Content Menu

● The Evolution of PCB Manufacturing

● Understanding Surface Mount Technology

>> Key Features of SMT

● Why SMT is Essential for PCB Manufacturing

>> 1. Increased Component Density

>> 2. Miniaturization of Electronic Devices

>> 3. Improved Performance and Reliability

>> 4. Cost-Effective Manufacturing

>> 5. Flexibility in Design and Production

● The SMT Manufacturing Process

● Challenges and Considerations in SMT PCB Manufacturing

>> 1. Initial Investment

>> 2. Component Size and Handling

>> 3. Thermal Management

>> 4. Solder Joint Inspection

● Future Trends in SMT PCB Manufacturing

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What is the main difference between SMT and through-hole technology?

>> 2. How does SMT contribute to the miniaturization of electronic devices?

>> 3. What are the cost benefits of using SMT in PCB manufacturing?

>> 4. Are there any limitations to using SMT in PCB manufacturing?

>> 5. How is the quality of SMT assembly ensured in PCB manufacturing?

● Citations:

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, particularly in the realm of Printed Circuit Board (PCB) production. This advanced technology has become an indispensable part of modern PCB manufacturing, offering numerous advantages over traditional through-hole techniques. In this article, we will explore the reasons why SMT technology is essential for PCB manufacturing and how it has transformed the landscape of electronic device production.

The Evolution of PCB Manufacturing

Before delving into the importance of SMT, it's crucial to understand the evolution of PCB manufacturing. Traditionally, through-hole technology was the primary method used for assembling electronic components on PCB boards. This technique involved inserting component leads through holes drilled in the PCB and soldering them on the opposite side. While effective, this method had limitations in terms of component density, board size, and production efficiency.

As electronic devices became more compact and sophisticated, the need for a more advanced manufacturing technique became apparent. This led to the development of Surface Mount Technology, which has since become the preferred method for PCB assembly in most applications.

