Content Menu

● The Rise of Flex PCBs in Modern Electronics

● Understanding SMT Assembly for Flex PCBs

● The Crucial Role of Flex PCB SMT Tooling

>> Precision and Accuracy

>> Handling Delicate Materials

>> Maintaining Flatness

>> Temperature Control

● Advanced Flex PCB SMT Tooling Techniques

>> Automated Flexible Board Handling

>> Dual Lane Transport Rails

>> Thin Board Capable Pick and Place Machines

>> Laser Cutting and High-Precision Printing

● The Impact of Flex PCB SMT Tooling on Product Development

>> Miniaturization

>> Enhanced Functionality

>> Improved Reliability

>> Cost Reduction

● Challenges in Flex PCB SMT Assembly

>> Material Handling

>> Component Placement

>> Thermal Management

>> Design Considerations

● Future Trends in Flex PCB SMT Tooling

>> AI and Machine Learning Integration

>> Advanced Materials

>> Increased Automation

>> 3D Printed Tooling

● The Role of Flex PCB SMT Tooling in Industry 4.0

>> Data-Driven Manufacturing

>> IoT Integration

>> Customization and Flexibility

● Environmental Considerations

>> Material Efficiency

>> Energy Efficiency

>> Recyclability

● Conclusion

● FAQs

>> 1. What is flex PCB SMT tooling?

>> 2. How does flex PCB SMT tooling differ from traditional PCB assembly tools?

>> 3. What are the main challenges in flex PCB SMT assembly?

>> 4. How does flex PCB SMT tooling contribute to product miniaturization?

>> 5. What future developments can we expect in flex PCB SMT tooling?

● Citations:

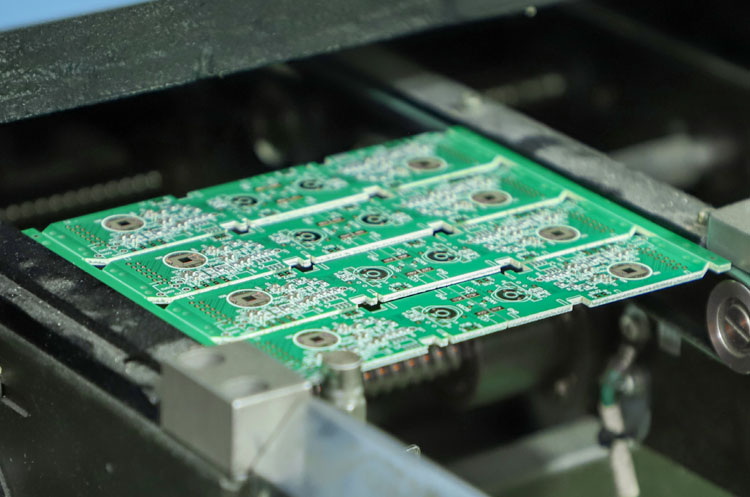

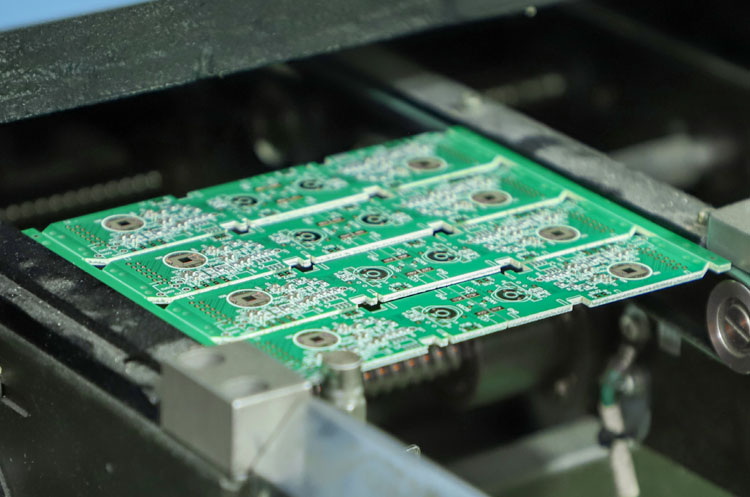

In the rapidly evolving world of electronics manufacturing, flex PCB SMT tooling has emerged as a critical component in the production of advanced electronic products. As devices become smaller, lighter, and more complex, the demand for flexible printed circuit boards (PCBs) and surface mount technology (SMT) has skyrocketed. This article explores the importance of flex PCB SMT tooling and its impact on the electronics industry.

