Content Menu

● Introduction

● What is AOI?

● The Importance of AOI in SMT Lines

● How AOI Enhances Quality and Efficiency

● Challenges Addressed by AOI

● Technological Advancements in AOI

>> The Role of AI in Enhancing AOI

>> Integration with Other Inspection Methods

● Common Challenges Faced by AOI Systems

>> Strategies for Overcoming Challenges

● Conclusion

● FAQ

>> 1. What is the primary function of AOI in SMT lines?

>> 2. How does AOI improve production efficiency?

>> 3. What challenges does AOI address in SMT lines?

>> 4. What are recent advancements in AOI technology?

>> 5. Why is AOI considered cost-effective?

● Citations:

Introduction

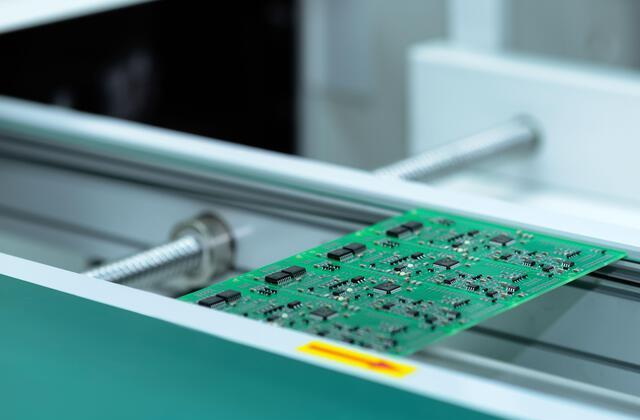

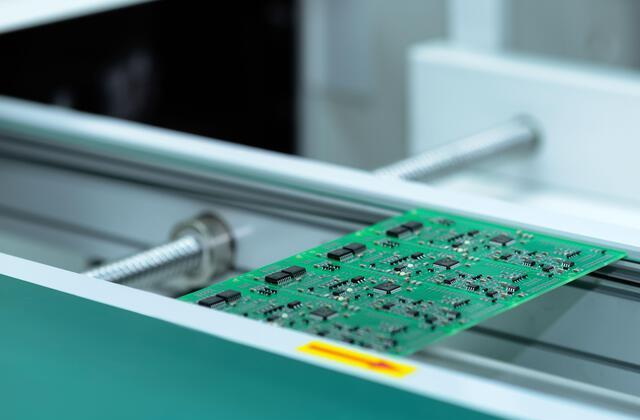

Automated Optical Inspection (AOI) has emerged as a pivotal technology in the Surface Mount Technology (SMT) industry, playing a crucial role in ensuring the quality and efficiency of electronic manufacturing processes. As the demand for high-quality electronic products increases, so does the complexity of printed circuit boards (PCBs), making reliable inspection methods essential. This article delves into the significance of AOI in SMT line inspection, exploring its functions, advantages, challenges it addresses, and recent technological advancements.

What is AOI?

Automated Optical Inspection (AOI) is a visual inspection technology that utilizes high-resolution cameras and sophisticated software algorithms to identify defects in PCBs. The fundamental principle behind AOI is to compare captured images of assembled PCB surfaces against predefined standards or templates. This comparison allows AOI systems to detect a wide range of issues, including misaligned components, soldering defects, and missing parts. By automating the inspection process, AOI significantly reduces the reliance on manual inspections, which are often prone to human error.

The Importance of AOI in SMT Lines

AOI is indispensable in SMT lines for several compelling reasons:

- Early Detection of Defects: AOI systems enable manufacturers to identify defects early in the production process, minimizing the risk of faulty products reaching customers.

- Cost Reduction: By catching defects before they escalate into more significant issues, AOI helps reduce rework costs and material waste.

- Real-Time Feedback: AOI provides immediate feedback to operators, allowing for quick adjustments to production processes and enhancing overall efficiency.

- High Throughput: Modern AOI systems can inspect thousands of components per minute, making them ideal for high-speed manufacturing lines.

How AOI Enhances Quality and Efficiency

The automation of the inspection process through AOI significantly enhances both quality and efficiency in SMT lines. Key benefits include:

- Increased Speed: AOI systems can process images rapidly, enabling quick defect detection without slowing down production lines.

- Consistency: Unlike human inspectors, AOI systems maintain a consistent level of accuracy and precision across inspections, reducing variability in quality control.

- Error Reduction: By minimizing human intervention, AOI reduces the likelihood of errors associated with manual inspections.

