Content Menu

● Understanding Surface Mount Technology

>> Key Components of SMT Equipment

>> The SMT Process

● Advantages of SMT Equipment

>> 1. Increased Efficiency

>> 2. Smaller Footprint

>> 3. Higher Component Density

>> 4. Cost-Effectiveness

>> 5. Improved Reliability

● Challenges in SMT Manufacturing

>> 1. Initial Investment Costs

>> 2. Complexity of Components

>> 3. Fragility of Components

>> 4. Need for Advanced Quality Control

● The Future of SMT Equipment

● Conclusion

● Related Questions

>> 1. What is Surface Mount Technology (SMT)?

>> 2. What are some key pieces of equipment used in SMT?

>> 3. How does SMT compare to Through-Hole Technology?

>> 4. What are common applications for SMT?

>> 5. What challenges does SMT face?

Surface Mount Technology (SMT) has become a cornerstone of modern electronics manufacturing, enabling the production of compact, efficient, and high-performance electronic devices. The evolution of SMT has transformed how electronic components are assembled onto printed circuit boards (PCBs), offering significant advantages over traditional methods such as Through-Hole Technology (THT). This article delves into the importance of SMT equipment in contemporary electronics manufacturing, exploring its benefits, processes, and challenges.

Understanding Surface Mount Technology

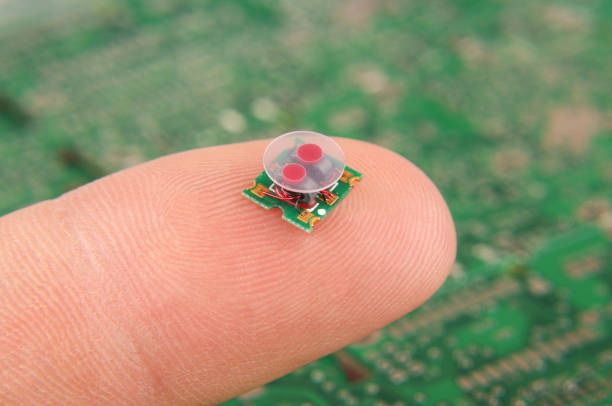

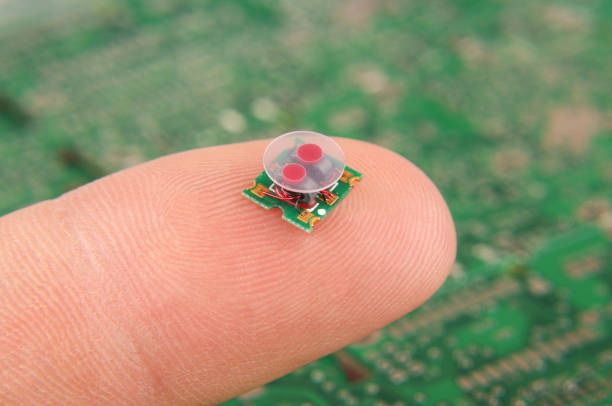

SMT refers to a method where electronic components are mounted directly onto the surface of PCBs. This technique eliminates the need for drilling holes in the boards, allowing for a more streamlined assembly process. The components used in SMT, known as Surface Mount Devices (SMDs), are generally smaller and lighter than their through-hole counterparts. This reduction in size not only saves space on the PCB but also enhances the overall performance of electronic devices by allowing for higher component density and improved signal integrity.

Key Components of SMT Equipment

The effectiveness of SMT is largely dependent on specialized equipment designed to automate various stages of the assembly process. Key pieces of SMT equipment include:

- Solder Paste Printer: Applies solder paste onto the PCB pads where components will be placed.

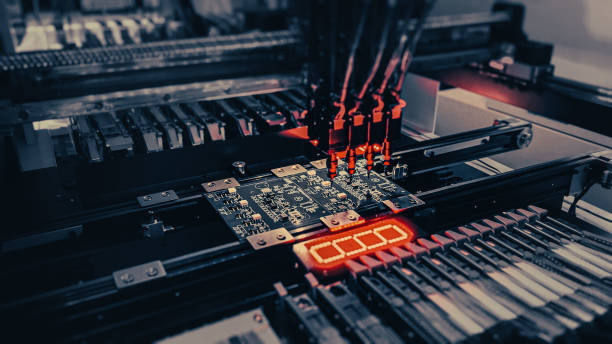

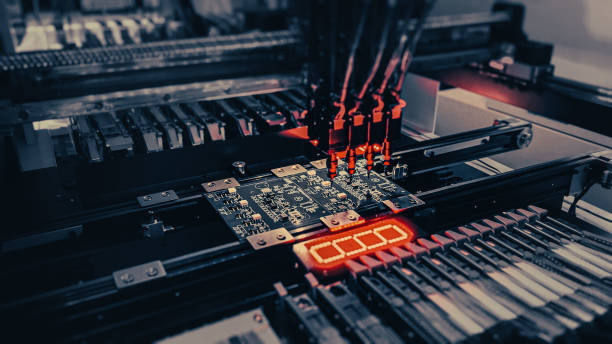

- Pick-and-Place Machine: Automatically places SMDs onto the solder paste-covered pads with high precision and speed.

