Content Menu

● Introduction

● What is SMT Line Assembling?

● Advantages of Wholesale SMT Line Assembling

>> 1. Increased Production Efficiency

>> 2. Cost-Effectiveness

>> 3. Improved Quality Control

>> 4. Flexibility and Scalability

>> 5. Enhanced Workplace Safety

>> 6. Streamlined Supply Chain Management

>> 7. Environmental Sustainability

● How to Choose the Right Wholesale SMT Line

>> 1. Production Volume

>> 2. Component Types

>> 3. Budget

>> 4. Supplier Reputation

>> 5. Technical Support and Training

● Case Studies: Success Stories in Wholesale SMT Line Assembling

>> Case Study 1: Automotive Electronics Manufacturer

>> Case Study 2: Consumer Electronics Company

>> Case Study 3: Medical Device Manufacturer

● Conclusion

● FAQ

>> 1. What is the main advantage of using SMT over traditional assembly methods?

>> 2. How does automation improve quality control in SMT assembly?

>> 3. Can a wholesale SMT line be customized for specific production needs?

>> 4. What are the typical components used in an SMT line?

>> 5. How can I ensure the safety of my workers in an SMT assembly environment?

Introduction

In the fast-paced world of electronics manufacturing, efficiency and precision are paramount. Surface Mount Technology (SMT) has revolutionized the way electronic components are assembled onto printed circuit boards (PCBs). For businesses looking to enhance their production capabilities, investing in a wholesale SMT line assembling can be a game-changer. This article explores the numerous benefits of adopting wholesale SMT line assembling for your assembly line, providing insights into its advantages, operational efficiencies, and long-term value.

What is SMT Line Assembling?

