Content Menu

● Introduction

● What is Surface Mount Technology (SMT)?

● Benefits of SMT in PCB Assembly

>> 1. Increased Efficiency

>> 2. Cost Reduction

>> 3. Enhanced Design Flexibility

>> 4. Improved Reliability

>> 5. Automation and Reduced Human Error

● The SMT Process

>> 1. Solder Paste Printing

>> 2. Component Placement

>> 3. Reflow Soldering

● Recent Advancements in SMT Technology

>> 1. Miniaturization

>> 2. Integration with AI

>> 3. Adoption of Advanced Materials

>> 4. Sustainable Practices

>> 5. Smart Manufacturing

● Challenges and Considerations

● Case Studies: Success Stories in Automated SMT Assembly Implementation

>> Company A's Journey to Automation

>> Company B's Lean Manufacturing Approach

>> Company C's Scalability with SMT Automation

● Future Trends in PCB Assembly with SMT

>> 1. Flexible PCBs

>> 2. Internet of Things (IoT) Integration

>> 3. Enhanced Testing Methods

>> 4. Advanced Packaging Technologies

>> 5. Continuous Improvement through Data Analytics

● Conclusion

● FAQs

>> 1. What are the main advantages of SMT over traditional methods?

>> 2. How does SMT impact the size of PCBs?

>> 3. What industries benefit most from SMT?

>> 4. Are there any downsides to using SMT?

>> 5 . How does automation play role in SMT?

Introduction

Surface Mount Technology (SMT) has fundamentally transformed the landscape of printed circuit board (PCB) assembly. As electronic devices evolve to become more compact and sophisticated, the need for efficient and reliable assembly processes has surged. SMT enables the direct mounting of components onto the surface of PCBs, eliminating the necessity for drilling holes and creating a more streamlined production workflow. This article will delve into the reasons behind SMT's revolutionary impact on PCB assembly, exploring its benefits, the SMT process, advancements in technology, challenges it presents, and future trends in the industry.

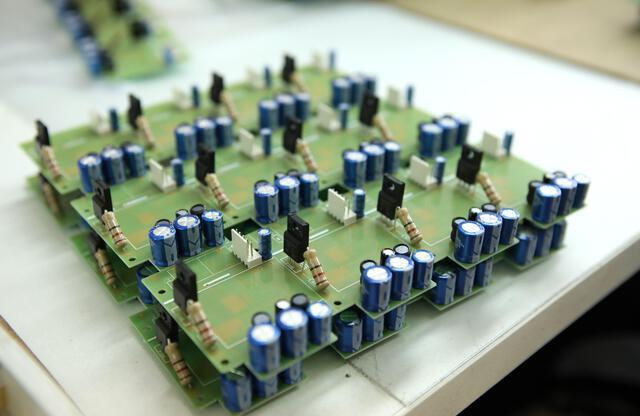

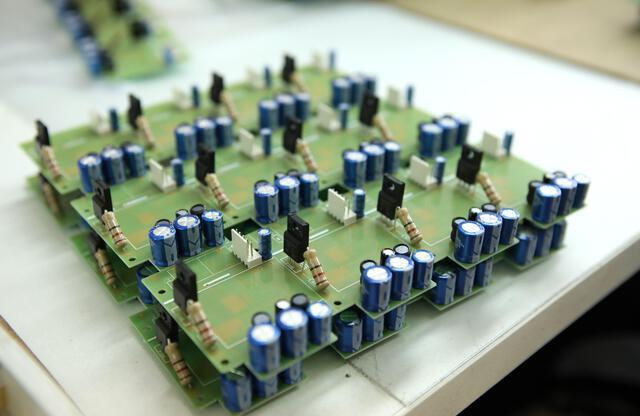

What is Surface Mount Technology (SMT)?

SMT refers to a method of assembling electronic components directly onto the surface of a PCB. Unlike traditional through-hole technology, where components are inserted into drilled holes, SMT components are mounted on pads on the board's surface. This approach not only conserves space but also facilitates a higher density of components, making it ideal for contemporary electronic devices.

