Content Menu

● Understanding SMT Parts Counters

>> What is an SMT Parts Counter?

>> The Importance of Accurate Counting

● Key Benefits of Automated SMT Parts Counters

>> 1. Enhanced Accuracy

>> 2. Increased Efficiency

>> 3. Labor Cost Savings

>> 4. Real-Time Data Tracking

>> 5. Improved Workflow Integration

>> 6. Reduced Waste

>> 7. Scalability

● Features to Look for in an Automated SMT Parts Counter

>> 1. Counting Technology

>> 2. User-Friendly Interface

>> 3. Integration Capabilities

>> 4. Speed and Capacity

>> 5. Durability and Maintenance

● Case Studies: Success Stories of Automated SMT Parts Counters

>> Case Study 1: Electronics Manufacturer A

>> Case Study 2: Automotive Component Supplier B

● The Future of Automated Counting Technology

● Challenges and Considerations When Implementing Automated SMT Parts Counters

>> Initial Investment Costs

>> Training Requirements

>> Integration Complexity

>> Maintenance Needs

● Conclusion

● FAQ

>> 1. What types of components can be counted using an automated SMT parts counter?

>> 2. How does an automated SMT parts counter improve inventory management?

>> 3. Can automated SMT parts counters integrate with existing manufacturing systems?

>> 4. What maintenance is required for an automated SMT parts counter?

>> 5. How do I choose the right automated SMT parts counter for my business?

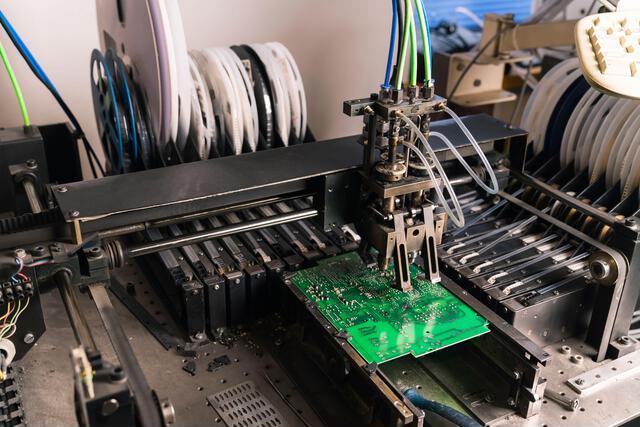

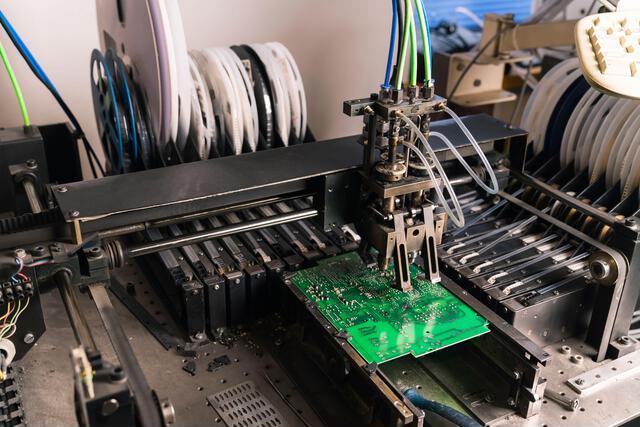

In the fast-paced world of electronics manufacturing, efficiency and accuracy are paramount. As companies strive to optimize their production processes, one technology that has gained significant attention is the automated Surface Mount Technology (SMT) parts counter. This innovative tool streamlines inventory management, reduces human error, and enhances overall productivity. In this article, we will explore the numerous benefits of investing in an automated SMT parts counter, examine its features, and discuss how it can transform your manufacturing operations.

Understanding SMT Parts Counters

What is an SMT Parts Counter?

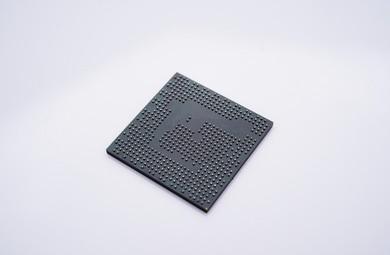

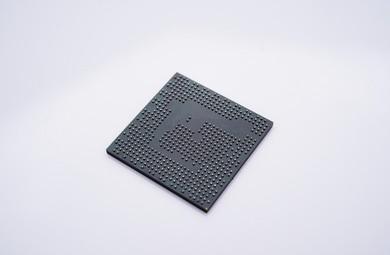

An SMT parts counter is a specialized device designed to automate the counting and tracking of electronic components used in surface mount technology. These counters utilize advanced sensors and software to accurately count parts as they pass through the system. By automating this process, manufacturers can significantly reduce the time and labor associated with manual counting.

The Importance of Accurate Counting

Accurate counting of SMT parts is crucial for several reasons:

- Inventory Management: Maintaining accurate inventory levels helps prevent stockouts and overstock situations, which can lead to production delays or increased costs.

- Cost Efficiency: Reducing errors in counting can save money by minimizing waste and ensuring that components are available when needed.

- Quality Control: Accurate counts contribute to better quality control by ensuring that the correct components are used in production runs.

Key Benefits of Automated SMT Parts Counters

Investing in an automated SMT parts counter offers several compelling advantages:

1. Enhanced Accuracy

Automated counters eliminate the risk of human error associated with manual counting. By using advanced sensors and algorithms, these devices provide precise counts of components, ensuring that manufacturers have the right quantities for their production needs. This accuracy is essential for maintaining quality standards and meeting customer expectations.

