Content Menu

● Understanding SMT PCB Assembly

● Why China Leads in SMT PCB Assembly Services

>> 1. Cost Efficiency

>> 2. Advanced Technology

>> 3. Skilled Workforce

>> 4. High Production Capacity

>> 5. Efficient Supply Chain

>> 6. Quality Standards

● Benefits of Outsourcing to China SMT PCB Assembly Manufacturers

>> Additional Benefits:

● Challenges Faced by Chinese Manufacturers

>> Addressing the Challenges:

● The Future of SMT PCB Assembly in China

● Conclusion

● FAQs

>> 1. Why are labor costs lower for China SMT PCB assembly manufacturers?

>> 2. How do Chinese manufacturers ensure high-quality PCBs?

>> 3. What industries benefit most from China's SMT PCB assembly services?

>> 4. Can small businesses outsource to China SMT PCB assembly manufacturers?

>> 5. What are the key regions for PCB manufacturing in China?

China has emerged as the global epicenter for SMT (Surface Mount Technology) PCB assembly services, driven by its robust manufacturing ecosystem, cost advantages, technological advancements, and skilled workforce. This article explores the reasons behind China's dominance in this field, the benefits of outsourcing to China SMT PCB assembly manufacturers, and the challenges they navigate to maintain their leadership position.

Understanding SMT PCB Assembly

Surface Mount Technology (SMT) is a method of mounting electronic components directly onto the surface of a printed circuit board (PCB). This process is essential for modern electronics manufacturing due to its ability to handle compact designs and high-density circuits.

The typical SMT PCB assembly process includes:

1. Solder Paste Application: Applying solder paste to PCB pads using stencils.

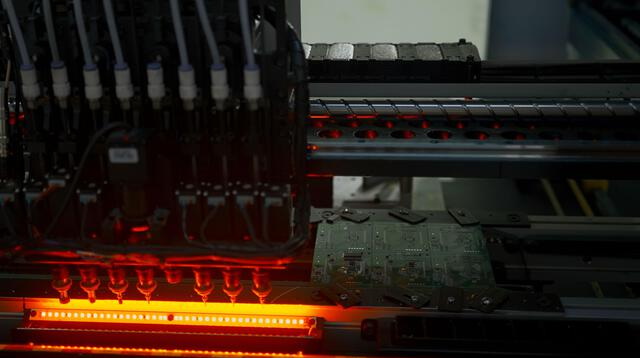

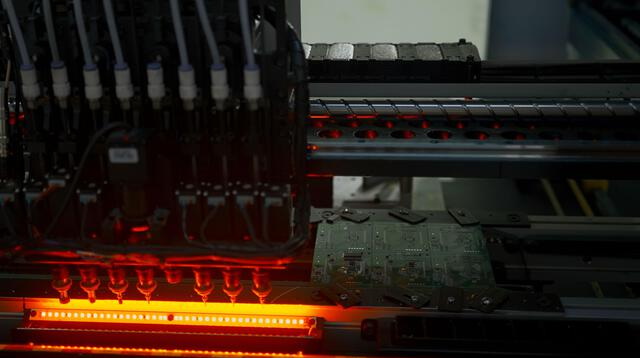

2. Pick-and-Place: Automated machines place components onto the solder paste.

3. Reflow Soldering: Heating the board in a reflow oven to secure components.

4. Inspection and Testing: Using automated optical inspection (AOI) and X-ray systems for quality assurance.

China's expertise in these processes has made it a global leader in SMT PCB assembly services.

Why China Leads in SMT PCB Assembly Services

1. Cost Efficiency

One of the primary reasons companies choose China SMT PCB assembly manufacturers is cost savings. Labor costs in China are significantly lower than in Western countries, and the availability of raw materials locally reduces production expenses. Additionally, outsourcing eliminates the need for companies to invest in expensive equipment and certifications.

The cost advantage extends beyond just labor. China's well-developed infrastructure, including efficient transportation networks and modern industrial parks, contributes to overall cost reduction. These factors allow manufacturers to offer competitive pricing without compromising on quality, making China an attractive option for businesses of all sizes.

