Content Menu

● Understanding the Stencil Mask for SMT

● What Are Laser-Cut SMT Stencils?

● Advantages of Laser-Cut Stencils in SMT Manufacturing

>> 1. Superior Precision and Aperture Accuracy

>> 2. Enhanced Solder Paste Deposition Consistency

>> 3. Faster Production and Turnaround Times

>> 4. Increased Durability and Longer Stencil Life

>> 5. Capability to Produce Complex and Fine-Pitch Stencils

>> 6. Cost-Effectiveness Over Time

● The Laser Cutting Process for SMT Stencils

● Impact of Laser-Cut Stencils on SMT Assembly Quality

● Additional Considerations for SMT Manufacturers Using Laser-Cut Stencils

>> Integration with Automated SMT Lines

>> Environmental and Safety Benefits

>> Customization and Flexibility

>> Maintenance and Cleaning

● Future Trends in Laser-Cut Stencil Technology

● Conclusion

● FAQ

>> 1. What is a stencil mask for SMT and why is it important?

>> 2. How does laser cutting improve the quality of SMT stencils?

>> 3. Can laser-cut stencils handle fine-pitch components?

>> 4. What materials are used for laser-cut SMT stencils?

>> 5. Are laser-cut stencils more expensive than chemically etched stencils?

Surface Mount Technology (SMT) has revolutionized electronics manufacturing by enabling the placement of tiny components on printed circuit boards (PCBs) with high precision and efficiency. A critical element in the SMT assembly process is the stencil mask for SMT, which serves as the template for applying solder paste onto the PCB pads. Among the different methods of producing these stencils, laser-cut stencils have become the preferred choice for many SMT manufacturers worldwide. This article explores why laser-cut stencils are essential in SMT manufacturing, highlighting their advantages, production process, and impact on quality and efficiency.

