Content Menu

● Understanding SMT PCB Manufacturing and the Role of Steel Boards

● Why Stainless Steel is the Preferred Material for SMT PCB Steel Boards

>> 1. Superior Durability and Longevity

>> 2. Excellent Chemical and Corrosion Resistance

>> 3. High Dimensional Stability and Precision

>> 4. Easy Cleaning and Maintenance

>> 5. Compatibility with Advanced SMT Processes

● Benefits of Using Stainless Steel SMT PCB Steel Boards in Manufacturing

● The SMT Manufacturing Process and Stainless Steel's Role

>> Solder Paste Printing

>> Stencil Cleaning and Maintenance

>> Integration with Automated Lines

● Comparison with Other SMT PCB Steel Board Materials

● Innovations in Stainless Steel SMT PCB Steel Boards

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What makes stainless steel better than other materials for SMT PCB steel boards?

>> 2. How does the stainless steel stencil affect solder paste printing quality?

>> 3. Can stainless steel stencils be used for very fine-pitch SMT components?

>> 4. How does stainless steel contribute to cost savings in SMT PCB manufacturing?

>> 5. What cleaning methods are recommended for stainless steel SMT stencils?

● Citations:

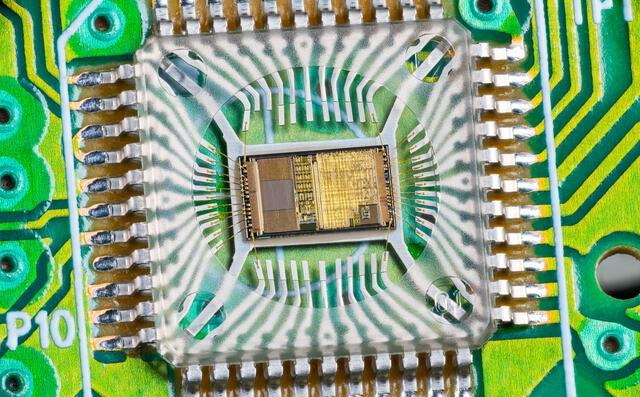

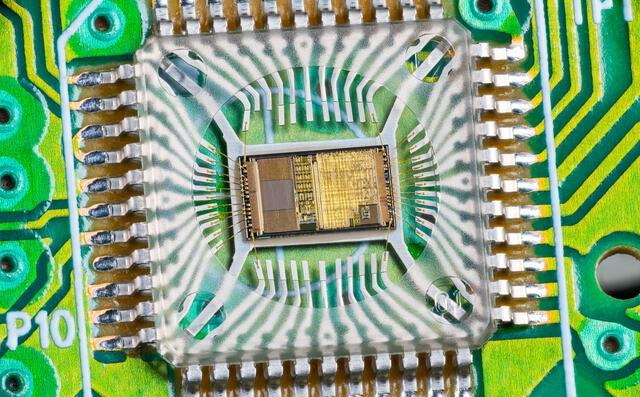

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by enabling high-density, miniaturized, and automated assembly of printed circuit boards (PCBs). A critical component in the SMT PCB manufacturing process is the stencil used for solder paste printing. Among various materials available for SMT PCB steel boards and stencils, stainless steel has emerged as the preferred choice due to its unique properties and advantages. This article explores why stainless steel is ideal for SMT PCB manufacturing, focusing on its benefits, role in the SMT process, and how it enhances quality and efficiency.

Understanding SMT PCB Manufacturing and the Role of Steel Boards

SMT PCB manufacturing involves mounting electronic components directly onto the surface of PCBs, rather than inserting component leads through holes as in traditional through-hole technology. This method allows for much higher component density, smaller PCB sizes, and faster automated assembly.

A key step in SMT manufacturing is solder paste printing, where solder paste is applied precisely onto the PCB pads to enable component soldering. This is done using a stencil or steel board that acts as a template, allowing solder paste to be deposited only on the desired pads. The quality and durability of the stencil directly affect the solder paste application, and thus the overall quality of the SMT assembly.

The smt pcb steel board—commonly referred to as the stencil—is a thin sheet, usually made of metal, that has apertures corresponding to the PCB pads where solder paste needs to be deposited. The stencil is aligned carefully over the PCB, and solder paste is spread across it, allowing paste to pass through the apertures onto the PCB surface. The precision of this process is critical, especially as PCB designs become more complex and component pitches shrink.