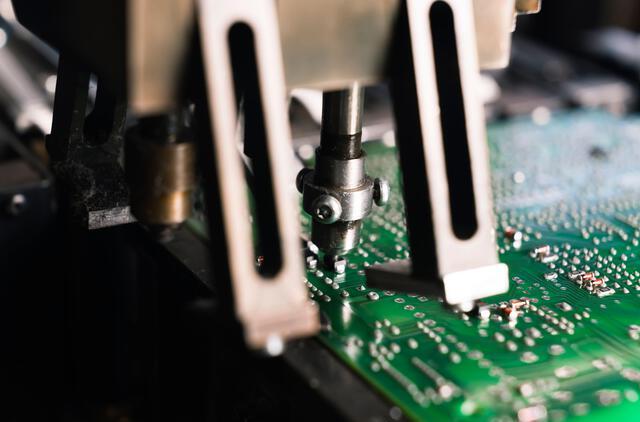

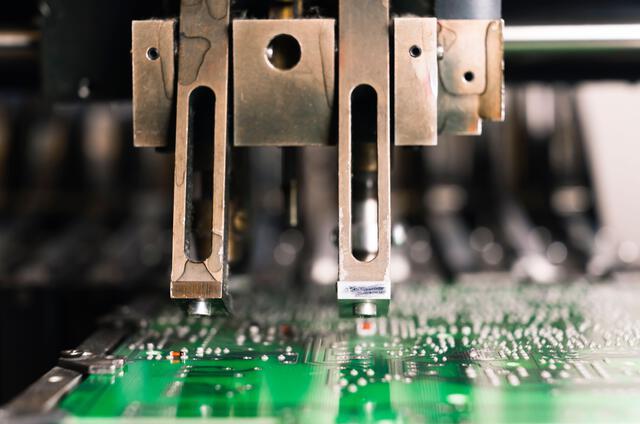

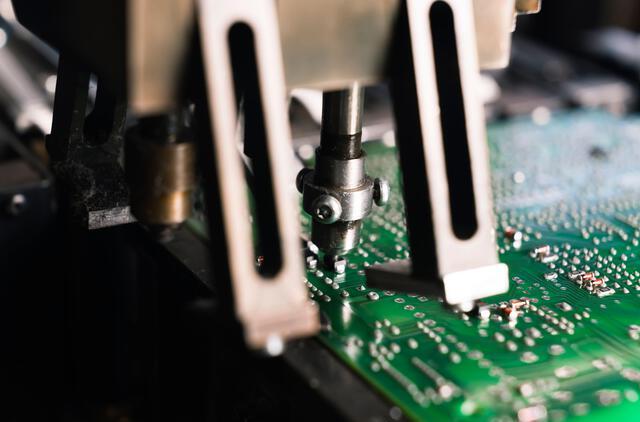

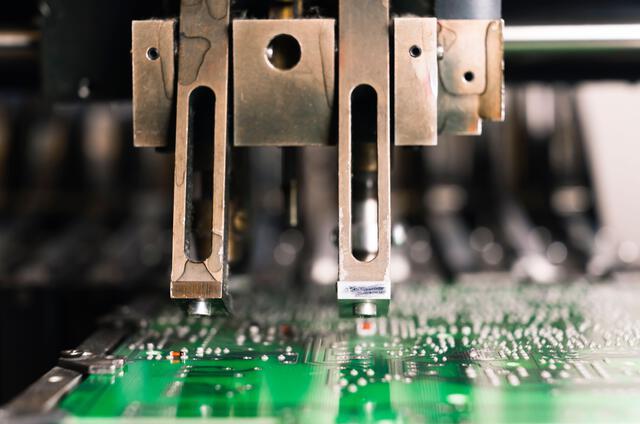

Surface Mount Technology (SMT) is a method used to mount electronic components directly onto the surface of PCBs. Unlike traditional through-hole technology, which requires components to be inserted into holes drilled in the board, SMT allows for a more compact design and higher component density. An SMT line consists of various machines and equipment that automate the assembly process, including:

- Pick and Place Machines: These machines accurately place components onto the PCB.

- Solder Paste Printers: They apply solder paste to the PCB pads where components will be placed.

- Reflow Ovens: These ovens heat the assembled boards to melt the solder, creating strong electrical connections.

- Inspection Systems: Automated optical inspection (AOI) systems check for defects in the assembly process.

Advantages of Wholesale SMT Line Assembling

1. Increased Production Efficiency

One of the primary reasons to consider wholesale SMT line assembling is the significant increase in production efficiency. Automated systems can operate continuously, reducing the time required for assembly. This leads to higher output rates and the ability to meet growing market demands without compromising quality. According to industry reports, companies that have adopted SMT lines have seen production rates increase by up to 50% compared to traditional methods.

2. Cost-Effectiveness

Investing in a wholesale SMT line can lead to substantial cost savings in the long run. While the initial investment may be significant, the reduction in labor costs, material waste, and production time can offset these expenses. Additionally, wholesale purchasing often provides better pricing on equipment and components, further enhancing cost-effectiveness. For instance, companies can save up to 30% on component costs by purchasing in bulk through wholesale suppliers.

3. Improved Quality Control

With automated systems, the consistency and quality of the assembled products improve dramatically. Machines are programmed to perform tasks with high precision, reducing the likelihood of human error. Furthermore, integrated inspection systems can detect defects early in the process, allowing for immediate corrections and minimizing the risk of faulty products reaching the market. This level of quality control is essential in industries such as automotive and medical devices, where product reliability is critical.

4. Flexibility and Scalability

Wholesale SMT line assembling offers flexibility in production. Manufacturers can easily adjust their assembly lines to accommodate different product designs or production volumes. This scalability is crucial for businesses that need to adapt to changing market conditions or customer demands. For example, a company that produces both consumer electronics and industrial components can switch between different assembly configurations without significant downtime.

5. Enhanced Workplace Safety

Automation reduces the need for manual labor in potentially hazardous environments. By minimizing human involvement in repetitive and dangerous tasks, companies can create a safer workplace, reducing the risk of accidents and injuries. Moreover, automated systems often come with safety features that protect workers from machinery hazards, further enhancing workplace safety.

6. Streamlined Supply Chain Management

Wholesale SMT line assembling can also streamline supply chain management. By integrating various processes into a single assembly line, companies can reduce lead times and improve inventory management. This integration allows for just-in-time production, where components are delivered and assembled as needed, minimizing excess inventory and associated costs.