Benefits of SMT in PCB Assembly

1. Increased Efficiency

A primary advantage of SMT is its capacity to enhance production efficiency. The process is highly automated, significantly reducing assembly time. Automated machines can place components with precision and speed, leading to increased throughput in PCB production lines. For instance, advanced pick-and-place machines can achieve placement speeds of up to 50,000 components per hour, ensuring that manufacturers can meet rising demand without sacrificing quality.

2. Cost Reduction

SMT contributes to lower manufacturing costs by minimizing manual labor and reducing the number of steps in the assembly process. Companies can save on labor costs and production time, while the smaller size of SMT components allows for more efficient material usage, further driving down costs. As a result, many manufacturers have reported reductions in overall production costs by as much as 25% after implementing SMT processes.

3. Enhanced Design Flexibility

The flexibility offered by SMT allows designers to create intricate and compact circuit layouts. With the ability to place components on both sides of the PCB, designers can optimize space and enhance device performance. This is particularly advantageous in industries where size and weight are critical factors, such as aerospace and medical devices.

4. Improved Reliability

SMT enhances reliability in electronic assemblies by reducing mechanical stress on components since they are securely mounted on the PCB's surface. Additionally, automation minimizes human error, resulting in higher quality and more consistent products. The use of solder paste instead of traditional soldering techniques also reduces the likelihood of cold solder joints, further enhancing reliability.

5. Automation and Reduced Human Error

The integration of automation into SMT processes significantly reduces the likelihood of errors that may occur during manual assembly. Automated pick-and-place machines and soldering robots ensure accurate component placement and soldering, leading to fewer defects and improved overall quality.

The SMT Process

The SMT process can be divided into three main stages:

1. Solder Paste Printing

The initial step involves applying solder paste to the PCB pads using a stencil. This paste contains tiny solder particles mixed with flux, which aids in the soldering process.

2. Component Placement

Once solder paste is applied, components are placed onto the PCB using automated machines programmed to pick components from reels and position them accurately on the solder paste.

3. Reflow Soldering

After placement, the PCB passes through a reflow oven where heat melts the solder paste, creating a permanent bond between the components and the PCB.

Recent Advancements in SMT Technology

The field of SMT is continuously evolving with technological advancements that further enhance its capabilities:

1. Miniaturization

Recent breakthroughs have centered around pushing the limits of miniaturization in electronic components. Manufacturers are now able to produce ultra-fine pitch components with smaller solder joints and increased density. This trend is particularly critical in industries requiring compact designs such as wearables and IoT devices.

2. Integration with AI

Artificial Intelligence (AI) has become a driving force in various industries, including PCB assembly. AI algorithms optimize manufacturing processes by analyzing extensive datasets to predict potential defects and improve quality control standards. Machine learning models power automated inspection systems that identify soldering issues with unparalleled accuracy.

3. Adoption of Advanced Materials

The use of advanced materials such as polyimide or ceramic substrates enhances thermal management and durability in PCBs. These materials are crucial for applications requiring high-frequency signals or operating under extreme conditions.

4. Sustainable Practices

There is a notable shift towards lead-free soldering technologies in response to environmental concerns. New alloy compositions contribute to better thermal performance while minimizing environmental impact.

5. Smart Manufacturing

The rise of Industry 4.0 has led to smarter manufacturing processes where IoT-enabled devices monitor production lines in real-time. This integration allows for predictive maintenance and improved operational efficiency.

Challenges and Considerations

Despite its numerous advantages, SMT also poses challenges:

- Component Fragility: The smaller components used in SMT are often more delicate than their through-hole counterparts, necessitating precise handling during assembly.

- Initial Investment: The initial investment in SMT equipment can be higher than traditional methods, which may deter some manufacturers from adopting this technology.

- Repair Complexity: Repairing defective boards can be more complex due to component density; specialized tools may be required for desoldering small parts without damaging adjacent ones.

- Thermal Management: As component density increases on PCBs due to SMT practices, managing heat dissipation becomes critical to prevent overheating and ensure reliable operation over time.

