Content Menu

● Understanding Mini SMT Stencils

>> The Evolution of SMT Stencils

● Advantages of Using Mini SMT Stencils

>> Precision and Consistency

>> Time and Cost Efficiency

>> Reduced Defects and Rework

>> Compatibility with Automation

● Design Considerations for Mini SMT Stencils

>> Aperture Design

>> Stencil Thickness

>> Material Selection

● Manufacturing Processes for Mini SMT Stencils

>> Laser Cutting

>> Chemical Etching

>> Electroforming

● Best Practices for Using Mini SMT Stencils

>> Proper Alignment

>> Stencil Cleaning

>> Storage and Handling

>> Solder Paste Selection

● Applications of Mini SMT Stencils

>> High-Density PCB Assembly

>> Prototyping and Small-Batch Production

>> Rework and Repair

>> Specialized Electronics

● Future Trends in Mini SMT Stencil Technology

>> Nano-Coatings

>> 3D-Printed Stencils

>> Integration with Industry 4.0

● Conclusion

● FAQ

>> 1. What is the ideal thickness for a mini SMT stencil?

>> 2. How long does a mini SMT stencil typically last?

>> 3. Can I create a mini SMT stencil at home?

>> 4. How do I clean a mini SMT stencil?

>> 5. What are the alternatives to using a mini SMT stencil?

● Citations:

In the world of electronics manufacturing, precision and efficiency are paramount. As components continue to shrink and circuit boards become more densely populated, the need for accurate and reliable soldering techniques has never been greater. Enter the mini SMT stencil, a game-changing tool that has revolutionized the way we approach surface mount technology (SMT) soldering. This article will explore the numerous benefits and applications of mini SMT stencils, shedding light on why they have become an indispensable asset in both professional and hobbyist electronics assembly.

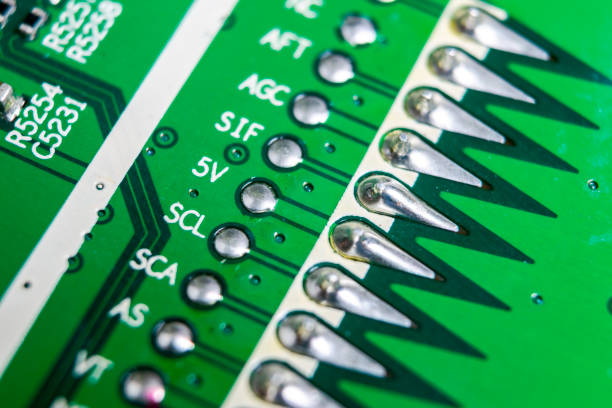

Understanding Mini SMT Stencils

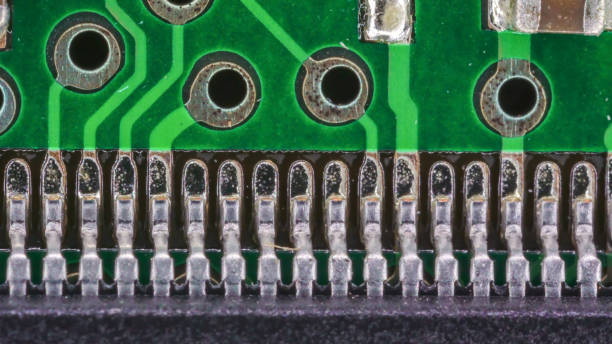

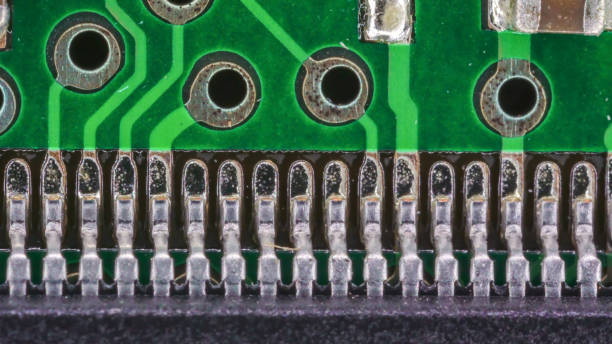

Mini SMT stencils are precision-engineered tools designed to facilitate the accurate application of solder paste to printed circuit boards (PCBs). These stencils are typically made from thin sheets of stainless steel or other durable materials, with carefully cut apertures that correspond to the solder pad locations on a PCB[1]. The mini SMT stencil serves as a template, allowing for the precise deposition of solder paste onto the board, ensuring that each component receives the correct amount of solder for a reliable connection.

