Content Menu

● Introduction

● What is SMT PCB Assembly?

● The Importance of Prototyping in Electronics

>> Key Benefits of Prototyping:

● Advantages of SMT PCB Assembly for Prototyping

>> Detailed Advantages:

● Challenges and Considerations

● Innovations Driving SMT Forward

>> 1. Automation Technologies

>> 2. Advanced Materials

>> 3. AI Integration

>> 4. Additive Manufacturing

>> 5. Enhanced Testing Techniques

● Future Trends in SMT PCB Assembly

>> 1. Miniaturization

>> 2. Sustainability Initiatives

>> 3. Industry 4.0 Adoption

>> 4. Customization Capabilities

>> 5. Enhanced Collaboration Tools

● Conclusion

● FAQ

>> 1. What is the difference between SMT and through-hole technology?

>> 2. How does SMT improve the prototyping process?

>> 3. What are the cost benefits of using SMT for prototyping?

>> 4. Can SMT be used for all types of PCBs?

>> 5. What are the common challenges in SMT PCB assembly?

● Citations:

Introduction

Surface Mount Technology (SMT) PCB assembly has transformed the electronics industry, particularly in the prototyping phase. This article delves into why SMT PCB assembly is essential for prototyping, highlighting its advantages, challenges, and overall impact on electronics development.

What is SMT PCB Assembly?

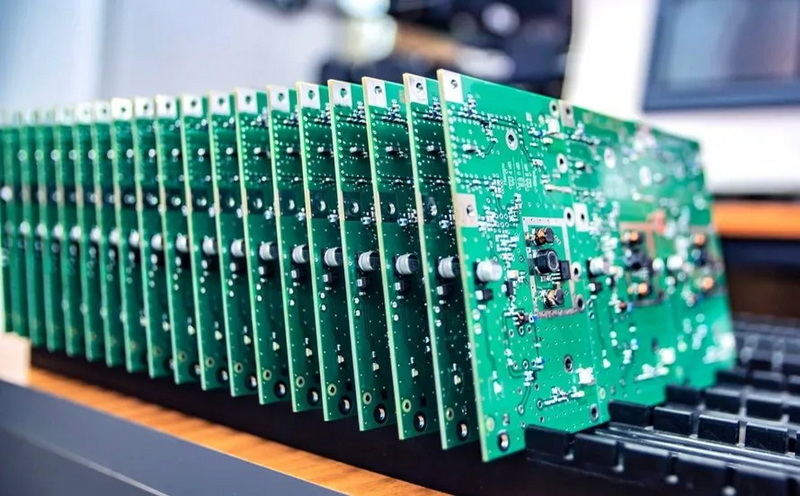

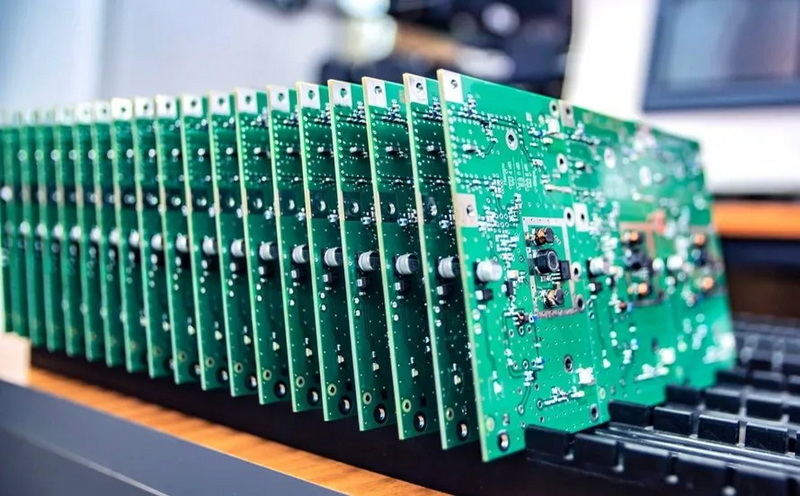

SMT PCB assembly involves mounting electronic components directly onto the surface of a printed circuit board (PCB). Unlike traditional through-hole technology, which requires drilling holes in the PCB, SMT eliminates this step, making the process faster and more efficient. Automated machines are used to place components with high precision, ensuring reliability and performance.

