Content Menu

● Introduction to SMD Taping Machines

● Functionality of SMD Taping Machines

● Benefits of SMD Taping Machines

● Role in PCB Assembly

● Advantages of SMT in PCB Assembly

● Challenges and Limitations

● Future Trends in PCB Assembly

● SMD Splicing and Its Importance

● Conclusion

● Frequently Asked Questions

>> 1. What is the primary function of an SMD taping machine?

>> 2. How does an SMD taping machine improve production efficiency?

>> 3. What are the environmental benefits of using SMD taping machines in PCB assembly?

>> 4. Can SMD taping machines handle a variety of component sizes?

>> 5. How do SMD taping machines contribute to reducing labor costs?

● Citations:

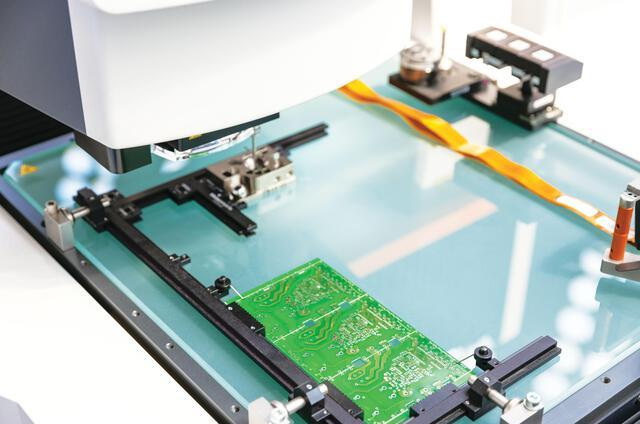

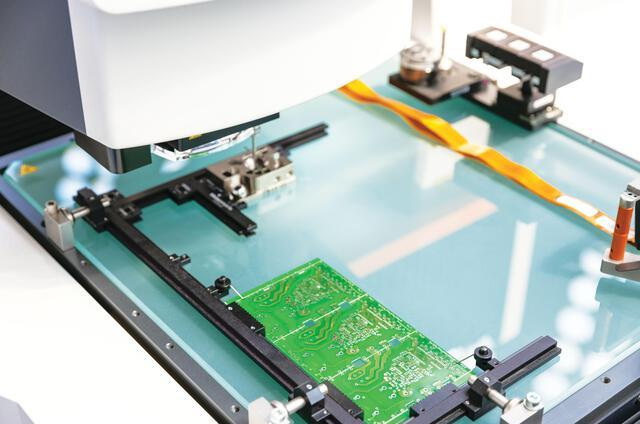

In the modern electronics manufacturing industry, Surface Mount Technology (SMT) has become a cornerstone for efficient and cost-effective production of printed circuit boards (PCBs). A crucial component in this process is the SMD taping machine, which plays a vital role in preparing electronic components for automated assembly onto PCBs. This article will delve into the importance of SMD taping machines in PCB assembly, exploring their functions, benefits, and how they contribute to the overall efficiency and quality of electronic manufacturing.

Introduction to SMD Taping Machines

SMD taping machines are specialized devices designed to package electronic components into reels of tape. This process involves placing components into pre-molded cavities on a carrier tape, which is then sealed with cover tape to protect the components during transportation and storage. The use of these machines is essential for maintaining the integrity and organization of components, ensuring they are ready for automated assembly.

Functionality of SMD Taping Machines

SMD taping machines operate by automatically sealing and furling components onto reels. They support various component widths, typically ranging from 8 to 88 mm, and can handle different types of components, including SOP8, SOP14, and SOP16 IC chips. These machines are controlled by Programmable Logic Controllers (PLCs), which ensure stable temperature control and accurate counting, making them highly reliable and efficient[2].

For instance, the DT-1000S SMD taping machine by Semiki offers advanced features such as automatic sealing and furling, with adjustable sealing times and temperatures. This machine can handle up to 6000 components per hour, making it suitable for high-volume production environments[2].

Benefits of SMD Taping Machines

1. Increased Production Efficiency: By automating the packaging process, SMD taping machines significantly reduce manual intervention, thereby minimizing errors such as misplacement or component damage. This automation enhances production efficiency and ensures smooth integration with the production line.

2. Improved Compatibility with Pick-and-Place Machines: The standardized packaging format produced by these machines makes it easier to feed components into pick-and-place machines, reducing setup time and potential errors during assembly.

3. Enhanced Component Storage and Transportation: The reel packaging system is ideal for mass production and long-term storage, simplifying inventory management and logistics. It also protects components from damage and environmental factors during transportation.

4. Lower Labor Costs and Reduced Human Error: Automated packaging ensures precise organization of components, reducing assembly mistakes and component damage associated with manual handling.

5. Improved Product Quality: High-end machines often include electrostatic discharge (ESD) protection, safeguarding sensitive components like semiconductors during packaging and transport.

Role in PCB Assembly

In PCB assembly, SMD taping machines are essential for preparing components for the Surface Mount Technology (SMT) process. SMT involves mounting components directly onto the surface of a PCB using solder paste, which is then melted to secure the components in place. The efficiency of this process relies heavily on the precise packaging and delivery of components from the taping machine to the pick-and-place equipment.