The Evolution of SMT Stencils

The development of mini SMT stencils is closely tied to the evolution of surface mount technology itself. As electronic components have become smaller and more intricate, the need for precise solder paste application has grown exponentially. Traditional methods of manual solder paste application proved inadequate for the fine-pitch components and high-density boards that are now commonplace in modern electronics[5].

Mini SMT stencils emerged as a solution to these challenges, offering a level of accuracy and consistency that was previously unattainable. By enabling the controlled deposition of solder paste, these stencils have played a crucial role in improving the quality and reliability of SMT assemblies.

Advantages of Using Mini SMT Stencils

The adoption of mini SMT stencils in electronics assembly processes brings a host of benefits that contribute to improved product quality, increased efficiency, and reduced costs.

Precision and Consistency

One of the primary advantages of using a mini SMT stencil is the unparalleled precision it offers in solder paste application. The laser-cut apertures in the stencil ensure that solder paste is deposited only where it is needed, in precisely the right amount[1]. This level of accuracy is particularly crucial when working with fine-pitch components, where even slight variations in solder volume can lead to defects or unreliable connections.

Time and Cost Efficiency

Implementing mini SMT stencils in the assembly process can significantly reduce production time and costs. By enabling the simultaneous application of solder paste to multiple pads, stencils eliminate the need for time-consuming manual dispensing methods[5]. This increased efficiency translates to higher throughput and lower labor costs, making mini SMT stencils an attractive option for both small-scale and large-volume production.

Reduced Defects and Rework

The precision offered by mini SMT stencils leads to a marked reduction in soldering defects. Common issues such as solder bridging, insufficient solder, and component misalignment are minimized when using a well-designed stencil[3]. As a result, the need for rework and touch-ups is greatly reduced, saving time and resources while improving overall product quality.

Compatibility with Automation

Mini SMT stencils are highly compatible with automated assembly processes. When used in conjunction with pick-and-place machines and reflow ovens, these stencils enable a fully automated SMT assembly line. This compatibility not only increases production speed but also ensures consistent results across large batches of PCBs[5].

Design Considerations for Mini SMT Stencils

Creating an effective mini SMT stencil requires careful consideration of various design factors. These considerations are crucial for ensuring optimal performance and solder paste release.

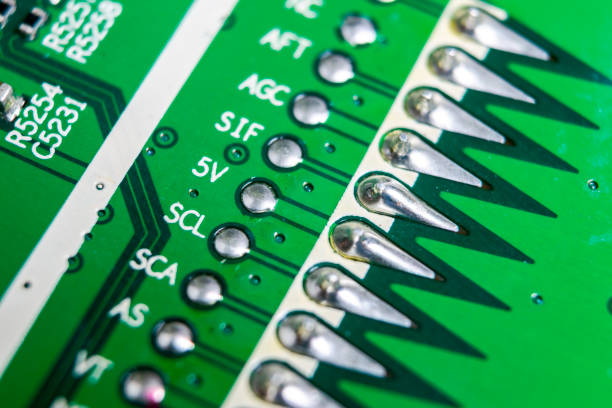

Aperture Design

The design of stencil apertures is perhaps the most critical aspect of mini SMT stencil creation. Aperture size, shape, and orientation must be carefully calculated to achieve the desired solder paste volume and release characteristics[8]. For fine-pitch components, special aperture designs such as "home plate" or "U-shaped" openings may be employed to improve paste release and prevent bridging.

Stencil Thickness

Selecting the appropriate stencil thickness is essential for achieving the right balance between solder paste volume and release performance. Thinner stencils generally offer better release characteristics but may not provide sufficient solder volume for larger components. Conversely, thicker stencils can accommodate more solder paste but may struggle with release for fine-pitch parts[8].

Material Selection

The choice of stencil material can significantly impact performance. While stainless steel is the most common material due to its durability and cost-effectiveness, other options such as nickel or polymer-coated stencils may offer advantages in specific applications[6]. The material selection should consider factors such as durability, flexibility, and surface properties that affect solder paste release.

Manufacturing Processes for Mini SMT Stencils

The production of high-quality mini SMT stencils involves sophisticated manufacturing techniques that ensure precision and repeatability.

Laser Cutting

Laser cutting is the most prevalent method for creating mini SMT stencils. This process uses high-powered lasers to cut apertures into the stencil material with exceptional accuracy[4]. Laser cutting offers the advantage of producing clean, precise edges and can accommodate complex aperture designs with ease.

