Content Menu

● Understanding EMS and PCB Assembly

>> What is EMS?

>> What is PCB Assembly?

● The EMS PCB Assembly Process

>> 1. PCB Fabrication

>> 2. Component Placement

>> 3. Soldering

>> 4. Testing and Quality Assurance

● Benefits of Choosing EMS for PCB Assembly

>> 1. Cost-Effectiveness

>> 2. Access to Advanced Technology and Expertise

>> 3. Flexibility and Scalability

>> 4. Reduced Lead Times

>> 5. Enhanced Quality Control

>> 6. Focus on Core Competencies

>> 7. Supply Chain Management

>> 8. Comprehensive Services

>> 9. Regulatory Compliance

>> 10. Risk Mitigation

● Choosing the Right EMS Provider

>> Technical Capabilities

>> Quality Certifications

>> Capacity and Scalability

>> Communication and Transparency

>> Financial Stability

● The Future of EMS in PCB Assembly

>> Increased Automation

>> Industry 4.0 Integration

>> Sustainability Focus

>> Customization and Flexibility

● Conclusion

● FAQ

>> 1. What is the difference between SMT and THT in PCB assembly?

>> 2. How does EMS help with supply chain management in PCB assembly?

>> 3. What quality standards are typically followed in EMS PCB assembly?

>> 4. How does EMS contribute to reducing time-to-market for new electronic products?

>> 5. What are the environmental considerations in EMS PCB assembly?

● Citations:

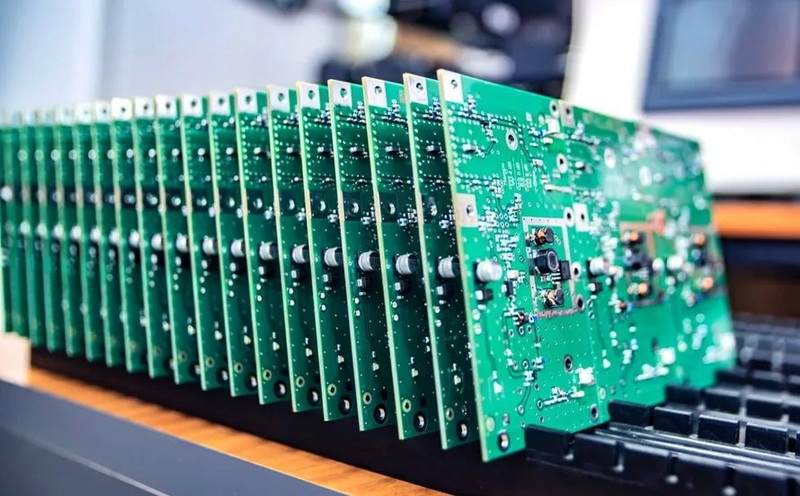

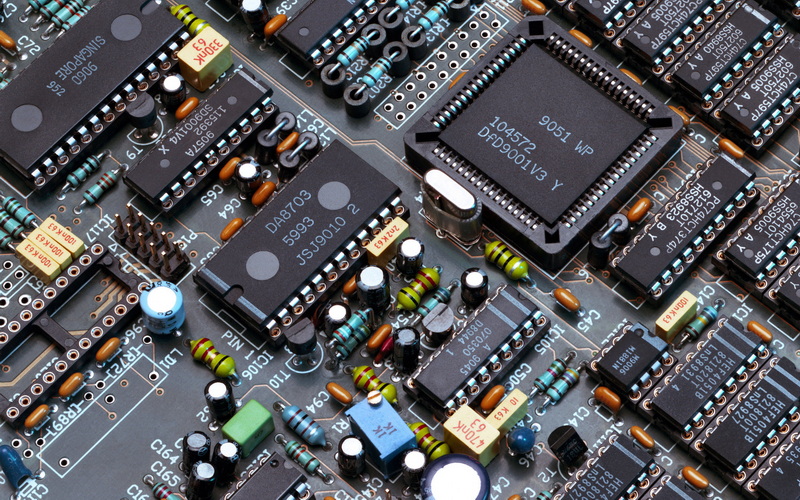

In today's rapidly evolving electronics industry, the demand for high-quality, efficient, and cost-effective PCB assembly solutions has never been greater. Electronic Manufacturing Services (EMS) providers have emerged as key players in meeting these demands, offering a wide range of benefits for companies looking to streamline their PCB assembly processes. This article will explore the numerous advantages of choosing EMS for your PCB assembly needs, delving into the intricacies of the EMS process and highlighting why it has become an indispensable part of the electronics manufacturing landscape.

Understanding EMS and PCB Assembly

Before we dive into the benefits of EMS for PCB assembly, it's essential to understand what these terms mean and how they relate to each other.

What is EMS?

