Content Menu

● Understanding SMT and Its Storage Needs

>> The Sensitivity of SMT Components and PCBs

● Benefits of Proper SMT PCB Storage Solutions

● Types of SMT PCB Storage Solutions

>> Conductive and ESD-Safe Storage Bins

>> SMT Reel Shelving Units

>> Automated Storage Towers

>> Mobile Smart Racks

>> Moisture Barrier Packaging and Controlled Environment Storage

>> Specialized PCB Storage Racks

● Best Practices for SMT PCB Storage

>> 1. Implement ESD-Safe Handling and Storage

>> 2. Maintain Controlled Humidity

>> 3. Organize Inventory Logically

>> 4. Use Automated Tracking Systems

>> 5. Position Storage Close to Production

>> 6. Regularly Inspect Stored Components

>> 7. Train Staff on Storage Protocols

● Impact on Manufacturing Efficiency and Product Quality

● Conclusion

● FAQ

>> 1. What are the main risks of improper SMT PCB storage?

>> 2. How do ESD-safe storage bins protect SMT components?

>> 3. What is the advantage of automated SMT storage towers?

>> 4. Why is moisture control important in SMT PCB storage?

>> 5. How can manufacturers optimize inventory management with SMT PCB storage solutions?

In the fast-evolving world of electronics manufacturing, Surface Mount Technology (SMT) has become the dominant method for assembling printed circuit boards (PCBs). SMT allows for the efficient placement of smaller components directly onto the surface of PCBs, enabling higher density, improved performance, and cost-effective mass production. However, the advantages of SMT can only be fully realized if the components and PCBs are stored properly throughout the manufacturing process. Proper SMT PCB storage solutions are essential to protect sensitive components, maintain production efficiency, and ensure product quality.

This article explores why proper SMT PCB storage is critical for your manufacturing process, the types of storage solutions available, and best practices to optimize your SMT assembly line.

Understanding SMT and Its Storage Needs

Surface Mount Technology involves mounting electronic components directly onto the surface of PCBs without the need for drilling holes. This method supports miniaturization, higher circuit density, and automated assembly lines, making it the preferred technology for modern electronics manufacturing.

However, SMT components and PCBs are highly sensitive to environmental factors such as electrostatic discharge (ESD), moisture, dust, and physical damage. Improper storage can lead to component degradation, solderability issues, and ultimately, product failures. Therefore, implementing effective SMT PCB storage solutions is a strategic imperative.

The Sensitivity of SMT Components and PCBs

- Electrostatic Discharge (ESD): SMT components are often made with delicate semiconductor materials that can be irreparably damaged by ESD. ESD-safe storage bins and environments are necessary to mitigate this risk.

- Moisture Sensitivity: Many SMT components absorb moisture, which can cause “popcorning” or delamination during solder reflow. Controlled humidity storage and moisture barrier packaging are critical.

- Physical Damage: Small components and PCBs can be easily scratched, bent, or broken if not stored correctly, leading to assembly defects or failures.

- Temperature Fluctuations: Extreme or rapid temperature changes can affect solder paste and component integrity, making temperature-controlled storage important.

Understanding these vulnerabilities highlights why investing in the right SMT PCB storage solutions is not optional but essential to maintain manufacturing quality and reliability.

Benefits of Proper SMT PCB Storage Solutions

Implementing proper SMT PCB storage solutions brings multiple benefits that directly impact manufacturing quality and efficiency:

- Protection Against ESD: Using conductive or ESD-safe storage bins prevents electrostatic discharge, protecting sensitive components from damage.

- Organized Inventory Management: SMT reel shelving units and automated storage systems facilitate efficient component organization, reducing retrieval time and minimizing errors.

- Space Optimization: Modern SMT storage solutions like compact towers and mobile smart racks maximize storage capacity while minimizing floor space usage.

- Enhanced Production Flow: Close-to-production storage systems ensure components are readily available at the assembly line, reducing downtime and improving throughput.

- Accurate Component Tracking: Advanced storage systems with barcode or RFID tracking prevent mix-ups and enable real-time inventory monitoring, ensuring the right components are used at the right time.

- Reduced Waste and Cost: Proper storage extends the shelf life of components, reducing scrap and rework costs.

