Content Menu

● The Evolution of Surface Mount Technology

● Key Advantages of Surface Mount Technology

>> 1. Increased Component Density

>> 2. Reduced Size and Weight

>> 3. Enhanced Performance

>> 4. Cost Efficiency

>> 5. Design Flexibility

● Applications of Surface Mount Technology

● Challenges Associated with Surface Mount Technology

● Future Trends in Surface Mount Technology

● Conclusion

● Related Questions

>> 1. What Are the Main Differences Between Surface Mount Technology and Through-Hole Technology?

>> 2. How Does Surface Mount Technology Improve Manufacturing Efficiency?

>> 3. What Types of Components Are Commonly Used in Surface Mount Technology?

>> 4. What Are Some Challenges Faced When Using Surface Mount Technology?

>> 5. How Is Surface Mount Technology Expected to Evolve in the Future?

Surface Mount Technology (SMT) has become a cornerstone of modern electronics manufacturing, significantly influencing the design and functionality of electronic devices. As the demand for smaller, more efficient, and high-performing devices continues to rise, SMT has emerged as an essential technology for achieving these goals. This article delves into the reasons why SMT is crucial for miniaturizing electronic devices, exploring its applications, benefits, and future prospects.

The Evolution of Surface Mount Technology

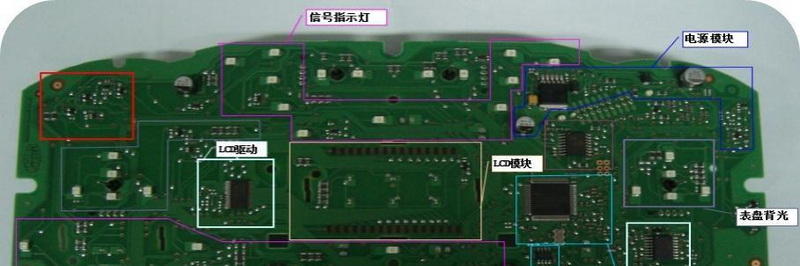

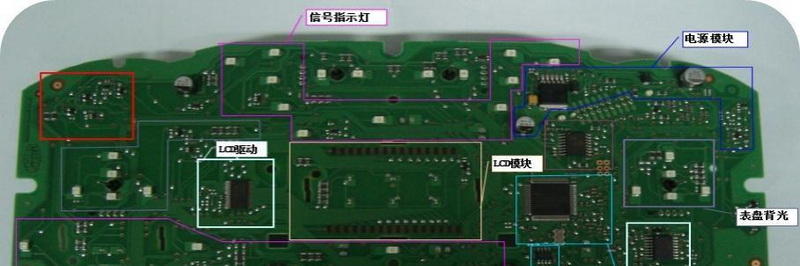

Initially developed in the 1960s, Surface Mount Technology was designed to address the limitations of traditional Through-Hole Technology (THT). In THT, components are inserted into drilled holes on a printed circuit board (PCB), which restricts the density and size of components that can be used. SMT revolutionized this process by allowing components to be mounted directly onto the surface of PCBs. This shift not only improved manufacturing efficiency but also facilitated the production of smaller and more complex electronic devices.

Key Advantages of Surface Mount Technology

1. Increased Component Density

One of the primary advantages of SMT is its ability to increase component density on PCBs. By eliminating the need for holes, SMT allows for more components to be placed within a given area. This is particularly advantageous in consumer electronics, where space is at a premium. Devices such as smartphones, tablets, and wearables benefit from this increased density, enabling manufacturers to pack more functionality into smaller form factors.

2. Reduced Size and Weight

SMT components are generally smaller than their through-hole counterparts due to their design features. For instance, surface-mount devices (SMDs) often have shorter leads or no leads at all, which contributes to a significant reduction in overall board size. This reduction in size not only makes devices lighter but also enhances their portability—an essential factor in today's mobile-centric world.

3. Enhanced Performance

The performance of electronic devices is greatly improved through the use of SMT. Shorter electrical paths between components reduce signal interference and resistance, leading to faster signal transmission and higher processing speeds. This is particularly important in high-frequency applications such as telecommunications and data processing where performance is critical.

4. Cost Efficiency

SMT contributes to cost efficiency in several ways:

- Automated Assembly: SMT processes are highly automated, reducing labor costs and increasing production speed. Automated pick-and-place machines can place thousands of components per hour with high precision.

- Material Savings: The compact nature of SMT means that less material is required for PCBs compared to traditional methods, leading to lower production costs.

- Reduced Board Count: By allowing more components on a single board, SMT can decrease the number of boards needed for a device, further cutting costs.

5. Design Flexibility

The flexibility offered by SMT allows designers to create innovative circuit layouts that were previously impossible with THT. Components can be placed on both sides of the PCB, maximizing space utilization and enabling more complex designs. This flexibility also supports advanced features such as multi-layer boards and integrated circuits.

Applications of Surface Mount Technology

SMT is widely used across various industries due to its numerous advantages:

- Consumer Electronics: Smartphones, tablets, laptops, and wearables utilize SMT for their compact designs.