The Importance of Prototyping in Electronics

Prototyping is a critical step in electronics development. It allows engineers to test and validate designs before mass production, significantly reducing the risk of errors and ensuring product quality. By creating a prototype, manufacturers can identify and address potential issues early in the development process, saving time and resources.

Key Benefits of Prototyping:

- Design Validation: Prototyping verifies that the design functions as intended.

- Error Identification: Early detection of design flaws minimizes costly mistakes during mass production.

- Time Efficiency: Rapid prototyping accelerates time-to-market by enabling quicker iterations.

Advantages of SMT PCB Assembly for Prototyping

SMT offers numerous advantages that make it particularly suitable for prototyping:

- Automation and Efficiency: SMT enables automated assembly processes, reducing manual labor and increasing production speed.

- Compact and Lightweight Designs: SMT components are smaller and lighter than those used in through-hole technology, allowing for more compact devices.

- Cost-Effectiveness: The reduced need for drilling and manual work lowers production costs significantly.

- High Component Density: SMT allows for a higher density of components on the PCB, optimizing space usage and functionality.

- Improved Performance and Reliability: SMT ensures better electrical performance and mechanical stability due to its design characteristics.

Detailed Advantages:

1. Quicker and More Accurate Mounting: Automation in SMT leads to faster component placement with higher accuracy, which is crucial during prototyping when rapid iterations are necessary.

2. Maximized Space on Circuit Boards: The compact nature of SMT components allows engineers to utilize board space effectively, facilitating miniaturization without sacrificing performance.

3. Higher Packing Density: With no need for drilling holes, more components can be placed on a PCB, which is especially beneficial for devices with limited space.

4. Versatility: SMT can be used alongside through-hole components in hybrid designs, allowing flexibility in product development.

5. Enhanced Signal Integrity: The proximity of components on SMT boards reduces signal paths, improving responsiveness and performance.

6. Reduced Heat Generation: The efficient design of SMT helps dissipate heat more effectively than traditional methods, which is crucial for high-performance applications.

7. Compatibility with Advanced Technologies: As technology evolves, SMT supports integration with advanced features like wireless communication modules and sensors that require compact designs.

Challenges and Considerations

While SMT offers significant advantages, it also presents challenges that need to be addressed:

- Specialized Equipment Requirements: The need for advanced machinery can increase initial setup costs.

- Handling Small Components: The small size of SMT components can complicate handling and assembly processes.

- Thermal Profiling Requirements: Precise thermal management is crucial during soldering to avoid damage to sensitive components.

- Inspection Difficulties: Due to the small sizes and numerous solder joints of most SMD components, inspection becomes challenging. Identifying defects or faults can be time-consuming, especially when dealing with complex packages like ball grid arrays (BGAs).

- Fragility of Components: Surface mount components are generally more delicate than their through-hole counterparts; they can be easily damaged if mishandled or dropped during the manufacturing process or while in use.

Addressing these challenges requires expertise and careful planning but can lead to successful outcomes in prototyping.

Innovations Driving SMT Forward

The landscape of SMT PCB assembly continues to evolve with several innovations that enhance its capabilities:

1. Automation Technologies

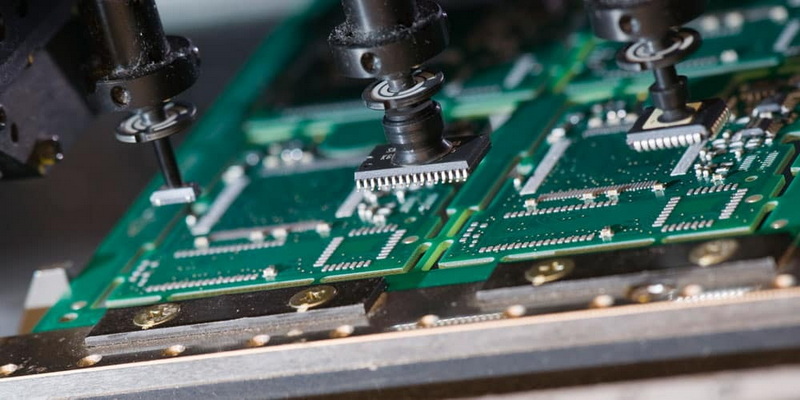

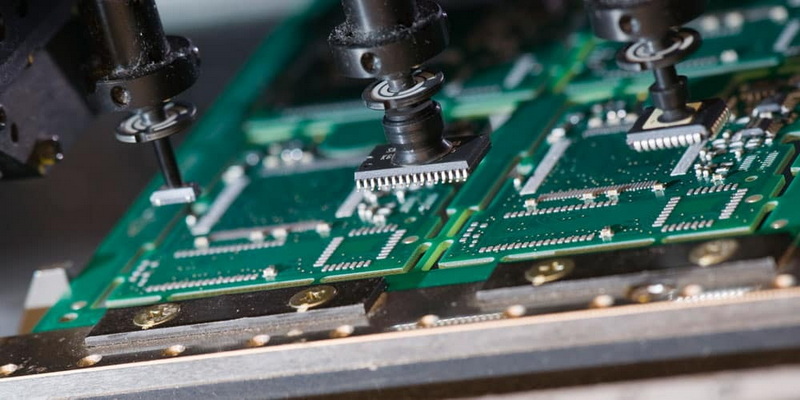

Automation technologies are revolutionizing SMT assembly by incorporating robotics that improve efficiency and precision. Automated pick-and-place machines can quickly assemble components with high accuracy, significantly reducing labor costs and production times. This automation is particularly advantageous during the prototyping phase when speed is essential.

2. Advanced Materials

The use of advanced materials in PCBs has improved thermal management and durability. Manufacturers are increasingly adopting flexible PCBs that can bend or conform to specific shapes while maintaining excellent electrical performance. This flexibility opens up opportunities for innovative designs while ensuring functionality across various applications.

3. AI Integration

Artificial intelligence (AI) is being integrated into the PCB assembly process to optimize manufacturing efficiency. AI-powered systems can predict defects before they occur, enhancing quality control during production. This predictive capability ensures that only high-quality products reach the market while minimizing waste.

4. Additive Manufacturing

Additive manufacturing techniques such as 3D printing are gaining traction in PCB prototyping. These methods allow for rapid prototyping of complex designs without the constraints associated with traditional subtractive methods. By enabling layer-by-layer construction, additive manufacturing helps minimize waste while facilitating innovative design solutions.

5. Enhanced Testing Techniques

As the complexity of electronic devices increases, so does the need for sophisticated testing methods. Advanced inspection technologies such as automated optical inspection (AOI) and X-ray inspection are becoming standard practices in ensuring quality throughout the assembly process. These techniques enable early detection of defects, improving overall product reliability.

Future Trends in SMT PCB Assembly

The future of SMT PCB assembly looks promising with several trends shaping its trajectory:

1. Miniaturization

As consumer demand for smaller devices grows, manufacturers are focusing on miniaturization without compromising performance. This trend drives innovation in component design and manufacturing techniques to produce compact electronic assemblies that deliver exceptional functionality.

2. Sustainability Initiatives

With increasing awareness of environmental impacts, there is a growing emphasis on sustainable practices within PCB manufacturing. Manufacturers are exploring eco-friendly materials and processes that minimize waste while adhering to regulations such as RoHS (Restriction of Hazardous Substances) directives.

3. Industry 4.0 Adoption

The integration of Industry 4.0 principles into PCB manufacturing emphasizes connectivity between machines and systems for real-time monitoring and predictive maintenance. This shift enhances operational efficiency while reducing downtime through proactive management strategies.