Electronic Manufacturing Services (EMS) refers to a comprehensive range of services provided by specialized companies to design, manufacture, test, and distribute electronic components and assemblies[2]. EMS providers offer a one-stop solution for companies looking to outsource their electronics manufacturing needs, allowing them to focus on their core competencies such as product design and marketing.

What is PCB Assembly?

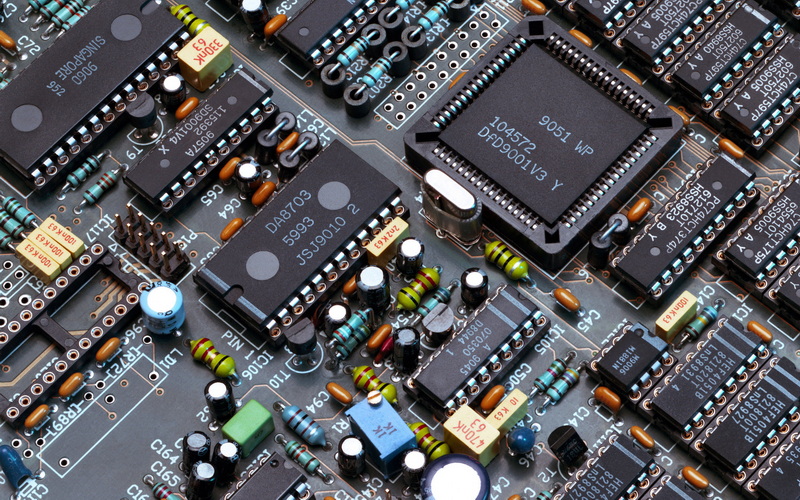

Printed Circuit Board (PCB) assembly is a crucial part of the electronics manufacturing process. It involves placing and soldering electronic components onto printed circuit boards[2]. This process adheres to strict industry standards, such as the IPC-A-610 standard, to ensure quality and reliability.

The EMS PCB Assembly Process

The EMS PCB assembly process is a complex and multi-faceted operation that involves several key steps:

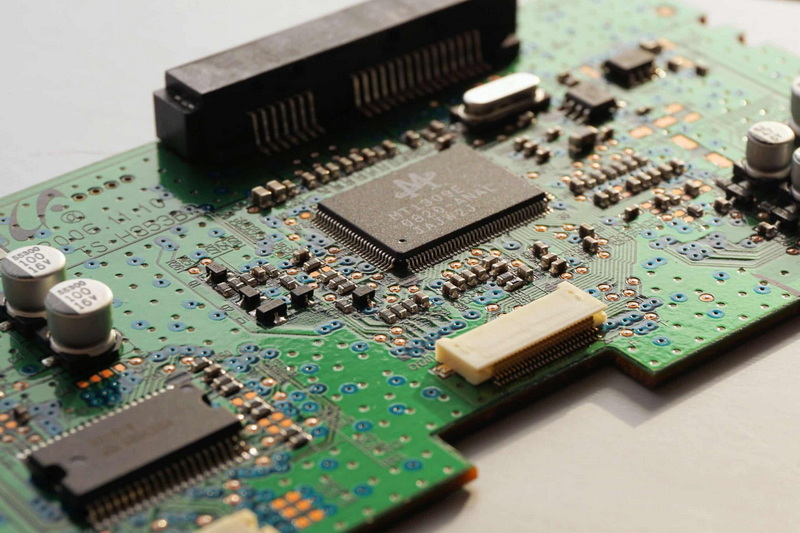

1. PCB Fabrication

The process begins with PCB fabrication, where the bare circuit boards are manufactured based on the design specifications[6]. This involves etching copper layers, drilling holes for component leads, and applying solder mask and silkscreen.

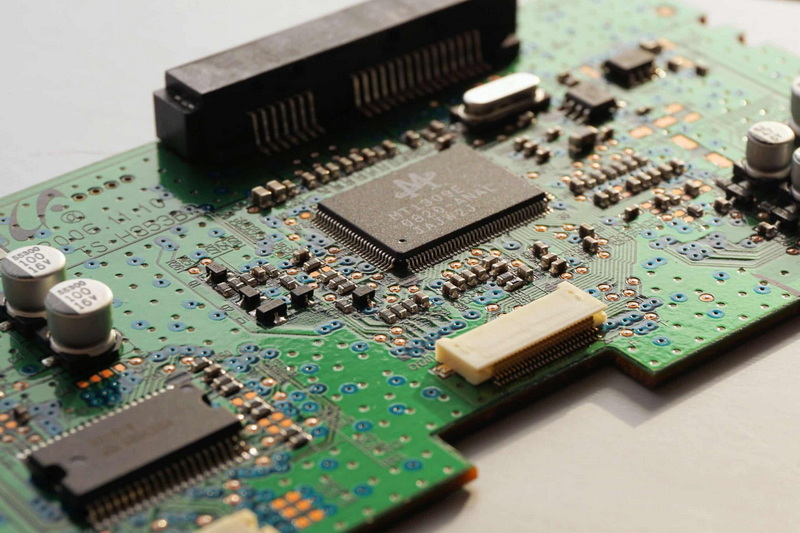

2. Component Placement

Once the PCBs are fabricated, the next step is to place the electronic components onto the board. This is typically done using two main techniques:

- Surface Mount Technology (SMT): SMT involves mounting electronic components directly onto the PCB surface, allowing for higher component density and smaller PCB sizes[2].

