Content Menu

● Introduction to SMT Stencils

>> Importance of SMT Stencils in PCB Assembly

● Benefits of High-Quality SMT Stencil Makers

● Advanced Technologies in SMT Stencil Production

>> Nano Coatings and Dual-Layer Stencils

● Types of SMT Stencils

● SMT Stencil Materials

● Design Considerations for SMT Stencils

● SMT Stencil Printing Process

● Troubleshooting Common Issues

● Role of SMT Stencil Printers

● Economic and Environmental Considerations

● Conclusion

● FAQs

>> 1. What is the primary function of an SMT stencil in PCB assembly?

>> 2. How does the thickness of an SMT stencil affect solder paste deposition?

>> 3. What are the benefits of using a high-quality SMT stencil maker?

>> 4. What types of materials are commonly used for SMT stencils?

>> 5. How often should an SMT stencil be replaced?

● Citations:

In the realm of Surface Mount Technology (SMT), precision and efficiency are paramount for achieving high-quality electronic products. One crucial component that plays a pivotal role in this process is the SMT stencil. An SMT stencil maker is essential for producing these stencils, which are used to apply solder paste onto printed circuit boards (PCBs) with accuracy and consistency. In this article, we will delve into the importance of investing in a high-quality SMT stencil maker and explore how it can enhance your PCB assembly process.

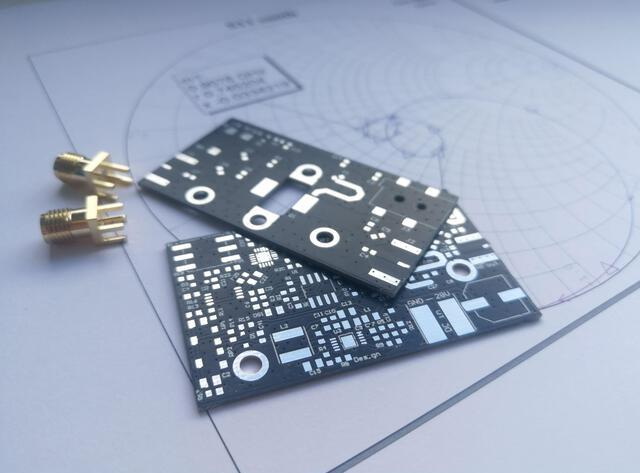

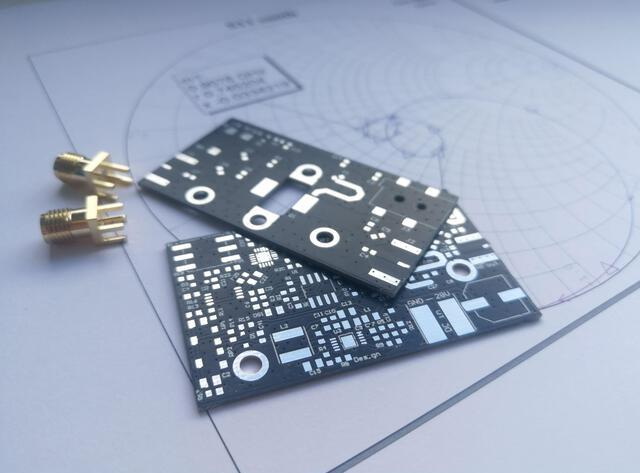

Introduction to SMT Stencils

SMT stencils are thin sheets of material, typically stainless steel or nickel, with precise openings that match the pads on a PCB. These openings allow for the controlled deposition of solder paste, ensuring that each component receives the correct amount of solder. The stencil acts as a template, guiding the solder paste application process to prevent defects such as bridging or tombstoning, which can occur due to excessive or insufficient solder.

Importance of SMT Stencils in PCB Assembly

1. Precise Solder Paste Deposition: SMT stencils ensure that solder paste is applied accurately and consistently across all pads on the PCB. This precision is critical for preventing defects and ensuring reliable solder joints.

2. Consistent Solder Paste Volume: The thickness of the stencil determines the volume of solder paste deposited on each pad. Consistency in solder paste volume is essential for maintaining uniform soldering quality and reducing defects.

3. Increased Efficiency: Using an SMT stencil significantly speeds up the solder paste application process. Unlike manual methods, which are time-consuming and prone to errors, stencils allow for simultaneous application of solder paste to all pads, enhancing production efficiency.

