Content Menu

● Introduction to SMT Stencils

● Importance of SMT Stencil Design

● SMT Stencil Design Guidelines

● Types of SMT Stencils

● Manufacturing Methods for SMT Stencils

● Expanded Discussion on Manufacturing Methods

>> Laser Cutting

>> Chemical Etching

● Future Trends in SMT Stencil Technology

● Challenges and Considerations

● Best Practices for SMT Stencil Usage

● Impact of SMT Stencil Design on PCB Manufacturing Efficiency

● Role of SMT Stencils in Supporting Advanced Technologies

● Advanced Materials and Coatings for SMT Stencils

● Impact of SMT Stencil Design on Product Reliability

● Role of SMT Stencil Design in Reducing Production Costs

● Impact of SMT Stencil Design on Environmental Sustainability

● Conclusion

● FAQs

>> 1. What is the primary purpose of an SMT stencil in PCB assembly?

>> 2. What are the common materials used for making SMT stencils?

>> 3. What are the main types of SMT stencils?

>> 4. How does the thickness of an SMT stencil affect its performance?

>> 5. What are some future trends in SMT stencil technology?

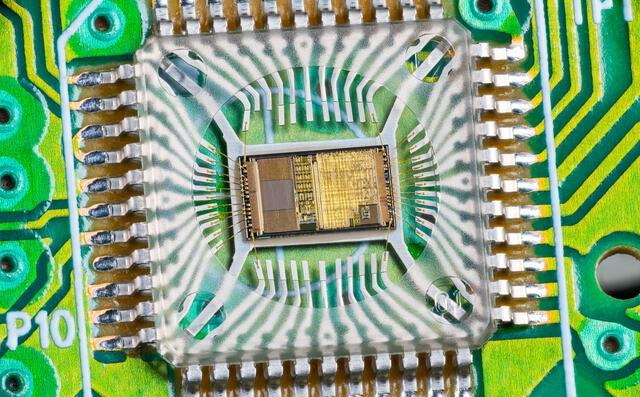

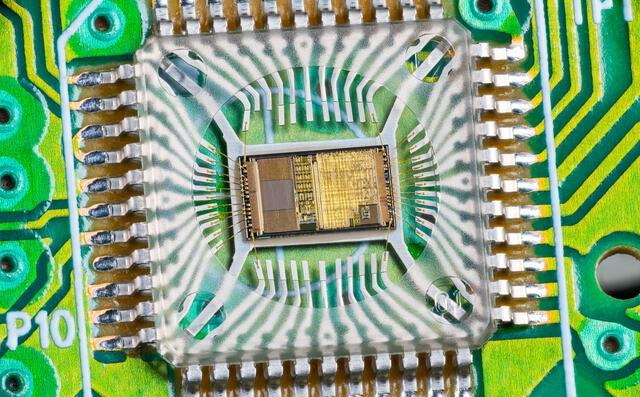

In the realm of electronics manufacturing, Surface Mount Technology (SMT) plays a pivotal role in ensuring efficiency and precision in printed circuit board (PCB) assembly. Central to this process is the SMT stencil, a tool indispensable for the accurate application of solder paste. The design of these stencils is critical for achieving high-quality solder joints, which directly impact the functionality and reliability of the final product. This article delves into the importance of SMT stencil design guidelines and their role in successful PCB manufacturing.

Introduction to SMT Stencils

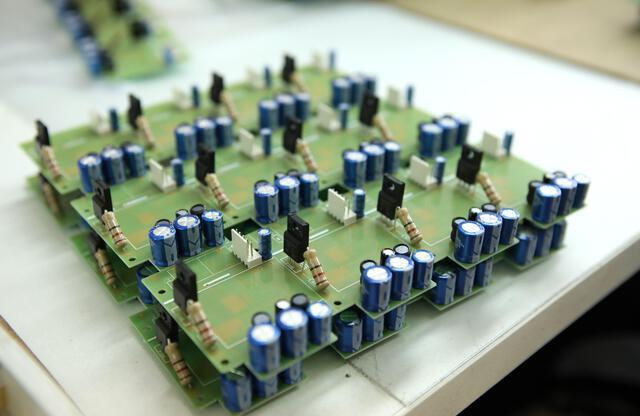

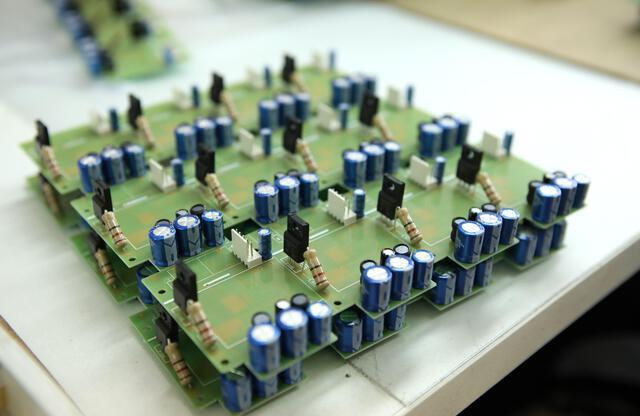

SMT stencils are thin sheets of material, typically made from stainless steel or nickel, with precision-cut apertures that match the locations of SMT components on a PCB. These apertures allow solder paste to be deposited in exact locations before components are mounted, ensuring accurate and consistent solder paste application. The precision and consistency provided by SMT stencils are essential for minimizing defects such as solder bridging and ensuring reliable electrical connections.