Chemical Etching

While less common for mini SMT stencils, chemical etching remains a viable manufacturing method for certain applications. This process involves using a photoresist mask and chemical solution to create apertures in the stencil material[8]. Chemical etching can be cost-effective for larger apertures or thicker stencils but generally lacks the precision of laser cutting for fine-pitch applications.

Electroforming

Electroforming is a specialized process that produces exceptionally smooth aperture walls, making it ideal for ultra-fine-pitch applications. This method involves electroplating nickel onto a substrate to create the stencil foil[6]. While more expensive and time-consuming than other methods, electroformed stencils offer superior performance for the most demanding SMT applications.

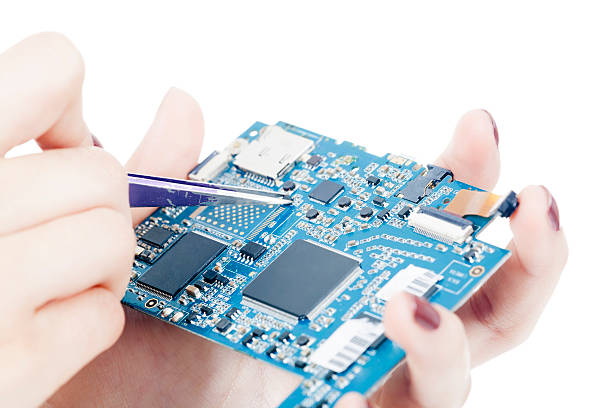

Best Practices for Using Mini SMT Stencils

To maximize the benefits of mini SMT stencils, it's essential to follow best practices in their use and maintenance.

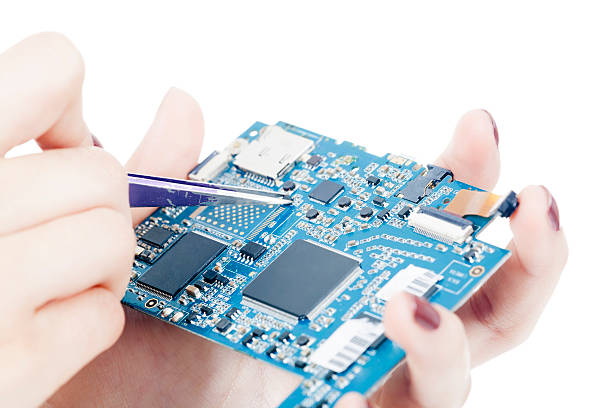

Proper Alignment

Accurate alignment of the stencil with the PCB is crucial for achieving precise solder paste deposition. Many manufacturers use fiducial marks on both the stencil and PCB to ensure proper alignment[3]. Advanced stencil printers may incorporate vision systems for automated alignment.

Stencil Cleaning

Regular cleaning of the mini SMT stencil is essential for maintaining print quality and preventing defects. Stencils should be cleaned after a certain number of prints or when switching between different solder paste types. Automated stencil cleaning systems can significantly improve efficiency in high-volume production environments[1].

Storage and Handling

Proper storage and handling of mini SMT stencils are crucial for preserving their accuracy and extending their lifespan. Stencils should be stored flat in a clean, dry environment and handled with care to prevent warping or damage to the delicate apertures[3].

Solder Paste Selection

Choosing the right solder paste is essential for optimal performance with mini SMT stencils. The paste's rheological properties, such as viscosity and thixotropy, should be compatible with the stencil design and aperture sizes[5]. Consulting with solder paste manufacturers can help in selecting the best formulation for specific applications.

Applications of Mini SMT Stencils

The versatility of mini SMT stencils makes them suitable for a wide range of applications in electronics manufacturing.

High-Density PCB Assembly

Mini SMT stencils are indispensable for assembling high-density PCBs with fine-pitch components. These stencils enable the precise application of solder paste to tightly spaced pads, facilitating the reliable connection of components such as BGAs, QFNs, and 0201 or smaller passive components[5].

Prototyping and Small-Batch Production

For electronics prototyping and small-batch production, mini SMT stencils offer a cost-effective solution for achieving professional-quality solder joints. They allow hobbyists and small-scale manufacturers to produce PCB assemblies with a level of precision that was previously only attainable in large-scale production environments[7].

Rework and Repair

Mini SMT stencils can be invaluable tools for PCB rework and repair operations. Custom-designed stencils for specific components or board areas enable precise reapplication of solder paste during component replacement or touch-up work[3].

Specialized Electronics

In industries such as aerospace, medical devices, and military applications, where reliability and precision are paramount, mini SMT stencils play a crucial role in ensuring the quality of electronic assemblies. These stencils enable the production of high-reliability PCBs that must meet stringent performance and durability standards[5].