Understanding the Stencil Mask for SMT

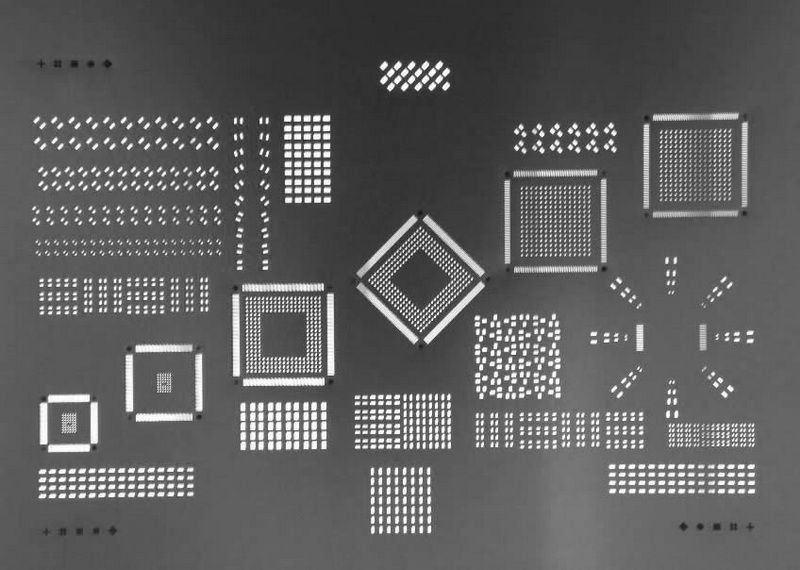

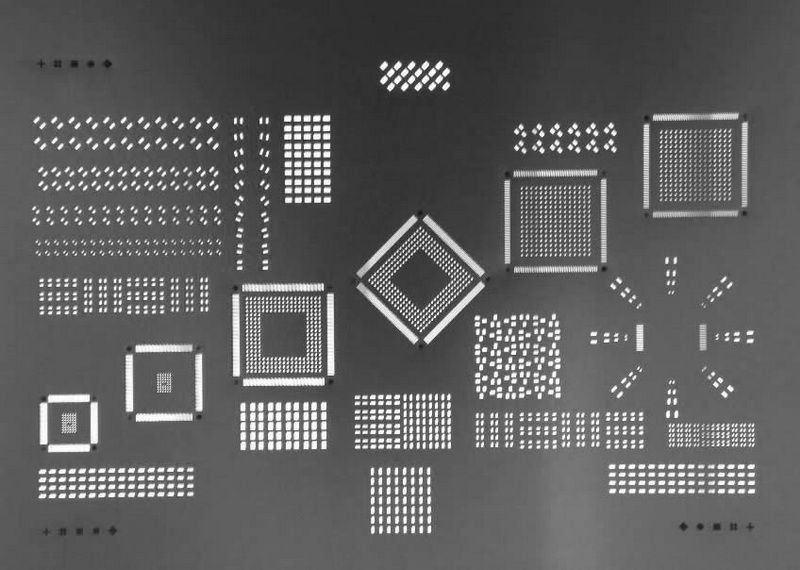

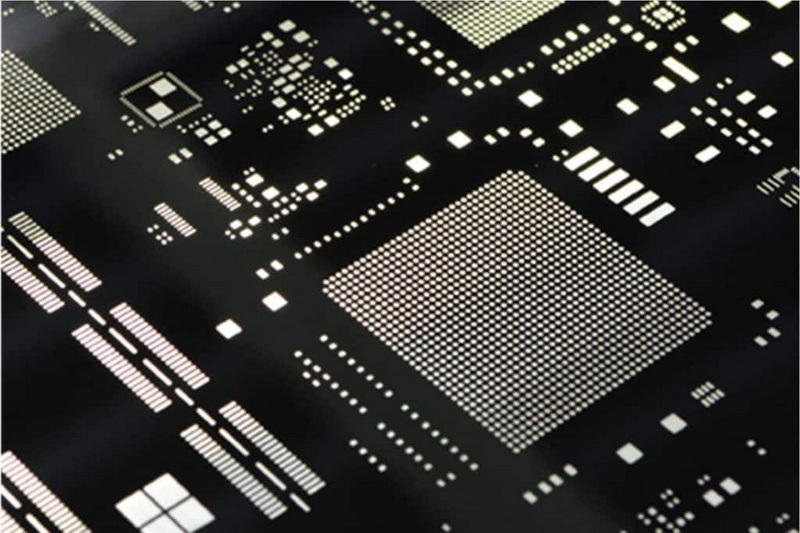

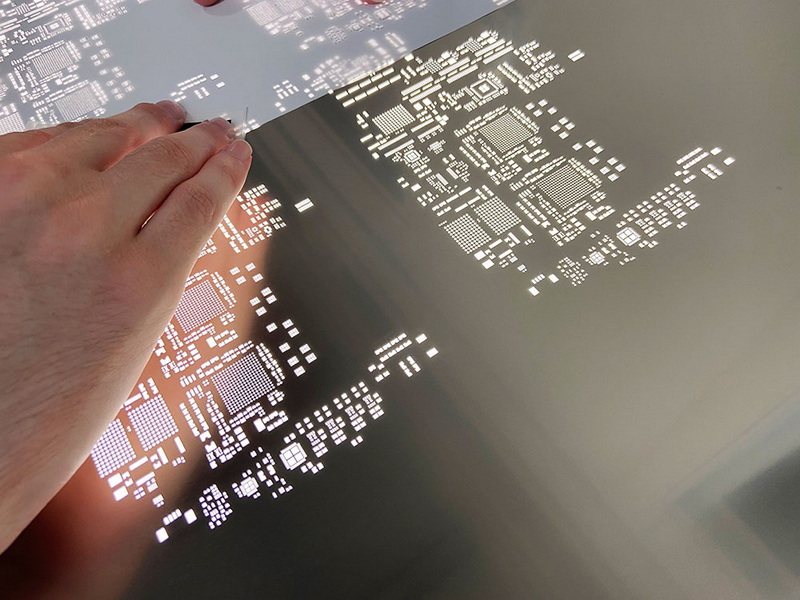

A stencil mask for SMT is a thin sheet, usually made of stainless steel, with precisely cut apertures that correspond to the solder pads on a PCB. During the solder paste printing process, the stencil is aligned over the PCB, and solder paste is spread across the stencil surface. The paste passes through the apertures and deposits onto the PCB pads in the exact amount and location required for component placement.