- Improved Product Reliability: By maintaining component integrity, proper storage contributes to the overall reliability of the final electronic product.

These benefits collectively contribute to a smoother, more cost-effective manufacturing process with higher yield rates.

Types of SMT PCB Storage Solutions

A variety of SMT PCB storage solutions are available to meet different manufacturing needs. Choosing the right combination depends on your production scale, component types, and environmental requirements.

Conductive and ESD-Safe Storage Bins

These bins are made from materials that dissipate static electricity, protecting components from ESD damage. They are modular and stackable, allowing for organized storage of small SMT components and PCBs. ESD-safe bins often come with lids to prevent dust contamination and physical damage.

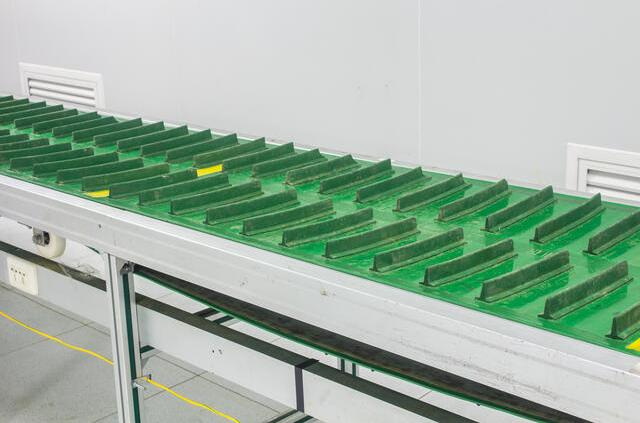

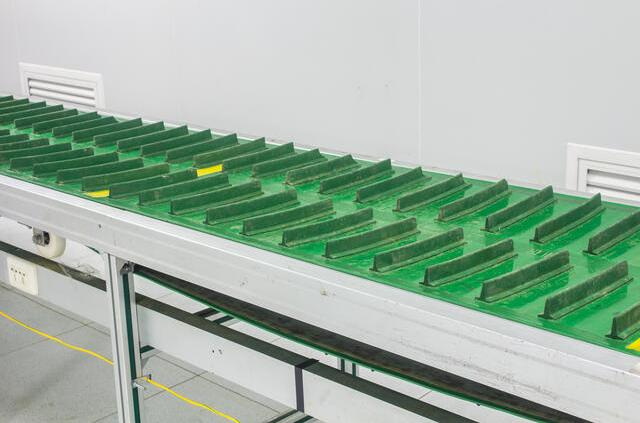

SMT Reel Shelving Units

Designed specifically for storing reels of SMT components, these shelving units keep reels secure and easily accessible. They support efficient material handling and can be integrated with automated pick-and-place systems. Shelving units often feature adjustable racks to accommodate various reel sizes.

Automated Storage Towers

Systems like the MYTower 7+ offer high-density storage with capacities exceeding 1,000 reels in a compact footprint. They provide automated retrieval and return-to-storage functions, reducing manual labor and errors. These towers often integrate with warehouse management software (WMS) and manufacturing execution systems (MES) to streamline inventory control.

Mobile Smart Racks

These racks can be moved close to the SMT assembly line, bringing components directly to production without losing inventory tracking accuracy. This flexibility enhances workflow efficiency and reduces the risk of component damage during transport.

Moisture Barrier Packaging and Controlled Environment Storage

To prevent moisture-related defects, SMT components are often stored in moisture barrier bags with desiccants and humidity indicators. Controlled environment cabinets or rooms maintain optimal humidity levels to preserve component integrity. Dry cabinets with humidity control settings (typically below 10% RH) are standard in many SMT manufacturing facilities.

Specialized PCB Storage Racks

PCBs themselves require careful storage to avoid warping, contamination, or damage. Specialized PCB storage racks are designed to hold boards vertically or horizontally with cushioned supports to prevent bending and scratches. These racks often incorporate ESD-safe materials and dust covers.

Best Practices for SMT PCB Storage

To maximize the benefits of SMT PCB storage solutions, manufacturers should adopt the following best practices:

1. Implement ESD-Safe Handling and Storage

Use ESD-safe bins, shelving, and work surfaces throughout the storage and assembly areas. Train personnel on ESD precautions, including grounding procedures and proper handling techniques. Regularly audit ESD control measures to ensure compliance.