Advantages of SMT in PCB Assembly

1. Space Efficiency: SMT allows for higher component density on PCBs, enabling more compact designs and reducing the overall size of electronic devices.

2. Cost-Effectiveness: SMT components are generally cheaper than through-hole components, and the process eliminates the need for drilling holes, reducing material and labor costs.

3. Environmental Benefits: SMT is more environmentally friendly as it often uses lead-free soldering, reducing toxic waste.

4. Speed and Reliability: SMT enables faster production cycles and improves the reliability of electronic circuits due to shorter lead lengths and reduced propagation delay.

5. Mechanical Performance: SMT components offer better mechanical performance under shock and vibration conditions, partly due to lower mass and reduced cantilevering[1].

Challenges and Limitations

While SMD taping machines and SMT offer numerous advantages, there are challenges associated with this technology:

- Component Size and Handling: The small size of SMD components can make manual repair and prototyping difficult.

- Thermal Stress: Solder joints in SMT can be susceptible to thermal stress, potentially leading to reliability issues.

Future Trends in PCB Assembly

The PCB assembly industry is evolving rapidly, with trends such as miniaturization, automation, and sustainability becoming increasingly important. High-Density Interconnect (HDI) technology is gaining prominence, enabling smaller and more powerful electronic devices[3][6]. Additionally, AI-driven manufacturing is transforming the industry by enhancing efficiency, reducing errors, and improving quality control[3][6].

SMD Splicing and Its Importance

In the context of SMD taping machines, SMD splicing plays a crucial role in maintaining continuous production flow. SMD splicing involves joining two reels of SMD components together, which can be done manually or automatically using specialized machines. Automatic splicing machines are particularly beneficial as they increase accuracy and reduce downtime, thereby enhancing overall production efficiency[7].

Conclusion

In conclusion, SMD taping machines are indispensable in the PCB assembly process, particularly in the context of Surface Mount Technology. They enhance production efficiency, reduce costs, and improve component quality by automating the packaging process. As the electronics industry continues to evolve towards more compact and efficient designs, the role of SMD taping machines will remain critical in supporting these advancements.

Frequently Asked Questions

1. What is the primary function of an SMD taping machine?

An SMD taping machine is used to package electronic components into reels of tape, preparing them for automated assembly onto PCBs. This process involves placing components into pre-molded cavities on a carrier tape, which is then sealed with cover tape.

2. How does an SMD taping machine improve production efficiency?

By automating the packaging process, SMD taping machines reduce manual intervention, minimize errors, and ensure components are precisely organized for pick-and-place machines, thereby enhancing production efficiency and reducing setup time.

3. What are the environmental benefits of using SMD taping machines in PCB assembly?

The use of SMD taping machines supports environmentally friendly practices by reducing manual handling errors and promoting the use of lead-free soldering in SMT, which is more environmentally friendly than traditional through-hole technology.

4. Can SMD taping machines handle a variety of component sizes?

Yes, SMD taping machines are capable of handling components of various widths, typically ranging from 8 to 88 mm, and can be customized for larger sizes if needed.

5. How do SMD taping machines contribute to reducing labor costs?

By automating the packaging process, SMD taping machines significantly reduce the need for manual labor, thereby lowering labor costs and minimizing errors associated with human handling.

Citations:

[1] https://en.wikipedia.org/wiki/Surface-mount_technology

[2] https://www.semiki.com/en/products-2/may-dong-goi-linh-kien-smd-taping-machine-dt1000s-912

[3] https://www.pcbpower.us/blog/top-trends-pcb-assembly

[4] https://www.forceone-am.com/en/a-SMT_what%20is%20SMT%20and%20SMD.html

[5] https://www.melss.com/semiconductor-manufacturing-solutions/taping-machine-for-semiconductor-packaging-from-adaptsys/

[6] https://novaenginc.com/future-of-circuit-board-assembly/

[7] https://www.allsmt.com/SMT-splicing-tapes-and-Extenders-a-valuable-aid-in-electronics-production

[8] https://www.aptautomation.com/mt-35-tapereel-machine

[9] https://www.giiresearch.com/report/smrc1403533-smd-taping-machine-market-forecasts-global.html

[10] https://www.hayawin.com/resources/smt-assembly-advantages-and-applications.html

[11] https://systemationeuro.com/smd-taping-reeling/

[12] https://www.mycronic.com/product-areas/pcb-assembly/news-and-press-releases/news/ten-key-smt-trends-you-need-to-know/

[13] https://www.seamarkzm.com/the-role-of-smd-reel-counter-machines-in-pcb-manufacturing.html

[14] https://www.youtube.com/watch?v=7VX1goGB8rM

[15] https://riversideintegratedsolutions.com/what-is-the-next-big-trend-in-pcba/

[16] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[17] https://sbcgroup.com.mx/en/encintadora-tape-and-reel/

[18] https://www.rhsmt.com/news/smt-industrys-future-trends-the-impact-of-ai-and-automation/

[19] https://www.pcbcart.com/article/content/smt-process-to-cost-reduction.html

[20] https://vestalelectronics.com/services/smd-tape-and-reel-services/