2. Advanced Technology

China's investment in state-of-the-art manufacturing technologies ensures high-quality outputs. From high-speed pick-and-place machines to automated optical inspection systems, Chinese manufacturers leverage cutting-edge tools to produce reliable PCBs with precision.

Many China SMT PCB assembly manufacturers have embraced Industry 4.0 principles, incorporating smart manufacturing technologies such as:

- Internet of Things (IoT) sensors for real-time production monitoring

- Artificial Intelligence (AI) for predictive maintenance and quality control

- Big Data analytics for process optimization and yield improvement

These technological advancements not only improve production efficiency but also enhance the overall quality and reliability of the assembled PCBs.

3. Skilled Workforce

China boasts a large pool of skilled engineers and technicians who specialize in electronics manufacturing. This expertise enables manufacturers to handle complex designs, including multilayer PCBs and miniaturized components like 0201 packages.

The country's focus on STEM education has resulted in a steady supply of qualified professionals entering the workforce. Many Chinese universities offer specialized programs in electronics manufacturing, ensuring that graduates are well-prepared for the industry's demands.

Furthermore, China SMT PCB assembly manufacturers often provide ongoing training and development programs for their employees, keeping them updated with the latest industry trends and technologies.

4. High Production Capacity

With thousands of manufacturers spread across regions like Shenzhen, Dongguan, and Guangzhou, China has unparalleled production capacity. This allows for both small-batch prototyping and large-scale production runs, meeting diverse customer needs.

The concentration of manufacturers in specific regions creates industrial clusters, fostering competition and innovation. These clusters also facilitate knowledge sharing and collaboration, further enhancing the overall capabilities of the Chinese SMT PCB assembly industry.

5. Efficient Supply Chain

China's well-integrated supply chain ensures quick access to components, reducing lead times significantly. Proximity to suppliers minimizes delays and enhances flexibility in scaling production up or down based on demand.

The country's vast network of component suppliers, PCB fabricators, and assembly houses creates a comprehensive ecosystem that can handle every aspect of PCB production. This vertical integration allows for better coordination, faster problem-solving, and more efficient resource allocation.

Moreover, many China SMT PCB assembly manufacturers have established strong relationships with global component distributors, ensuring access to a wide range of parts, including hard-to-find or obsolete components.

6. Quality Standards

Chinese manufacturers adhere to international quality standards such as ISO9001, UL, RoHS, and IPC certifications. Rigorous testing methods like AOI, X-ray inspection, and functional testing ensure reliable products.

To maintain their competitive edge, many Chinese manufacturers have invested heavily in quality management systems and processes. These include:

- Six Sigma methodologies for process improvement

- Lean manufacturing principles for waste reduction

- Statistical Process Control (SPC) for maintaining consistent quality

By implementing these advanced quality control measures, China SMT PCB assembly manufacturers can meet and often exceed the stringent requirements of industries such as aerospace, medical devices, and automotive electronics.

Benefits of Outsourcing to China SMT PCB Assembly Manufacturers

Outsourcing SMT PCB assembly services to China offers several advantages:

- Lower Operational Costs: Avoid capital investments in equipment and labor.

- Faster Turnaround Times: Proximity to component suppliers accelerates production cycles.

- Access to Expertise: Skilled professionals provide design optimization and error detection.

- Scalability: Manufacturers can handle varying order volumes with ease.

- Flexibility: Low minimum order quantities allow for market testing and iterations.

Additional Benefits:

1. One-Stop Solution: Many Chinese manufacturers offer end-to-end services, from PCB design and fabrication to assembly and testing, simplifying the supply chain for customers.

2. Customization Options: With their vast resources and expertise, Chinese manufacturers can accommodate a wide range of customization requests, from special materials to unique form factors.

3. Rapid Prototyping: The concentration of suppliers and manufacturers in China enables quick turnaround times for prototypes, accelerating product development cycles.

4. Global Logistics Support: Many China SMT PCB assembly manufacturers have established partnerships with international shipping companies, offering seamless logistics solutions for global customers.