The Rise of Flex PCBs in Modern Electronics

Flexible printed circuit boards have revolutionized the electronics industry by offering a versatile alternative to traditional rigid PCBs. These bendable circuits can conform to irregular shapes, making them ideal for compact and lightweight devices[1]. The ability to fit into tight spaces and withstand repeated flexing has made flex PCBs indispensable in various applications, from smartphones to medical devices and automotive electronics.

Understanding SMT Assembly for Flex PCBs

Surface Mount Technology (SMT) is the preferred method for assembling components on flex PCBs. This process involves placing and soldering electronic components directly onto the surface of the board, rather than through holes[2]. SMT assembly offers several advantages, including higher component density, improved electrical performance, and reduced production costs.

The Crucial Role of Flex PCB SMT Tooling

Flex PCB SMT tooling refers to the specialized equipment and processes used to handle, align, and assemble flexible circuit boards. This tooling is crucial for several reasons:

Precision and Accuracy

Flex PCBs require extremely precise component placement due to their thin and flexible nature. SMT tooling ensures that components are placed accurately, even on boards that may bend or warp during the assembly process[1].

Handling Delicate Materials

Flexible circuits are more delicate than rigid PCBs and can be easily damaged during assembly. Specialized tooling is designed to handle these materials gently, preventing tears, creases, or other damage that could compromise the circuit's integrity[3].

Maintaining Flatness

One of the biggest challenges in flex PCB assembly is maintaining board flatness during the SMT process. Custom tooling, such as vacuum plates and specialized clamping systems, helps keep the flexible board flat and stable during component placement and soldering[1].

Temperature Control

Flex PCBs are sensitive to high temperatures and thermal shocks. Advanced SMT tooling includes dedicated flexible board reflow ovens with adjustable heaters and cooling systems to control warpage and ensure proper solder joint formation[1].

Advanced Flex PCB SMT Tooling Techniques

As the demand for more complex flex PCB designs grows, manufacturers are developing innovative tooling techniques to meet these challenges:

Automated Flexible Board Handling

Specialized conveyor systems with adjustable vacuum grips have been developed to securely transport flex PCBs through the assembly line. These systems can accommodate boards of varying thicknesses and flexibilities[1].

Dual Lane Transport Rails

This innovation allows for the simultaneous loading of stiffened and non-stiffened flex boards on separate lanes, increasing production efficiency and flexibility[1].