Challenges Addressed by AOI

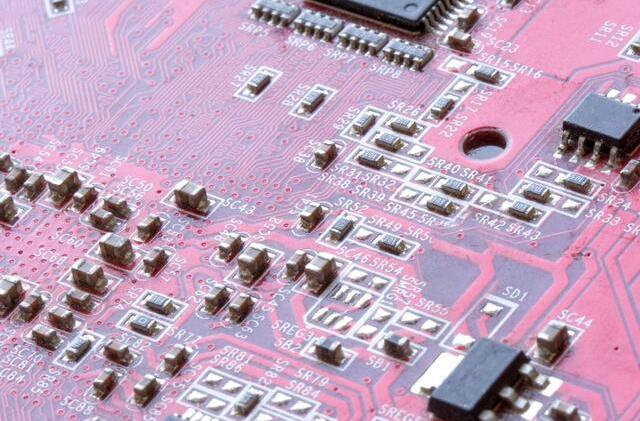

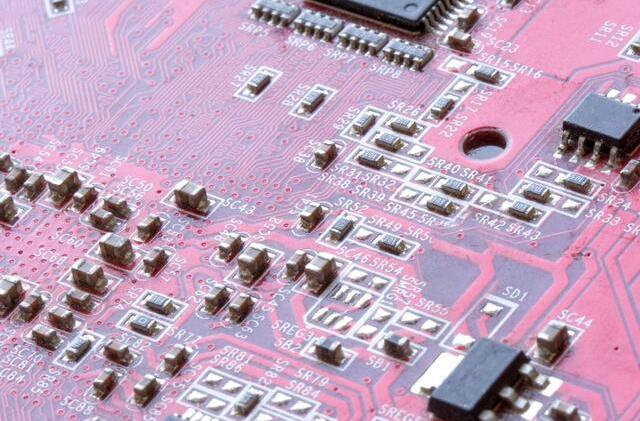

The increasing complexity and miniaturization of electronic components present significant challenges for SMT lines. AOI effectively addresses several common issues:

- Soldering Defects: Insufficient or excessive solder can lead to poor electrical connections. AOI systems can detect these issues promptly.

- Component Misalignment: With smaller components becoming more prevalent, ensuring proper alignment is critical. AOI can identify misaligned components that may not be visible to the naked eye.

- Connectivity Issues: Problems such as open circuits or short circuits can be detected early through detailed inspections performed by AOI systems.

Technological Advancements in AOI

The field of Automated Optical Inspection is continuously evolving with technological advancements that enhance its capabilities. Notable developments include:

- 3D AOI Systems: These systems provide enhanced accuracy by capturing three-dimensional images of PCBs, allowing for better detection of solder joint quality and component placement.

- Machine Learning Integration: Incorporating machine learning algorithms enables AOI systems to improve their defect detection capabilities over time by learning from previous inspections.

- In-Line Inspection Systems: These systems allow for real-time monitoring during production processes, providing immediate feedback and facilitating quicker corrective actions.

The Role of AI in Enhancing AOI

Artificial Intelligence (AI) has begun to reshape how manufacturers approach Automated Optical Inspection. AI-driven AOI systems utilize advanced image recognition capabilities that enhance speed and accuracy. These systems can automatically match components to the right library using deep learning algorithms, which speeds up setup times and improves inspection accuracy. Furthermore, AI can measure 3D components that aren't included in existing libraries, making inspections faster and smarter than ever before[4][9].

Integration with Other Inspection Methods

While AOI is a powerful tool on its own, it is often used in conjunction with other inspection methods such as In-Circuit Testing (ICT) and Automated X-ray Inspection (AXI). This multi-faceted approach ensures comprehensive defect detection:

- In-Circuit Testing (ICT): Focuses on checking the electrical performance of individual components but may miss certain visual defects that AOI excels at identifying.

- Automated X-ray Inspection (AXI): Ideal for detecting internal defects such as voids or cracks within solder joints that are not visible externally. Combining these methods allows manufacturers to achieve higher overall quality assurance[19][21].

Common Challenges Faced by AOI Systems

Despite its many advantages, implementing an Automated Optical Inspection system is not without challenges:

- False Positives and Negatives: High rates of false positives can lead to unnecessary rework while false negatives can allow defective products to pass through quality control undetected[26].

- Adaptability Issues: As product designs evolve rapidly, the ability of an AOI system to adapt quickly becomes crucial. Recalibrating for different component types can be time-consuming[11][26].

- Maintenance Costs: Regular upkeep is necessary to ensure optimal performance; however, this can add significant operational costs over time[26].

Strategies for Overcoming Challenges

To mitigate these challenges effectively:

1. Implement Advanced Algorithms: Utilizing machine learning algorithms can enhance defect recognition capabilities while reducing false positives and negatives.

2. Develop Modular Systems: Modular designs allow for quick recalibration when new products are introduced into production lines.

3. Invest in Predictive Maintenance Technologies: These technologies help foresee potential issues before they escalate into costly repairs or downtime[26].

Conclusion

In summary, Automated Optical Inspection (AOI) is a critical component of SMT line inspection that significantly enhances product quality and manufacturing efficiency. By enabling early defect detection, reducing costs associated with rework, and adapting to technological advancements such as AI integration and 3D imaging capabilities, AOI has become indispensable in modern electronics manufacturing. As the industry continues to evolve towards greater complexity and miniaturization, the role of AOI will only grow more vital in ensuring high-quality electronic products reach consumers.

