Content Menu

● The Evolution of PCB Assembly

● Advantages of SMT in PCB Assembly

>> Miniaturization and Space Efficiency

>> Improved Performance and Reliability

>> Cost-Effectiveness and Production Efficiency

>> Versatility and Design Flexibility

● Applications of SMT in Various Industries

>> Consumer Electronics

>> Automotive Electronics

>> Medical Devices

>> Aerospace and Defense

>> Industrial Automation

● Challenges and Considerations in SMT PCB Assembly

>> Heat Management

>> Rework and Repair

>> Initial Investment

>> Design for Manufacturability (DFM)

● The Future of SMT in PCB Assembly

>> Miniaturization Trends

>> Integration with Advanced Technologies

>> Sustainability and Environmental Considerations

>> Industry 4.0 and Smart Manufacturing

● Conclusion

● FAQ

>> 1. What is the main difference between SMT and through-hole technology?

>> 2. How does SMT improve PCB assembly efficiency?

>> 3. Are there any disadvantages to using SMT for PCB assembly?

>> 4. Can SMT and through-hole technology be used together on the same PCB?

>> 5. How has SMT impacted the development of modern electronic devices?

● Citations:

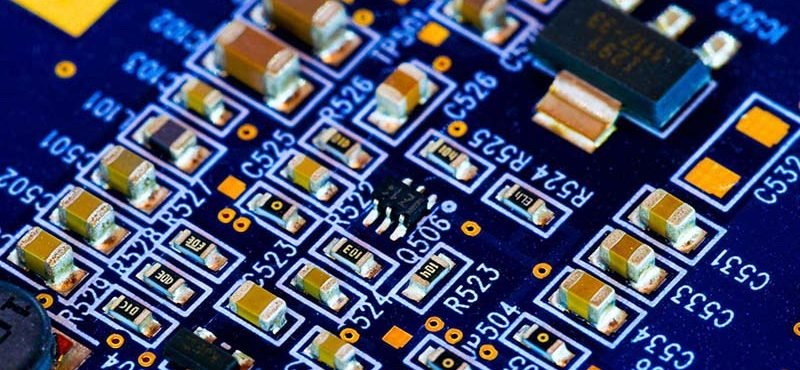

In the ever-evolving world of electronics manufacturing, Surface Mount Technology (SMT) has emerged as a game-changer, revolutionizing the way printed circuit boards (PCBs) are assembled. As the demand for smaller, faster, and more efficient electronic devices continues to grow, SMT has become the preferred method for PCB assembly, offering numerous advantages over traditional through-hole technology (THT). This article will explore the reasons why SMT is the superior choice for PCB assembly and how it has transformed the electronics industry.