Importance of SMT Stencil Design

Effective SMT stencil design is crucial for several reasons:

1. Precision and Accuracy: Properly designed stencils ensure that solder paste is applied only where needed, reducing errors like bridging and insufficient solder. This precision is vital for modern PCBs with increasingly smaller components.

2. Efficiency and Productivity: Stencils streamline the PCB assembly process by enabling simultaneous solder paste application across multiple boards, which accelerates production throughput and helps meet tight deadlines.

3. Quality Control: Consistent solder paste deposition improves product quality and reliability by enhancing electrical conductivity and mechanical stability, meeting industry standards for performance and reliability.

4. Cost Savings: Accurate solder paste application minimizes material waste and reduces the need for rework or repairs, leading to higher first-pass yield rates and lower overall production costs.

SMT Stencil Design Guidelines

To optimize SMT stencil performance, several design guidelines must be considered:

- Aperture Size and Shape: The size and shape of stencil apertures should match the PCB pads while accounting for solder paste properties and desired solder joint profiles. Common aperture shapes include rectangles, circles, and home plates. For optimal performance, the aperture width should be slightly larger than the pad width to accommodate paste shrinkage during reflow, and the aperture length should be equal to or slightly longer than the pad length.

- Stencil Thickness: Selecting the appropriate stencil thickness is critical for achieving optimal solder paste volume and print quality. Thinner stencils are ideal for fine-pitch components but may struggle with sufficient paste volume, while thicker stencils can provide robust deposits but may hinder paste release. The choice of thickness depends on the specific PCB design, component specifications, and solder paste characteristics.

- Aspect Ratio and Area Ratio: The aspect ratio (aperture width divided by stencil thickness) and area ratio (aperture area divided by aperture wall area) are crucial for determining paste release efficiency. A minimum aspect ratio of 1.5 and an area ratio of 0.66 are recommended for optimal performance.

- Material Selection: Stainless steel is the most commonly used material due to its hardness, longevity, and corrosion resistance. However, copper may be used for specific applications requiring better electrical conductivity.

Types of SMT Stencils

SMT stencils come in different forms to meet varied production needs:

- Framed SMT Stencils: Known for their durability, framed stencils are perfect for high-volume manufacturing. The rigid frame provides stability during solder paste application, ensuring consistent results across multiple PCBs.

- Frameless SMT Stencils: These stencils are flexible and cost-effective, ideal for prototypes and small-scale production. They are easy to handle and store, adapting well to evolving PCB designs.

- Prototype SMT Stencils: Rapid prototyping benefits from these stencils, allowing engineers to quickly test new PCB layouts. They support agility in product development, enabling fast adjustments based on initial tests and feedback.

Manufacturing Methods for SMT Stencils

The manufacturing process for SMT stencils involves precise techniques to ensure accurate aperture creation:

- Laser Cutting: This is the most common and precise method for creating stencil apertures. High-powered lasers are used to cut the desired aperture shapes and sizes into the stencil material, offering excellent accuracy and repeatability. This method is ideal for creating fine-pitch apertures and complex designs.

- Chemical Etching: An alternative process that involves using a photoresist mask and chemical solution to create apertures. While less precise than laser cutting, it can be cost-effective for larger apertures or thicker stencils.

Expanded Discussion on Manufacturing Methods

Laser Cutting

Laser cutting is the most precise method for creating stencil apertures. It offers excellent accuracy and repeatability, making it ideal for fine-pitch components and complex designs. The process involves using high-powered lasers to cut the desired aperture shapes and sizes into the stencil material. This method is widely adopted due to its ability to produce precise apertures with minimal waste and high consistency.

Chemical Etching

Chemical etching is an alternative process that involves using a photoresist mask and chemical solution to create apertures. While less precise than laser cutting, it can be cost-effective for larger apertures or thicker stencils. This method is beneficial when high precision is not required, and cost savings are a priority.

Future Trends in SMT Stencil Technology

The evolution of SMT stencil technology continues to drive innovation:

- Nano-coatings and Surface Treatments: Advanced nano-coatings improve solder paste release and reduce adhesion, enhancing print quality and fine-pitch component printing. They also require less frequent cleaning, prolonging stencil life.

- Additive Manufacturing and Customization: 3D printing enables custom-designed SMT stencils with intricate geometries and tailored aperture designs. This flexibility accommodates unique PCB layouts and component configurations.