5. Multilingual Support: To cater to an international clientele, many Chinese manufacturers provide customer support in multiple languages, facilitating clear communication throughout the production process.

Challenges Faced by Chinese Manufacturers

Despite their strengths, Chinese manufacturers face challenges such as:

1. Supply Chain Bottlenecks: High demand during peak seasons can strain resources.

2. Labor Shortages: Rising labor costs and workforce availability are growing concerns.

3. Global Competition: Other countries are investing heavily in electronics manufacturing.

4. Environmental Regulations: Stricter laws on waste management increase operational costs.

Addressing the Challenges:

To maintain their leadership position, China SMT PCB assembly manufacturers are actively working to address these challenges:

1. Supply Chain Optimization: Implementing advanced inventory management systems and diversifying supplier networks to mitigate bottlenecks.

2. Automation and Robotics: Investing in automation technologies to reduce reliance on manual labor and improve efficiency.

3. Innovation Focus: Emphasizing research and development to stay ahead of global competitors, particularly in emerging technologies like 5G, IoT, and AI.

4. Sustainable Practices: Adopting eco-friendly manufacturing processes and materials to comply with environmental regulations while reducing long-term costs.

5. Workforce Development: Collaborating with educational institutions to develop specialized training programs, ensuring a steady supply of skilled workers.

The Future of SMT PCB Assembly in China

As the electronics industry continues to evolve, China SMT PCB assembly manufacturers are positioning themselves to meet future challenges and opportunities:

1. 5G and IoT Integration: With the rollout of 5G networks and the proliferation of IoT devices, Chinese manufacturers are gearing up to handle the increased demand for high-frequency, high-density PCBs.

2. Miniaturization: As electronic devices become smaller and more powerful, manufacturers are investing in technologies to handle ultra-fine pitch components and microelectronics assembly.

3. Flexible and Wearable Electronics: Chinese manufacturers are developing capabilities to produce flexible PCBs and integrate electronics into wearable devices, catering to the growing market for smart wearables.

4. Green Manufacturing: In response to global environmental concerns, many manufacturers are adopting eco-friendly practices, such as lead-free soldering and energy-efficient production processes.

5. Industry 4.0 Implementation: Continued investment in smart manufacturing technologies will further enhance productivity, quality, and customization capabilities.

Conclusion

China's dominance in SMT PCB assembly services is rooted in its cost advantages, technological prowess, skilled workforce, and efficient supply chain management. By continuously innovating and adhering to stringent quality standards, Chinese manufacturers remain the preferred choice for businesses worldwide.

As the electronics industry faces new challenges and opportunities, China SMT PCB assembly manufacturers are well-positioned to adapt and maintain their leadership role. Their ability to offer cost-effective, high-quality, and flexible manufacturing solutions continues to attract global customers across various industries.

The combination of advanced technology, a skilled workforce, and a comprehensive supply chain ecosystem makes China an unparalleled hub for SMT PCB assembly services. As the industry evolves, Chinese manufacturers are poised to lead the way in innovation, quality, and efficiency, ensuring their continued dominance in the global electronics manufacturing landscape.

FAQs

1. Why are labor costs lower for China SMT PCB assembly manufacturers?

Labor costs are lower due to China's large workforce and competitive wages compared to Western countries. This enables manufacturers to offer cost-effective services without compromising quality.

2. How do Chinese manufacturers ensure high-quality PCBs?

They employ advanced technologies like automated optical inspection (AOI), X-ray systems, and functional testing while adhering to international standards such as ISO9001 and RoHS certifications.

3. What industries benefit most from China's SMT PCB assembly services?

Industries such as consumer electronics, automotive, medical devices, telecommunications, and industrial equipment benefit from China's expertise in producing high-quality PCBs at scale.

4. Can small businesses outsource to China SMT PCB assembly manufacturers?

Yes, many Chinese manufacturers accept low minimum order quantities, making it feasible for startups and small businesses to outsource prototyping or small-scale production.

5. What are the key regions for PCB manufacturing in China?

Shenzhen is the leading hub due to its concentration of suppliers and skilled workforce. Other key regions include Dongguan and Guangzhou.