7. Environmental Sustainability

As businesses increasingly focus on sustainability, wholesale SMT line assembling can contribute to greener manufacturing practices. Automated systems typically generate less waste compared to manual assembly processes. Additionally, the compact design of SMT components allows for more efficient use of materials, reducing the overall environmental impact of production.

How to Choose the Right Wholesale SMT Line

When considering a wholesale SMT line for your assembly line, several factors should be taken into account:

1. Production Volume

Assess your production needs to determine the appropriate scale of the SMT line. High-volume production may require more advanced machinery capable of handling larger quantities efficiently. Conversely, smaller operations may benefit from more flexible, modular systems that can be easily reconfigured.

2. Component Types

Different SMT lines are designed to handle various types of components. Ensure that the line you choose can accommodate the specific components you plan to use in your products. For instance, if your products include a mix of large and small components, look for a line that offers versatility in component handling.

3. Budget

Establish a budget for your investment. While wholesale options can provide cost savings, it's essential to balance quality and price to ensure a worthwhile investment. Consider not only the initial purchase price but also ongoing maintenance and operational costs.

4. Supplier Reputation

Research potential suppliers to find reputable manufacturers with a track record of providing reliable SMT equipment. Customer reviews and case studies can offer valuable insights into the performance and support offered by suppliers. A good supplier will also provide training and technical support to help you maximize the efficiency of your SMT line.

5. Technical Support and Training

Consider the level of technical support and training provided by the supplier. Proper training for your staff is crucial to maximizing the efficiency and effectiveness of the SMT line. Look for suppliers that offer comprehensive training programs and ongoing support to address any issues that may arise during operation.

Case Studies: Success Stories in Wholesale SMT Line Assembling

Case Study 1: Automotive Electronics Manufacturer

An automotive electronics manufacturer implemented a wholesale SMT line to enhance its production capabilities. By automating the assembly process, the company increased its production efficiency by 40% and reduced labor costs by 25%. The integration of automated inspection systems also improved product quality, leading to a significant decrease in warranty claims.

Case Study 2: Consumer Electronics Company

A consumer electronics company faced challenges in meeting growing demand for its products. By investing in a wholesale SMT line, the company was able to scale its production quickly. The flexibility of the SMT line allowed the company to switch between different product designs with minimal downtime, resulting in a 30% increase in overall production capacity.

Case Study 3: Medical Device Manufacturer

A medical device manufacturer adopted a wholesale SMT line to ensure the highest quality standards for its products. The automated systems provided consistent quality control, reducing defects by 50%. Additionally, the company benefited from reduced lead times, allowing it to respond more quickly to market demands.

Conclusion

Investing in wholesale SMT line assembling can significantly enhance your assembly line's efficiency, quality, and overall productivity. By automating the assembly process, businesses can reduce costs, improve safety, and adapt to changing market demands. As the electronics industry continues to evolve, adopting advanced manufacturing technologies like SMT will be essential for staying competitive. The benefits of wholesale SMT line assembling extend beyond immediate production gains; they contribute to long-term sustainability and success in a rapidly changing market.

FAQ

1. What is the main advantage of using SMT over traditional assembly methods?

The main advantage of SMT is its ability to allow for higher component density and smaller PCB designs, leading to more compact and efficient electronic devices.

2. How does automation improve quality control in SMT assembly?

Automation reduces human error and ensures consistent application of solder and placement of components, leading to higher quality and fewer defects.

3. Can a wholesale SMT line be customized for specific production needs?

Yes, many suppliers offer customizable SMT lines that can be tailored to meet specific production requirements, including different component types and production volumes.

4. What are the typical components used in an SMT line?

Typical components include pick and place machines, solder paste printers, reflow ovens, and inspection systems.

5. How can I ensure the safety of my workers in an SMT assembly environment?

Implementing automation reduces the need for manual labor in hazardous tasks, and providing proper training and safety equipment can further enhance workplace safety.