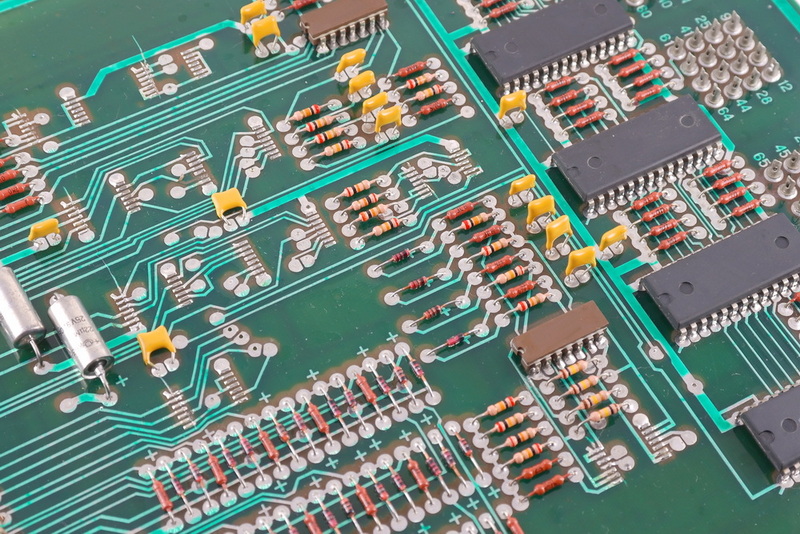

The Evolution of PCB Assembly

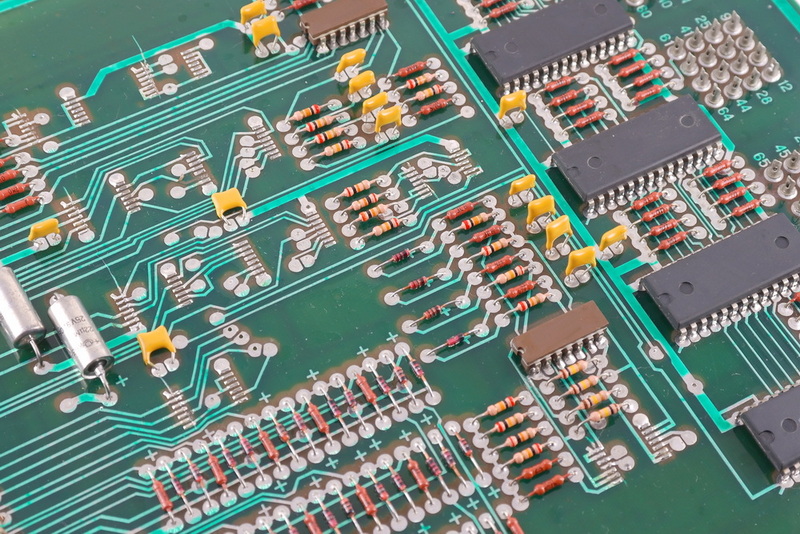

Before delving into the benefits of SMT, it's essential to understand the evolution of PCB assembly techniques. Traditionally, through-hole technology was the standard method for assembling electronic components on PCBs. This process involved inserting component leads through pre-drilled holes in the board and soldering them on the opposite side. While effective, THT had limitations in terms of component density, automation, and overall efficiency.

Enter Surface Mount Technology, a revolutionary approach that emerged in the 1980s. SMT involves placing components directly onto the surface of the PCB, eliminating the need for through-holes and enabling a more streamlined assembly process. This innovation has since become the cornerstone of modern electronics manufacturing.

Advantages of SMT in PCB Assembly

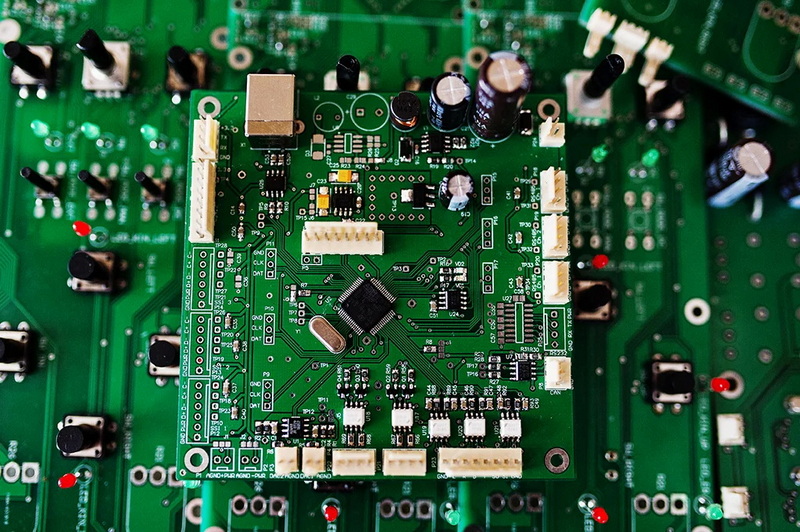

Miniaturization and Space Efficiency

One of the most significant advantages of SMT in PCB assembly is its ability to achieve higher component density[1]. SMT components are typically much smaller than their through-hole counterparts, often weighing just one-tenth of their THT equivalents[1]. This reduction in size allows for more components to be placed on a single board, resulting in smaller and lighter PCBs[3].

The compact nature of SMT components enables designers to create more sophisticated circuits within a limited space. This is particularly crucial in today's world, where consumer electronics are becoming increasingly smaller and more powerful. From smartphones to wearable devices, SMT has made it possible to pack advanced functionality into compact form factors.

Improved Performance and Reliability

SMT offers several performance benefits that make it superior to traditional assembly methods:

1. Enhanced Signal Integrity: The shorter signal paths enabled by SMT result in improved signal integrity[9]. This is particularly important for high-frequency applications where signal quality is paramount.

2. Lower Resistance and Inductance: SMT connections have lower resistance and inductance compared to through-hole connections[4]. This leads to better and more predictable high-frequency performance, making SMT ideal for modern high-speed electronic devices.

3. Better EMC Performance: The smaller package size and reduced lead inductance of SMT components contribute to improved electromagnetic compatibility (EMC) performance[4]. This means less radiated emissions and better overall electromagnetic interference (EMI) characteristics.

4. Increased Reliability: SMT assemblies are generally more robust and durable due to stronger solder joints and reduced risk of mechanical failure[5]. This increased reliability is crucial for applications in harsh environments or those requiring long-term operation.