4. Compatibility with Automated Assembly: SMT stencils are indispensable for automated assembly lines. They work seamlessly with solder paste printers, enabling rapid and precise application of solder paste to multiple PCBs in succession. This automation boosts production speed and consistency, making SMT stencils crucial for high-volume manufacturing.

Benefits of High-Quality SMT Stencil Makers

Investing in a high-quality SMT stencil maker offers several benefits:

- Precision and Accuracy: High-quality stencil makers utilize advanced laser cutting technology to create precise openings in the stencil, ensuring accurate solder paste deposition and minimizing defects.

- Material Selection and Durability: These makers can work with a variety of materials, including stainless steel and nickel, which are known for their durability and resistance to wear. This ensures that the stencils can withstand repeated use without compromising performance.

- Customization: High-quality stencil makers can produce stencils tailored to specific PCB designs and component requirements. This customization is vital for complex or high-density PCBs where precision is paramount.

- Efficiency and Cost-Effectiveness: By reducing errors and defects, high-quality stencil makers help minimize rework and material waste, leading to cost savings and improved production efficiency.

Advanced Technologies in SMT Stencil Production

Recent advancements in SMT stencil technology have further enhanced their performance and longevity. For instance, StenTech's BluPrint™ CVD Surface Treatment offers improved stencil performance by providing a smooth, high-gloss surface that enhances corrosion resistance and solder paste transfer efficiency[1][4]. This technology is particularly beneficial for high-volume production, where consistency and reliability are crucial.

Nano Coatings and Dual-Layer Stencils

Nano coatings applied to stencil surfaces improve paste release characteristics and reduce blocking, enhancing the overall efficiency of the solder paste application process[7]. Additionally, dual-layer stencil technology allows for the simultaneous printing of solder paste and adhesive, supporting the assembly of components with different material requirements[7]. These innovations underscore the evolving nature of SMT stencil technology and its role in optimizing PCB assembly processes.

Types of SMT Stencils

SMT stencils come in various types, each suited to different production needs:

- Framed Stencils: These are ideal for high-volume production and automated assembly. The stencil is permanently fixed in a frame, ensuring high accuracy and consistency.

- Frameless Stencils: These are more versatile and cost-effective, allowing the stencil to be reused with different frames. They are suitable for smaller production runs or prototyping.

- Prototype Stencils: Designed for low-volume or prototype PCB assembly, these stencils are cost-effective and help reduce assembly time.

- Electroformed Stencils: Made from nickel, these stencils offer smooth aperture walls, enhancing solder paste release and making them suitable for fine-pitch components.

SMT Stencil Materials

The choice of material for an SMT stencil affects its performance and durability:

- Stainless Steel: The most common material, stainless steel stencils are durable, cost-effective, and compatible with most solder pastes and cleaning agents.

- Nickel: Nickel stencils, particularly electroformed ones, provide smooth aperture walls for improved paste release and are suitable for ultra-fine pitch applications.

Design Considerations for SMT Stencils

Effective stencil design is crucial for optimal solder paste deposition:

- Aperture Size and Shape: Apertures should be slightly larger than the pad size to accommodate paste shrinkage during reflow. Round or square apertures are common, but other shapes may be used for specific components.

- Stencil Thickness: The thickness determines the solder paste volume. Thicker stencils are used for larger components, while thinner ones are suitable for smaller components.

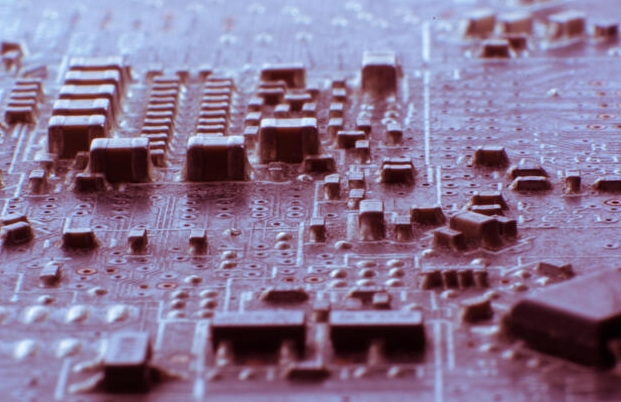

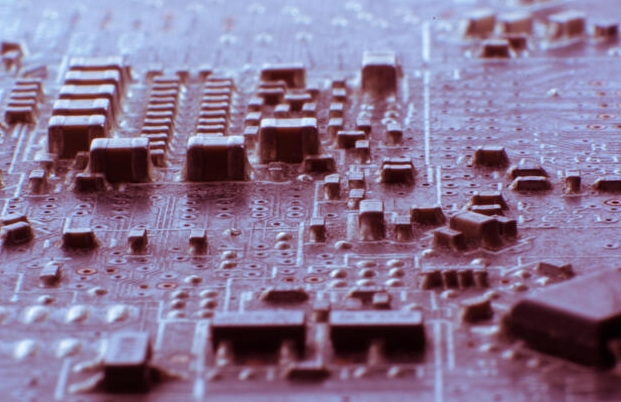

SMT Stencil Printing Process

The stencil printing process is a critical step in SMT assembly:

- Solder Paste Selection: Choosing the right solder paste is essential for achieving optimal printing results. Factors such as alloy composition, particle size, and viscosity must be considered.

- Printing Parameters: Adjusting parameters like squeegee pressure and print speed can optimize paste deposition and minimize defects.

Troubleshooting Common Issues

Common issues during the stencil printing process include insufficient or excessive solder paste deposition. Solutions involve adjusting stencil thickness, aperture size, and printing parameters[3]. Additionally, ensuring proper stencil cleaning and maintenance can prevent issues related to paste blocking or smearing.

Role of SMT Stencil Printers

SMT stencil printers play a pivotal role in achieving precision in PCB assembly. These printers offer advanced technology that ensures flawless deposition of solder paste onto PCBs, providing adaptable solutions for diverse printing requirements[8]. Their precision and efficiency make them indispensable for modern electronics manufacturing, where high-quality output is paramount.

Economic and Environmental Considerations

In today's competitive electronics manufacturing landscape, companies face economic challenges such as reduced product life cycles and increased demand for product variants[6]. To address these challenges, manufacturers must optimize their processes to reduce inefficiencies and waste. High-quality SMT stencil makers and printers help achieve this by minimizing defects and enhancing production efficiency.

Moreover, the industry is moving towards more environmentally friendly practices, such as using biodegradable and lower-toxicity solder pastes[7]. This shift not only reduces environmental impact but also aligns with consumer preferences for sustainable products.

Conclusion

Investing in a high-quality SMT stencil maker is essential for achieving precision, efficiency, and quality in PCB assembly. By understanding the benefits and types of SMT stencils, manufacturers can optimize their production processes, reduce defects, and enhance product reliability. As technology continues to evolve, innovations like advanced coatings and dual-layer stencils will further enhance the role of SMT stencils in electronics manufacturing.

FAQs

1. What is the primary function of an SMT stencil in PCB assembly?

An SMT stencil is used to ensure precise and consistent deposition of solder paste onto PCB pads, reducing defects and improving product quality.

2. How does the thickness of an SMT stencil affect solder paste deposition?

The thickness of the stencil determines the volume of solder paste applied to each pad. Thicker stencils deposit more solder paste, making them suitable for larger components.

3. What are the benefits of using a high-quality SMT stencil maker?

High-quality stencil makers provide precision, customization, and durability, enhancing production efficiency and reducing costs by minimizing defects and material waste.

4. What types of materials are commonly used for SMT stencils?

Stainless steel and nickel are the most common materials used for SMT stencils. Stainless steel is durable and cost-effective, while nickel offers smooth aperture walls for improved paste release.

5. How often should an SMT stencil be replaced?

The lifespan of an SMT stencil depends on factors like material, usage frequency, and maintenance. Generally, stainless steel stencils last for 20,000 to 50,000 prints, while nickel stencils can last up to 100,000 prints or more.

Citations:

[1] https://smttoday.com/2024/02/29/stentechs-photo-stencil-specialized-products-division-facility-update-completed/

[2] https://www.twistedtraces.com/blog/understanding-smt-stencils-the-backbone-of-electronics-manufacturing

[3] https://www.pcb-hero.com/blogs/lisas-column/surface-mount-technology-common-problems-and-solutions-for-efficient-smt-assembly

[4] https://www.stentech.com/company/cvd-treatment-for-smt-stencils

[5] https://nagisha.co.id/smt-stencil-roll/

[6] https://blog.intraratio.com/revolutionizing-smt-manufacturing-amidst-economic-challenges

[7] https://www.elepcb.com/blog/pcb-stencil-smt-assembly/

[8] https://www.smtfactory.com/Precision-Unleashed-The-Crucial-Role-of-SMT-Stencil-Printers-in-Achieving-Flawless-PCB-Assembly-id46183497.html