Content Menu

● Gujarat's Strategic Advantages

>> Geographical Location

>> Industrial Infrastructure

>> Economic Contribution

● Government Initiatives and Policies

>> Gujarat Electronics Policy (2022-28)

>> Semiconductor Policy

>> Incentives for Strategic Electronics

● The PCB SMT Manufacturing Ecosystem in Gujarat

>> PCB Design Services

>> PCB Fabrication Capabilities

>> PCB Assembly Services

>> Component Sourcing

● The Role of SMT in Gujarat's Electronics Manufacturing

>> SMT Process

>> Advantages of SMT

>> Applications of SMT in Gujarat

● Key Players in Gujarat's PCB SMT Manufacturing Sector

>> Jayshree Instruments

>> PlinTroNics

>> Roots EMS

● Future Prospects for PCB SMT Manufacturing in Gujarat

>> Growing Demand

>> Government Support

>> Investments in Semiconductor Manufacturing

>> Skilled Workforce

● Challenges and Opportunities

>> Challenges

>> Opportunities

● Conclusion

● FAQ

>> 1. What is PCB SMT manufacturing?

>> 2. Why has Gujarat become a key hub for PCB SMT manufacturing in India?

>> 3. What are the main government initiatives supporting PCB SMT manufacturing in Gujarat?

>> 4. What are the advantages of SMT in PCB manufacturing?

>> 5. What are the future prospects for PCB SMT manufacturing in Gujarat?

● Citations:

Gujarat, a state located on the western coast of India, has emerged as a crucial hub for Printed Circuit Board (PCB) and Surface Mount Technology (SMT) manufacturing in India. This development is not a coincidence but the result of strategic planning, government initiatives, and the state's inherent advantages. In this article, we will explore the factors that have contributed to Gujarat's rise as a key player in the electronics manufacturing sector, with a particular focus on PCB and SMT production.

Gujarat's Strategic Advantages

Gujarat's ascent as a PCB SMT manufacturing hub can be attributed to several strategic advantages that the state possesses:

Geographical Location

Gujarat boasts the longest coastline among all Indian states, stretching 1,600 kilometers[3]. This extensive coastline provides excellent connectivity for international trade and logistics, making it easier for manufacturers to import raw materials and export finished products. The state's 42 ports and 12 domestic airports, including two international airports, further enhance its connectivity[3].

Industrial Infrastructure

The state has consistently invested in developing its industrial infrastructure. With 106 product clusters and 60 notified special economic zones (SEZs), Gujarat offers a conducive environment for manufacturing activities[3]. This robust infrastructure has been instrumental in attracting both domestic and foreign investments in the electronics sector.

Economic Contribution

Gujarat has been a significant contributor to India's overall GDP, consistently accounting for 8% of the country's economic output[3]. This economic strength has allowed the state to invest in developing sectors like electronics manufacturing, including PCB SMT production.

Government Initiatives and Policies

The rise of Gujarat as a PCB SMT manufacturing hub has been significantly bolstered by proactive government policies and initiatives:

Gujarat Electronics Policy (2022-28)

The state government has launched the Gujarat Electronics Policy (2022-28) to promote faster and inclusive growth in the electronics sector, with a particular focus on strategic electronics[5]. This policy aims to establish Gujarat Electronics Manufacturing (GEM) clusters at strategic locations within the state[5].

Semiconductor Policy

Gujarat has also introduced a distinct policy for semiconductor manufacturing (2022-27), aligning with the India Semiconductor Mission[5]. This policy provides subsidies on land required for FAB projects and aims to generate over 200,000 employment opportunities in the next five years[5].

Incentives for Strategic Electronics

The Gujarat Electronics Policy 2022-28 specifically incentivizes the manufacturing of strategic electronics products[5]. This focus on strategic electronics, which includes PCB SMT manufacturing, has been a key driver in attracting investments in this sector.

The PCB SMT Manufacturing Ecosystem in Gujarat

The PCB SMT manufacturing ecosystem in Gujarat has been developing rapidly, supported by various factors:

PCB Design Services

Several companies in Gujarat offer specialized PCB design services. These firms employ accomplished CAD tool users with in-depth knowledge of PCB design[4]. They have expertise in designing PCB layouts for various components, including BGA, FPAGA, Arm/Micro processors, SMT and THT, Analog and Digital circuits, Split Power Planes, and Blind/Buried vias[4].

PCB Fabrication Capabilities

Gujarat has developed significant capabilities in PCB fabrication. Companies in the state can build multi-layer PCBs, including 4 layer, 6 layer, and 10 layer printed circuit boards[4]. They offer both prototype and rigid flex PCB manufacturing services, catering to various industries such as Aerospace, Defense, Automotive, Railways, Metering, Medical, Industrial Electronics, and Telecom[4].