Understanding Surface Mount Technology

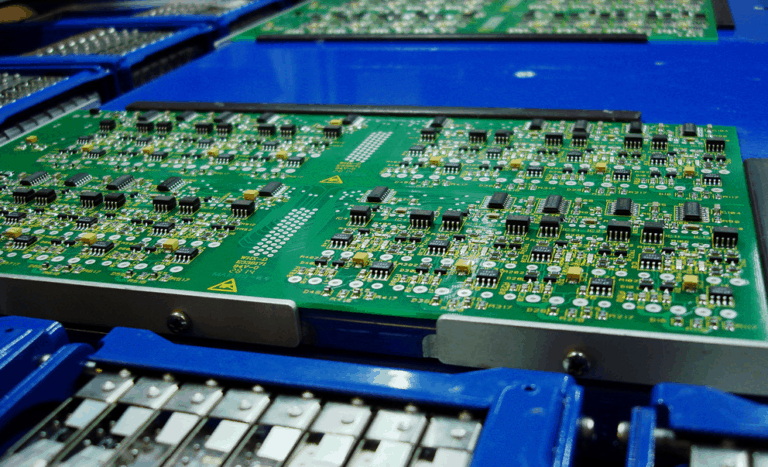

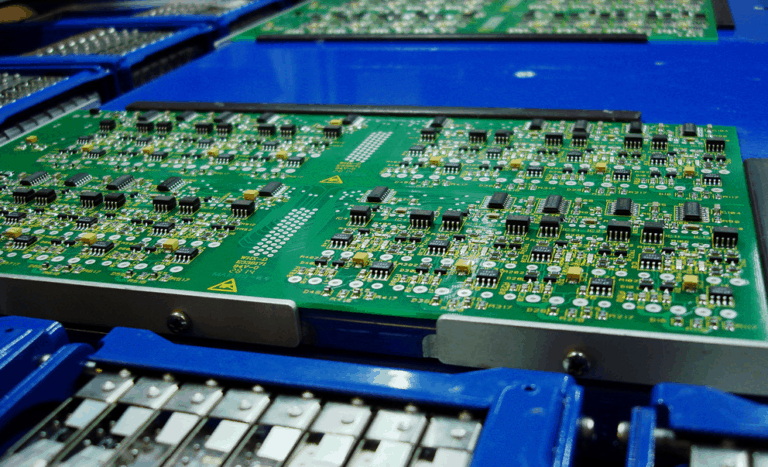

Surface Mount Technology is a method where electronic components are mounted directly onto the surface of a PCB board. Unlike through-hole technology, SMT components (known as Surface Mount Devices or SMDs) have small leads or no leads at all. Instead, they have flat contacts, small bumps, or short pins that are soldered directly onto the PCB surface.

Key Features of SMT

1. Miniaturization: SMT components are significantly smaller than their through-hole counterparts.

2. Higher Component Density: More components can be placed on a single PCB board.

3. Dual-Sided Mounting: Components can be mounted on both sides of the PCB.

4. Automated Assembly: SMT is highly compatible with automated manufacturing processes.

Why SMT is Essential for PCB Manufacturing

1. Increased Component Density

One of the primary reasons SMT technology is essential for PCB manufacturing is its ability to significantly increase component density on a PCB board. SMT components are much smaller than through-hole components, allowing for more components to be placed in a given area. This increased density is crucial for creating compact electronic devices that are in high demand in today's market[1][3].

For instance, a smartphone's PCB board requires a high density of components to fit all necessary functions within a small form factor. SMT makes this possible by allowing manufacturers to place more components closer together without compromising functionality or reliability.

2. Miniaturization of Electronic Devices

The trend towards smaller, lighter, and more portable electronic devices has been a driving force in the electronics industry for decades. SMT technology is essential in achieving this miniaturization. By using smaller components and allowing for higher density placement, SMT enables the production of PCB boards that are significantly smaller and lighter than those produced using through-hole technology[1][5].

This miniaturization is not just about making devices smaller for the sake of it. It opens up new possibilities for product design and functionality. Wearable technology, for example, would not be feasible without the miniaturization capabilities offered by SMT.

3. Improved Performance and Reliability

SMT technology contributes to improved performance and reliability of PCB boards in several ways:

- Reduced Electrical Noise: The shorter leads and closer proximity of components in SMT reduce electrical noise and interference, leading to better signal integrity[3].

- Better Heat Dissipation: SMT components often have better thermal characteristics due to their direct contact with the PCB surface, allowing for more efficient heat dissipation.

- Enhanced Mechanical Performance: SMT components are less susceptible to shock and vibration due to their lower profile and direct surface mounting[5].

These factors combine to create PCB boards that are not only more compact but also more reliable and better performing, which is crucial in many applications, from consumer electronics to aerospace and medical devices.

4. Cost-Effective Manufacturing

While the initial investment in SMT equipment can be substantial, the technology offers significant cost savings in the long run, making it essential for competitive PCB manufacturing:

- Reduced Material Costs: SMT components are generally less expensive than their through-hole counterparts due to their smaller size and simpler construction[3].

- Lower Labor Costs: The highly automated nature of SMT assembly reduces the need for manual labor, cutting down on labor costs and potential human errors[1].

- Faster Production: SMT allows for much faster assembly times compared to through-hole technology, increasing overall production efficiency[5].

These cost savings are particularly important in high-volume production scenarios, where even small savings per unit can translate to significant overall cost reductions.

5. Flexibility in Design and Production

SMT technology offers greater flexibility in both PCB design and production processes:

- Double-Sided Assembly: SMT allows components to be mounted on both sides of a PCB board, maximizing space utilization[1].

- Mixed Technology Boards: SMT can be combined with through-hole technology on the same board, offering the best of both worlds when necessary.

- Easier Prototyping and Revisions: The automated nature of SMT assembly makes it easier to prototype and revise designs quickly.

This flexibility is crucial in today's fast-paced electronics market, where rapid product development and the ability to quickly adapt designs are key competitive advantages.

