Content Menu

● Proven Track Record in the Industry

● Innovative Technology

● Comprehensive Product Range

● User-Friendly Interfaces

● Excellent Support and Service

● Cost Efficiency

● Sustainability Initiatives

● Integration with Industry 4.0

● High Customization Potential

● Conclusion

● FAQ

>> 1. What types of products does Yamaha offer for SMT lines?

>> 2. How does Yamaha ensure the quality of its SMT equipment?

>> 3. What kind of training does Yamaha provide for new users?

>> 4. Are there any sustainability practices associated with Yamaha's products?

>> 5. How can I access technical support if I encounter issues with my Yamaha equipment?

● Citations:

Setting up a Surface Mount Technology (SMT) line is a critical decision for manufacturers looking to enhance their production capabilities. The choice of equipment and technology can significantly impact the efficiency, quality, and cost-effectiveness of the manufacturing process. Among various options available in the market, Yamaha stands out as a leading provider of SMT solutions. This article delves into the reasons why Yamaha should be your top choice for SMT line setup.

Proven Track Record in the Industry

Yamaha has been a key player in the electronics manufacturing industry for decades. With a rich history dating back to 1887, the company has evolved from a musical instrument manufacturer to a global leader in automation and robotics.

- Experience and Expertise: Yamaha's extensive experience in manufacturing and engineering provides customers with confidence in their products. Their knowledge of SMT processes is unparalleled, ensuring that their equipment is designed to meet the highest industry standards.

- Global Presence: Yamaha operates in numerous countries, allowing them to understand diverse market needs and adapt their solutions accordingly. This global reach ensures that customers receive support and service wherever they are located.

Innovative Technology

Yamaha is at the forefront of technological advancements in SMT equipment. Their commitment to research and development has led to several innovations that enhance productivity and quality.

- High-Speed Placement Machines: Yamaha's placement machines are known for their speed and accuracy. Models like the YSM series utilize advanced vision systems and AI algorithms to ensure precise component placement, significantly reducing errors and rework.

- Flexible Production Solutions: Yamaha's systems are designed to handle a wide variety of components and board sizes, making them ideal for manufacturers who require flexibility in their production lines. This adaptability allows businesses to respond quickly to changing market demands.

- Advanced Programming Software: Yamaha's programming software includes features like real-time data analytics, which helps manufacturers monitor production metrics closely. This capability aids in identifying bottlenecks and optimizing workflows, thus enhancing overall efficiency.

Comprehensive Product Range

Yamaha offers a comprehensive range of products that cater to various aspects of the SMT process, from printing to inspection.

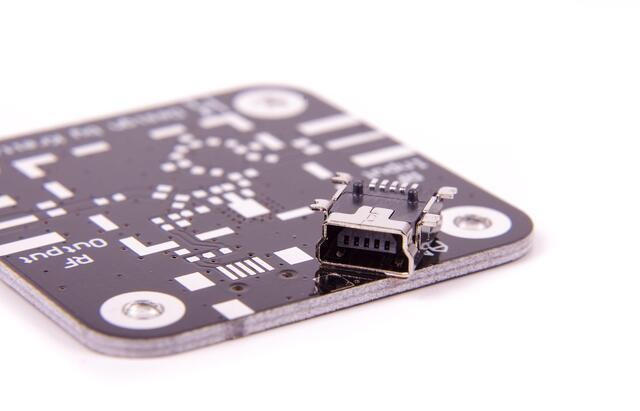

- Screen Printers: Their screen printers are engineered for high precision and consistency, ensuring optimal solder paste application on PCBs.

- Pick-and-Place Machines: Yamaha's pick-and-place machines are renowned for their speed and accuracy, capable of handling complex assemblies with ease. The YRM20 model, for example, offers flexible dual-lane modular capabilities with a placement speed of up to 120,000 components per hour (CPH).

- Inspection Systems: Quality control is vital in SMT manufacturing. Yamaha provides advanced inspection systems that utilize both automated optical inspection (AOI) and X-ray inspection technologies to ensure that every component is placed correctly.

User-Friendly Interfaces

One of the standout features of Yamaha's SMT equipment is its user-friendly interface.

- Intuitive Software: The software used in Yamaha machines is designed with usability in mind, allowing operators to quickly learn how to use the systems effectively. This reduces training time and increases overall productivity.

- Remote Monitoring Capabilities: Many Yamaha machines come equipped with remote monitoring features that allow operators to track production metrics in real-time. This capability helps identify potential issues before they become significant problems.

Excellent Support and Service

Choosing Yamaha means benefiting from their exceptional customer support services.