Future Trends in Mini SMT Stencil Technology

As electronics continue to evolve, so too will the technology behind mini SMT stencils. Several trends are shaping the future of this essential tool:

Nano-Coatings

Advanced nano-coatings are being developed to enhance the surface properties of mini SMT stencils. These coatings can improve solder paste release, reduce the need for cleaning, and extend stencil lifespan[6].

3D-Printed Stencils

Additive manufacturing technologies are opening up new possibilities for stencil production. 3D-printed stencils offer the potential for rapid prototyping and custom designs, particularly for low-volume or specialized applications[4].

Integration with Industry 4.0

As manufacturing moves towards greater automation and data exchange, mini SMT stencils are being integrated into smart factory systems. This integration enables real-time monitoring of stencil performance, predictive maintenance, and automated process optimization[5].

Conclusion

Mini SMT stencils have become an indispensable tool in the world of surface mount technology, offering unparalleled precision, efficiency, and reliability in solder paste application. From high-volume production lines to hobbyist workbenches, these stencils have revolutionized the way we approach PCB assembly. By enabling the accurate deposition of solder paste, mini SMT stencils contribute to higher-quality electronic products, reduced manufacturing costs, and increased production efficiency.

As electronics continue to shrink and become more complex, the role of mini SMT stencils will only grow in importance. Ongoing advancements in stencil design, materials, and manufacturing processes promise to further enhance their capabilities, ensuring that mini SMT stencils remain at the forefront of electronics assembly technology for years to come.

FAQ

1. What is the ideal thickness for a mini SMT stencil?

The ideal thickness for a mini SMT stencil depends on several factors, including the size of the components being soldered and the desired solder paste volume. Generally, stencil thicknesses range from 3 to 8 mils (0.076 to 0.203 mm). For fine-pitch components, thinner stencils (3-5 mils) are often preferred for better paste release, while thicker stencils (6-8 mils) may be used for larger components requiring more solder volume[8].

2. How long does a mini SMT stencil typically last?

The lifespan of a mini SMT stencil can vary depending on usage, maintenance, and storage conditions. With proper care, a high-quality stainless steel stencil can last for thousands of prints. However, factors such as the abrasiveness of the solder paste, cleaning frequency, and handling can affect longevity. Regular inspection and careful handling can help extend the life of a mini SMT stencil[3].

3. Can I create a mini SMT stencil at home?

While professional-grade mini SMT stencils are typically manufactured using specialized equipment, it is possible to create simple stencils at home for prototyping or small-scale projects. Methods such as using laser-cut Mylar sheets or photo-etching techniques can be employed by hobbyists. However, these DIY methods may not achieve the same level of precision as professionally manufactured stencils, especially for fine-pitch components[7].

4. How do I clean a mini SMT stencil?

Cleaning a mini SMT stencil is crucial for maintaining print quality. For manual cleaning, use a lint-free cloth or wipe with a suitable cleaning solution designed for removing solder paste residues. Avoid using abrasive materials that could damage the stencil. For more thorough cleaning, specialized ultrasonic cleaning systems or automated stencil washers can be used. Always follow the manufacturer's recommendations for cleaning products and methods[1].

5. What are the alternatives to using a mini SMT stencil?

While mini SMT stencils are highly effective for solder paste application, alternatives exist for certain applications. These include:

- Manual solder paste dispensing using syringes or pneumatic dispensers

- Solder paste jet printing technology for highly customizable deposition

- Adhesive tape stencils for simple, low-volume applications

- Solder preforms for specific component types

However, these alternatives often lack the precision, speed, and consistency offered by mini SMT stencils, especially for high-density or high-volume production[5].

Citations:

[1] https://www.elepcb.com/blog/pcb-stencil-smt-assembly/

[2] https://www.youtube.com/watch?v=ZG5vVcc39uk

[3] https://www.pcbpower.us/blog/what-are-stencils-and-how-to-use-them-3

[4] https://www.eurocircuits.com/assembly-manufacturing-technology/making-solder-paste-stencils/

[5] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[6] https://app.lpkfusa.com/articles/stencil/Conquering%20SMT%20Stencil%20Challenges%202009-03.pdf

[7] https://electronics.stackexchange.com/questions/301689/stencil-at-home-with-extremely-small-parts

[8] https://pcbpit.com/smt-stencil-a-comprehensive-guide/

[9] https://www.pcbelec.com/the-production-process-of-pcb-smt-stencil.html