Content Menu

● What are SMT Shields?

>> Key Features and Benefits

>> Types of SMT Shields

>> Materials Used in SMT Shields

● How SMT Shields Work: The Science Behind EMI Protection

>> Grounding and Shielding Effectiveness

● Applications of SMT Shields

>> Real-World Examples

● Selecting the Right SMT Shield: Key Considerations

● Working with an SMT Shield Manufacturer

>> Key Considerations When Choosing a Manufacturer

● The Future of SMT Shields

● Conclusion: Are SMT Shields the Ultimate Solution?

● Frequently Asked Questions (FAQs)

>> Q1: What is the difference between EMI and RFI?

>> Q2: How do I determine the required shielding effectiveness for my application?

>> Q3: Can SMT shields be used in high-temperature applications?

>> Q4: Are there any drawbacks to using SMT shields?

>> Q5: How can I find a reliable SMT shield manufacturer?

>> Q6: What are SMT grounding pads?

>> Q7: What are the benefits of using a clip and can system?

SMT shields, also known as surface mount shields or SMD shields, are conductive enclosures designed to be directly mounted onto a printed circuit board (PCB) using surface mount technology[10]. They serve as a barrier against electromagnetic radiation, preventing it from either escaping from or entering into a specific area of the PCB[7].

Key Features and Benefits

* EMI/RFI Protection: The primary function of an SMT shield is to block or attenuate EMI and radio frequency interference (RFI), ensuring the proper functioning of sensitive components and circuits[7][10].

* Surface Mountable: Designed for automated assembly using standard SMT equipment, reducing manufacturing costs and improving production efficiency[5][8].

* Space Saving: SMT shields are typically compact and low-profile, making them ideal for densely populated PCBs where space is at a premium[10].

* Customizable: Available in various shapes, sizes, and materials to suit specific application requirements[1][7].

* Replaceable/Removable: Some SMT shield designs allow for easy removal and replacement for rework, inspection, or component replacement[9][10].

* Grounding: Many SMT shields incorporate grounding features to enhance shielding effectiveness[2][5].