- Comprehensive Training Programs: Yamaha offers extensive training programs for operators and technicians, ensuring that users can maximize the capabilities of their equipment.

- Responsive Technical Support: In case of any issues, Yamaha's technical support team is readily available to assist customers, minimizing downtime and keeping production running smoothly.

Cost Efficiency

Investing in Yamaha SMT solutions can lead to significant cost savings over time.

- Reduced Waste: The precision of Yamaha's equipment minimizes material waste during production, leading to lower costs per unit.

- Long-Term Reliability: Yamaha's commitment to quality means that their machines are built to last, reducing the need for frequent replacements or repairs.

Sustainability Initiatives

As manufacturers increasingly focus on sustainability, Yamaha has made strides in creating eco-friendly solutions.

- Energy Efficiency: Many of Yamaha's machines are designed with energy-saving features that reduce power consumption during operation.

- Recyclable Materials: The company emphasizes using recyclable materials in its packaging and product design, contributing to a more sustainable production environment.

Integration with Industry 4.0

Yamaha's commitment to innovation extends into the realm of Industry 4.0, where smart manufacturing practices are becoming increasingly important.

- Data-Driven Manufacturing: With advanced software tools like the Production Analytics Dashboard and the Intelligent Factory data communication platform, manufacturers can achieve real-time monitoring of machine performance and production processes. This integration supports predictive maintenance and optimizes operational efficiency.

- Enhanced Automation: The incorporation of AI and machine learning technologies allows for improved automation within SMT lines. These advancements enable manufacturers to adapt quickly to various production demands while maintaining high levels of accuracy and efficiency.

High Customization Potential

Yamaha understands that different manufacturers have unique needs based on their specific products and market demands.

- Modular Design Features: Many of Yamaha's machines feature modular designs that allow users to customize their setups based on specific production requirements. This adaptability is crucial for companies needing quick changeovers between different product lines or configurations.

- Flexible Component Handling: Yamaha machines can handle an extensive range of components—from tiny chips (0201 metric) to larger connectors—making them suitable for diverse manufacturing needs across multiple industries such as consumer electronics, automotive electronics, medical devices, and more.

Conclusion

Choosing Yamaha for your SMT line setup is a decision backed by decades of experience, innovative technology, comprehensive product offerings, user-friendly interfaces, excellent support services, cost efficiency, sustainability initiatives, integration with Industry 4.0 practices, and high customization potential. By investing in Yamaha's solutions, manufacturers can enhance their production capabilities while ensuring high-quality output and operational efficiency.

In an ever-evolving industry where precision and speed are paramount, Yamaha stands out as a reliable partner for any business looking to optimize its SMT processes while adapting swiftly to market changes.

FAQ

1. What types of products does Yamaha offer for SMT lines?

Yamaha offers a wide range of products including screen printers, pick-and-place machines, inspection systems, and software solutions tailored for SMT processes.

2. How does Yamaha ensure the quality of its SMT equipment?

Yamaha employs rigorous testing procedures during manufacturing and utilizes advanced technologies such as automated optical inspection (AOI) and X-ray inspection in their equipment design.

3. What kind of training does Yamaha provide for new users?

Yamaha provides comprehensive training programs covering machine operation, maintenance procedures, and troubleshooting techniques to ensure users can effectively operate their equipment.

4. Are there any sustainability practices associated with Yamaha's products?

Yes, Yamaha focuses on energy efficiency in its machinery design and uses recyclable materials in packaging as part of its commitment to sustainability.

5. How can I access technical support if I encounter issues with my Yamaha equipment?

Yamaha offers responsive technical support through various channels including phone support, email assistance, and online resources available on their website.

Citations:

[1] https://smt.yamaha-motor-robotics.de/boosting-smt-throughput-with-single-and-dual-lane-upgrades/

[2] https://core-emt.com/pick-place

[3] https://core-emt.com/blog/smt-news-1/new-yamaha-smt-innovations-presented-78

[4] https://smt.yamaha-motor-robotics.de

[5] https://www.reddit.com/r/PrintedCircuitBoard/comments/f5zdkv/bringing_smt_in_house/

[6] https://www.swfuliusmt.com/2024/07/12/understanding-smt-lines-the-backbone-of-modern-electronics-manufacturing/

[7] https://global.yamaha-motor.com/business/smt/concept/

[8] https://www.renex.pl/en/publications/innovations-in-yamaha-electronics-manufacturing-equipment/

[9] https://global.yamaha-motor.com/business/smt/

[10] https://www.gssmt-parts.com/what-are-the-key-advantages-of-using-a-yamaha-smt-machine-in-modern-electronics-manufacturing.html