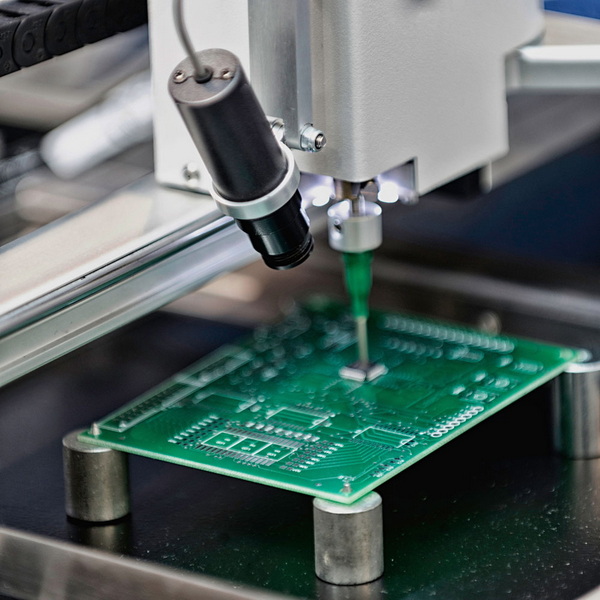

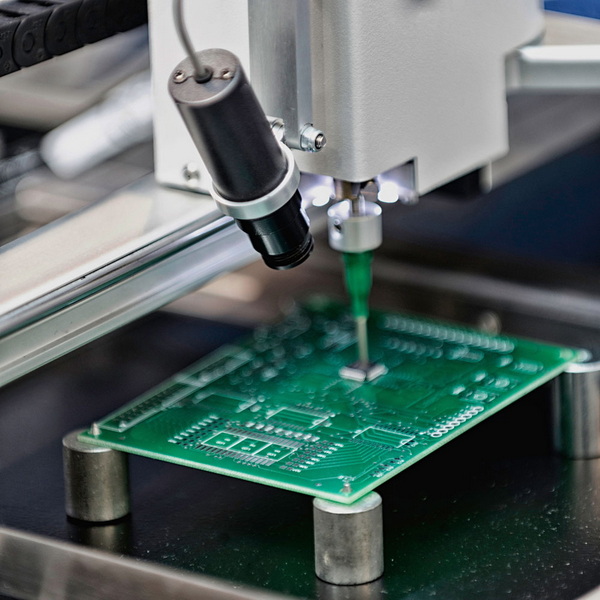

Thin Board Capable Pick and Place Machines

Advanced pick and place machines are designed to handle thinner boards and smaller components, crucial for the miniaturization trends in flex PCB design[1].

Laser Cutting and High-Precision Printing

These technologies enable more precise manufacturing of flex PCBs, improving overall quality and reliability[2].

The Impact of Flex PCB SMT Tooling on Product Development

The advancements in flex PCB SMT tooling have had a profound impact on product development across various industries:

Miniaturization

By enabling the efficient assembly of flexible circuits, SMT tooling has played a crucial role in the ongoing trend of electronics miniaturization. This has led to the development of smaller, lighter, and more portable devices[2].

Enhanced Functionality

The ability to create complex, three-dimensional circuit designs with flex PCBs has allowed engineers to pack more functionality into smaller spaces. This has been particularly beneficial in wearable technology and IoT devices[3].

Improved Reliability

Advanced SMT tooling techniques have resulted in more reliable flex PCB assemblies. This is especially important in critical applications such as medical devices and automotive electronics, where failure is not an option[6].

Cost Reduction

While the initial investment in specialized flex PCB SMT tooling can be significant, it often leads to long-term cost savings. The increased efficiency, reduced material waste, and improved yield rates contribute to lower overall production costs[2].

Challenges in Flex PCB SMT Assembly

Despite the advancements in tooling, flex PCB SMT assembly still presents several challenges:

Material Handling

The delicate nature of flex PCBs requires careful handling throughout the assembly process. Even with specialized tooling, there's always a risk of damage to the flexible substrate[3].

Component Placement

Achieving precise component placement on a flexible substrate can be more challenging than on rigid boards. This is particularly true for fine-pitch components and areas of the board that may experience bending during use[7].

Thermal Management

Flex PCBs are more sensitive to heat than rigid boards. Balancing the need for proper solder joint formation with the risk of thermal damage requires careful control of the reflow process[1].

Design Considerations

Designers must consider the unique properties of flex PCBs when planning component placement. Areas that will experience frequent bending should be kept free of components or reinforced with stiffeners[7].

Future Trends in Flex PCB SMT Tooling

As technology continues to advance, we can expect to see further innovations in flex PCB SMT tooling:

AI and Machine Learning Integration

Artificial Intelligence and Machine Learning algorithms are being integrated into SMT assembly processes to optimize component placement, predict potential issues, and improve overall efficiency[3].

Advanced Materials

The development of new, more flexible and durable materials for PCB substrates will require corresponding advancements in SMT tooling to handle these materials effectively[3].

Increased Automation

As demand for flex PCBs grows, we can expect to see more fully automated assembly lines capable of handling a wide range of flex PCB designs with minimal human intervention[2].

3D Printed Tooling

The use of 3D printing technology to create custom tooling for unique flex PCB designs is likely to become more prevalent, offering greater flexibility in manufacturing processes[5].

The Role of Flex PCB SMT Tooling in Industry 4.0

The concept of Industry 4.0, or the fourth industrial revolution, heavily relies on the integration of smart technologies in manufacturing processes. Flex PCB SMT tooling plays a crucial role in this paradigm shift:

Data-Driven Manufacturing

Advanced SMT tooling often includes sensors and data collection capabilities. This allows manufacturers to gather real-time information about the assembly process, enabling data-driven decision-making and continuous improvement[2].

IoT Integration

The Internet of Things (IoT) relies heavily on flexible and compact electronic designs. The ability to efficiently produce these designs using advanced flex PCB SMT tooling is crucial for the continued growth of IoT applications[6].

Customization and Flexibility

Industry 4.0 emphasizes the ability to quickly adapt to changing market demands. Flex PCB SMT tooling, with its ability to handle a wide range of designs and materials, provides the flexibility needed for rapid product iterations and customization[2].