- Reflow Oven: Heats the assembled PCB to melt the solder paste, creating permanent connections between the components and the board.

- Automated Optical Inspection (AOI): Inspects the finished assemblies for defects such as misalignment or insufficient solder.

The SMT Process

The SMT manufacturing process typically consists of several critical steps:

1. Solder Paste Printing: A stencil is used to apply solder paste onto specific areas of the PCB.

2. Component Placement: The pick-and-place machine accurately positions components on the solder paste.

3. Reflow Soldering: The PCB is heated in a reflow oven, allowing the solder to melt and bond with the components.

4. Inspection: Automated systems check for defects to ensure quality control.

5. Rework (if necessary): Any identified issues are addressed through rework processes.

Advantages of SMT Equipment

The adoption of SMT equipment offers numerous advantages that have made it indispensable in electronics manufacturing:

1. Increased Efficiency

SMT allows for a higher degree of automation compared to traditional methods. Automated machines can place thousands of components per hour, significantly reducing assembly time and labor costs.

2. Smaller Footprint

SMT components are smaller than through-hole components, which leads to reduced board size and weight. This compactness is crucial for modern electronic devices that demand portability without sacrificing performance.

3. Higher Component Density

With SMT, more components can be placed on a single PCB without increasing its size. This capability enables manufacturers to design more complex circuits within limited space, catering to consumer demands for multifunctional devices.

4. Cost-Effectiveness

Although initial investments in SMT equipment can be high, the long-term savings from reduced material usage, lower labor costs, and faster production times make it a cost-effective solution for mass production.

5. Improved Reliability

The soldering process in SMT creates stronger mechanical connections than traditional methods, enhancing device reliability and performance under various conditions.

Challenges in SMT Manufacturing

Despite its advantages, SMT also presents certain challenges that manufacturers must navigate:

1. Initial Investment Costs

Setting up an SMT line requires significant capital investment in specialized machinery and training for operators. For small manufacturers or startups, this can be a barrier to entry.

2. Complexity of Components

As electronic devices become more sophisticated, the complexity of SMDs increases as well. This complexity can lead to challenges in placement accuracy and inspection processes.

3. Fragility of Components

SMDs are often more fragile than through-hole components, making them susceptible to damage during handling or assembly processes.

4. Need for Advanced Quality Control

The miniaturization of components necessitates advanced quality control measures to prevent defects that may not be visible to the naked eye. Automated inspection systems must be highly accurate and reliable.

The Future of SMT Equipment

As technology continues to advance, so too will SMT equipment and techniques. Innovations such as 3D printing integration and enhanced automation promise to further streamline production processes and improve product quality. Additionally, ongoing research into new materials and component designs will likely expand the capabilities and applications of SMT in various industries.

Conclusion

In conclusion, SMT equipment plays a crucial role in modern electronics manufacturing by enabling efficient assembly processes that produce compact and reliable electronic devices. The advantages offered by SMT—such as increased efficiency, smaller footprints, higher component density, cost-effectiveness, and improved reliability—make it an essential technology in today's fast-paced market. While challenges exist, ongoing advancements in technology promise to enhance the capabilities and applications of SMT further.

Related Questions

1. What is Surface Mount Technology (SMT)?

Surface Mount Technology (SMT) is an assembly method where electronic components are attached directly to the surface of PCBs without needing drilled holes.

2. What are some key pieces of equipment used in SMT?

Key equipment includes solder paste printers, pick-and-place machines, reflow ovens, and automated optical inspection systems.

3. How does SMT compare to Through-Hole Technology?

SMT allows for smaller components with higher density on PCBs compared to THT, which requires larger components and drilled holes.

4. What are common applications for SMT?

SMT is widely used in consumer electronics, automotive systems, telecommunications devices, medical equipment, and industrial controls.

5. What challenges does SMT face?

Challenges include high initial investment costs, complexity in handling fragile components, and the need for advanced quality control measures.