Content Menu

● Introduction

● The Evolution of PCB Assembly

● Advantages of SMT in PCB Assembly

>> 1. Increased Component Density

>> 2. Reduced Weight and Size

>> 3. Enhanced Performance

>> 4. Automation and Cost Efficiency

>> 5. Flexibility in Design

>> 6. Sustainability

● The SMT Assembly Process

● Challenges and Considerations

● Advanced Applications of SMT

>> 1. Consumer Electronics

>> 2. Automotive Industry

>> 3. Medical Devices

>> 4. Aerospace Applications

>> 5. IoT Devices

● Future Trends Influencing SMT

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology (SMT)?

>> 2. What are the advantages of SMT over through-hole technology?

>> 3. How does SMT improve the performance of electronic devices?

>> 4. What is the SMT assembly process?

>> 5. Are there any challenges associated with SMT?

● Citations:

Introduction

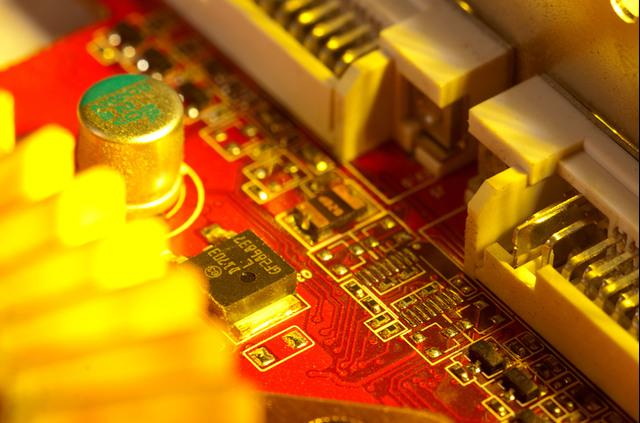

Surface Mount Technology (SMT) has fundamentally transformed the landscape of printed circuit board (PCB) assembly. By allowing electronic components to be mounted directly onto the surface of PCBs, SMT eliminates the need for drilling holes, which was a hallmark of traditional through-hole technology. This innovation has made SMT the preferred method for PCB assembly in modern electronics manufacturing. In this article, we will delve into why SMT is critical in contemporary PCB assembly, highlighting its advantages, process, challenges, and overall impact on the electronics industry.

The Evolution of PCB Assembly

Historically, PCB assembly relied heavily on through-hole technology. This method involved inserting components into drilled holes and soldering them from the opposite side. While effective, it had significant limitations:

- Larger Component Sizes: Through-hole components are generally bulkier compared to their surface-mounted counterparts.

- Increased Weight: The need for larger components often resulted in heavier boards.

- Longer Assembly Times: The manual insertion and soldering processes were time-consuming.

The introduction of SMT in the 1980s marked a pivotal shift in PCB manufacturing, enabling the production of smaller, lighter, and more complex electronic devices. This evolution has been driven by the increasing demand for compact and efficient electronics in various applications.

Advantages of SMT in PCB Assembly

1. Increased Component Density

One of the most significant advantages of SMT is its ability to accommodate a higher density of components on a PCB. SMT components are typically smaller than their through-hole counterparts, allowing manufacturers to place more components within a given area. This increased density is particularly beneficial for compact devices such as smartphones and wearable technology.

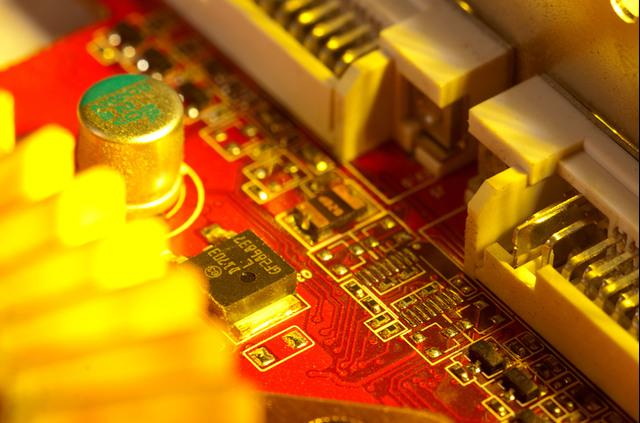

2. Reduced Weight and Size

SMT components are lighter and smaller, contributing to an overall reduction in the size and weight of electronic devices. This is essential in industries where portability is crucial, such as consumer electronics and aerospace. The smaller footprint of SMT also allows for more efficient use of space within devices, facilitating innovative designs.

3. Enhanced Performance

The design of SMT components allows for shorter electrical paths, which can improve signal integrity and reduce electromagnetic interference (EMI). Additionally, SMT enables better thermal management since components can be placed closer together, allowing for more efficient heat dissipation. This characteristic is particularly important in high-frequency applications where performance is critical.