4. Customization Capabilities

The demand for customized electronic products is rising as consumers seek tailored solutions that meet specific needs. Manufacturers are adapting their processes to accommodate shorter production runs while maintaining high quality through flexible equipment setups capable of handling diverse designs efficiently.

5. Enhanced Collaboration Tools

Collaboration tools that facilitate communication between design teams and manufacturers are becoming increasingly important as projects grow more complex. These tools help streamline workflows by providing real-time feedback during the prototyping phase, ensuring alignment between stakeholders throughout development cycles.

Conclusion

SMT PCB assembly is a game-changer in the prototyping phase of electronics development. Its automation, efficiency, and ability to produce compact and reliable designs make it an essential technology for modern electronics. By leveraging SMT, manufacturers can accelerate product development, reduce costs, and ensure high-quality outcomes. The combination of rapid prototyping capabilities with the advantages of SMT positions it as a critical component in the successful launch of electronic products.

FAQ

1. What is the difference between SMT and through-hole technology?

SMT mounts components directly onto the PCB surface without drilling holes, while through-hole technology requires leads to be inserted into drilled holes. SMT is generally faster and more space-efficient than through-hole technology.

2. How does SMT improve the prototyping process?

SMT enhances prototyping by enabling automated assembly processes that reduce errors while allowing quick iterations and adjustments based on testing results.

3. What are the cost benefits of using SMT for prototyping?

Using SMT reduces costs by minimizing manual labor requirements, decreasing material usage due to fewer drilled holes, and speeding up production times.

4. Can SMT be used for all types of PCBs?

While versatile, SMT may not be suitable for all applications—especially those requiring high-power or high-stress connections where through-hole components might be preferred.

5. What are the common challenges in SMT PCB assembly?

Common challenges include managing small component sizes during assembly, ensuring precise soldering techniques are followed, maintaining equipment calibration for optimal performance, inspection difficulties due to component size, and fragility concerns during handling or operation.

Citations:

[1] https://www.wevolver.com/article/smt-process

[2] https://levisonenterprises.com/5-advantages-to-using-smt/

[3] https://www.pcbgogo.com/Article/Innovations_in_printed_circuit_board_assembly__trends_and_techniques.html

[4] https://www.pcbpower.us/blog/unveiling-the-advantages-and-disadvantages-of-surface-mount-technology

[5] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[6] https://www.oem-pcb.com/news/pcb-assembly-trends-that-are-shaping-the-futur-83660182.html

[7] https://www.macrofab.com/blog/smt-assembly-vs-through-hole/

[8] https://www.hayawin.com/news-5-advantages-to-using-smt-in-your-electronic-manufacturing-project.html

[9] https://www.rs-online.com/designspark/latest-pcb-technology-and-industry-trends

[10] https://blog.matric.com/what-is-smt-assembly

[11] https://www.linkedin.com/advice/1/what-benefits-challenges-using-surface-mount-technology

[12] https://emsginc.com/resources/the-evolution-of-surface-mount-technology/

[13] https://www.mycronic.com/product-areas/pcb-assembly/news-and-press-releases/news/ten-key-smt-trends-you-need-to-know/

[14] https://www.vse.com/blog/2020/05/07/surface-mount-technology-advantages-and-disadvantages-for-pcb-assembly/

[15] https://www.comarch.com/iot-plant/blog/prototyping-of-electronic-devices-using-smt-assembly-in-the-comarch-iot-plant/

[16] https://www.circuits-central.com/blog/the-future-of-pcb-manufacturing-emerging-technologies-and-trends-part-2/

[17] https://www.pcbjhy.com/blog/pros-and-cons-of-smt-pcb-assembly/

[18] https://www.technotronix.us/pcbblog/top-trends-in-printed-circuit-board-manufacturing-for-2024/

[19] https://en.wikipedia.org/wiki/Surface-mount_technology

[20] https://www.atmwa.com.au/new-trends-in-pcb-assembly-what-to-expect-in-2023/