Case Studies: Success Stories in Automated SMT Assembly Implementation

Several companies have successfully implemented automated SMT assembly processes:

Company A's Journey to Automation

Company A faced challenges with manual assembly processes due to increasing customer demand for their innovative consumer electronics products. By investing in an automated SMT assembly line equipped with advanced pick-and-place machines and reflow ovens, they increased production speed by 40% while reducing defects by 30%. The transition not only improved their output but also allowed them to maintain high-quality standards that their customers had come to expect.

Company B's Lean Manufacturing Approach

Company B integrated lean manufacturing principles into their automated SMT operations after recognizing inefficiencies within their existing processes. By streamlining workflows and eliminating wasteful practices alongside their new equipment investments, they reduced material waste by 50% while improving cycle times by 35%. Their focus on quality control boosted employee morale and productivity as workers felt empowered by their contributions toward operational excellence.

Company C's Scalability with SMT Automation

A startup named Company C needed to scale production quickly due to market demand for their cutting-edge IoT devices. They invested in modular automated SMT equipment that allowed them to double their production capacity within six months without compromising quality or increasing labor costs significantly.

Future Trends in PCB Assembly with SMT

As technology continues to advance at an unprecedented pace, several trends are emerging that will shape the future landscape of PCB assembly using SMT:

1. Flexible PCBs

Flexible printed circuit boards (FPCBs) are gaining traction due to their adaptability in various applications such as wearable devices or compact consumer electronics where space constraints exist. The integration of flexible substrates with SMT techniques will enable even more innovative designs that cater specifically to user needs.

2. Internet of Things (IoT) Integration

With IoT devices becoming ubiquitous across industries—from smart homes to industrial automation—SMT will play an essential role in producing these interconnected systems efficiently while maintaining reliability standards necessary for critical applications.

3. Enhanced Testing Methods

As complexity increases within PCBs assembled using SMT methods—particularly concerning multi-layer designs—there will be an emphasis on enhanced testing techniques like Automated Optical Inspection (AOI) or X-ray inspection systems capable of identifying defects quickly before products reach consumers.

4. Advanced Packaging Technologies

Emerging packaging technologies such as System-in-Package (SiP) or Package-on-Package (PoP) configurations will allow manufacturers greater flexibility when designing compact solutions that integrate multiple functions into single units while leveraging existing SMT capabilities effectively.

5. Continuous Improvement through Data Analytics

Data analytics tools will become integral for manufacturers looking to optimize their production lines further by analyzing performance metrics over time—allowing them not only identify bottlenecks but also predict maintenance needs proactively based on historical trends observed during operation cycles.

Conclusion

In conclusion, Surface Mount Technology is revolutionizing PCB assembly processes by enhancing efficiency, reducing costs, improving design flexibility, ensuring high reliability standards while adapting rapidly evolving technological advancements like AI integration or sustainable practices into its framework effectively addressing modern challenges faced across various industries including consumer electronics automotive medical devices telecommunications among others .

As demand for smaller more complex electronic devices continues grow ,SMT will undoubtedly play pivotal role shaping future landscape electronics manufacturing enabling companies innovate creatively respond ever-changing market dynamics .

FAQs

1. What are the main advantages of SMT over traditional methods?

SMT provides increased efficiency, lower costs, enhanced design flexibility, improved reliability, and reduced human error compared to traditional through-hole methods.

2. How does SMT impact the size of PCBs?

SMT allows for a higher density of components on a PCB, enabling smaller and more compact designs essential for modern electronic devices.

3. What industries benefit most from SMT?

Industries such as aerospace, medical devices, consumer electronics, automotive electronics telecommunications benefit significantly from SMT due their need compact reliable electronic assemblies .

4. Are there any downsides to using SMT?

Some downsides include fragility smaller components higher initial investment equipment compared traditional methods .

5 . How does automation play role in SMT?

Automation reduces human error increases production speed ensures consistent quality by using machines precise component placement soldering .