Content Menu

● Understanding SMT and Its Importance

>> What is SMT?

● The Role of Vacuum Pickup Tools in PCB Assembly

>> What is an SMT Vacuum Pickup Tool?

>> Benefits of Using an SMT Vacuum Pickup Tool

● Types of SMT Vacuum Pickup Tools

>> Choosing the Right Tool

● Best Practices for Using an SMT Vacuum Pickup Tool

● Applications Beyond PCB Assembly

● Conclusion

● FAQ

>> 1. What types of components can be handled with an SMT vacuum pickup tool?

>> 2. How does a vacuum pickup tool work?

>> 3. Are there DIY options available for creating a vacuum pickup tool?

>> 4. How do I maintain my SMT vacuum pickup tool?

>> 5. Can I use a vacuum pickup tool with automated pick-and-place machines?

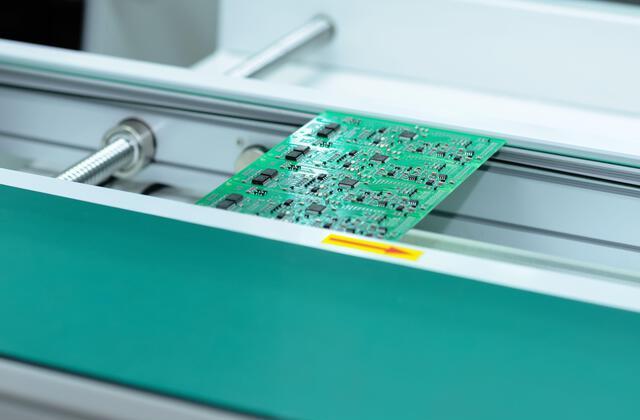

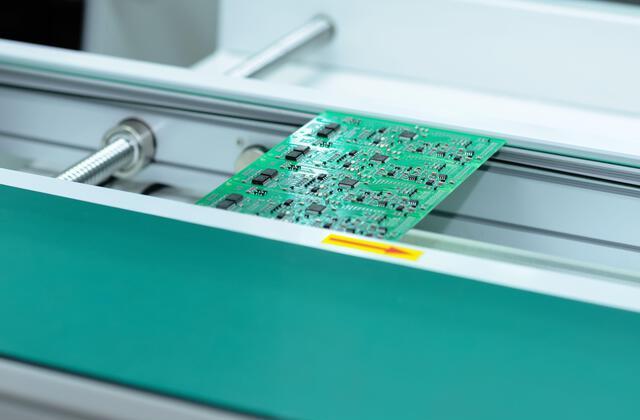

The world of electronics manufacturing has evolved significantly over the years, with Surface Mount Technology (SMT) becoming the standard for assembling electronic components onto printed circuit boards (PCBs). One essential tool in this process is the SMT vacuum pickup tool. This article explores the reasons why using an SMT vacuum pickup tool is crucial for efficient and effective PCB assembly, highlighting its benefits, types, and best practices.

Understanding SMT and Its Importance

What is SMT?

Surface Mount Technology (SMT) involves mounting electronic components directly onto the surface of a PCB. This method has largely replaced traditional through-hole technology due to its numerous advantages:

- Higher Component Density: SMT allows for more components to be placed on a smaller board, which is essential for modern electronic devices that require compact designs.

- Improved Electrical Performance: Shorter lead lengths and reduced parasitic capacitance enhance signal integrity, making SMT ideal for high-speed applications.

- Cost-Effectiveness: Although the initial setup costs can be higher, SMT reduces overall production costs through lower labor requirements and faster assembly times.

- Automation Compatibility: SMT processes are highly amenable to automation, leading to increased efficiency and consistency in production.

Given these advantages, it's clear that mastering SMT assembly techniques is vital for any electronics manufacturer.

The Role of Vacuum Pickup Tools in PCB Assembly

What is an SMT Vacuum Pickup Tool?