The quality of the stencil directly affects solder paste deposition, which in turn influences solder joint reliability, component placement accuracy, and overall assembly yield. Therefore, the manufacturing method of the stencil is crucial for SMT process success.

What Are Laser-Cut SMT Stencils?

Laser-cut SMT stencils are created by using high-precision laser cutting machines to cut the apertures into the stencil material. Unlike traditional chemical etching methods, laser cutting uses a focused laser beam to vaporize the metal in the stencil, producing clean, smooth, and highly accurate apertures.

Laser cutting technology allows for the creation of complex aperture shapes with very fine pitch and tight tolerances, which are essential for modern electronics that use increasingly smaller and more densely packed components.

Advantages of Laser-Cut Stencils in SMT Manufacturing

1. Superior Precision and Aperture Accuracy

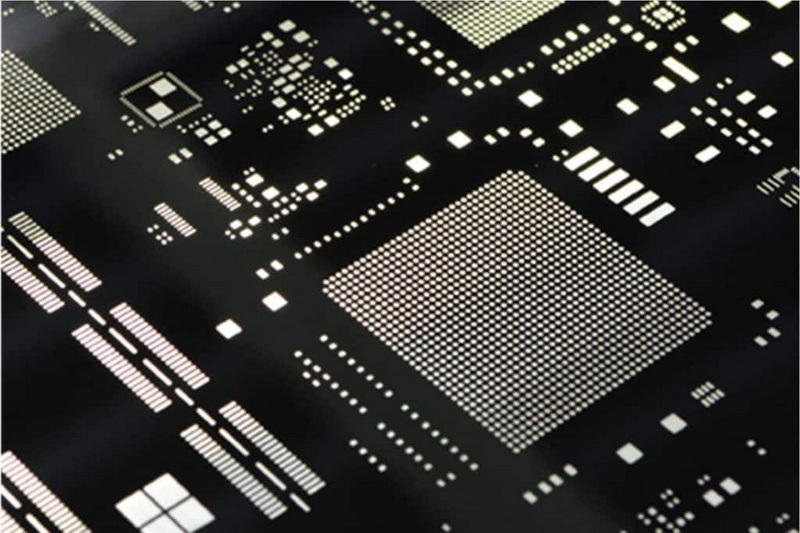

Laser-cutting technology offers unparalleled precision in stencil aperture creation. The laser beam can be controlled with extreme accuracy, resulting in apertures with exact dimensions and sharp edges. This precision is critical for fine-pitch components where even slight deviations can cause solder bridging or insufficient solder joints.

The smooth aperture walls produced by laser cutting ensure consistent solder paste release, improving print quality and reducing defects during assembly. This level of accuracy is difficult to achieve with chemical etching, which can produce uneven aperture edges and inconsistent dimensions.

2. Enhanced Solder Paste Deposition Consistency

The smooth and clean aperture walls of laser-cut stencils facilitate better solder paste release onto the PCB pads. This leads to more consistent solder paste volume and distribution, which is vital for reliable solder joints.

Inconsistent solder paste deposition can cause defects such as tombstoning, solder bridging, or insufficient solder joints. Laser-cut stencils minimize these risks by ensuring uniform paste printing every time, which contributes to higher first-pass yields and reduces rework costs.

3. Faster Production and Turnaround Times

Laser cutting is a rapid and efficient process compared to traditional chemical etching. The digital nature of laser cutting means stencil designs can be quickly programmed and cut without the need for chemical baths or masks.

This speed enables manufacturers to respond swiftly to design changes or urgent production needs, reducing lead times and improving overall manufacturing agility. Faster stencil production supports just-in-time manufacturing and helps meet tight delivery schedules in the electronics industry.

