Content Menu

● Understanding SMT Production Lines

>> What is SMT?

>> Key Components of an SMT Production Line

● Advantages of SMT Production Lines

>> 1. Increased Component Density

>> 2. Cost Efficiency

>> 3. Enhanced Reliability and Performance

>> 4. Flexibility in Design

>> 5. Streamlined Manufacturing Process

>> 6. Reduced Environmental Impact

>> 7. Improved Thermal Management

● Challenges Associated with SMT Production Lines

● Future Trends in SMT Production Lines

>> 1. Industry 4.0 Integration

>> 2. Miniaturization of Components

>> 3. Advanced Materials Development

>> 4. Increased Automation

>> 5. Sustainability Initiatives

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology (SMT)?

>> 2. What are the main advantages of using an SMT production line?

>> 3. How does an SMT production line improve manufacturing efficiency?

>> 4. What challenges do manufacturers face with SMT?

>> 5. Can both SMT and through-hole technologies be used on the same PCB?

Surface Mount Technology (SMT) has revolutionized the field of electronics manufacturing, particularly in the assembly of printed circuit boards (PCBs). The SMT production line is integral to this process, providing numerous advantages that enhance efficiency, reduce costs, and improve product quality. This article delves into the significance of SMT production lines in PCB assembly, examining their components, benefits, challenges, and the overall impact on the electronics industry.

Understanding SMT Production Lines

What is SMT?

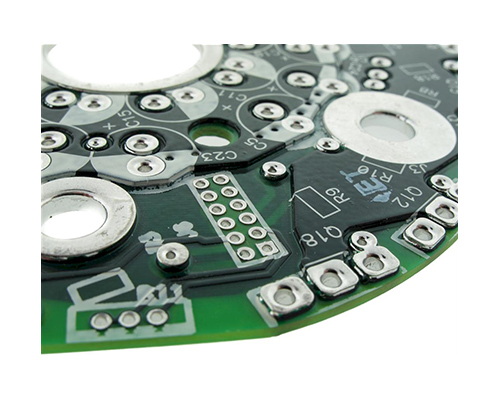

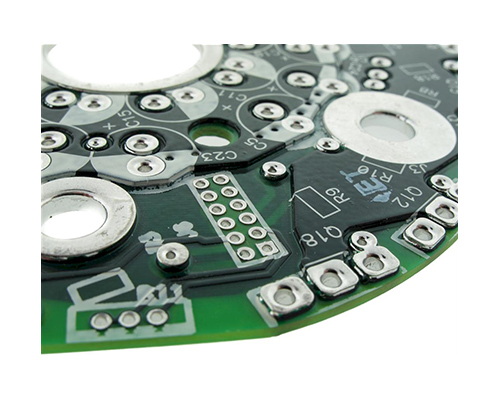

Surface Mount Technology (SMT) is a method used to mount electronic components directly onto the surface of a PCB. Unlike traditional through-hole technology, where components are inserted into drilled holes on the board, SMT allows for a more compact design by eliminating the need for holes. This technique has become increasingly popular due to its ability to accommodate smaller, lighter components while maximizing space and efficiency on PCBs.

Key Components of an SMT Production Line

An efficient SMT production line consists of several critical components:

- Solder Paste Printer: This machine applies solder paste to the PCB in precise locations where components will be placed. The accuracy of this step is crucial as it determines the quality of solder joints formed during reflow.