Cost-Effectiveness and Production Efficiency

SMT has revolutionized the economics of electronics manufacturing:

1. Automated Assembly: SMT allows for highly automated production processes. Some placement machines can place over 136,000 components per hour[4], significantly reducing labor costs and increasing production speed.

2. Reduced Material Costs: The smaller size of SMT components and the elimination of through-holes result in reduced material usage and lower overall production costs[3].

3. Faster Time-to-Market: The efficiency of SMT assembly processes enables faster production cycles, allowing manufacturers to bring products to market more quickly[5].

4. Lower Setup Costs: SMT typically requires lower initial setup costs for mass production using automated equipment[4].

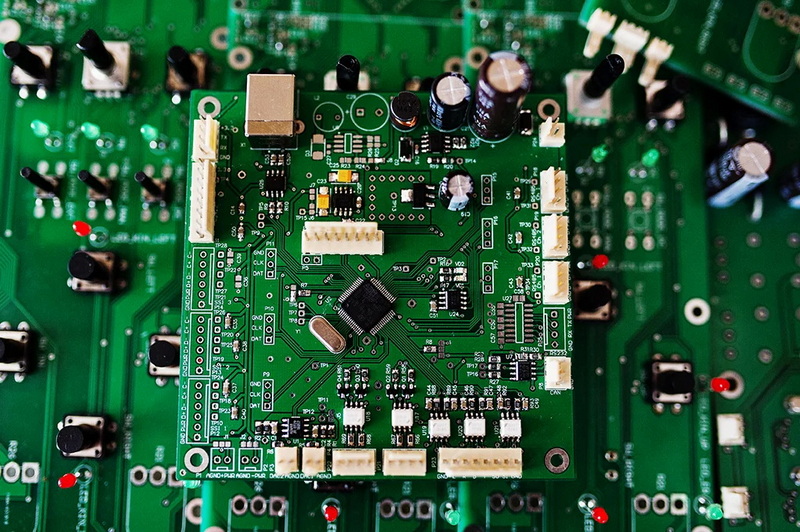

Versatility and Design Flexibility

SMT offers unparalleled versatility in PCB design and assembly:

1. Dual-Sided Assembly: Components can be placed on both sides of the PCB, maximizing board real estate and enabling more complex designs[4].

2. Wide Range of Component Types: SMT supports a diverse array of component types, from simple resistors and capacitors to complex microprocessors and BGAs (Ball Grid Arrays)[5].

3. Compatibility with Traditional Methods: SMT can coexist with through-hole technology on the same board, allowing designers to leverage the strengths of both methods when necessary[3].

Applications of SMT in Various Industries

The advantages of SMT have made it the preferred choice across numerous industries:

Consumer Electronics

The consumer electronics sector has perhaps benefited the most from SMT. Smartphones, tablets, laptops, and wearable devices all rely heavily on SMT for their compact and efficient designs[5]. The ability to create smaller, lighter, and more powerful devices has driven innovation in this space, leading to the smart devices we use daily.

Automotive Electronics

The automotive industry has embraced SMT for various applications, including:

- Advanced Driver-Assistance Systems (ADAS)

- Infotainment systems

- Engine Control Units (ECUs)

- Electric vehicle battery management systems

SMT's reliability and ability to withstand harsh environments make it ideal for automotive applications where performance and safety are critical[5].

Medical Devices

The medical industry leverages SMT for creating compact and reliable devices such as:

- Portable diagnostic tools

- Implantable medical devices

- Medical imaging equipment

- Patient monitoring systems

The small form factor and high reliability of SMT assemblies are particularly valuable in medical applications where space is limited and device failure is not an option[5].

Aerospace and Defense

SMT plays a crucial role in aerospace and defense applications, where weight reduction and reliability are paramount. Examples include:

- Avionics systems

- Satellite communications equipment

- Radar and sonar systems

- Missile guidance systems

The ability of SMT to produce lightweight, high-performance electronics is invaluable in these demanding applications.

Industrial Automation

The industrial sector benefits from SMT in various ways:

- Control systems for manufacturing equipment

- Sensors and data acquisition devices

- Robotic systems

- Industrial IoT devices

SMT's durability and compact design make it well-suited for the often harsh environments found in industrial settings[5].

Challenges and Considerations in SMT PCB Assembly

While SMT offers numerous advantages, it's important to consider some challenges associated with this technology:

Heat Management

The compact nature of SMT assemblies can lead to heat dissipation issues. Proper thermal management strategies, such as the use of heat sinks or thermal vias, may be necessary for high-power applications.

