Content Menu

● The Evolution of PCB Assembly

● The Role of PCB SMT Equipment in Modern Electronics Manufacturing

>> Key Components of PCB SMT Equipment

● The Critical Importance of PCB SMT Equipment

>> 1. Precision and Accuracy

>> 2. Increased Production Speed and Efficiency

>> 3. Consistency and Reliability

>> 4. Miniaturization Capabilities

>> 5. Flexibility and Adaptability

● The Impact of PCB SMT Equipment on Product Quality

>> Enhanced Electrical Performance

>> Increased Durability

>> Improved Thermal Management

● The Future of PCB SMT Equipment

>> 1. Integration of Artificial Intelligence

>> 2. Industry 4.0 and Smart Factories

>> 3. Handling of Even Smaller Components

>> 4. Increased Automation

>> 5. Eco-Friendly Solutions

● Conclusion

● FAQ

>> 1. What is the main difference between SMT and through-hole technology?

>> 2. How does PCB SMT equipment contribute to miniaturization in electronics?

>> 3. What are the key advantages of using PCB SMT equipment in manufacturing?

>> 4. How does PCB SMT equipment impact the overall quality of electronic products?

>> 5. What future developments can we expect in PCB SMT equipment?

● Citations:

In today's rapidly evolving electronics industry, the demand for smaller, faster, and more reliable electronic devices continues to grow. At the heart of this technological revolution lies the printed circuit board (PCB) and the advanced equipment used in its assembly process. Surface Mount Technology (SMT) has emerged as a game-changing approach to PCB assembly, and the equipment used in this process plays a crucial role in ensuring the production of high-quality electronic products.

The Evolution of PCB Assembly

Before delving into the importance of PCB SMT equipment, it's essential to understand the evolution of PCB assembly techniques. Traditionally, through-hole technology was the primary method used for mounting components on PCBs. However, as electronics became more complex and miniaturized, the limitations of through-hole technology became apparent[3].

SMT emerged as a superior alternative, offering numerous advantages over its predecessor. This technology allows for the direct mounting of components onto the surface of the PCB, eliminating the need for drilling holes and inserting component leads[4].

The Role of PCB SMT Equipment in Modern Electronics Manufacturing

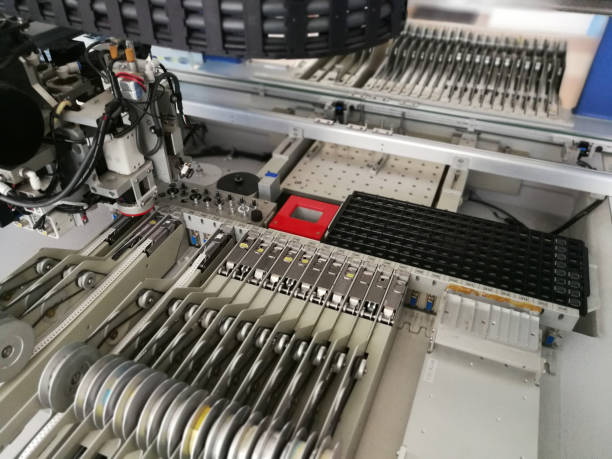

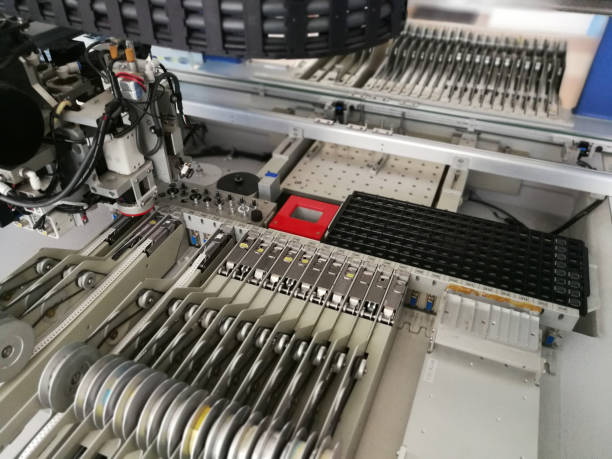

PCB SMT equipment has revolutionized the electronics manufacturing industry by enabling the production of smaller, more efficient, and highly reliable electronic devices. These sophisticated machines are designed to handle the intricate process of placing and soldering surface mount components onto PCBs with incredible precision and speed[7].