4. Increased Durability and Longer Stencil Life

Laser-cut stencils are typically made from high-quality stainless steel, such as SUS 304 or fine grain stainless steel. These materials provide excellent durability, wear resistance, and corrosion resistance, which extend the stencil's usable life.

Additionally, laser-cut stencils undergo post-processing treatments such as electropolishing, which smooths the aperture walls further and enhances printing quality for fine-pitch components. Some manufacturers also apply nano coatings to reduce solder paste adhesion to the stencil surface, facilitating easier cleaning and maintenance.

5. Capability to Produce Complex and Fine-Pitch Stencils

Modern electronics often require extremely fine-pitch components with very small solder pads. Laser cutting technology enables the production of stencils with very small apertures and complex shapes that are not feasible with chemical etching.

The ability to produce multi-thickness or step stencils with laser cutting also allows for optimized solder paste volumes for different components on the same PCB, enhancing assembly quality and reliability.

6. Cost-Effectiveness Over Time

While laser-cut stencils may have a higher initial cost compared to chemically etched ones, their superior durability and printing quality reduce the frequency of stencil replacements and minimize defects in assembly. This leads to cost savings in the long run through reduced scrap, rework, and downtime.

The Laser Cutting Process for SMT Stencils

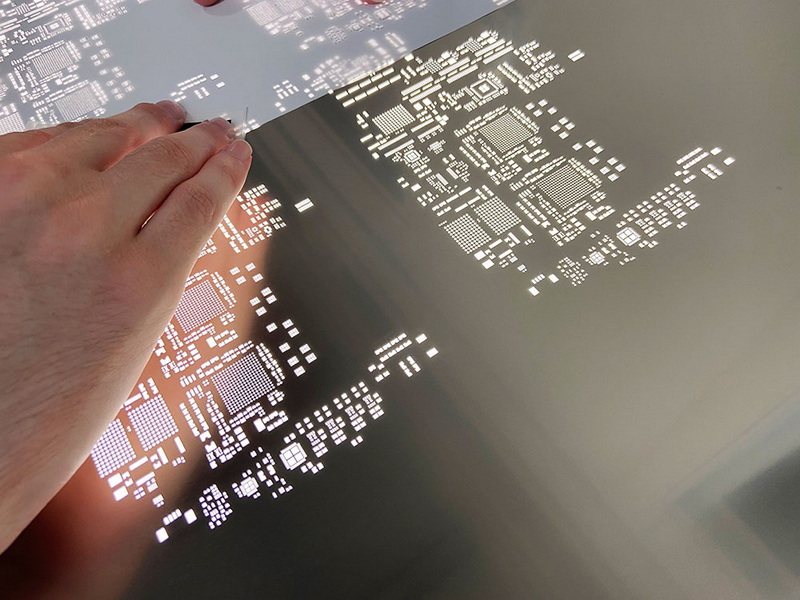

The laser cutting process for SMT stencils involves several key steps:

- Design Preparation: The stencil design is created digitally, matching the PCB pad layout precisely.

- Material Selection: High-quality stainless steel sheets are chosen, with thickness typically ranging from 0.05mm to 0.3mm depending on the application.

- Laser Cutting: A fiber laser or similar high-performance laser source cuts the apertures with high precision. The laser parameters are carefully controlled to maintain consistent beam size and power for uniform cuts.

- Post-Processing: Stencils undergo electropolishing to smooth aperture walls and may receive nano coatings to improve solder paste release and stencil longevity.

- Quality Inspection: Stencils are inspected for dimensional accuracy, aperture quality, and surface finish before shipping to customers.

Impact of Laser-Cut Stencils on SMT Assembly Quality

The use of laser-cut stencils significantly improves SMT assembly quality by ensuring:

- Accurate and consistent solder paste volume on each pad

- Reduced solder defects such as bridging, insufficient solder, and tombstoning

- Improved component placement accuracy due to reliable solder joints

- Higher first-pass yields and lower rework rates

- Enhanced capability to handle fine-pitch and complex PCB designs

These benefits translate into more reliable electronic products, higher manufacturing throughput, and lower overall production costs.