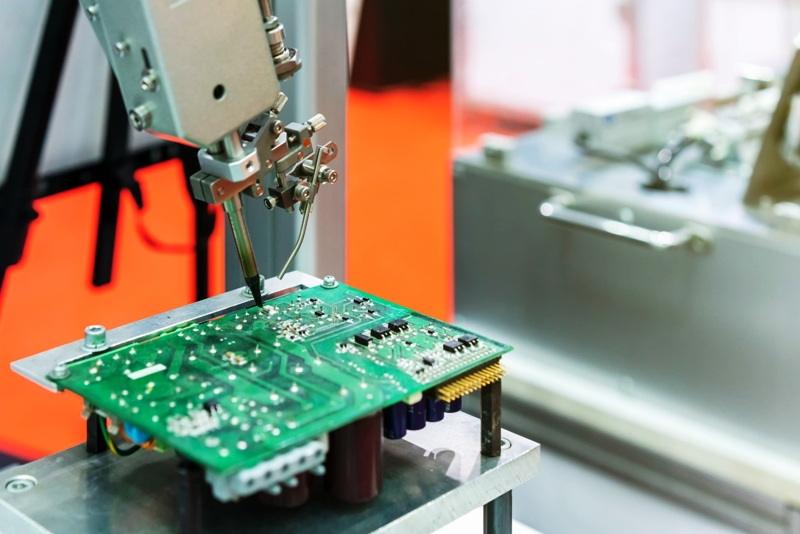

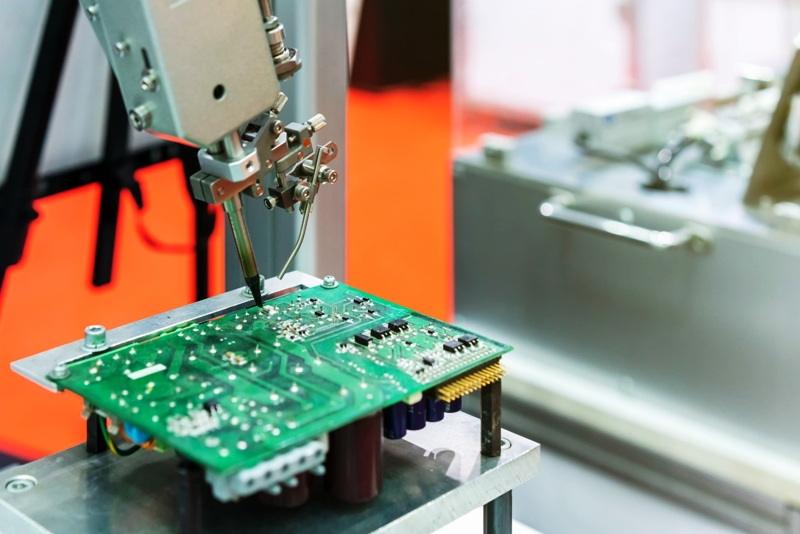

PCB Assembly Services

The state offers comprehensive PCB assembly services, including Turnkey Assembly, Consigned Assembly, and Partially Consigned Assembly[4]. These services cover both SMT and through-hole technology (THT) assembly processes.

Component Sourcing

Gujarat's PCB SMT manufacturing ecosystem is supported by robust component sourcing capabilities. Companies in the state work with major global distributors like RS Components, Digikey, Mouser, Element 14, and Arrow, ensuring reliable and traceable component supply[4].

The Role of SMT in Gujarat's Electronics Manufacturing

Surface Mount Technology (SMT) plays a crucial role in Gujarat's electronics manufacturing sector:

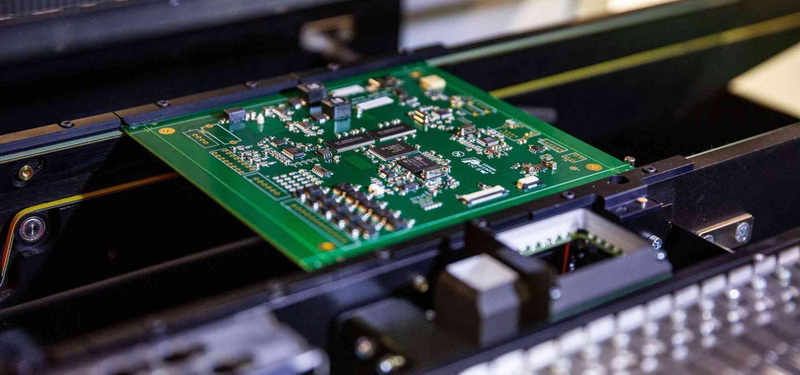

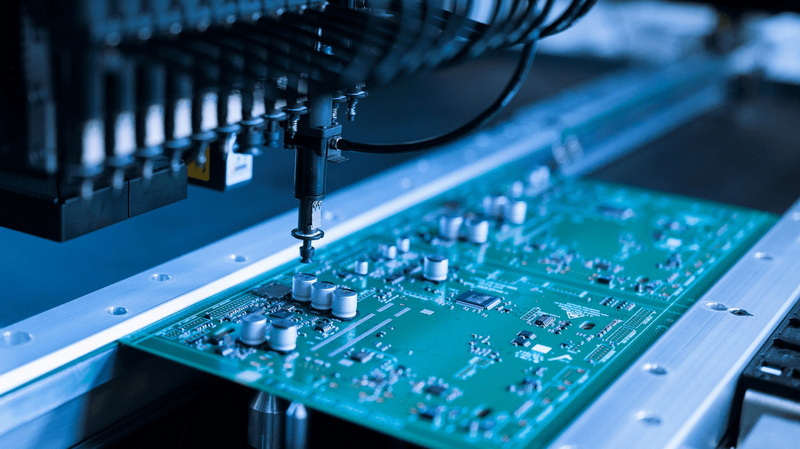

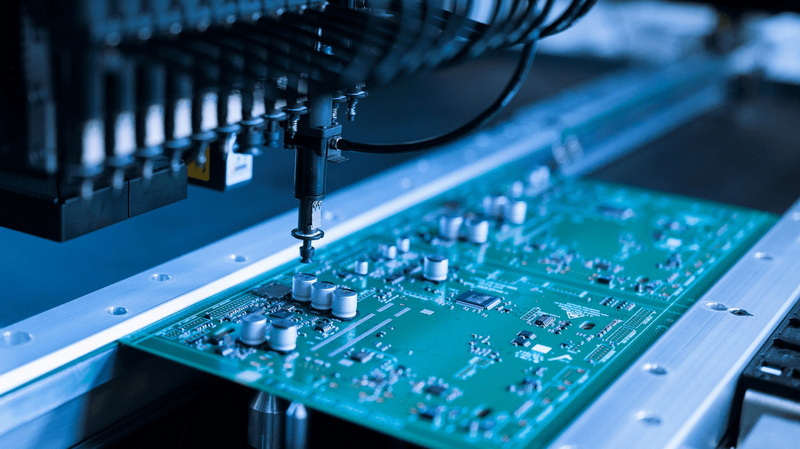

SMT Process

SMT is a process where electrical components are directly mounted on the surface of a PCB[1]. In the SMT PCB assembly process, solder paste is applied to the connection pads, components are placed, and then the board is passed through a reflow oven to melt the solder paste, forming electrical and mechanical connections[1].

Advantages of SMT

SMT offers several advantages over traditional through-hole technology, including:

1. Higher component density

2. Smaller and lighter products

3. Faster assembly process

4. Better performance at high frequencies

5. Lower production costs for high-volume manufacturing

Applications of SMT in Gujarat

In Gujarat, SMT is used in the production of various electronic devices, including:

1. Consumer electronics

2. Industrial applications

3. Medical devices

4. Automotive electronics

5. Telecommunications equipment

Key Players in Gujarat's PCB SMT Manufacturing Sector

Several companies have established themselves as key players in Gujarat's PCB SMT manufacturing sector:

Jayshree Instruments

Jayshree Instruments is recognized as one of the best PCB assembly companies in Gujarat[1]. They offer a variety of services and capabilities that add value to the product, including through-hole PCB assembly and SMT PCB assembly[1].

PlinTroNics

PlinTroNics is a specialized PCB design company in Gujarat, offering services for high-speed frequency multilayer PCBs[4]. They provide low-cost electronics manufacturing services (EMS) and cater to various markets, including aerospace, defense, automotive, and medical sectors[4].

Roots EMS

Roots EMS has been offering SMT Assembly Services in India, including Gujarat, for many years[7]. They specialize in surface mount PCB assembly services and cater to clients in various industries[7].

Future Prospects for PCB SMT Manufacturing in Gujarat

The future of PCB SMT manufacturing in Gujarat looks promising, driven by several factors:

Growing Demand

As technology continues to proliferate across various sectors in India, the demand for semiconductor chips and electronic devices is escalating[2]. This trend is expected to drive the growth of PCB SMT manufacturing in Gujarat.

Government Support

The state government's commitment to developing Gujarat as a global hub for semiconductor and electronics manufacturing is likely to provide continued support to the PCB SMT manufacturing sector[8].

Investments in Semiconductor Manufacturing

Gujarat is set to manufacture India's first "Make in India" chip in 2024, as announced by Union Minister Ashwini Vaishnaw[8]. This development is expected to boost the entire electronics manufacturing ecosystem in the state, including PCB SMT manufacturing.

