Content Menu

● Understanding SMT and Its Importance

● Key Components of a Fully Automatic SMT Production Line

● Advantages of Choosing a Wholesale Fully Automatic SMT Production Line

>> 1. Enhanced Efficiency

>> 2. Consistent Quality

>> 3. Cost Reduction

>> 4. Flexibility and Scalability

>> 5. Improved Data Management

● Challenges and Solutions

● Case Studies: Successful Implementations

● Future Trends in SMT Technology

● Conclusion

● FAQ

>> 1. What is an SMT production line?

>> 2. How does automation improve efficiency in SMT lines?

>> 3. What are the key components of an SMT production line?

>> 4. Is it cost-effective to invest in an automated SMT line?

>> 5. How do I choose the right SMT production line for my needs?

In the rapidly evolving landscape of electronics manufacturing, businesses are constantly seeking ways to enhance efficiency, reduce costs, and improve product quality. One of the most significant advancements in this field is the adoption of Surface Mount Technology (SMT) production lines, particularly fully automatic systems. This article explores the compelling reasons why investing in a wholesale fully automatic SMT production line can be a game-changer for your business.

Understanding SMT and Its Importance

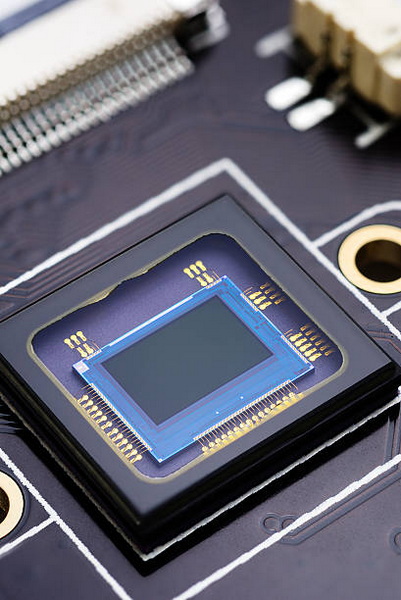

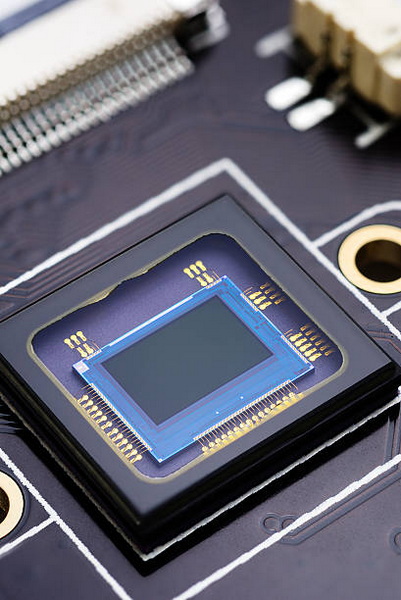

Surface Mount Technology (SMT) is a method used to mount electronic components directly onto the surface of printed circuit boards (PCBs). Unlike traditional through-hole technology, which requires components to be inserted into holes on the PCB, SMT allows for a more compact and efficient assembly process. The advantages of SMT include:

- Higher Component Density: SMT enables a greater number of components to be placed on a PCB, leading to smaller and lighter electronic devices.

- Improved Performance: Shorter electrical paths reduce resistance and inductance, enhancing signal integrity and overall performance.

- Cost Efficiency: Reduced material waste and lower labor costs contribute to overall savings in production.

Understanding these benefits is crucial for businesses looking to stay competitive in an industry that demands innovation and efficiency.

Key Components of a Fully Automatic SMT Production Line

A fully automatic SMT production line consists of several critical components that work together to streamline the manufacturing process. These include:

- Stencil Printer: Applies solder paste to the PCB with high precision, ensuring that the right amount is deposited in the correct locations.

- Pick-and-Place Machine: Automatically picks up components from feeders and places them onto the soldered pads on the PCB.

- Reflow Oven: Melts the solder paste to create strong electrical connections between components and the PCB.

- Automated Optical Inspection (AOI): Inspects assembled boards for defects such as misaligned components or soldering issues.

- Conveyor System: Facilitates smooth movement of PCBs through various stages of production.

Each component plays a vital role in ensuring that the production line operates efficiently and produces high-quality products consistently.

Advantages of Choosing a Wholesale Fully Automatic SMT Production Line

Investing in a wholesale fully automatic SMT production line offers numerous benefits that can significantly impact your business operations:

1. Enhanced Efficiency

Fully automatic SMT lines are designed for high-speed operation, allowing for rapid production cycles. Automation reduces manual intervention, which not only speeds up processes but also minimizes human error. This efficiency is crucial for meeting tight deadlines and high-volume demands in today's competitive market.

Moreover, automated systems can operate continuously without breaks, further increasing output. This capability allows manufacturers to scale their operations quickly without compromising quality or efficiency.

2. Consistent Quality

Automation ensures that every board is manufactured under identical conditions, leading to consistent quality across all products. The precision of automated machines reduces variability in component placement and soldering, resulting in fewer defects and higher reliability.

With advanced inspection technologies integrated into these lines, manufacturers can detect defects early in the production process, allowing for immediate corrective actions. This proactive approach not only enhances product quality but also reduces waste associated with rework or scrap.