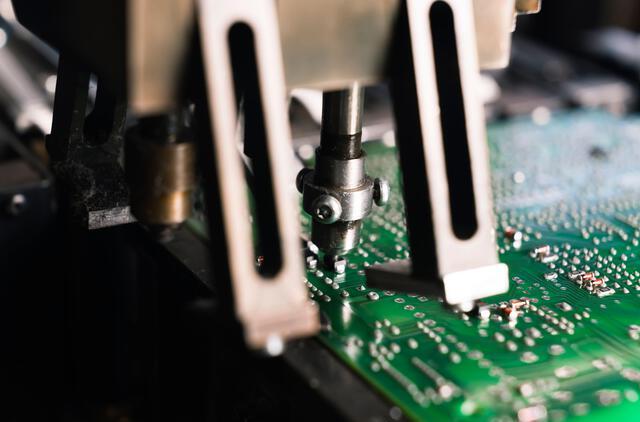

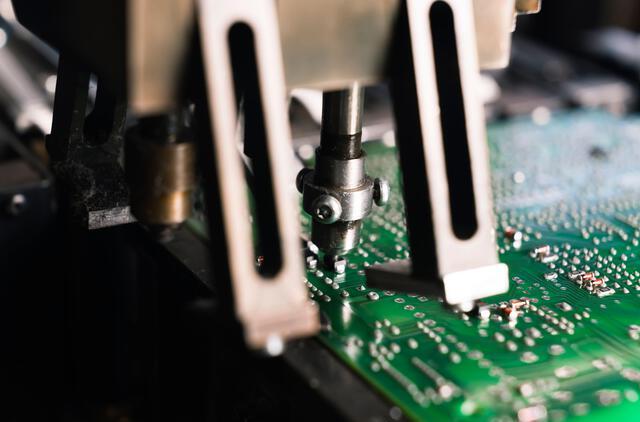

An SMT vacuum pickup tool is a specialized device designed to handle delicate components during the assembly process. It uses suction to securely grip components without causing damage, making it far superior to traditional methods like tweezers or forceps.

Benefits of Using an SMT Vacuum Pickup Tool

1. Precision Handling: The vacuum pickup tool allows for precise placement of components on the PCB, reducing the risk of misalignment or damage during handling.

2. Reduced Component Damage: Unlike tweezers that can apply excessive pressure, vacuum tools grip components gently, minimizing the risk of cracking or breaking sensitive parts.

3. Increased Efficiency: Using a vacuum tool can significantly speed up the assembly process. Operators can pick and place components quickly and accurately, leading to faster production times.

4. Versatility: These tools can handle various component sizes and shapes, making them suitable for different types of SMT applications.

5. Enhanced Ergonomics: Vacuum pickup tools are designed to reduce operator fatigue by providing a more comfortable grip compared to traditional hand tools.

6. Better Control in Tight Spaces: In many modern PCBs, space is at a premium. The design of vacuum pickup tools allows operators to maneuver in tight spaces effectively without compromising on precision.

7. Reduction in Contamination Risks: By using a vacuum tool, operators minimize direct contact with components, which helps reduce contamination from oils or dirt from fingers that could affect soldering quality.

8. Improved Quality Control: With enhanced precision and reduced handling damage, the overall quality of assembled PCBs improves significantly when using vacuum pickup tools.

Types of SMT Vacuum Pickup Tools

SMT vacuum pickup tools come in various designs and functionalities, catering to different needs in PCB assembly:

- Manual Vacuum Pickup Tools: These are typically handheld devices that use a simple mechanism (like a squeeze bulb) to create suction. They are cost-effective and easy to use for small-scale projects or prototyping.

- Battery-Powered Tools: These tools offer more convenience with automatic suction capabilities. They are ideal for larger production runs where speed and efficiency are crucial.

- Electric Vacuum Pickup Stations: For high-volume production environments, electric stations provide consistent suction power and often include features like adjustable suction strength and multiple nozzles for different component sizes.

Choosing the Right Tool

Selecting the appropriate type of SMT vacuum pickup tool depends on several factors:

- Volume of Production: For low-volume or prototype work, manual tools may suffice. In contrast, high-volume production may require battery-powered or electric models for efficiency.

- Component Types: Different components may require specific nozzles or suction strengths; therefore, it's essential to consider the types of components you will be handling regularly.