Rework and Repair

Reworking SMT assemblies can be more challenging than through-hole boards. Specialized equipment and skilled technicians are often required to replace or repair SMT components without damaging the PCB or adjacent parts.

Initial Investment

While SMT can lead to cost savings in the long run, the initial investment in equipment and training can be substantial. This may pose a challenge for smaller manufacturers or those with limited production volumes.

Design for Manufacturability (DFM)

SMT requires careful consideration of design for manufacturability principles. Factors such as component placement, solder pad design, and thermal management must be addressed during the design phase to ensure successful assembly[6].

The Future of SMT in PCB Assembly

As technology continues to advance, SMT is expected to evolve further:

Miniaturization Trends

The trend towards even smaller components and higher-density assemblies is likely to continue. This will drive innovations in SMT processes and equipment to handle increasingly miniature components.

Integration with Advanced Technologies

SMT is likely to be integrated with other advanced manufacturing technologies, such as 3D printing and flexible electronics, opening up new possibilities for electronic device design and production.

Sustainability and Environmental Considerations

As environmental concerns grow, the focus on sustainable manufacturing practices will increase. SMT may evolve to incorporate more eco-friendly materials and processes, such as lead-free solders and energy-efficient production methods.

Industry 4.0 and Smart Manufacturing

The integration of SMT with Industry 4.0 concepts, such as IoT and data analytics, will lead to smarter, more efficient production lines. This could result in further improvements in quality, speed, and cost-effectiveness.

Conclusion

Surface Mount Technology has undoubtedly revolutionized PCB assembly, offering numerous advantages over traditional through-hole methods. From enabling the creation of smaller, more powerful electronic devices to improving manufacturing efficiency and reducing costs, SMT has become the backbone of modern electronics production.

The benefits of SMT in terms of miniaturization, performance, reliability, and versatility make it the preferred choice across a wide range of industries, from consumer electronics to aerospace and defense. While challenges exist, ongoing advancements in SMT processes and equipment continue to address these issues, further solidifying its position as the dominant PCB assembly method.

As we look to the future, SMT is poised to evolve alongside other emerging technologies, driving innovation in electronics design and manufacturing. For businesses involved in electronics production, embracing SMT is not just a choice but a necessity to remain competitive in an increasingly technology-driven world.

FAQ

1. What is the main difference between SMT and through-hole technology?

Surface Mount Technology (SMT) involves placing components directly onto the surface of the PCB, while through-hole technology requires inserting component leads through pre-drilled holes in the board. SMT allows for smaller components, higher density, and more efficient automated assembly[4].

2. How does SMT improve PCB assembly efficiency?

SMT improves efficiency through automated placement of components, faster production times, and the ability to place components on both sides of the PCB. Some SMT placement machines can place over 136,000 components per hour, significantly reducing assembly time and labor costs[4].

3. Are there any disadvantages to using SMT for PCB assembly?

While SMT offers many advantages, it does have some challenges. These include potential heat management issues due to component density, more complex rework procedures, and a higher initial investment in equipment and training[9].

4. Can SMT and through-hole technology be used together on the same PCB?

Yes, SMT and through-hole technology can be used together on the same PCB. This approach, known as mixed technology, allows designers to leverage the strengths of both methods when necessary, such as using through-hole for components that require higher mechanical strength[3].

5. How has SMT impacted the development of modern electronic devices?

SMT has enabled the creation of smaller, lighter, and more powerful electronic devices. It has been crucial in the development of compact consumer electronics like smartphones and wearables, as well as advanced systems in automotive, medical, and aerospace industries. SMT's ability to achieve high component density and improved performance has been a key driver of innovation in electronics[5].

Citations:

[1] https://levisonenterprises.com/5-advantages-to-using-smt/

[2] https://www.wevolver.com/article/smt-vs-smd-vs-tht-a-comprehensive-guide-to-electronics-assembly-techniques

[3] https://www.sonicmfg.com/what-are-the-advantages-of-surface-mount-technology-in-pcba/

[4] https://en.wikipedia.org/wiki/Surface_mount

[5] https://www.zetwerk.com/resources/knowledge-base/electronics-manufacturing-services-ems/smt-pcb-assembly-processes-benefits-and-applications/

[6] https://www.macrofab.com/blog/smt-assembly-vs-through-hole/

[7] https://geospacemfg.com/blog/smt-assembly-technology/

[8] https://www.wevolver.com/article/through-hole-vs-surface-mount-unveiling-the-optimal-pcb-assembly-technique

[9] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/