Why Stainless Steel is the Preferred Material for SMT PCB Steel Boards

1. Superior Durability and Longevity

Stainless steel stencils are renowned for their exceptional strength and durability. Unlike other materials such as brass or nickel, stainless steel withstands repeated use without deforming or wearing out quickly. This longevity is crucial in high-volume SMT PCB manufacturing where stencils must endure thousands of printing cycles.

The mechanical robustness of stainless steel means that it resists bending, warping, and abrasion during the printing process. This ensures that the stencil maintains its exact shape and aperture dimensions over time, which is essential for consistent solder paste deposition.

2. Excellent Chemical and Corrosion Resistance

During SMT assembly, stencils are exposed to solder paste, flux, cleaning agents, and other chemicals. Stainless steel offers excellent resistance to corrosion and chemical attack, maintaining its dimensional stability and surface integrity over time. This resistance ensures consistent solder paste printing quality and reduces stencil maintenance and replacement costs.

Corrosion resistance also means that stainless steel stencils do not degrade or oxidize easily, which could otherwise cause solder paste contamination or stencil clogging. This property is especially important in environments with high humidity or exposure to cleaning solvents.

3. High Dimensional Stability and Precision

The accuracy of solder paste deposition depends heavily on the stencil's dimensional stability. Stainless steel maintains its shape and aperture size even under thermal cycling and mechanical stress during the SMT process. This stability allows for precise solder paste printing, critical for fine-pitch components and high-density SMT PCB steel boards.

Dimensional stability also means that the stencil apertures do not enlarge or deform, which could lead to excessive or insufficient solder paste application. This precision is vital for modern PCBs that feature components with pitches as small as 0.3 mm or less.

4. Easy Cleaning and Maintenance

Stainless steel surfaces are smooth and non-porous, making them easier to clean after solder paste printing. Efficient cleaning prevents paste buildup and clogging of stencil apertures, which can cause defects in solder joints. The ease of cleaning also supports rapid turnaround times in production environments.

Cleaning methods such as ultrasonic cleaning or stencil cleaning machines work effectively on stainless steel, removing solder paste residues without damaging the stencil. This reduces downtime and helps maintain consistent print quality throughout production runs.

5. Compatibility with Advanced SMT Processes

Modern SMT manufacturing often involves complex PCBs with very fine-pitch components and multilayer designs. Stainless steel stencils can be laser-cut with high precision apertures tailored for these advanced requirements. Their mechanical strength supports frameless or borderless steel mesh designs that improve solder paste printing accuracy and efficiency.

Moreover, stainless steel stencils are compatible with various surface finishes and solder paste types, making them versatile for different SMT PCB manufacturing needs. They also support advanced printing techniques, such as step stencils or electroformed stencils, which further enhance solder paste volume control and printing quality.

Benefits of Using Stainless Steel SMT PCB Steel Boards in Manufacturing

- Higher Component Density and Miniaturization: The precision and durability of stainless steel stencils enable printing of very fine solder paste deposits, supporting ultra-small components and high-density PCB layouts.

- Improved Automation Efficiency: Stainless steel stencils withstand the rigors of automated solder paste printers and pick-and-place machines, reducing downtime and errors.

- Enhanced Product Reliability: Consistent solder paste application leads to reliable solder joints, which improve the overall performance and lifespan of SMT PCB assemblies.

- Cost-Effectiveness in Volume Production: Although stainless steel stencils may have a higher initial cost than alternatives, their long service life and reduced defect rates lower total manufacturing costs in medium to high-volume production.

- Reduced Defect Rates: The precision and stability of stainless steel SMT PCB steel boards reduce solder bridging, insufficient solder, and other common defects, leading to higher first-pass yields.

- Environmental Resistance: Stainless steel's resistance to corrosion and chemical attack makes it suitable for various manufacturing environments, including those with high humidity or exposure to aggressive cleaning agents.

The SMT Manufacturing Process and Stainless Steel's Role

The SMT manufacturing process typically includes solder paste printing, component placement, and reflow soldering. Stainless steel SMT PCB steel boards are primarily involved in the solder paste printing stage:

Solder Paste Printing

The stainless steel stencil is aligned over the PCB, and solder paste is spread across it. The paste passes through the stencil apertures onto the PCB pads. The stencil's precision ensures the correct amount and placement of solder paste, which is critical for forming strong, reliable solder joints.

Stencil Cleaning and Maintenance

After printing, the stainless steel stencil is cleaned to remove residual solder paste, preserving aperture integrity for the next cycle. Regular cleaning prevents clogging, which can cause solder defects and reduce print quality.