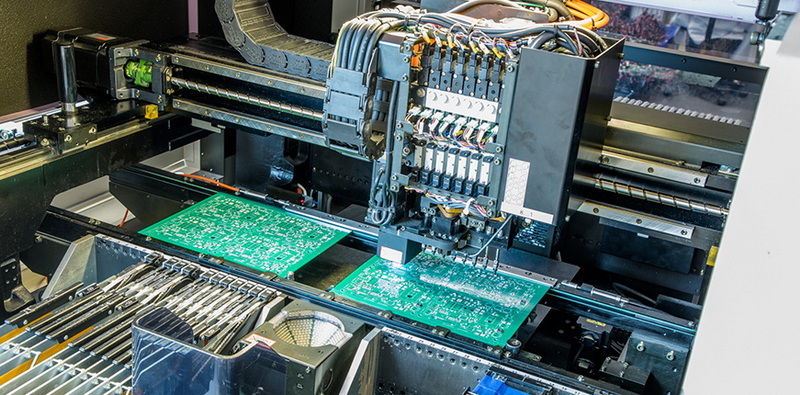

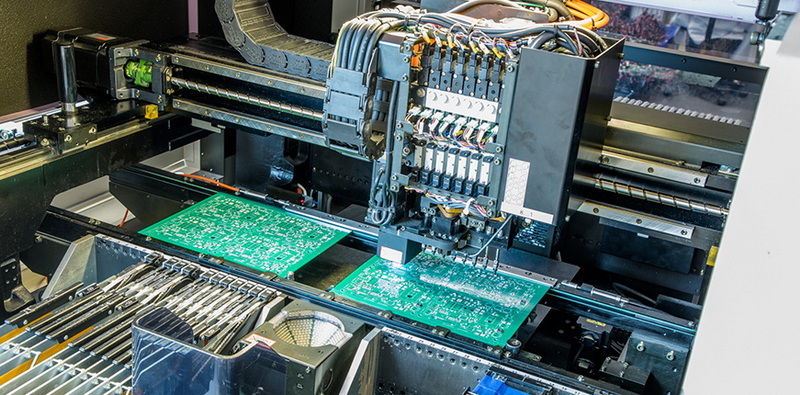

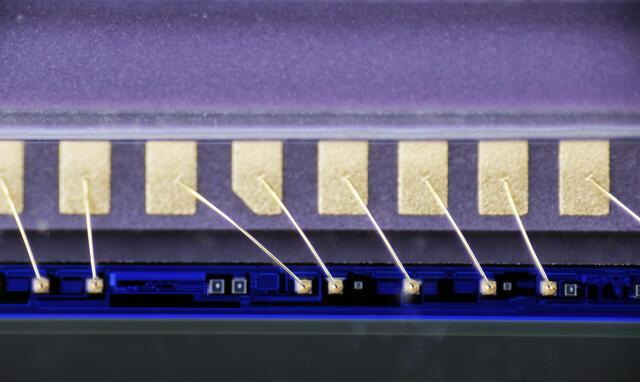

- Pick and Place Machine: This automated device picks up surface mount devices (SMDs) and places them accurately onto the solder paste-covered pads on the PCB. High-speed pick and place machines can handle thousands of components per hour, significantly speeding up production.

- Reflow Oven: After component placement, PCBs pass through a reflow oven where heat is applied to melt the solder paste, creating strong electrical connections between components and the board. The temperature profile in the reflow oven is meticulously controlled to ensure optimal soldering conditions.

- Inspection Systems: Automated Optical Inspection (AOI) systems check for defects in component placement and soldering. These systems use cameras and software algorithms to detect misalignments or insufficient solder, ensuring high-quality output.

- Test Equipment: Functional testing equipment ensures that assembled PCBs operate correctly before they are packaged for shipment. This testing phase is critical for identifying any functional issues early in the production process.

Advantages of SMT Production Lines

The importance of SMT production lines in PCB assembly can be attributed to several key advantages:

1. Increased Component Density

SMT allows for a higher density of components on a PCB. Since SMDs are mounted directly onto the surface without leads extending through holes, manufacturers can fit more components into a smaller area. This capability is crucial for modern electronic devices that require compact designs, such as smartphones and wearable technology.

2. Cost Efficiency

The reduction in size and weight of PCBs translates into lower material costs and reduced shipping expenses. Additionally, SMT production lines require less manual labor compared to traditional methods, further decreasing operational costs. The automation involved in SMT processes leads to faster production cycles and less waste.

3. Enhanced Reliability and Performance

SMT provides improved electrical performance due to shorter signal paths and reduced lead inductance. These characteristics enhance signal integrity and allow for higher frequency operations, making SMT ideal for advanced electronic applications.

4. Flexibility in Design

SMT accommodates various component types and sizes, allowing designers greater flexibility when creating complex circuits. The ability to place components on both sides of a PCB further maximizes available space.

5. Streamlined Manufacturing Process

The automation inherent in SMT production lines significantly speeds up the manufacturing process. Tasks that previously took hours can now be completed in minutes due to advanced machinery like pick-and-place systems and reflow ovens. This efficiency not only accelerates production but also improves overall product quality by minimizing human error.

6. Reduced Environmental Impact

The efficiency gained from SMT production lines also contributes to a reduced environmental footprint. By minimizing material waste during manufacturing processes and lowering energy consumption through optimized machinery operation, companies can operate more sustainably.

7. Improved Thermal Management

Modern electronic devices generate significant heat during operation. SMT allows for better thermal management solutions by facilitating the integration of thermal vias and heat sinks directly onto PCBs. This design flexibility helps maintain optimal operating temperatures for sensitive electronic components.