Skilled Workforce

Gujarat is becoming a preferred destination for electronic appliance manufacturers due to the availability of skilled labor at lower costs[5]. This factor is likely to continue attracting investments in the PCB SMT manufacturing sector.

Challenges and Opportunities

While Gujarat has made significant strides in becoming a key hub for PCB SMT manufacturing, there are both challenges and opportunities ahead:

Challenges

1. Global Competition: Gujarat needs to compete with established global hubs for PCB SMT manufacturing, particularly in East Asia.

2. Technological Advancements: Keeping pace with rapidly evolving technologies in PCB and SMT manufacturing can be challenging.

3. Supply Chain Management: Ensuring a stable and efficient supply chain for components and raw materials is crucial.

Opportunities

1. Import Substitution: There's a significant opportunity to reduce India's dependence on imported electronic components.

2. Export Potential: With its strategic location and port infrastructure, Gujarat can become a major exporter of PCBs and electronic products.

3. Innovation Hub: Gujarat can position itself as an innovation hub for PCB SMT technologies, attracting R&D investments.

Conclusion

Gujarat has emerged as a key hub for PCB SMT manufacturing in India, driven by its strategic advantages, supportive government policies, and a developing ecosystem of design, fabrication, and assembly services. The state's focus on developing the electronics and semiconductor manufacturing sectors, coupled with its infrastructure and skilled workforce, positions it well to capitalize on the growing demand for electronic products both domestically and globally.

As Gujarat continues to invest in this sector and attract more investments, it has the potential to become not just a national leader but also a global player in PCB SMT manufacturing. The success of this sector in Gujarat could serve as a model for other Indian states and contribute significantly to India's goal of becoming a global electronics manufacturing hub.

The journey of Gujarat in becoming a PCB SMT manufacturing hub is a testament to the power of strategic planning, policy support, and ecosystem development. As the electronics industry continues to evolve, Gujarat's role in this sector is likely to become increasingly important, contributing to India's economic growth and technological advancement.

FAQ

1. What is PCB SMT manufacturing?

PCB SMT manufacturing refers to the process of producing Printed Circuit Boards (PCBs) using Surface Mount Technology (SMT). This involves designing the PCB, fabricating the board, and then mounting components directly onto the surface of the board using automated pick-and-place machines and reflow soldering techniques.

2. Why has Gujarat become a key hub for PCB SMT manufacturing in India?

Gujarat has become a key hub for PCB SMT manufacturing due to several factors, including its strategic geographical location, robust industrial infrastructure, supportive government policies, availability of skilled labor, and a developing ecosystem of PCB design, fabrication, and assembly services.

3. What are the main government initiatives supporting PCB SMT manufacturing in Gujarat?

The main government initiatives include the Gujarat Electronics Policy (2022-28), which aims to promote growth in the electronics sector, and the Gujarat Semiconductor Policy (2022-27), which provides incentives for semiconductor manufacturing. These policies offer various subsidies and incentives to attract investments in the electronics manufacturing sector, including PCB SMT manufacturing.

4. What are the advantages of SMT in PCB manufacturing?

SMT offers several advantages in PCB manufacturing, including higher component density, smaller and lighter products, faster assembly processes, better performance at high frequencies, and lower production costs for high-volume manufacturing. These benefits make SMT the preferred technology for many modern electronic devices.

5. What are the future prospects for PCB SMT manufacturing in Gujarat?

The future prospects for PCB SMT manufacturing in Gujarat are promising. With growing demand for electronic devices, continued government support, upcoming investments in semiconductor manufacturing, and the availability of a skilled workforce, Gujarat is well-positioned to become a global hub for PCB SMT manufacturing in the coming years.

Citations:

[1] https://www.jinst.in/services/pcb-assembly-manufacturing-service/

[2] https://www.entrepreneur.com/en-in/news-and-trends/gujarat-will-be-global-destination-for-semiconductor/468196

[3] https://indextb.com/files/2024/2/91effbf2-a67d-4b10-87d4-48aa3eb0cc9e_PCB%20Manufacturing.pdf

[4] https://plintronics.com/india/gujarat/

[5] https://indextb.com/files/2024/2/58ce632d-490a-4669-ad93-3dc8ade4a85d_Strategic%20Electronics%20Manufacturing.pdf

[6] https://www.globenewswire.com/en/news-release/2020/11/20/2130951/28124/en/China-SMT-Capacity-Study-and-Database-Directory-2020.html

[7] https://rootsems.com/surface-mount-technology-services-india/

[8] https://theprint.in/economy/gujarat-aims-to-become-a-global-hub-for-semiconductor-and-electronics-manufacturing-cm-bhupendra-patel/1919301/

[9] https://en.wikipedia.org/wiki/Electronics_and_semiconductor_manufacturing_industry_in_India