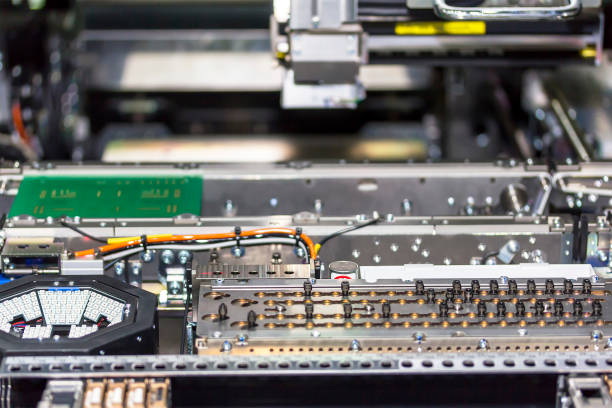

4. Automation and Cost Efficiency

SMT is highly compatible with automated assembly processes, significantly reducing labor costs and increasing production speed. Automated pick-and-place machines can quickly and accurately position components on PCBs, leading to faster turnaround times and lower manufacturing costs. This efficiency is especially advantageous for high-volume production runs.

5. Flexibility in Design

SMT allows for greater flexibility in PCB design. Engineers can create more complex circuit layouts without the constraints imposed by through-hole technology. This flexibility enables the integration of advanced features and functionalities into electronic devices, driving innovation within the industry.

6. Sustainability

In an era where businesses are more accountable for their environmental impact, SMT offers an eco-friendlier alternative. The efficient use of materials and reduction in waste contribute to a more sustainable manufacturing process. SMT also allows for the use of lead-free solder materials, which are better for the environment.

The SMT Assembly Process

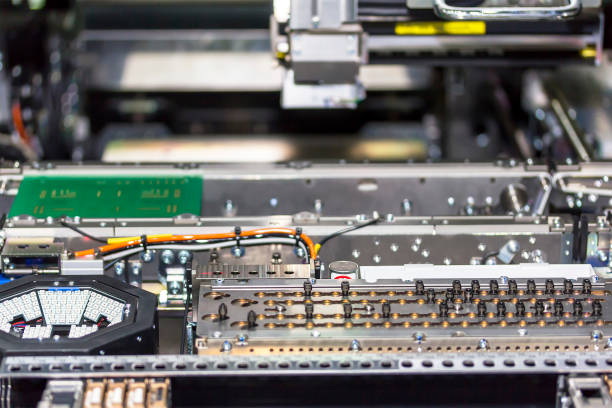

The SMT assembly process consists of several key steps:

1. Solder Paste Printing: Solder paste is applied to the PCB using a stencil to ensure that the correct amount is deposited on each pad.

2. Component Placement: Automated machines place SMT components onto the solder paste-covered pads.

3. Reflow Soldering: The assembled PCB is heated in a reflow oven, causing the solder paste to melt and create strong electrical connections between the components and the PCB.

4. Inspection and Testing: After soldering, PCBs undergo inspection and testing to ensure quality and functionality.

This streamlined process enhances efficiency while maintaining high standards of quality control.

Challenges and Considerations

While SMT offers numerous advantages, it also presents challenges that manufacturers must address:

- Manual Assembly Difficulty: The smaller size of SMT components can make manual assembly and repair more challenging compared to through-hole technology.

- Reliability Concerns: The reliability of solder joints can be a concern, especially in high-stress applications where mechanical stress may occur.

- Equipment Costs: The initial investment in specialized equipment for SMT can be higher than that required for through-hole technology.

Manufacturers must carefully consider these factors when designing and assembling PCBs to ensure optimal performance and reliability.

Advanced Applications of SMT

As technology advances, SMT continues to evolve with new applications emerging across various sectors:

1. Consumer Electronics

In consumer electronics, where miniaturization is crucial, SMT facilitates the development of compact devices like smartphones, tablets, and laptops. The ability to pack more functionality into smaller spaces has made it possible to create powerful yet portable gadgets that meet consumer demands.

2. Automotive Industry

The automotive sector increasingly relies on SMT for advanced driver-assistance systems (ADAS), infotainment systems, and electric vehicle technologies. As vehicles become smarter with integrated electronics, SMT's ability to support high-density layouts becomes essential for meeting performance requirements while adhering to space constraints within vehicles.

3. Medical Devices

The medical industry benefits from SMT due to its ability to produce small yet reliable devices essential for diagnostics and monitoring equipment. These devices often require high precision and reliability under varying conditions—attributes that SMT inherently provides due to its compact design and improved thermal management capabilities.

4. Aerospace Applications

In aerospace applications where weight reduction is critical without sacrificing performance or reliability, SMT plays a vital role in developing lightweight electronic systems used in aircraft navigation systems and satellite communications.

5. IoT Devices

The rise of Internet of Things (IoT) devices has further amplified the relevance of SMT as these devices often require small form factors with high functionality levels—characteristics that are best achieved through surface mount technologies.