Additional Considerations for SMT Manufacturers Using Laser-Cut Stencils

Integration with Automated SMT Lines

Laser-cut stencils are highly compatible with automated SMT production lines. Their precision and consistency ensure that automated solder paste printers can operate at optimal speeds without sacrificing print quality. This integration reduces manual intervention and increases throughput, which is essential for high-volume electronics manufacturing.

Environmental and Safety Benefits

Compared to chemical etching, laser cutting is a cleaner process that avoids the use of hazardous chemicals and waste disposal issues. This makes laser-cut stencil production more environmentally friendly and safer for workers, aligning with increasing industry regulations and corporate sustainability goals.

Customization and Flexibility

Laser cutting offers great flexibility in stencil design. Manufacturers can easily customize aperture shapes, sizes, and stencil thicknesses to suit specific PCB designs and component requirements. This adaptability supports rapid prototyping and iterative design improvements without significant cost or time penalties.

Maintenance and Cleaning

Laser-cut stencils are easier to clean due to their smooth aperture walls and optional nano coatings. Efficient cleaning maintains stencil performance over many printing cycles, reducing downtime and ensuring consistent solder paste deposition throughout production runs.

Future Trends in Laser-Cut Stencil Technology

As electronics continue to miniaturize and increase in complexity, stencil technology will evolve to meet new challenges. Emerging trends include:

- Advanced Coatings: Development of more effective anti-solder paste adhesion coatings to further extend stencil life and improve print quality.

- Multi-Layer and Step Stencils: Enhanced laser cutting techniques to produce stencils with varying thicknesses on a single sheet, optimizing solder paste volume for diverse component types.

- Integration with Digital Manufacturing: Use of AI and machine learning to optimize stencil design and printing parameters, improving yield and reducing defects.

- Alternative Materials: Exploration of new materials that combine durability with lighter weight or enhanced thermal properties.

These innovations will reinforce the role of laser-cut stencils as a critical enabler of high-quality SMT assembly in the future.

Conclusion

SMT manufacturers rely heavily on laser-cut stencils because they offer unmatched precision, consistency, and durability essential for modern electronics assembly. The laser cutting process produces stencil masks for SMT with smooth aperture walls and exact dimensions, enabling superior solder paste deposition and reducing defects. Faster production times and the ability to create complex, fine-pitch apertures further enhance manufacturing efficiency and flexibility. Although laser-cut stencils may have a higher upfront cost, their long-term benefits in yield improvement and stencil longevity make them the preferred choice in the SMT industry. As electronics continue to evolve toward smaller and more complex designs, laser-cut stencil technology will remain a cornerstone of high-quality SMT assembly.

FAQ

1. What is a stencil mask for SMT and why is it important?

A stencil mask for SMT is a thin metal sheet with precisely cut openings that allow solder paste to be applied accurately to PCB pads during SMT assembly. It is important because it controls the amount and placement of solder paste, directly affecting solder joint quality and assembly reliability.

2. How does laser cutting improve the quality of SMT stencils?

Laser cutting provides highly accurate and clean aperture edges with smooth walls, which ensures consistent solder paste release and precise paste volume. This reduces defects like solder bridging and insufficient solder joints, improving overall assembly quality.

3. Can laser-cut stencils handle fine-pitch components?

Yes, laser cutting technology can produce very small and complex apertures needed for fine-pitch components, which are difficult or impossible to achieve with traditional chemical etching methods.

4. What materials are used for laser-cut SMT stencils?

High-quality stainless steel, such as SUS 304 or fine grain stainless steel, is commonly used. These materials offer durability, corrosion resistance, and good mechanical strength for repeated stencil use.

5. Are laser-cut stencils more expensive than chemically etched stencils?

Laser-cut stencils may have a higher initial cost, but their superior durability, printing quality, and reduced defect rates lead to cost savings over time by minimizing rework and stencil replacements.