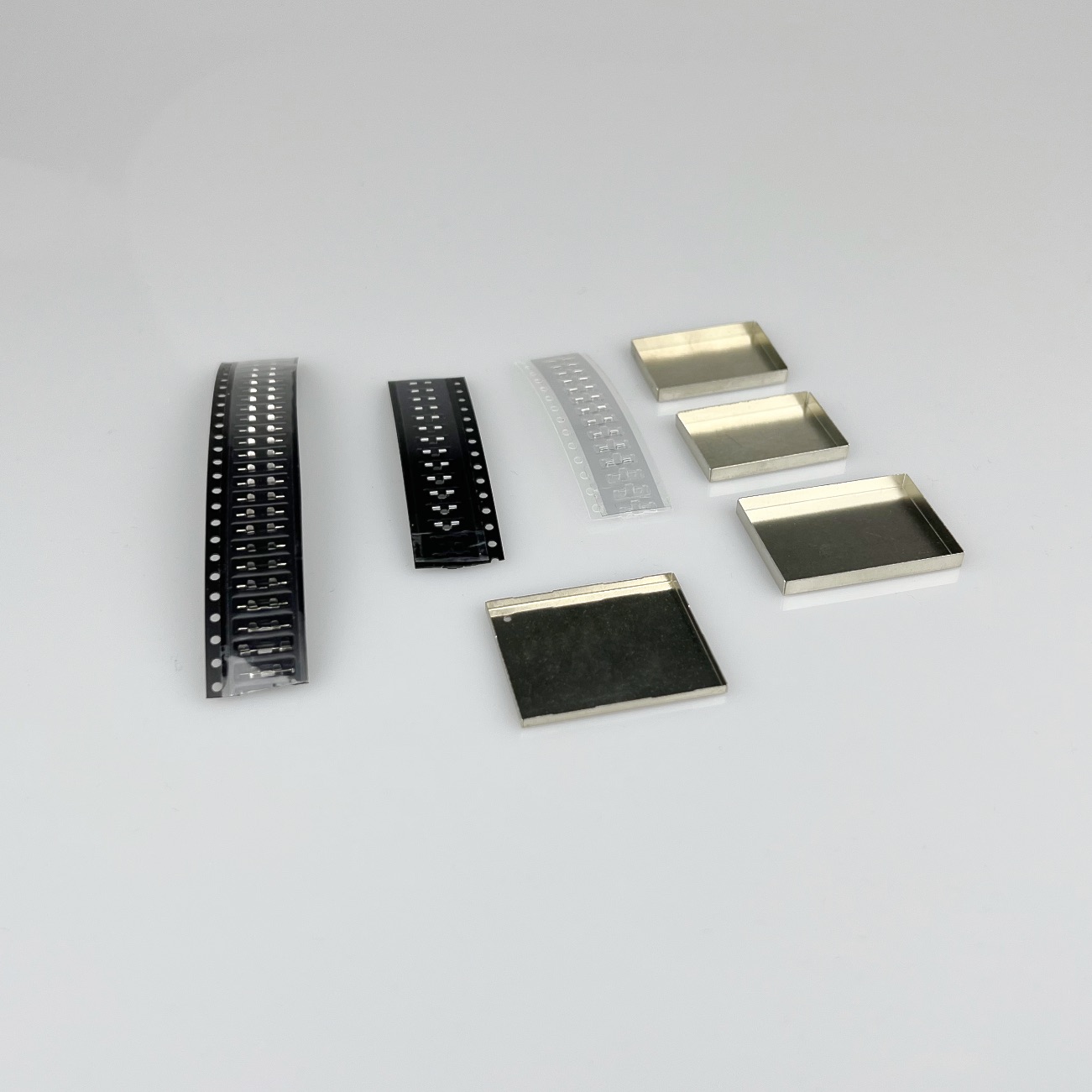

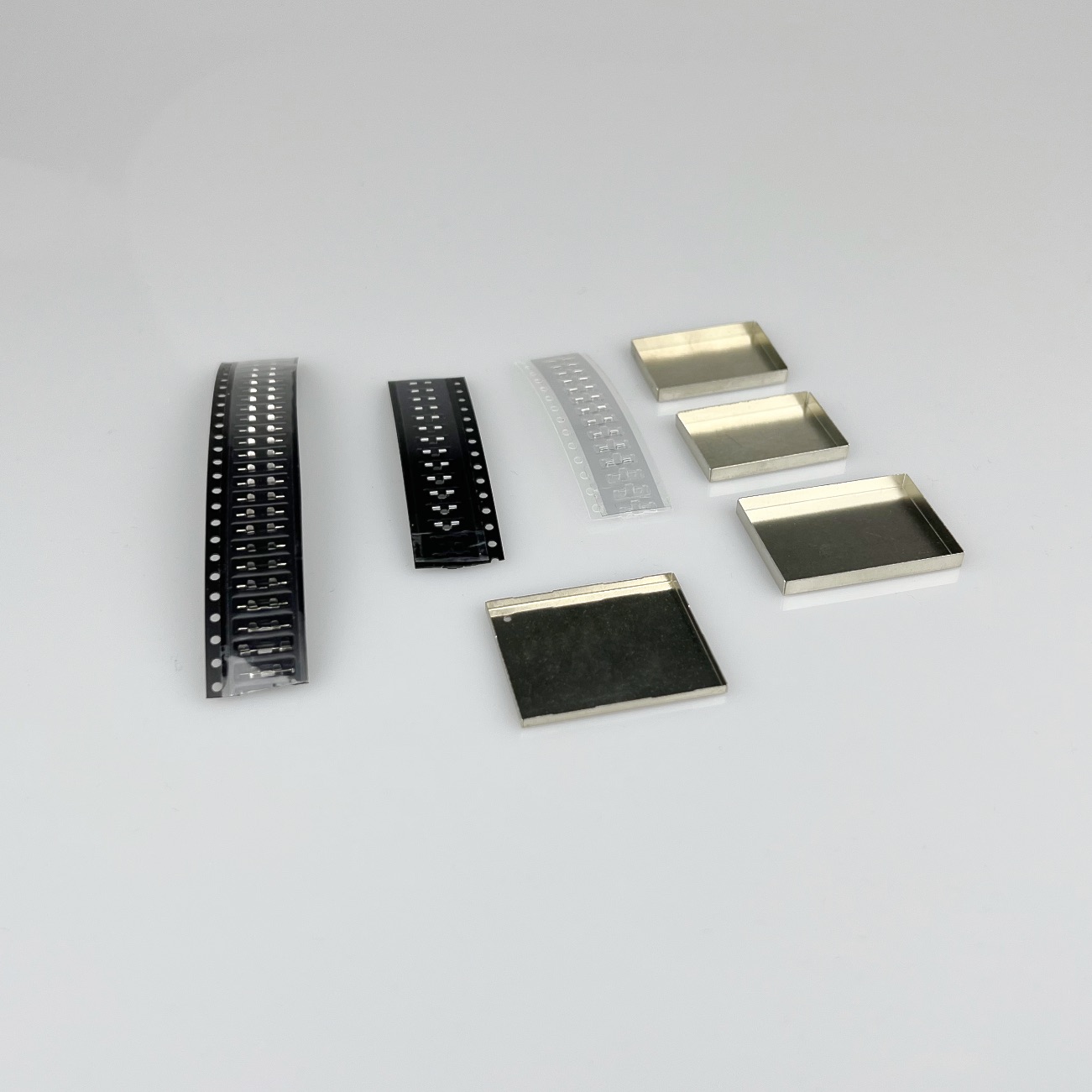

Types of SMT Shields

Several types of SMT shields cater to different needs and applications:

* One-Piece Shields: Simple, cost-effective shields that provide basic EMI protection[7].

* Two-Piece Shields (Clip-and-Can): Consist of a frame (fence) soldered to the PCB and a removable cover (can). This design allows for easy access to the shielded components[7][9].

* Multi-Cavity Shields: Feature multiple compartments within a single shield, enabling the isolation of different sections of a circuit[7][10].

* SMD Shields: Small, individual shields designed to protect specific components[10].

Materials Used in SMT Shields

The choice of material for an SMT shield is critical to its performance. Common materials include:

* Tin-Plated Steel: Offers good shielding effectiveness and corrosion resistance.

* Nickel Silver: Provides excellent shielding performance and solderability.

* Copper Alloys: Exhibit high conductivity and are suitable for high-frequency applications.

* Stainless Steel: Offers high strength and corrosion resistance.

* Conductive Plastics: Lightweight and can be molded into complex shapes.

* Soft Ferromagnetic Materials: Superior material characteristics such as high linearity and very low hysteresis[4].

How SMT Shields Work: The Science Behind EMI Protection

SMT shields function based on the principles of electromagnetic field containment and reflection. When an electromagnetic wave encounters a conductive shield, several phenomena occur:

* Reflection: A portion of the electromagnetic wave is reflected off the surface of the shield. The effectiveness of reflection depends on the conductivity of the shield material.

* Absorption: Some of the electromagnetic energy is absorbed by the shield material and converted into heat. The amount of absorption depends on the material's properties and the frequency of the wave.

* Multiple Reflections: Electromagnetic waves may reflect multiple times within the shield enclosure before exiting which reduces the energy of the electromagnetic wave.

By effectively reflecting and absorbing electromagnetic radiation, SMT shields minimize the amount of EMI that can affect sensitive components. The effectiveness of a shield is typically measured in decibels (dB) of attenuation. Higher dB values indicate better shielding performance.