Future Trends Influencing SMT

As we look ahead at trends shaping PCB assembly methods like SMT:

- Integration with AI: Artificial Intelligence (AI) will increasingly be integrated into manufacturing processes to optimize component placement accuracy and predict maintenance needs based on real-time data analytics.

- Flexible PCBs: The growth of flexible PCBs will open new avenues for product design by allowing manufacturers to create curvilinear shapes that were previously impossible with traditional rigid boards.

- 3D Printing: Innovations such as 3D printing will revolutionize prototyping capabilities within PCB manufacturing by enabling rapid iterations without extensive setup changes.

- Sustainable Practices: As environmental concerns grow globally, manufacturers will focus on sustainable practices including waste reduction strategies throughout production processes while adhering to regulations regarding hazardous materials.

- Advanced Materials: The use of advanced materials like polyimide or ceramic substrates will enhance thermal management capabilities while supporting higher frequency operations necessary for next-generation communication technologies such as 5G networks.

Conclusion

In conclusion, Surface Mount Technology plays a critical role in modern PCB assembly due to its ability to increase component density, reduce weight and size, enhance performance, improve cost efficiency through automation, provide design flexibility, and promote sustainability practices within manufacturing processes. As demand continues to grow for smaller yet more powerful electronic devices across various industries—from consumer electronics to automotive—the importance of adopting innovative technologies like SMT cannot be overstated.

FAQ

1. What is Surface Mount Technology (SMT)?

Surface Mount Technology (SMT) is a method of mounting electronic components directly onto the surface of a printed circuit board (PCB) without needing drilled holes.

2. What are the advantages of SMT over through-hole technology?

SMT offers several advantages including increased component density, reduced weight and size, enhanced performance due to shorter electrical paths, compatibility with automated assembly processes which lowers manufacturing costs.

3. How does SMT improve the performance of electronic devices?

SMT improves performance by allowing shorter electrical paths which enhance signal integrity; it also improves thermal management due to closer component placement which is crucial for high-frequency applications.

4. What is the SMT assembly process?

The SMT assembly process includes solder paste printing on pads, automated component placement onto those pads covered with solder paste followed by reflow soldering; finally inspection/testing ensures quality control.

5. Are there any challenges associated with SMT?

Yes challenges include difficulties in manual assembly due to small component sizes; potential reliability issues with solder joints under mechanical stress conditions; higher initial equipment costs compared to traditional methods.

Citations:

[1] https://hyepeak.com/blog/surface-mount-technology-pros-and-cons/

[2] https://www.pcbpower.us/blog/the-future-of-pcb-assembly-trends-challenges-and-opportunities

[3] https://cygnuscorp.com/surface-mount-technology-smt-vs-through-hole-technology-a-complete-comparison/

[4] https://arkcircuits.com/blog/impact-of-smt-on-modern-pcb-design/

[5] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[6] https://www.technotronix.us/pcbblog/top-trends-in-printed-circuit-board-manufacturing-for-2024/

[7] https://www.candorind.com/blog/surface-mount-vs-through-hole/

[8] https://www.grandviewresearch.com/industry-analysis/surface-mount-technology-market-report

[9] https://rootsems.com/advantages-and-disadvantages-of-surface-mount-technology/

[10] https://www.wellpcb.com/blog/pcb-manufacturing/latest-advances-in-pcb-manufacturing-technology/

[11] https://www.mpe-electronics.co.uk/2024/10/22/advantages-and-disadvantages-of-surface-mount-technology

[12] https://www.circuits-central.com/blog/pcb-assembly-in-2024-and-beyond-what-does-the-future-hold/

[13] https://www.wevolver.com/article/through-hole-vs-surface-mount-unveiling-the-optimal-pcb-assembly-technique

[14] https://www.munciepower.com/company/blog_detail/muncie_power_products_establishes_surface_mount_technology_line_offering_innovative_solutions_for_customers

[15] https://www.pcbpower.us/blog/unveiling-the-advantages-and-disadvantages-of-surface-mount-technology

[16] https://www.rigiflex.com/blog/7-pcb-manufacturing-trends-in-2024-and-beyond/

[17] https://www.lioncircuits.com/blog/posts/smt-vs-through-hole

[18] https://emsginc.com/resources/the-evolution-of-surface-mount-technology/

[19] https://www.linkedin.com/pulse/latest-trends-technological-innovations-pcb-industry-2024-yolin-gan-hddac

[20] https://www.epectec.com/articles/differences-between-through-hole-and-surface-mount-pcb-designs.html

[21] https://www.ablcircuits.co.uk/blog/what-is-the-smt-process-and-why-should-oems-care/

[22] https://ksnpcb.com/surface-mount-vs-through-hole/

[23] https://www.linkedin.com/pulse/surface-mount-technology-market-size-growth-industry-next-p-virkhe-fbngc

[24] https://www.linkedin.com/pulse/surface-mounted-vs-through-hole-technologywhich-batter-ohyes-gloal

[25] https://blog.thedigisource.com/through-hole-smt

[26] https://www.altestcorp.com/surface-mount-technology/