Key Components of PCB SMT Equipment

1. Pick and Place Machines: These are the workhorses of SMT assembly lines. They rapidly and accurately place components onto the PCB surface[4].

2. Reflow Ovens: These ovens heat the PCB to melt the solder paste and create permanent connections between components and the board[4].

3. Solder Paste Printers: These machines apply a precise amount of solder paste to the PCB before component placement[4].

4. Automated Optical Inspection (AOI) Systems: These systems use high-resolution cameras and advanced algorithms to inspect PCBs for defects[7].

5. X-ray Inspection Systems: These are used to inspect hidden solder joints and detect internal defects in components[7].

The Critical Importance of PCB SMT Equipment

1. Precision and Accuracy

One of the primary reasons PCB SMT equipment is critical for high-quality electronic products is its unparalleled precision and accuracy. SMT equipment can place components with tolerances as tight as 0.05mm, ensuring that even the smallest components are correctly positioned[7].

This level of precision is crucial for several reasons:

- It allows for the production of more compact devices by maximizing the use of PCB real estate[3].

- It reduces the likelihood of short circuits and other electrical issues caused by misaligned components[3].

- It ensures optimal performance of the final product by maintaining the intended circuit design[7].

2. Increased Production Speed and Efficiency

PCB SMT equipment significantly enhances production speed and efficiency compared to manual assembly methods or older technologies. Modern pick and place machines can place thousands of components per hour, dramatically reducing production times[5].

This increased speed and efficiency offer several benefits:

- It allows manufacturers to meet growing demand and tight production schedules[5].

- It reduces labor costs associated with manual assembly[5].

- It enables the production of larger quantities of PCBs, leading to economies of scale[5].

3. Consistency and Reliability

Consistency is key in electronics manufacturing, and PCB SMT equipment excels in this area. These machines can perform the same tasks repeatedly with minimal variation, ensuring that each PCB produced meets the same high standards[7].

This consistency translates to several advantages:

- It reduces the number of defective units, minimizing waste and rework[7].

- It improves the overall reliability of the final product[3].

- It allows for better quality control and easier troubleshooting of issues[7].

4. Miniaturization Capabilities

As electronic devices continue to shrink in size while increasing in functionality, the ability to work with extremely small components becomes crucial. PCB SMT equipment is designed to handle these miniature components, often referred to as surface mount devices (SMDs)[3].

The miniaturization capabilities of SMT equipment offer several benefits:

- It enables the production of smaller, lighter electronic devices[3].

- It allows for more components to be placed on a single PCB, increasing functionality[3].

- It supports the development of wearable technology and other compact electronic devices[5].

5. Flexibility and Adaptability

Modern PCB SMT equipment is highly flexible and adaptable, capable of handling a wide range of component types and PCB designs. This flexibility is crucial in an industry where product designs are constantly evolving[4].

The adaptability of SMT equipment provides several advantages:

- It allows manufacturers to quickly switch between different product lines[4].

- It supports the production of both high-volume and low-volume runs[4].

- It enables the integration of new component types as they become available[4].

The Impact of PCB SMT Equipment on Product Quality

The use of advanced PCB SMT equipment directly contributes to the production of higher quality electronic products. Here's how:

Enhanced Electrical Performance

SMT components typically have shorter lead lengths and smaller packages compared to through-hole components. This results in reduced parasitic capacitance and inductance, leading to better high-frequency performance[1].

The improved electrical characteristics contribute to:

- Better signal integrity in high-speed circuits[1].

- Reduced electromagnetic interference (EMI)[1].

- Improved overall device performance[1].

Increased Durability

PCBs assembled using SMT equipment often exhibit greater durability compared to those assembled using through-hole technology. This is due to several factors:

- SMT components are directly soldered to the PCB surface, creating a stronger mechanical bond[3].

- The smaller size of SMT components reduces the stress on solder joints during thermal cycling[3].

- The absence of through-holes in the PCB maintains its structural integrity[3].

Improved Thermal Management

The compact nature of SMT assemblies can lead to better thermal management in electronic devices. This is particularly important as devices become more powerful and generate more heat[1].

Improved thermal management results in:

- Increased device reliability and longevity[1].

- Better performance in high-temperature environments[1].