- Integrated Inspection and Quality Assurance: Emerging technologies integrate automated inspection systems into the stencil printing process, enabling real-time monitoring of solder paste deposition quality. Automated systems detect defects like insufficient solder paste volume or misalignment, ensuring adherence to manufacturing specifications.

Challenges and Considerations

Despite the advancements in SMT stencil technology, several challenges remain:

- Component Miniaturization: As components become smaller, the need for precise paste deposition increases, requiring stencils with finer tolerances.

- Material Selection: The choice of material affects stencil performance, with stainless steel being the most common due to its durability and resistance.

- Environmental Impact: SMT stencils contribute to sustainability by optimizing resource use and reducing material waste. Improved efficiency and minimized defects reduce energy consumption and carbon emissions.

Best Practices for SMT Stencil Usage

To maximize the effectiveness of SMT stencils, consider the following best practices:

- Proper Storage: Store stencils in a clean, dry environment, away from direct sunlight and extreme temperatures to maintain their integrity.

- Regular Maintenance: Clean stencils regularly to prevent solder paste buildup and ensure consistent performance.

- Stencil Inspection: Regularly inspect stencils for wear and tear, replacing them when necessary to maintain optimal print quality.

Impact of SMT Stencil Design on PCB Manufacturing Efficiency

The design of SMT stencils significantly impacts the efficiency of PCB manufacturing. By ensuring precise solder paste deposition, stencils streamline the assembly process, reducing the time and effort required for applying solder paste to individual pads. This efficiency is crucial for meeting tight production deadlines and maintaining competitiveness in the fast-paced electronics industry.

Role of SMT Stencils in Supporting Advanced Technologies

SMT stencils play a vital role in supporting technological advancements like miniaturization and increased functionality. They enable precise solder paste deposition for small, delicate components and high-density interconnections, crucial for developing compact, sophisticated electronic products. The ability of SMT stencils to adapt to diverse PCB designs and component configurations supports the integration of new technologies without compromising quality.

Advanced Materials and Coatings for SMT Stencils

The use of advanced materials and coatings in SMT stencils is becoming increasingly important. Nano-coatings improve solder paste release and reduce adhesion, enhancing print quality and fine-pitch component printing. These coatings also require less frequent cleaning, prolonging stencil life and reducing maintenance costs. Additionally, electropolishing can smooth out microscopic imperfections on the stencil surface, improving paste release and print quality, particularly beneficial for fine-pitch applications.

Impact of SMT Stencil Design on Product Reliability

The design of SMT stencils directly impacts the reliability of the final product. By ensuring consistent and precise solder paste deposition, stencils help maintain high-quality solder joints, which are critical for reliable electrical connections and product performance. Consistent solder paste application reduces defects such as solder bridging and tombstoning, enhancing overall product reliability and longevity.

Role of SMT Stencil Design in Reducing Production Costs

The design of SMT stencils plays a significant role in reducing production costs. By ensuring accurate and consistent solder paste deposition, stencils minimize material waste and reduce the need for rework or repairs. This leads to higher first-pass yield rates, lowering overall production costs and enhancing profitability for manufacturers.

Impact of SMT Stencil Design on Environmental Sustainability

SMT stencils contribute to environmental sustainability by optimizing resource use and reducing material waste. Improved efficiency and minimized defects reduce energy consumption and carbon emissions. Advanced materials and coatings promote longevity and recyclability, reducing environmental impact. As manufacturers focus on eco-friendly practices, the role of SMT stencils in supporting sustainable manufacturing processes becomes increasingly important.

Conclusion

SMT stencil design is a critical component of successful PCB manufacturing, ensuring precision, efficiency, and quality control in the assembly process. By understanding the types, materials, manufacturing processes, advantages, challenges, and future trends of SMT stencils, manufacturers can optimize production processes, reduce costs, and deliver reliable electronic products. As technology advances, SMT stencils will continue to play a pivotal role in driving innovation and excellence in PCB assembly.

FAQs

1. What is the primary purpose of an SMT stencil in PCB assembly?

An SMT stencil is used to apply solder paste to the PCB, ensuring accurate and consistent solder paste deposition for SMT components. This precision is essential for reliable electrical connections and product performance.

2. What are the common materials used for making SMT stencils?

The most common materials used for SMT stencils are stainless steel and nickel. Stainless steel is preferred due to its hardness, longevity, and corrosion resistance.

3. What are the main types of SMT stencils?

The main types of SMT stencils include framed stencils, frameless stencils, and prototype stencils. Framed stencils are used for high-volume manufacturing, frameless stencils for prototypes and small-scale production, and prototype stencils for rapid product development.

4. How does the thickness of an SMT stencil affect its performance?

The thickness of an SMT stencil affects the volume of solder paste applied. Thicker stencils provide more robust deposits but may hinder paste release, while thinner stencils are ideal for fine-pitch components but may struggle with sufficient paste volume.

5. What are some future trends in SMT stencil technology?

Future trends include the use of nano-coatings for improved paste release, additive manufacturing for custom stencil designs, and integrated inspection systems for real-time quality monitoring.