Grounding and Shielding Effectiveness

Proper grounding is essential for maximizing the effectiveness of an SMT shield[2][5]. A well-grounded shield provides a low-impedance path for induced currents, preventing them from circulating within the shielded enclosure and causing further interference. Grounding can be achieved through various methods, such as:

* Direct Connection to Ground Plane: Soldering the shield directly to the PCB's ground plane.

* Grounding Pads: Using dedicated grounding pads on the PCB to connect the shield.

* SMT Grounding Pads: Conductive silicone gasket laminated with a solderable metal strip[5].

Applications of SMT Shields

SMT shields find widespread use in various electronic devices and industries, including:

* Telecommunications: Mobile phones, routers, and base stations[2].

* Automotive Electronics: Engine control units (ECUs), infotainment systems, and advanced driver-assistance systems (ADAS)[2].

* Consumer Electronics: Smartphones, tablets, laptops, and gaming consoles[2].

* Medical Devices: Pacemakers, hearing aids, and diagnostic equipment.

* Industrial Equipment: Programmable logic controllers (PLCs), sensors, and control systems.

* Aerospace: Communication systems, navigation equipment, and flight control systems.

* High-Speed Communication Devices: Routers, 5G communication systems and high-frequency switches[2].

Real-World Examples

* Smartphones: SMT shields are used to isolate sensitive RF circuitry from other components, preventing interference and ensuring reliable wireless communication[2].

* Automotive ECUs: SMT shields protect critical engine control electronics from the harsh electromagnetic environment within a vehicle[2].

* Medical Implants: SMT shields are essential for preventing EMI from affecting the operation of life-saving medical devices.

Selecting the Right SMT Shield: Key Considerations

Choosing the appropriate SMT shield for a specific application requires careful consideration of several factors:

* Frequency Range: The shield should provide adequate attenuation at the frequencies of concern.

* Shielding Effectiveness: The required level of shielding depends on the sensitivity of the shielded components and the intensity of the EMI environment.