- Budget Constraints: While advanced electric models offer great features, they come at a higher cost. It's essential to balance your budget with your production needs when selecting a tool.

Best Practices for Using an SMT Vacuum Pickup Tool

To maximize the effectiveness of an SMT vacuum pickup tool during PCB assembly, consider the following best practices:

1. Select the Right Nozzle Size: Different components require different nozzle sizes for optimal suction. Ensure you choose a nozzle that fits the component size to avoid slippage or damage.

2. Adjust Suction Power: Many advanced vacuum tools allow you to adjust suction strength based on the component being handled. Use lower suction for lightweight or fragile parts and higher suction for heavier components.

3. Maintain Cleanliness: Keep both the tool and components clean from dust or debris to ensure optimal performance and prevent contamination during assembly.

4. Practice Proper Technique: Familiarize yourself with the tool's operation before starting on actual assemblies. Practice helps in developing a steady hand for precise placement.

5. Regular Maintenance: Ensure your vacuum pickup tool is well-maintained by checking seals and cleaning nozzles regularly to prevent loss of suction power over time.

6. Training Operators: Proper training on how to use vacuum pickup tools can greatly enhance productivity and reduce errors in component placement during assembly processes.

7. Use Anti-Static Precautions: Since many electronic components are sensitive to static electricity, using anti-static wrist straps or mats while operating vacuum tools can prevent damage from electrostatic discharge (ESD).

8. Monitor Performance Regularly: Regularly check the performance of your vacuum pickup tool by testing suction strength and ensuring nozzles are functioning correctly; this helps maintain consistent quality in your assembly process.

Applications Beyond PCB Assembly

While primarily used in PCB assembly processes, SMT vacuum pickup tools have applications across various industries:

- Medical Device Manufacturing: In this sector, precision is paramount; vacuum pickup tools help handle delicate sensors and micro-components safely during assembly.

- Automotive Electronics: As vehicles become increasingly reliant on electronics, using these tools ensures reliable assembly of critical components like sensors and control units.

- Consumer Electronics Production: From smartphones to home appliances, vacuum pickup tools facilitate efficient assembly processes in consumer electronics manufacturing by allowing quick handling of small parts.

- Aerospace Components Assembly: The aerospace industry demands high standards; thus, using reliable handling tools like vacuum pickups ensures that sensitive electronic parts are assembled correctly without damage.

Conclusion

The use of an SMT vacuum pickup tool is essential in modern PCB assembly processes. Its ability to handle delicate components with precision not only enhances efficiency but also ensures high-quality results in electronic manufacturing. By adopting best practices and selecting the right type of tool for specific applications, manufacturers can significantly improve their production capabilities while minimizing errors and component damage.

As electronics continue to evolve towards smaller, more complex designs, incorporating effective tools like the SMT vacuum pickup tool will be crucial in staying competitive in this fast-paced industry.

In summary, investing in an SMT vacuum pickup tool not only streamlines your PCB assembly process but also contributes positively to product quality and operational efficiency—making it an indispensable asset in any electronics manufacturing setup.

FAQ

1. What types of components can be handled with an SMT vacuum pickup tool?

Vacuum pickup tools can handle a wide range of surface mount components including resistors, capacitors, integrated circuits (ICs), and more complex packages like QFPs or BGAs.

2. How does a vacuum pickup tool work?

A vacuum pickup tool creates suction through a nozzle that grips the component securely when activated, allowing it to be lifted and placed accurately on a PCB without damaging it.

3. Are there DIY options available for creating a vacuum pickup tool?

Yes, many enthusiasts create DIY vacuum pickup tools using basic materials such as syringes or aquarium pumps combined with tubing and nozzles, providing an affordable alternative for hobbyists or small-scale projects.

4. How do I maintain my SMT vacuum pickup tool?

Regular maintenance includes cleaning nozzles, checking seals for leaks, and ensuring that all parts are functioning correctly to maintain optimal suction power.

5. Can I use a vacuum pickup tool with automated pick-and-place machines?

Absolutely! Many automated pick-and-place machines utilize robotic arms equipped with vacuum nozzles specifically designed for efficiently handling various surface mount components during mass production.