FAQ

1. What is the primary function of AOI in SMT lines?

The primary function of AOI is to inspect printed circuit boards (PCBs) for defects such as misaligned components, soldering issues, and missing parts to ensure product quality and reliability.

2. How does AOI improve production efficiency?

AOI improves production efficiency by automating the inspection process, reducing defect detection time, eliminating human error, and providing real-time feedback for immediate adjustments.

3. What challenges does AOI address in SMT lines?

AOI addresses challenges such as miniaturization of components, increasing PCB complexity, and the need for high-speed inspections by providing precise and reliable detection capabilities.

4. What are recent advancements in AOI technology?

Recent advancements include the development of 3D AOI systems for enhanced accuracy, machine learning integration for improved defect detection capabilities, and in-line inspection systems for real-time monitoring.

5. Why is AOI considered cost-effective?

AOI is cost-effective because it identifies defects early in the production process, reducing rework needs and minimizing material waste while ensuring high-quality output.

Citations:

[1] https://www.zjyingxing.com/info/what-is-the-role-of-aoi-machines-in-the-smt-in-91506284.html

[2] https://levisonenterprises.com/automated-optical-inspection/

[3] https://www.neodensmt.com/news/what-are-the-problems-of-aoi-detection-in-smt-38253467.html

[4] https://www.manufacturingtomorrow.com/news/2024/04/30/revolutionizing-smt-tht-technology-advanced-ai-inspection-with-ict-aoi-machine/22671/

[5] https://www.ipc.org/system/files/technical_resource/E10&S04_02.pdf

[6] https://www.fs-pcba.com/smt-aoi-inspection/

[7] https://www.raypcb.com/aoi-pcba/

[8] http://www.ymh-teknoloji.com/images/cyberoptics/AddressingHighPrecisionAutomatedOpticalInspection.pdf

[9] https://core-emt.com/blog/smt-news-1/the-future-of-ai-in-aoi-smarter-faster-aoi-inspections-within-smt-lines-130

[10] https://www.electronicsforu.com/market-verticals/industrial/automated-optical-inspection-smt-environment

[11] https://id.hct-smt.com/blog/common-challenges-in-aoi-testing-and-effective-strategies-to-overcome-them

[12] https://www.smtfactory.com/what-makes-smt-aoi-ai-inspection-technology-superior.html

[13] https://accelonix.nl/gopel-electronic-aoi-case-study-the-advantages-of-one-inspection-vendor/

[14] https://www.rayprasad.com/smt-placing-an-aoi-system-in-the-smt-line

[15] https://jlcpcb.com/blog/automated-optical-inspection

[16] https://jamindopcba.com/what-is-aoi-pcb-inspection/

[17] https://ipc.mitacmdt.com/en-US@Edge-AI-Driven-AOI-Technology-Revolutionizes-Automated-Inspection-Systems~PRDetail

[18] https://www.linkedin.com/pulse/smt-every-pcba-has-been-inspected-aoi-manual-visual-inspection-amy-su-aierc

[19] https://www.pcbcart.com/article/content/pcb-smt-assembly-AOI-ICT-AXI-comparison.html

[20] https://www.wevolver.com/article/automated-optical-inspection

[21] https://wellmanxray.com/blog/demystifying-aoi-and-axi-in-the-smt-industry/

[22] https://instrumental.com/resources/automate-failure-analysis/the-future-of-automated-optical-inspection-systems/

[23] https://www.kollmorgen.com/en-us/service-and-support/knowledge-center/success-stories/synqnet-case-study-agilent-technologies

[24] https://www.pcbgogo.com/Article/AOI_in_PCB_and_SMT_Production_Line.html

[25] https://www.advantech.com/en-us/resources/case-study/automated-optical-inspection-aoi-systems-for-pcb-manufacturing

[26] https://cygnuscorp.com/explore-the-common-challenges-faced-with-aoi-systems/

[27] https://www.electronicsforu.com/special/unveiling-vitroxs-latest-aoi-series-with-cutting-edge-technologies

[28] https://hawkerrichardson.com.au/case_study/smt-line-at-philips-dynalite/

[29] https://www.neodensmt.com/news/the-role-of-aoi-and-spi-in-smt-processing-61810983.html

[30] https://www.candorind.com/blog/automated-optical-inspection/

[31] https://www.linkedin.com/pulse/aoi-pcb-smt-production-line-rigid-flex-pcb-manufactuer-7btac

[32] https://vicoimaging.com/aoi-lens-in-ensuring-flawless-smt-and-smd-production/

[33] https://www.acceleratedassemblies.com/blog/automated-optical-inspection-aoi-for-pcb-testing-and-its-benefits

[34] https://www.pcbcart.com/article/content/aoi-system-for-smt-assembly.html

[35] https://trdsf.com/blogs/news/automated-optical-inspection-aoi-in-manufacturing