* Size and Space Constraints: The shield must fit within the available space on the PCB.

* Material Compatibility: The shield material should be compatible with the PCB materials and soldering process.

* Thermal Management: If the shielded components generate significant heat, the shield should provide adequate thermal dissipation.

* Cost: The cost of the shield should be balanced against its performance and other requirements.

* Mounting Style: Choose the correct mounting style[1].

* Environmental Considerations: Resistance to corrosion[7].

Working with an SMT Shield Manufacturer

Collaborating with a reputable SMT shield manufacturer is crucial for ensuring the success of your EMI shielding strategy. A good SMT shield manufacturer can offer:

* Design Assistance: Expertise in shield design and optimization[7].

* Customization: Ability to create custom shields tailored to specific requirements[1][7][10].

* Prototyping: Services for creating and testing shield prototypes.

* Manufacturing Capabilities: High-volume manufacturing capabilities to meet production demands[7].

* Quality Control: Rigorous quality control processes to ensure shield performance and reliability[7].

* Material Selection: Knowledge about the material such as tin-plated, SUS, or nickel-silver alloy[7].

Key Considerations When Choosing a Manufacturer

* Experience and Expertise: Look for a manufacturer with a proven track record in SMT shield design and manufacturing.

* Technical Capabilities: Ensure the manufacturer has the necessary equipment and expertise to meet your specific requirements.

* Quality Certifications: Check for certifications such as ISO 9001 to ensure quality management.

* Customer Support: Choose a manufacturer that provides excellent customer support and technical assistance.

The Future of SMT Shields

As electronic devices continue to evolve, the demand for effective EMI shielding solutions will only increase. SMT shields are expected to play an increasingly important role in protecting sensitive electronics from interference. Future trends in SMT shield technology include:

* Advanced Materials: Development of new materials with enhanced shielding properties and improved thermal performance.

* Miniaturization: Further reduction in shield size to accommodate even smaller devices.

* Integration with Other Components: Integration of shielding functionality into other components, such as connectors and IC packages.

* Smart Shields: Development of shields with embedded sensors and control circuitry for dynamic EMI management.

Conclusion: Are SMT Shields the Ultimate Solution?

SMT shields offer a versatile and effective solution for mitigating EMI in a wide range of electronic devices. Their compact size, ease of assembly, and customizable designs make them an attractive option for many applications. While not a universal solution for all EMI problems, SMT shields are undoubtedly a crucial tool in the arsenal of any electronics designer seeking to ensure the performance and reliability of their products. By carefully selecting the right shield and working with a reputable SMT shield manufacturer, engineers can effectively address EMI challenges and create robust, high-performance electronic devices.

Frequently Asked Questions (FAQs)

Q1: What is the difference between EMI and RFI?

A: EMI (Electromagnetic Interference) is a broader term that encompasses any unwanted electromagnetic energy that disrupts the operation of an electronic device. RFI (Radio Frequency Interference) is a specific type of EMI that occurs in the radio frequency range (typically 3 kHz to 300 GHz).

Q2: How do I determine the required shielding effectiveness for my application?

A: The required shielding effectiveness depends on the sensitivity of the shielded components and the intensity of the EMI environment. A thorough EMI analysis and testing may be necessary to determine the appropriate level of shielding.

Q3: Can SMT shields be used in high-temperature applications?

A: Yes, but it is essential to choose a shield material that can withstand the operating temperatures. Stainless steel and certain high-temperature plastics are suitable for high-temperature applications. Tech Etch provides high temperature fabric over foam[1].

Q4: Are there any drawbacks to using SMT shields?

A: SMT shields can add to the cost and complexity of the manufacturing process. They may also require additional space on the PCB. However, the benefits of EMI protection often outweigh these drawbacks.

Q5: How can I find a reliable SMT shield manufacturer?

A: Look for a manufacturer with experience, technical expertise, quality certifications, and excellent customer support. Ask for references and review their case studies to assess their capabilities.

Q6: What are SMT grounding pads?

A: SMT grounding pads are commonly used as a grounding contact on PCBs, providing reliable grounding and shielding performance. These pads are delivered in tape-and-reel packaging for automated placement with standard SMT equipment and comprised of a Ni-C loaded conductive silicone gasket laminated with a solderable metal strip for easy reflow[5].

Q7: What are the benefits of using a clip and can system?

A: Clip and can systems speed up board-level shielding, are faster to assemble, eliminate hand soldering, prevent hot spots and damage to vulnerable devices. The shield cans are also re-usable and easy to remove for rework and maintenance[9].