2. Increased Efficiency

Manual counting can be a time-consuming process that slows down production lines. Automated SMT parts counters operate quickly and efficiently, allowing for faster processing of components. This increased speed translates into shorter lead times and improved overall productivity.

3. Labor Cost Savings

By automating the counting process, companies can reduce their reliance on manual labor for inventory management tasks. This not only lowers labor costs but also allows employees to focus on more value-added activities within the production process.

4. Real-Time Data Tracking

Many modern automated SMT parts counters come equipped with data tracking capabilities that provide real-time insights into inventory levels. This information can be invaluable for making informed decisions about purchasing, production scheduling, and resource allocation.

5. Improved Workflow Integration

Automated SMT parts counters can be seamlessly integrated into existing manufacturing workflows. They can communicate with other systems such as Enterprise Resource Planning (ERP) software or Manufacturing Execution Systems (MES), ensuring that inventory data is synchronized across all platforms.

6. Reduced Waste

Accurate counting helps minimize waste by ensuring that excess components are not ordered or produced unnecessarily. This not only saves money but also contributes to more sustainable manufacturing practices.

7. Scalability

As businesses grow, their production needs often change. Automated SMT parts counters are scalable solutions that can adapt to varying production volumes without compromising accuracy or efficiency.

Features to Look for in an Automated SMT Parts Counter

When considering an investment in an automated SMT parts counter, it's essential to evaluate its features:

1. Counting Technology

Different counters utilize various technologies such as optical sensors, weight-based systems, or RFID tagging. Understanding these technologies will help you choose a counter that best fits your needs.

2. User-Friendly Interface

A user-friendly interface allows operators to easily navigate the system and access critical data without extensive training.

3. Integration Capabilities

Ensure that the counter can integrate smoothly with your existing systems for seamless data flow and management.

4. Speed and Capacity

Consider the speed at which the counter operates and its capacity for handling different sizes and types of components.

5. Durability and Maintenance

Investing in a durable machine that requires minimal maintenance will save you time and money in the long run.

Case Studies: Success Stories of Automated SMT Parts Counters

To illustrate the effectiveness of automated SMT parts counters, let's look at some real-world examples:

Case Study 1: Electronics Manufacturer A

Electronics Manufacturer A faced challenges with manual counting processes that led to frequent errors and production delays. After implementing an automated SMT parts counter, they reported a 30% reduction in counting time and a significant decrease in component discrepancies during assembly.

Case Study 2: Automotive Component Supplier B

Supplier B struggled with managing large inventories of small electronic components used in automotive applications. By investing in an automated counting solution, they improved their inventory accuracy by over 95%, leading to better production planning and reduced waste.

The Future of Automated Counting Technology

As technology continues to evolve, so too will the capabilities of automated SMT parts counters. Future advancements may include:

- Artificial Intelligence: AI could enhance counting accuracy further by learning from historical data patterns.

- IoT Integration: Internet of Things (IoT) connectivity may allow for even more sophisticated data tracking and inventory management systems.

- Enhanced User Interfaces: Future devices may feature more intuitive interfaces that facilitate easier operation and data analysis.

Challenges and Considerations When Implementing Automated SMT Parts Counters

While there are numerous benefits associated with automated SMT parts counters, it is crucial to consider potential challenges when implementing this technology:

Initial Investment Costs

The upfront cost of purchasing an automated SMT parts counter can be significant. Companies must weigh this investment against potential long-term savings from increased efficiency and reduced labor costs.

Training Requirements

Although many modern systems are designed to be user-friendly, staff may still require training to operate new equipment effectively. Investing in proper training is essential to maximize the benefits of automation.

Integration Complexity

Integrating new technology into existing manufacturing processes can sometimes be complex. Companies need to ensure that their current systems are compatible with new equipment to avoid disruptions during implementation.

Maintenance Needs

While automated systems generally require less maintenance than manual processes, they still need regular upkeep to function optimally. Companies should develop a maintenance plan to address potential issues proactively.

Conclusion

Investing in an automated SMT parts counter represents a strategic move for manufacturers looking to enhance efficiency, accuracy, and overall productivity in their operations. With benefits ranging from labor cost savings to improved inventory management, these devices offer a compelling solution for modern manufacturing challenges. As technology continues to advance, embracing automation will be crucial for staying competitive in the ever-evolving electronics market.

Automated SMT parts counters not only streamline operations but also provide critical data insights that empower companies to make informed decisions about their production processes. By reducing errors, improving workflow integration, and enabling real-time tracking of inventory levels, these tools play a vital role in modern electronics manufacturing.

FAQ

1. What types of components can be counted using an automated SMT parts counter?

Automated SMT parts counters are designed to handle a wide variety of electronic components including resistors, capacitors, integrated circuits (ICs), connectors, and more.

2. How does an automated SMT parts counter improve inventory management?

By providing accurate real-time counts of components, these counters help manufacturers maintain optimal inventory levels, reducing both stockouts and excess inventory situations.

3. Can automated SMT parts counters integrate with existing manufacturing systems?

Yes, many modern automated counters feature integration capabilities that allow them to work seamlessly with ERP systems, MES platforms, and other software used in manufacturing environments.

4. What maintenance is required for an automated SMT parts counter?

Most automated counters require minimal maintenance; however, regular cleaning of sensors and occasional software updates may be necessary to ensure optimal performance.

5. How do I choose the right automated SMT parts counter for my business?

Consider factors such as counting technology used, speed and capacity requirements, user interface design, integration capabilities with existing systems, and durability when selecting an automated SMT parts counter.