Content Menu

● What are Juki SMT Feeders?

>> The Significance of Feeders in SMT

● Types of Juki SMT Feeders

>> Tape Feeders

>> Stick/Tube Feeders

>> Bulk Feeders

>> Stack Stick Feeders

● Key Features of Juki SMT Feeders

● How to Select the Right Juki SMT Feeder

>> Component Size and Packaging

>> Production Volume and Speed

>> Machine Compatibility

>> Budget

● Maintenance and Troubleshooting

>> Regular Cleaning

>> Inspection

>> Adjustment

>> Troubleshooting Common Issues

● Leading Juki SMT Feeders Manufacturers and Suppliers

● The Future of Juki SMT Feeders

● Conclusion

● Frequently Asked Questions (FAQ)

>> Q1: What are Juki SMT Feeders used for?

>> Q2: What types of components can Juki SMT Feeders handle?

>> Q3: What should I consider when maintaining Juki SMT Feeders?

>> Q4: What are some common issues with Juki SMT Feeders?

>> Q5: Where can I purchase Juki SMT Feeders?

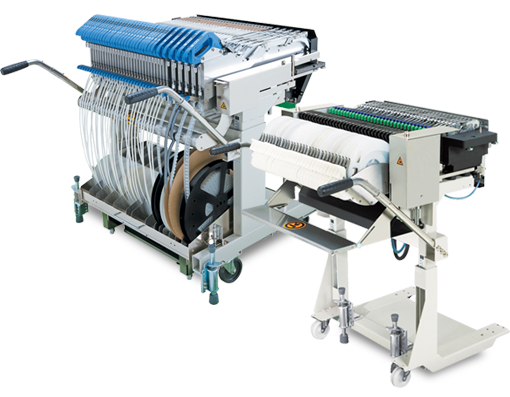

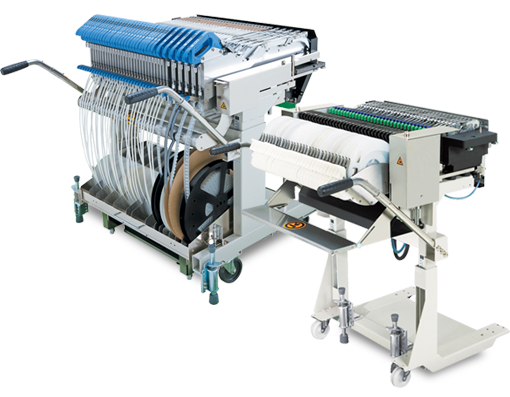

Juki SMT Feeders are precision-engineered devices that supply electronic components to SMT placement machines[1]. These feeders hold components, typically packaged on tape and reel or in sticks/tubes, and advance them to a designated pickup point where the placement head can reliably grab and position them onto the printed circuit board (PCB)[1][4]. Juki feeders are known for their accuracy, speed, and compatibility with a wide range of component sizes and types[1]. Shenzhen TY Electronic Technology Co., Ltd. produces top-quality Juki feeders designed with precision and built for accurate and efficient component placements[2].

The Significance of Feeders in SMT

* Component Delivery: Feeders ensure a consistent and reliable supply of components to the placement machine[1].

* Placement Accuracy: Precise component presentation minimizes placement errors[3].

* Production Speed: Fast and reliable feeding mechanisms increase throughput[1].

* Component Range: Different feeder types accommodate various component sizes and shapes[1].

* Overall Efficiency: Proper feeder maintenance reduces downtime and material waste[3].

Types of Juki SMT Feeders

Juki offers a variety of feeders to suit different SMT production needs[1].

Tape Feeders

Tape feeders are the most widely used type, designed for components supplied on tape and reel[1].

* Electronic Tape Feeders: Offer stable and fast supply of components, easy barcode reading, and higher uptime with easy-to-use splicing[1]. They can be used simultaneously with mechanical feeders[1].

* Mechanical Tape Feeders: Feature easy barcode reading, a stiffer cover structure, height adjustability, an improved locking mechanism, and a compact design[1]. They can be used simultaneously with electronic feeders[1]. Juki also offers spliceable tape feeders from 8mm (0402) through 24mm[1].

* General-Purpose Tape Feeders: Permits pitch selection by variable feed pitch[4].

* Dedicated Type Tape Feeders: Offers enhanced supply reliability[4].

Stick/Tube Feeders

Stick feeders are used for components packaged in tubes or sticks[1].

Bulk Feeders

Bulk Feeders feature a unique rotary-type alignment mechanism to minimize possible component damage[4]. They are driven by a built-in drive cylinder, requiring no air or electricity and can be easily attached or detached[4]. Because there is no generation of remnant materials, ISO 14000 is easy to achieve[4].

Stack Stick Feeders

By using a quick-change cartridge system, the changer mechanism ensures a continuous supply of components, drastically reducing the frequency of refilling[4]. Also, the belt conveyor and the pick-up positioning mechanism have been re-designed to enhance the stability of the supply of components, ensuring the highest pick reliability[4].

