Fixture Setup: Costs associated with setting up fixtures and tooling for SMT assembly lines can run into thousands of dollars. This includes programming pick-and-place machines and creating stencils for solder paste application[1][7].

- Mask/Film Tooling Charges: These are typically lower, ranging from $100 to $1000, but still contribute to overall costs. These charges are more significant for small production volumes[1].

- Iterative Design Review Cycles: The cost of iterative design review cycles during development can add up, especially if changes are made late in the process. This includes DMAC/online review cycles, which can cost between $50 and $100 per hour[1].

Testing and Validation Costs

Testing and validation processes are crucial for ensuring quality but add to the cost:

- Automated Optical Inspection (AOI): Machine-driven inspections for surface-mount assemblies.

- X-ray Inspection: Used for checking hidden solder joints in components like Ball Grid Arrays (BGAs).

- Functional Testing: Verifies that each board operates as intended. This step is essential for ensuring the reliability of the final product[7].

Shipping and Logistics Costs

While often overlooked, shipping logistics setup and coordination costs can also impact the final price:

- Shipping Fees: These can vary based on the destination and urgency of delivery. For international shipments, customs clearance and freight charges can add significant costs[1].

Equipment Maintenance and Depreciation

The cost of maintaining and depreciating equipment over its lifespan is a significant hidden cost:

- Machine Depreciation: The cost of equipment spread over its useful life. This includes the initial purchase price divided by the number of years the equipment is expected to operate effectively[7].

- Maintenance: Regular upkeep to ensure machinery operates efficiently. This includes routine checks, part replacements, and software updates[7].

Strategies for Managing Hidden Costs

Design for Manufacturing (DFM)

Collaborating with assembly vendors early in the design phase can help optimize board layout, component selection, and assembly processes, reducing complexities and costs. DFM principles include minimizing the number of layers, using standard components, and ensuring adequate spacing for automated placement[6].

Choose the Right Assembly Technology

Selecting the most cost-effective assembly technology based on product requirements can save costs. For example, SMT assembly is generally more economical than through-hole assembly for high-volume production due to its automation capabilities[3][4].

Consolidate Components

Minimizing the number of unique components simplifies procurement, inventory management, and assembly processes, leading to cost savings. Using a consistent set of components across different products can also lead to bulk discounts[3].

Order in Volume

Taking advantage of economies of scale by placing larger orders can significantly reduce per-unit costs. This is particularly effective for high-volume production runs where setup costs become negligible on a per-unit basis[8].

Partner with an Experienced Vendor

Working with a reliable vendor can provide cost-saving recommendations and efficient processes. Experienced vendors often have optimized workflows and can help manage hidden costs effectively[7].

SMT PCB Board Price Considerations

The SMT PCB board price varies widely based on factors such as component density, board complexity, and order quantity. Typical pricing ranges for SMT assembly are between $50 and $500 per panel. Understanding these factors and managing hidden costs effectively can help optimize the SMT PCB board price.

Impact of Design Complexity

Complex designs with multiple layers, fine traces, and dense component placement require advanced manufacturing techniques, increasing costs. Features like blind vias and controlled impedance add to this complexity[2][4].

Material Selection

The choice of PCB material significantly affects the cost. While FR-4 is cost-effective, specialized materials like flexible PCBs or high-frequency laminates are more expensive due to their unique properties[2][8].

Production Volume

Larger production volumes reduce per-unit costs due to economies of scale. Manufacturers can spread fixed expenses over more units, resulting in cost savings[8].

Balancing Cost and Performance

In electronics manufacturing, balancing cost with performance is crucial. While reducing costs is important, it should not compromise the quality or functionality of the PCB. Strategies like design optimization and strategic component selection can help achieve this balance without sacrificing performance[6].

Conclusion

In conclusion, while SMT PCB manufacturing involves several visible costs, there are also significant hidden costs that can impact the final SMT PCB board price. By understanding these costs and implementing strategies to manage them, manufacturers can optimize their production processes and reduce expenses. Effective communication with vendors and careful planning during the design phase are crucial for minimizing unexpected expenses.

Frequently Asked Questions

1. What are the primary factors influencing SMT PCB board price?

- The primary factors include material costs (PCB and components), labor expenses, equipment utilization, and design complexity. Additionally, non-recurring engineering fees, testing and validation costs, and shipping logistics can also impact the final price.

2. How can I estimate the SMT assembly cost for my project?

- Estimating SMT assembly cost involves analyzing material costs (PCB and components), labor costs, equipment costs, and other expenses like setup fees and testing. A structured approach includes creating a detailed BOM, assessing PCB fabrication costs, and estimating assembly process costs.

3. What are non-recurring engineering (NRE) fees, and how do they affect SMT PCB board price?

- NRE fees include costs for setting up tooling, iterative design reviews, and validating non-standard processes. These fees can significantly increase initial costs but become less impactful in high-volume production.

4. How does design complexity impact SMT PCB board price?

- Complex designs with dense component placement, multiple layers, and specialized features require more precise assembly techniques and specialized equipment, increasing costs. Simplifying designs can help reduce assembly expenses.

5. Can ordering in volume reduce SMT PCB board price?

- Yes, ordering in larger volumes can reduce per-unit costs due to economies of scale. This is particularly effective for high-volume production runs where setup costs become negligible on a per-unit basis.

Citations:

[1] https://www.elepcb.com/blog/the-factors-affecting-pcb-price/

[2] https://www.linkedin.com/pulse/what-factors-affect-pcb-cost-yolin-gan

[3] https://www.protoexpress.com/blog/how-to-reduce-pcb-assembly-cost/

[4] https://reprosupplies.co.za/what-factors-influence-the-cost-of-an-smt-assembly-project/

[5] https://www.nextpcb.com/blog/pcb-assembly-cost-affecting-factors-and-way-to-save-money

[6] https://www.pcbpower.us/blog/the-definitive-guide-to-reducing-pcb-assembly-costs-and-enhancing-efficiency

[7] https://www.pcbjhy.com/blog/how-much-does-pcb-assembly-cost/

[8] https://www.jycircuitboard.com/news/deciphering-pcb-manufacturing-price-factors-that-impact-pcb-price-473.html

[9] https://www.7pcb.com/blog/how-to-decrease-pcb-fabrication-assembly-costs

[10] https://www.andwinpcb.com/the-hidden-costs-of-pcb-manufacturing-equipment-revealing-the-price-tag-behind-a-high-tech-factory/

[11] https://rootsems.com/top-8-factors-affecting-pcb-price/

[12] https://www.protoexpress.com/pcb-cost-optimization/

[13] https://www.anypcba.com/blogs/pcb-manufacturing-knowledge/decoding-pcb-manufacturing-equipment-costs-a-comprehensive-guide.html

[14] https://www.7pcb.com/blog/factors-affecting-cost-pcb-production

[15] https://www.reddit.com/r/PCB/comments/12k56m8/what_steps_are_taken_to_reduce_the_cost_of_a/

[16] https://www.reddit.com/r/PrintedCircuitBoard/comments/xxg5aj/why_is_assembly_so_expensive/

[17] https://www.7pcb.com/blog/factors-affecting-cost-pcb-assembly

[18] https://www.pentalogix.com/blog/2022/12/12/how-to-reduce-pcb-fabrication-costs/

[19] https://www.pcbelec.com/pcb-assembly-cost-a-comprehensive-guide-for-cost-effective-pcb-manufacturing.html

[20] https://www.protoexpress.com/kb/pcb-price-composition/