Environmental Considerations

As the electronics industry faces increasing pressure to reduce its environmental impact, flex PCB SMT tooling is adapting to meet these challenges:

Material Efficiency

Advanced tooling techniques help reduce material waste during the assembly process, contributing to more sustainable manufacturing practices[2].

Energy Efficiency

Modern SMT tooling is designed with energy efficiency in mind, helping to reduce the overall carbon footprint of electronics manufacturing[1].

Recyclability

As flex PCBs become more prevalent, there's a growing focus on developing tooling and processes that facilitate the recycling of these circuits at the end of their lifecycle[5].

Conclusion

Flex PCB SMT tooling is undeniably crucial for the production of advanced electronic products. As devices continue to shrink in size while growing in complexity, the ability to efficiently assemble flexible circuits becomes increasingly important. The advancements in tooling techniques have enabled manufacturers to meet the demands for smaller, lighter, and more versatile electronic devices across various industries.

The future of flex PCB SMT tooling looks promising, with ongoing innovations in automation, materials science, and data-driven manufacturing. These developments will continue to push the boundaries of what's possible in electronic design and manufacturing, enabling the creation of even more advanced and sophisticated products.

As we move further into the era of Industry 4.0 and IoT, the importance of flex PCB SMT tooling will only grow. It will play a pivotal role in shaping the future of electronics, from wearable devices and medical implants to automotive systems and beyond. By enabling the efficient production of complex, flexible electronic circuits, this tooling is helping to drive innovation and progress across multiple sectors of the global economy.

FAQs

1. What is flex PCB SMT tooling?

Flex PCB SMT tooling refers to the specialized equipment and processes used for handling, aligning, and assembling flexible printed circuit boards using surface mount technology. This tooling is designed to address the unique challenges presented by the flexible nature of these circuits, ensuring precise component placement and reliable assembly[1][2].

2. How does flex PCB SMT tooling differ from traditional PCB assembly tools?

Flex PCB SMT tooling is specifically designed to handle the delicate and flexible nature of flex PCBs. It includes features like vacuum plates for maintaining flatness, gentler handling mechanisms to prevent damage, and temperature-controlled systems to manage the heat sensitivity of flex materials. Traditional PCB assembly tools are typically more rigid and may not accommodate the unique properties of flexible circuits[1][3].

3. What are the main challenges in flex PCB SMT assembly?

The main challenges in flex PCB SMT assembly include maintaining board flatness during component placement, managing the heat sensitivity of flexible materials, achieving precise component placement on a flexible substrate, and handling the delicate nature of flex PCBs without causing damage. These challenges require specialized tooling and techniques to overcome[1][3][7].

4. How does flex PCB SMT tooling contribute to product miniaturization?

Flex PCB SMT tooling enables the efficient assembly of flexible circuits, which can conform to irregular shapes and fit into tight spaces. This capability, combined with the ability to handle smaller components and achieve higher component densities, directly contributes to the ongoing trend of electronics miniaturization. It allows manufacturers to create smaller, lighter, and more compact devices without compromising functionality[2][3].

5. What future developments can we expect in flex PCB SMT tooling?

Future developments in flex PCB SMT tooling are likely to include increased integration of AI and machine learning for process optimization, advancements in handling new, more flexible PCB materials, greater automation in assembly processes, and the use of 3D printing for custom tooling solutions. We can also expect to see improvements in data collection and analysis capabilities, aligning with the trends of Industry 4.0[2][3][5].

Citations:

[1] https://www.raypcb.com/flexible-pcb-design-manufacturing-assembly/

[2] https://www.andwinpcb.com/advancements-in-flex-pcb-smt-assembly-techniques-and-benefits/

[3] https://swimbi.com/flex-pcb-smt-assembly-everything-you-need-to-know/

[4] https://www.ideaspcb.com/news/why-pcb-requires-the-use-of-tooling-strips-53058107.html

[5] https://www.epectec.com/flex/advanced-flex-and-rigid-flex-capabilities.html

[6] https://www.medicaldesignbriefs.com/component/content/article/46458-surface-mount-technology-for-pcb-assembly-use-case-and-smt-in-healthcare-systems

[7] https://resources.altium.com/p/flexible-circuit-assembly-thinking-through-component-placement

[8] https://www.allflexinc.com/flexible-circuits/