Challenges Associated with SMT Production Lines

While there are many benefits to using SMT production lines, some challenges must be addressed:

- Fragility of Components: SMDs can be more fragile than through-hole components, requiring careful handling during assembly. Manufacturers must implement best practices in handling and storage to avoid damage.

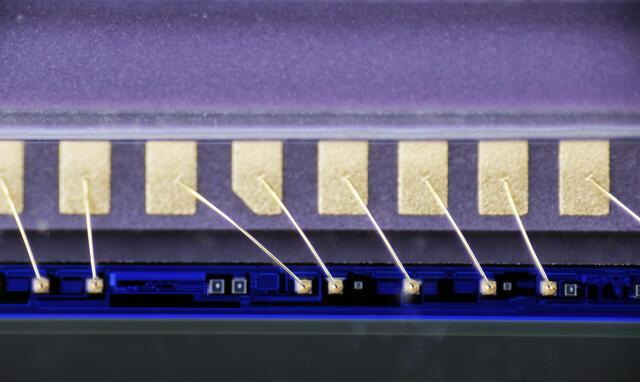

- Complexity of Inspection: Visual inspection of solder joints can be challenging due to the small size of SMT components, necessitating advanced inspection technologies such as X-ray inspection for hidden solder joints.

- Initial Investment Costs: Setting up an automated SMT line can require significant capital investment in machinery and training. However, this investment often pays off quickly through increased productivity and reduced labor costs over time.

- Process Control: Maintaining consistent quality across high-speed production runs requires rigorous process control measures. Manufacturers must continuously monitor equipment performance and product quality to ensure standards are met.

- Supply Chain Dependencies: The reliance on specific SMDs may create vulnerabilities in supply chains. Disruptions in component availability can impact production schedules, emphasizing the need for effective inventory management strategies.

Future Trends in SMT Production Lines

As technology continues to evolve, several trends are shaping the future of SMT production lines:

1. Industry 4.0 Integration

The move towards Industry 4.0 involves integrating smart manufacturing technologies such as IoT (Internet of Things) devices into SMT production lines. These technologies enable real-time monitoring of equipment performance, predictive maintenance scheduling, and enhanced data analytics capabilities that drive continuous improvement.

2. Miniaturization of Components

As consumer electronics demand smaller devices with more features, manufacturers are focusing on miniaturization techniques that allow even smaller SMDs to be used effectively on PCBs without compromising performance or reliability.

3. Advanced Materials Development

Research into new materials such as flexible substrates or high-performance solder alloys is underway to improve thermal management and mechanical strength in PCBs assembled using SMT processes.

4. Increased Automation

Automation will continue to play a crucial role in enhancing productivity within SMT production lines. Innovations such as collaborative robots (cobots) will work alongside human operators to further streamline workflows while maintaining high levels of precision.

5. Sustainability Initiatives

As environmental concerns grow, manufacturers are increasingly adopting sustainable practices within their SMT processes—such as using lead-free solder materials or implementing recycling programs for electronic waste—to meet regulatory requirements and consumer expectations.

Conclusion

The SMT production line is vital for modern PCB assembly processes. Its ability to enhance component density, reduce costs, improve reliability, provide design flexibility, streamline manufacturing, reduce environmental impact, and facilitate better thermal management makes it indispensable in today's fast-paced electronics industry. As technology continues to evolve alongside consumer demands for smaller, faster, and more reliable electronic devices, the importance of efficient SMT production lines will only increase.

FAQ

1. What is Surface Mount Technology (SMT)?

Surface Mount Technology (SMT) is a method used to mount electronic components directly onto the surface of printed circuit boards (PCBs), allowing for more compact designs compared to traditional through-hole technology.

2. What are the main advantages of using an SMT production line?

The main advantages include increased component density on PCBs, cost efficiency due to reduced material use and labor costs, enhanced reliability and performance through improved electrical characteristics, flexibility in design options, streamlined manufacturing processes, reduced environmental impact, and improved thermal management solutions.

3. How does an SMT production line improve manufacturing efficiency?

An SMT production line automates many processes involved in PCB assembly—such as solder paste application, component placement, and soldering—significantly reducing production time compared to manual methods while improving overall product quality.

4. What challenges do manufacturers face with SMT?

Challenges include the fragility of SMDs requiring careful handling during assembly; complexity in inspecting small solder joints effectively; high initial investment costs for setting up automated systems; maintaining consistent quality across high-speed runs; and supply chain dependencies that could disrupt production schedules.

5. Can both SMT and through-hole technologies be used on the same PCB?

Yes, it is possible to use both SMT and through-hole technologies on the same PCB. This hybrid approach allows designers to leverage the strengths of both methods based on specific component requirements.