- Automotive: Modern vehicles incorporate numerous electronic systems that rely on SMT for space-saving solutions.

- Telecommunications: High-performance networking equipment benefits from the density and speed enhancements provided by SMT.

- Healthcare: Medical devices often require miniaturization for portable diagnostics and monitoring equipment.

Challenges Associated with Surface Mount Technology

Despite its many advantages, SMT does come with challenges:

- Repair Complexity: The high density of components on SMT boards can make repairs more complicated compared to THT boards. Specialized tools and techniques are often required for rework.

- Thermal Management: As components become smaller and more powerful, managing heat dissipation becomes critical. Designers must consider thermal management strategies during the design phase.

- Initial Investment Costs: While SMT reduces manufacturing costs over time, the initial investment in specialized equipment can be significant.

Future Trends in Surface Mount Technology

As technology continues to evolve, several trends are shaping the future of Surface Mount Technology:

- Miniaturization: The push towards even smaller electronic devices will drive further innovations in SMT component design and manufacturing processes.

- Integration with AI and Automation: The integration of artificial intelligence in manufacturing processes will enhance precision in component placement and quality control.

- Sustainability: As environmental concerns grow, there will be a focus on developing sustainable materials and processes within SMT manufacturing.

Conclusion

Surface Mount Technology has fundamentally transformed how electronic devices are designed and manufactured. Its ability to facilitate miniaturization while enhancing performance makes it indispensable in today's fast-paced technological landscape. As industries continue to innovate and demand smaller yet more powerful devices grows, SMT will remain at the forefront of electronics manufacturing.

Related Questions

1. What Are the Main Differences Between Surface Mount Technology and Through-Hole Technology?

Surface Mount Technology (SMT) allows components to be mounted directly onto the surface of PCBs without drilling holes, while Through-Hole Technology requires leads to pass through holes drilled into the board. SMT typically offers higher component density and reduced size compared to THT.

2. How Does Surface Mount Technology Improve Manufacturing Efficiency?

SMT improves manufacturing efficiency through automated assembly processes that reduce labor costs and increase production speed. It allows for faster placement of components with specialized machines capable of handling high volumes quickly.

3. What Types of Components Are Commonly Used in Surface Mount Technology?

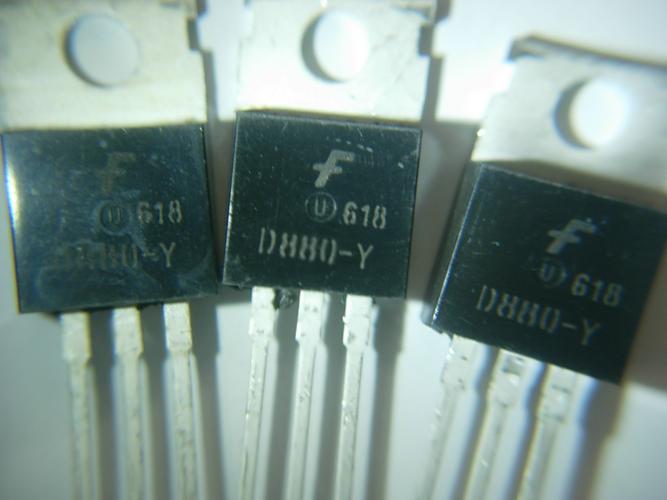

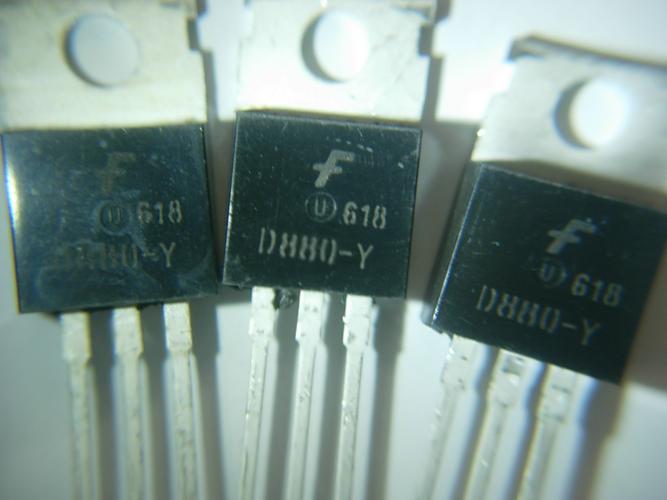

Common components used in SMT include resistors, capacitors, integrated circuits (ICs), diodes, transistors, and connectors—all designed specifically for surface mounting with smaller profiles than their through-hole counterparts.

4. What Are Some Challenges Faced When Using Surface Mount Technology?

Challenges include repair complexity due to high component density, thermal management issues related to heat dissipation from closely packed components, and higher initial investment costs for specialized equipment compared to traditional methods.

5. How Is Surface Mount Technology Expected to Evolve in the Future?

Future developments may include further miniaturization of components, increased automation using AI technologies for precision assembly, and a focus on sustainable practices within manufacturing processes as environmental concerns rise.