2. Maintain Controlled Humidity

Store moisture-sensitive components in dry cabinets or sealed packaging with desiccants. Monitor humidity levels continuously and use humidity indicator cards (HICs) to detect moisture ingress. Follow manufacturer guidelines on floor life and baking procedures for moisture-sensitive devices (MSDs).

3. Organize Inventory Logically

Group components by type, value, or production sequence to streamline retrieval. Label storage locations clearly and maintain an updated inventory database. Use color coding or barcodes to reduce picking errors.

4. Use Automated Tracking Systems

Employ barcode or RFID systems to monitor inventory levels and component movements accurately. Integration with production planning software enables just-in-time (JIT) inventory management, reducing stockouts and excess inventory.

5. Position Storage Close to Production

Minimize transport distance between storage and SMT lines to reduce handling time and potential damage. Mobile smart racks or automated storage towers located near assembly lines improve material flow and reduce downtime.

6. Regularly Inspect Stored Components

Check for signs of moisture ingress, physical damage, or ESD events and take corrective action promptly. Rotate stock using FIFO (first-in, first-out) or FEFO (first-expired, first-out) methods to prevent component obsolescence.

7. Train Staff on Storage Protocols

Ensure all employees understand the importance of proper storage and handling. Conduct regular training sessions and refreshers to maintain awareness and compliance.

Impact on Manufacturing Efficiency and Product Quality

Proper SMT PCB storage solutions directly influence manufacturing efficiency and product quality:

- Reduced Defects and Rework: Protecting components from ESD and moisture reduces soldering defects and assembly failures. This leads to fewer returns and warranty claims.

- Faster Production Cycles: Organized and automated storage systems speed up component retrieval and line feeding, increasing throughput.

- Lower Inventory Costs: Accurate tracking prevents overstocking and obsolescence, freeing up working capital.

- Improved Product Reliability: Maintaining component integrity ensures the final product meets performance and longevity expectations.

- Enhanced Compliance: Proper storage helps meet industry standards such as IPC and JEDEC, which are critical for quality certifications and customer trust.

By investing in robust SMT PCB storage solutions and best practices, manufacturers can build a competitive advantage through higher yield, faster time-to-market, and superior product quality.

Conclusion

Proper SMT PCB storage is a critical component of a successful electronics manufacturing process. By safeguarding sensitive components from ESD, moisture, and physical damage, and by optimizing inventory management and workflow efficiency, manufacturers can ensure high-quality assembly, reduce costs, and accelerate time-to-market. Investing in advanced SMT PCB storage solutions such as ESD-safe bins, reel shelving units, automated towers, and mobile racks is essential for maintaining competitive advantage in today's fast-paced electronics industry.

A well-implemented storage strategy not only protects valuable materials but also streamlines production, enhances traceability, and supports compliance with industry standards. As SMT technology continues to evolve, so too must the storage solutions that support it—making proper SMT PCB storage an indispensable pillar of modern electronics manufacturing.

FAQ

1. What are the main risks of improper SMT PCB storage?

Improper storage can lead to electrostatic discharge damage, moisture absorption causing solder defects like “popcorning,” and physical damage to components. These issues result in assembly failures, increased rework, and reduced product reliability.

2. How do ESD-safe storage bins protect SMT components?

ESD-safe bins are made from conductive or dissipative materials that prevent the buildup of static electricity. This protects sensitive components from electrostatic discharge damage during handling and storage.

3. What is the advantage of automated SMT storage towers?

Automated towers maximize storage density, enable quick and accurate retrieval of components, reduce manual handling errors, and can be integrated with production lines to improve efficiency and inventory control.

4. Why is moisture control important in SMT PCB storage?

Many SMT components are moisture sensitive; exposure to humidity can cause defects like “popcorning” during soldering, leading to component failure and reduced product quality. Controlled humidity storage and moisture barrier packaging prevent these issues.

5. How can manufacturers optimize inventory management with SMT PCB storage solutions?

By using barcode or RFID tracking systems integrated with inventory management software, manufacturers can achieve real-time visibility, reduce picking errors, implement just-in-time inventory, and prevent overstocking or stockouts.