Key Features of Juki SMT Feeders

Juki SMT Feeders are known for their features, which enhance SMT line performance[1].

* Stable Platform: Ensures steady and fast supply of ultra-small components[1].

* Increased Operability: Allows replenishment/change while the machine is running[1].

* 7-Segment LED Display: Shows feeder position, pitch, and status[1].

* Higher Uptime: Features easy-to-use splicing[1].

* Easy Barcode Reading: Simplifies component tracking[1].

* Compact Design: Contributes to efficient use of machine space[1].

How to Select the Right Juki SMT Feeder

Choosing the right Juki SMT Feeder depends on several factors related to your SMT production requirements[3].

Component Size and Packaging

* Tape Width: Select feeders that match the tape width of your components.

* Component Type: Consider whether components are standard, odd-form, or require specialized handling.

* Packaging Type: Determine whether components come in tape, sticks, or bulk.

Production Volume and Speed

* High-Speed Feeders: Opt for high-speed tape feeders if you need to maximize throughput[1].

* Automated Feeders: Consider automated feeders to minimize manual intervention[1].

Machine Compatibility

* Juki Placement Machines: Ensure that the feeders are compatible with your specific Juki placement machine model[1].

* Feeder Interfaces: Check that the feeders have the correct interface for communication and control[1].

Budget

* Cost-Effective Feeders: Balance performance requirements with budget constraints[2].

* Used Feeders: Consider purchasing used or refurbished feeders from reputable suppliers[3].

Maintenance and Troubleshooting

Proper maintenance is essential to keep Juki SMT Feeders operating smoothly and reliably[3].

Regular Cleaning

* Dust and Debris: Clean feeders regularly to remove dust, debris, and adhesive residue[3].

* Cleaning Solutions: Use approved cleaning solutions that won't damage feeder components[3].

Inspection

* Worn Parts: Inspect feeders for worn or damaged parts, such as springs, gears, and sensors[3].

* Replacement: Replace worn parts promptly to prevent feeder malfunctions[3].

Adjustment

* Proper Adjustment: Adjust the feeder settings to ensure optimal component presentation[3].

* Calibration: Calibrate the feeder to maintain accurate component positioning[4]. The feeder calibration jig is used to periodically adjust the pick position of the feeder to maintain high pick reliability, and the new camera and monitor dramatically simplify and speed the adjustment procedure[4].

Troubleshooting Common Issues

* Feeder Jams: Clear any jammed components or tape[3].

* Skipped Components: Check tape tension and feeder alignment[3].

* Misfeeds: Inspect feeder mechanisms for wear or damage[3].

* Picking Position Deviation: Manually correct the reclaiming coordinates of the SMT Feeder[3].

* Suction Nozzle Collisions: Reset the position of the suction nozzle in the system[3].

* Abnormal Reclaiming Due to Insufficient Vacuum: Check the vacuum pump and corresponding air circuit[3].

Leading Juki SMT Feeders Manufacturers and Suppliers

* Juki: As the original Juki SMT feeders manufacturer, Juki offers a comprehensive range of feeders and SMT solutions[8].

* Shenzhen TY Electronic Technology Co., Ltd.: Manufactures top-quality Juki feeders[2].

* Dobeter Electronics: Develops electric SMT feeders for Juki[5].

* Various Suppliers: Many suppliers offer Juki SMT feeders and parts[7].

The Future of Juki SMT Feeders

The future of Juki SMT Feeders is likely to be shaped by several trends.

* Smart Feeders: Integration of sensors, data analytics, and AI to optimize feeder performance and predict maintenance needs[1].

* Flexible Feeders: Development of feeders that can handle a wider range of component sizes and packaging types[1].

* Enhanced Reliability: Focus on robust designs and materials to minimize downtime[2].

Conclusion

Juki SMT Feeders are components of modern SMT assembly lines[1]. Understanding the different types of feeders, their key features, how to select the right ones, and how to maintain them is crucial for optimizing your production process[3]. By partnering with reputable suppliers and staying abreast of the latest technology trends, you can ensure that your SMT line operates at peak efficiency and delivers high-quality electronic products[8].

Frequently Asked Questions (FAQ)

Q1: What are Juki SMT Feeders used for?

Juki SMT Feeders are used to automatically supply electronic components to pick-and-place machines in SMT assembly lines[1]. They ensure a consistent and reliable supply of components for accurate placement onto PCBs[3].

Q2: What types of components can Juki SMT Feeders handle?

Juki SMT Feeders can handle a variety of components, including standard chip components, connectors, and other parts with various sizes and shapes[1].

Q3: What should I consider when maintaining Juki SMT Feeders?

Regular cleaning to remove dust and debris is essential. Also important are inspection for worn parts, and proper adjustment to ensure accurate component positioning[3][4].

Q4: What are some common issues with Juki SMT Feeders?

Common issues include feeder jams, skipped components, misfeeds, and picking position deviations[3].

Q5: Where can I purchase Juki SMT Feeders?

Juki SMT Feeders can be purchased directly from Juki and from various suppliers[5][7].