- Reduced need for additional cooling mechanisms in some applications[1].

The Future of PCB SMT Equipment

As technology continues to advance, PCB SMT equipment is evolving to meet new challenges and opportunities. Some emerging trends include:

1. Integration of Artificial Intelligence

AI is being incorporated into SMT equipment to enhance decision-making processes, improve defect detection, and optimize production parameters[7].

2. Industry 4.0 and Smart Factories

PCB SMT equipment is becoming increasingly connected, allowing for real-time monitoring, predictive maintenance, and seamless integration with other manufacturing systems[7].

3. Handling of Even Smaller Components

As components continue to shrink, SMT equipment manufacturers are developing new technologies to handle components as small as 0201 (0.6mm x 0.3mm) and even 01005 (0.4mm x 0.2mm)[4].

4. Increased Automation

The trend towards fully automated production lines is driving the development of more sophisticated SMT equipment that can operate with minimal human intervention[5].

5. Eco-Friendly Solutions

With growing environmental concerns, PCB SMT equipment manufacturers are focusing on developing more energy-efficient machines and processes that reduce waste and use fewer resources[5].

Conclusion

PCB SMT equipment plays a critical role in the production of high-quality electronic products. Its ability to deliver precision, speed, consistency, and miniaturization capabilities has revolutionized the electronics manufacturing industry. As technology continues to advance, the importance of PCB SMT equipment in ensuring product quality, reliability, and performance will only grow.

The future of electronics manufacturing lies in the continuous improvement and innovation of PCB SMT equipment. As we move towards smarter, more connected manufacturing processes, the integration of AI, IoT, and other advanced technologies will further enhance the capabilities of SMT equipment.

For manufacturers looking to stay competitive in the rapidly evolving electronics industry, investing in state-of-the-art PCB SMT equipment is not just an option—it's a necessity. The quality, efficiency, and innovation enabled by these sophisticated machines will continue to drive the development of smaller, faster, and more reliable electronic products that shape our modern world.

FAQ

1. What is the main difference between SMT and through-hole technology?

Surface Mount Technology (SMT) involves placing components directly onto the surface of a PCB, while through-hole technology requires components to be inserted through holes drilled in the board. SMT allows for more compact designs, faster assembly, and better performance in high-frequency applications[3].

2. How does PCB SMT equipment contribute to miniaturization in electronics?

PCB SMT equipment can handle extremely small components and place them with high precision. This capability allows manufacturers to design and produce smaller, more compact electronic devices while maintaining or even increasing functionality[3].

3. What are the key advantages of using PCB SMT equipment in manufacturing?

The main advantages include increased production speed and efficiency, higher precision and accuracy in component placement, improved product reliability, and the ability to produce more compact designs. Additionally, SMT equipment offers greater flexibility in handling various component types and PCB designs[5].

4. How does PCB SMT equipment impact the overall quality of electronic products?

PCB SMT equipment significantly enhances product quality by ensuring precise component placement, reducing assembly errors, improving electrical performance, and increasing product durability. The consistency and reliability offered by SMT equipment result in fewer defects and higher overall product quality[7].

5. What future developments can we expect in PCB SMT equipment?

Future developments in PCB SMT equipment are likely to include increased integration of artificial intelligence for improved decision-making and defect detection, greater connectivity for smart factory implementation, capabilities to handle even smaller components, higher levels of automation, and more eco-friendly solutions to reduce energy consumption and waste[7].

Citations:

[1] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[2] https://smtnet.com/library/index.cfm?fuseaction=browse_articles&start_at=296

[3] https://www.wevolver.com/article/smt-process

[4] https://www.viasion.com/blog/smt-manufacturing-process-step-by-step-guide/

[5] https://www.zetwerk.com/resources/knowledge-base/electronics-manufacturing-services-ems/how-smt-pcb-assembly-enhances-efficiency-in-electronics-production/

[6] https://www.advancedpcb.com/en-us/blog/the-most-common-uses-of-printed-circuit-boards-with-smt-technology/

[7] https://www.hct-smt.com/blog/revolutionizing-electronics-manufacturing--the-importance-of-smt-equipment

[8] https://vectorbluehub.com/smt-assembly

[9] https://blog.matric.com/what-is-smt-assembly

[10] https://www.pcbonline.com/blog/smt-manufacturing-process.html