The SMT Manufacturing Process

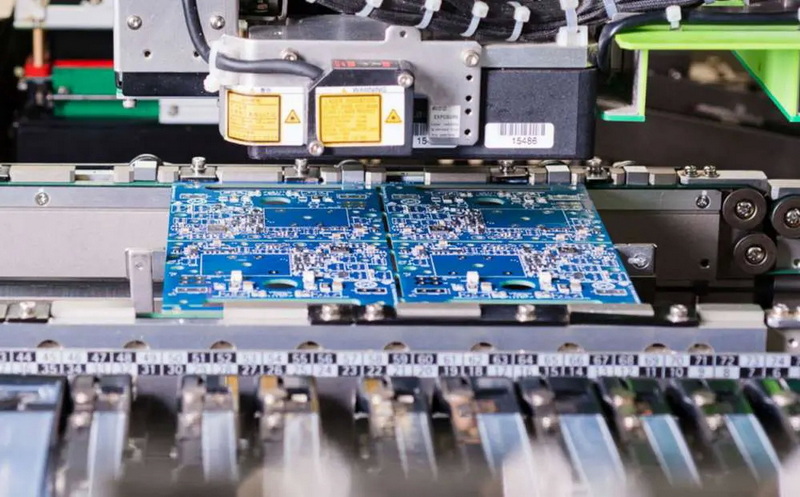

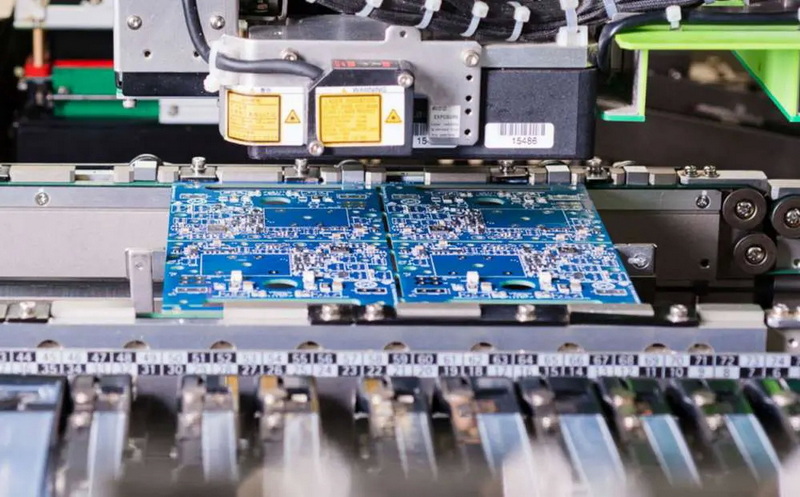

Understanding the SMT manufacturing process further illustrates why this technology is essential for modern PCB production. The process typically involves the following steps:

1. Solder Paste Application: A precise amount of solder paste is applied to the PCB using a stencil and squeegee or a jet printer.

2. Component Placement: SMT components are placed onto the PCB using automated pick-and-place machines. These machines can place thousands of components per hour with high accuracy.

3. Reflow Soldering: The PCB is passed through a reflow oven, where the solder paste melts and then cools, forming solid solder joints.

4. Inspection and Testing: Automated optical inspection (AOI) or X-ray inspection is used to check for defects, followed by functional testing.

This highly automated process allows for high-speed, high-precision assembly, which is essential for meeting the demands of modern electronics manufacturing.

Challenges and Considerations in SMT PCB Manufacturing

While SMT offers numerous advantages, it also presents some challenges that manufacturers must address:

1. Initial Investment

Setting up an SMT production line requires a significant initial investment in specialized equipment such as pick-and-place machines, reflow ovens, and inspection systems. However, this investment is often justified by the long-term benefits and cost savings[5].

2. Component Size and Handling

The small size of SMT components can make them difficult to handle manually. This necessitates the use of automated equipment and can pose challenges in repair and rework scenarios[5].

3. Thermal Management

The high component density achieved with SMT can lead to increased heat generation on the PCB board. Proper thermal management strategies must be implemented in the design phase to ensure reliable operation[3].