Integration with Automated Lines

Stainless steel stencils are compatible with high-speed automated printing machines, enabling efficient mass production. Their durability reduces the frequency of stencil replacement, minimizing machine downtime and production interruptions.

Comparison with Other SMT PCB Steel Board Materials

While stainless steel is the most popular choice, other materials like brass, nickel, and electroformed nickel are also used for SMT PCB steel boards. Here's how stainless steel compares:

| Material | Durability | Corrosion Resistance | Dimensional Stability | Cost | Suitability for Fine Pitch |

| Stainless Steel | High | Excellent | Excellent | Moderate | Excellent |

| Brass | Moderate | Poor | Moderate | Low | Limited |

| Nickel | Moderate | Good | Good | Moderate | Good |

| Electroformed Nickel | Low | Good | Very High | High | Excellent |

Stainless steel offers a balanced combination of durability, corrosion resistance, and dimensional stability at a reasonable cost, making it the preferred choice for most SMT PCB manufacturing applications.

Innovations in Stainless Steel SMT PCB Steel Boards

Advancements in manufacturing technology have further enhanced the capabilities of stainless steel stencils:

- Laser Cutting Technology: Enables highly precise aperture shapes and sizes, accommodating complex PCB designs.

- Electropolishing: Improves surface smoothness, reducing solder paste adhesion and facilitating easier cleaning.

- Step Stencils: Stainless steel stencils with varying thicknesses in different areas to optimize solder paste volume for components of different sizes.

- Frameless Stencils: Stainless steel mesh without a traditional frame, reducing stencil sag and improving print accuracy.

These innovations leverage the inherent properties of stainless steel to push the boundaries of SMT PCB manufacturing quality and efficiency.

Conclusion

Stainless steel is the optimal material choice for SMT PCB steel boards and stencils due to its unmatched durability, chemical resistance, dimensional stability, and ease of maintenance. These properties ensure precise, consistent solder paste printing, which is fundamental to the quality and reliability of SMT PCB assemblies. While the initial investment may be higher, stainless steel stencils provide cost savings through longevity and reduced defects, making them indispensable in modern SMT PCB manufacturing.

By choosing stainless steel for SMT PCB steel boards, manufacturers can achieve higher yields, support advanced PCB designs, and maintain efficient, reliable production lines. As SMT technology continues to evolve, stainless steel remains at the forefront, enabling the production of increasingly sophisticated and miniaturized electronic devices.

Frequently Asked Questions (FAQ)

1. What makes stainless steel better than other materials for SMT PCB steel boards?

Stainless steel offers superior durability, corrosion resistance, and dimensional stability compared to materials like brass or nickel. It maintains precision over many printing cycles and withstands chemical exposure, making it ideal for high-volume SMT PCB manufacturing.

2. How does the stainless steel stencil affect solder paste printing quality?

The stencil's precision and stability ensure that solder paste is deposited accurately on PCB pads in the correct volume. This accuracy is critical for forming reliable solder joints, especially for fine-pitch components on dense SMT PCB steel boards.

3. Can stainless steel stencils be used for very fine-pitch SMT components?

Yes, stainless steel stencils can be laser-cut with high precision to create apertures suitable for ultra-fine-pitch components, supporting advanced SMT PCB designs with high component density.

4. How does stainless steel contribute to cost savings in SMT PCB manufacturing?

Although stainless steel stencils have a higher upfront cost, their long lifespan and resistance to wear reduce the frequency of stencil replacement. This durability, combined with fewer defects and rework, lowers overall manufacturing costs in medium to high-volume production.

5. What cleaning methods are recommended for stainless steel SMT stencils?

Stainless steel stencils can be effectively cleaned using ultrasonic cleaning or specialized stencil cleaning machines. Their smooth surface facilitates easy removal of solder paste residues, maintaining stencil aperture integrity and printing quality.

Citations:

1.https://www.wevolver.com/article/smt-pcb-assembly-a-comprehensive-guide-to-surface-mount-technology-in-electronics

2.https://www.elepcb.com/blog/pcb-stencil-smt-assembly/

3.https://jlcpcb.com/blog/why-pcb-stencils-are-key-to-high-quality-smt-assembly

4.https://www.pcbpower.us/blog/what-are-stencils-and-how-to-use-them-3

5.https://www.pcbjhy.com/blog/pros-and-cons-of-smt-pcb-assembly/

6.https://www.pcbonline.com/blog/smt-manufacturing-process.html

7.https://patents.google.com/patent/CN112040669B/en

8.https://en.wikipedia.org/wiki/Surface-mount_technology

9.https://www.wevolver.com/article/smt-process