3. Cost Reduction

While the initial investment in a fully automatic SMT line may be significant, the long-term savings are substantial. Reduced labor costs, minimized material waste, and increased throughput contribute to lower overall production costs. Moreover, as your production scales, these savings multiply.

In addition to direct cost savings, automated lines can also lead to indirect savings by reducing lead times and improving inventory management. Faster production cycles mean that products can reach the market more quickly, allowing businesses to respond better to customer demand.

4. Flexibility and Scalability

Modern SMT production lines are highly adaptable. They can quickly switch between different product types without extensive reconfiguration. This flexibility allows businesses to respond swiftly to changing market demands or customer specifications.

For example, if a manufacturer needs to produce a new electronic device with different specifications from previous models, an automatic SMT line can accommodate this change with minimal downtime. This adaptability is essential in an industry characterized by rapid technological advancements and shifting consumer preferences.

5. Improved Data Management

Advanced automated systems often come equipped with software for real-time monitoring and data analysis. This capability allows manufacturers to track production metrics, identify bottlenecks, and make informed decisions to optimize processes continuously.

Data analytics can provide insights into machine performance, helping businesses understand when maintenance is needed or when processes can be improved. By leveraging data effectively, manufacturers can enhance overall productivity and reduce operational costs.

Challenges and Solutions

Despite the numerous advantages, transitioning to a fully automatic SMT production line can present challenges:

- High Initial Investment: The upfront cost can be daunting; however, many manufacturers find that financing options or leasing equipment can alleviate this burden. Additionally, considering total cost of ownership rather than just initial purchase price helps businesses make informed decisions about investments.

- Training Requirements: Staff may need training to operate new machinery effectively. Investing in comprehensive training programs can ensure that employees are proficient in using advanced technologies. Continuous training opportunities also help keep staff updated on new features or processes as technology evolves.

- Maintenance Needs: Automated systems require regular maintenance to function optimally. Establishing a routine maintenance schedule can prevent downtime and prolong equipment lifespan. Many companies also opt for service contracts with equipment suppliers to ensure timely support when issues arise.

Case Studies: Successful Implementations

Numerous companies have successfully integrated fully automatic SMT production lines into their operations:

1. XYZ Electronics: After implementing a fully automatic line, XYZ Electronics reported a 50% increase in production speed and a 30% reduction in defect rates within six months. Their ability to meet customer demand surged as they could produce more units without sacrificing quality.

2. ABC Technologies: By transitioning to automated processes, ABC Technologies was able to reduce labor costs by 40%, allowing them to reinvest savings into R&D for new products. This strategic reinvestment led them to develop innovative solutions that captured new market segments.

3. DEF Manufacturing: DEF Manufacturing faced challenges with inconsistent product quality due to manual assembly processes. After adopting an automated SMT line, they reported an impressive 95% reduction in defects over two years, significantly enhancing their reputation among clients.

These case studies illustrate how investing in automation not only improves operational efficiency but also fosters innovation within companies by freeing up resources for research and development efforts.

Future Trends in SMT Technology

As technology continues to evolve, several trends are shaping the future of SMT production lines:

- Integration of Artificial Intelligence (AI): AI is increasingly being integrated into manufacturing processes for predictive maintenance and quality control purposes. By analyzing data from machines in real-time, AI algorithms can predict failures before they occur and suggest adjustments for optimal performance.

- Increased Use of Robotics: Robotics technology is advancing rapidly, enabling more sophisticated automation solutions within SMT lines. Collaborative robots (cobots) are becoming common as they work alongside human operators to enhance productivity while ensuring safety.

- Sustainability Initiatives: With growing environmental concerns, manufacturers are focusing on sustainable practices within their operations. This includes reducing energy consumption during production processes and minimizing waste through efficient material usage.

- Smart Manufacturing: The concept of smart manufacturing involves leveraging IoT (Internet of Things) technologies to create interconnected systems that communicate seamlessly across different stages of production. This connectivity allows for real-time adjustments based on data analytics and enhances overall operational efficiency.

Conclusion

Investing in a wholesale fully automatic SMT production line represents a strategic move for businesses aiming to enhance their manufacturing capabilities. The benefits—ranging from improved efficiency and quality consistency to significant cost savings—make it an attractive option for companies looking to thrive in a competitive market.

As technology continues to advance with trends like AI integration and smart manufacturing practices emerging on the horizon, those who adopt these automated solutions will likely lead the industry with innovative products that meet consumer demands effectively while maintaining operational excellence.

FAQ

1. What is an SMT production line?

An SMT production line is a manufacturing setup where electronic components are mounted directly onto printed circuit boards using surface mount technology.

2. How does automation improve efficiency in SMT lines?

Automation reduces manual labor requirements and speeds up processes such as solder paste application and component placement, leading to faster production cycles.

3. What are the key components of an SMT production line?

Key components include stencil printers, pick-and-place machines, reflow ovens, AOI machines, and conveyor systems.

4. Is it cost-effective to invest in an automated SMT line?

Yes, while initial investments may be high, long-term savings from reduced labor costs and increased efficiency make it financially beneficial over time.

5. How do I choose the right SMT production line for my needs?

Consider factors such as production volume requirements, types of components used, available budget, and future scalability when selecting an SMT line configuration.