4. Solder Joint Inspection

The small size of SMT solder joints can make visual inspection challenging. Advanced inspection techniques such as X-ray inspection are often necessary to ensure quality[5].

Future Trends in SMT PCB Manufacturing

As technology continues to evolve, SMT is likely to remain essential in PCB manufacturing, with several trends shaping its future:

1. Even Smaller Components: The trend towards miniaturization is likely to continue, with even smaller SMT components being developed.

2. 3D Printing Integration: 3D printing technology may be integrated with SMT for creating custom PCB structures and components.

3. Advanced Materials: New solder materials and PCB substrates may be developed to enhance performance and reliability.

4. AI and Machine Learning: These technologies may be incorporated into SMT processes for improved efficiency and quality control.

5. Green Manufacturing: There will likely be a greater focus on environmentally friendly SMT processes and materials.

Conclusion

Surface Mount Technology has become an indispensable part of PCB manufacturing, driving advancements in electronic device design and production. Its ability to increase component density, facilitate miniaturization, improve performance and reliability, reduce costs, and offer design flexibility makes it essential for meeting the demands of modern electronics.

As we look to the future, SMT will continue to evolve, enabling even more sophisticated and compact electronic devices. While challenges exist, the benefits of SMT far outweigh the drawbacks, cementing its place as a cornerstone technology in PCB manufacturing.

For manufacturers and designers in the electronics industry, embracing and mastering SMT is not just an option—it's a necessity for staying competitive in a rapidly advancing field. As electronic devices continue to become more integral to our daily lives, the importance of SMT in PCB manufacturing will only grow, driving innovation and shaping the future of electronics.

Frequently Asked Questions (FAQ)

1. What is the main difference between SMT and through-hole technology?

Surface Mount Technology (SMT) involves mounting components directly onto the surface of a PCB board, while through-hole technology requires components to be inserted through holes in the board. SMT allows for higher component density, smaller board sizes, and more efficient automated assembly compared to through-hole technology.

2. How does SMT contribute to the miniaturization of electronic devices?

SMT contributes to miniaturization by using smaller components (SMDs) that can be placed closer together on a PCB board. This allows for more functionality to be packed into a smaller space, enabling the creation of compact electronic devices like smartphones, wearables, and other portable gadgets.

3. What are the cost benefits of using SMT in PCB manufacturing?

SMT offers several cost benefits, including reduced material costs due to smaller components, lower labor costs through automated assembly, and faster production times. While the initial investment in SMT equipment can be high, these factors contribute to significant cost savings in the long run, especially for high-volume production.

4. Are there any limitations to using SMT in PCB manufacturing?

While SMT offers many advantages, it does have some limitations. These include the need for specialized equipment, challenges in manual repair due to small component sizes, potential heat management issues due to high component density, and the need for advanced inspection techniques. However, for most applications, the benefits of SMT outweigh these limitations.

5. How is the quality of SMT assembly ensured in PCB manufacturing?

Quality in SMT assembly is ensured through a combination of precise process control and advanced inspection techniques. This includes accurate solder paste application, high-precision component placement using automated machines, carefully controlled reflow soldering, and post-assembly inspection using methods such as Automated Optical Inspection (AOI) and X-ray inspection. Additionally, functional testing is performed to verify the performance of the assembled PCB board.

Citations:

[1] https://www.sonicmfg.com/what-are-the-advantages-of-surface-mount-technology-in-pcba/

[2] https://smtnet.com/library/index.cfm?cat=all&fuseaction=browse_articles&maxrows=5&start_at=21

[3] https://levisonenterprises.com/5-advantages-to-using-smt/

[4] https://www.viasion.com/blog/smt-manufacturing-process-step-by-step-guide/

[5] https://www.pcb-hero.com/blogs/lisas-column/surface-mount-technology-advantages-and-disadvantages

[6] https://vectorbluehub.com/smt-assembly

[7] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[8] https://jhdpcb.com/blog/smt-manufacturing-technology/