- Through-Hole Technology (THT): In THT, component leads are inserted into holes drilled in the PCB and soldered to pads on the opposite side, providing strong mechanical bonds[2].

3. Soldering

After component placement, the boards undergo a soldering process to secure the components and create electrical connections. EMS providers use advanced soldering techniques to ensure high-quality connections[5].

4. Testing and Quality Assurance

Once assembly is complete, the PCBs undergo rigorous testing and quality assurance procedures to ensure they meet the required specifications and performance standards[6].

Benefits of Choosing EMS for PCB Assembly

Now that we understand the EMS PCB assembly process, let's explore the numerous benefits of choosing an EMS provider for your PCB assembly needs.

1. Cost-Effectiveness

One of the primary advantages of outsourcing PCB assembly to an EMS provider is cost-effectiveness. EMS companies can achieve economies of scale by handling large volumes of PCB assembly projects, which translates to lower costs for their clients[5]. By outsourcing, companies can save on equipment, labor, and other costs associated with in-house assembly[1].

2. Access to Advanced Technology and Expertise

EMS providers invest heavily in state-of-the-art equipment and technologies to stay competitive in the market. By choosing an EMS for your PCB assembly needs, you gain access to these advanced technologies without having to make significant capital investments yourself[6]. Moreover, EMS companies employ skilled professionals with extensive experience in PCB assembly, ensuring high-quality results[1].

3. Flexibility and Scalability

EMS providers offer flexible production capabilities, allowing them to handle different manufacturing volumes and PCB assembly services according to the demands of various clients in different manufacturing stages[1]. This scalability is particularly beneficial for companies with fluctuating production needs or those looking to expand their operations.

4. Reduced Lead Times

Outsourcing PCB assembly to an EMS provider can significantly reduce lead times. EMS companies have optimized processes, larger staff, and additional workspace, allowing them to complete projects more quickly than many in-house operations[3].

5. Enhanced Quality Control

Reliable EMS manufacturers have rigorous quality management systems and operation codes in place to ensure the highest standards of PCB assembly quality[1]. Many EMS providers implement multiple quality checks throughout the assembly process, including automated optical inspection (AOI) and X-ray inspection, to detect and correct any issues before the final product is delivered.

6. Focus on Core Competencies

By outsourcing PCB assembly to an EMS provider, companies can focus on their core competencies, such as product design, innovation, and marketing. This allows for more efficient use of internal resources and can lead to improved overall business performance[2].

7. Supply Chain Management

EMS providers often have established relationships with component suppliers and can leverage these connections to manage supply chain challenges effectively. This can include handling issues such as component shortages, obsolescence, and price fluctuations[5].

8. Comprehensive Services

Many EMS providers offer a wide range of services beyond just PCB assembly. These can include design assistance, prototyping, testing, and even full box-build assembly. This comprehensive approach can streamline the entire product development and manufacturing process[5].

9. Regulatory Compliance

EMS providers are well-versed in industry standards and regulatory requirements. They can ensure that your PCB assemblies comply with relevant regulations and certifications, such as RoHS (Restriction of Hazardous Substances) and UL (Underwriters Laboratories) standards[6].

10. Risk Mitigation

Outsourcing PCB assembly to an EMS provider can help mitigate various risks associated with electronics manufacturing. This includes risks related to equipment failure, workforce management, and quality control issues[3].

Choosing the Right EMS Provider

While the benefits of EMS for PCB assembly are clear, it's crucial to select the right EMS provider to maximize these advantages. Here are some factors to consider when choosing an EMS partner:

Technical Capabilities

Ensure that the EMS provider has the technical capabilities and expertise to meet your specific manufacturing needs. This includes the ability to manufacture complex PCBs, perform advanced assembly techniques, and conduct rigorous testing and quality assurance[6].

Quality Certifications

Look for EMS providers that hold relevant quality certifications, such as ISO 9001, ISO 13485 for medical devices, or AS9100 for aerospace applications. These certifications demonstrate a commitment to quality and adherence to industry standards[6].

Capacity and Scalability

Consider the EMS provider's production capacity and their ability to scale operations to meet your current and future needs. A good EMS partner should be able to handle both low-volume, high-mix production and high-volume orders[5].

Communication and Transparency

Effective communication is crucial in any outsourcing relationship. Choose an EMS provider that offers clear, transparent communication and is responsive to your needs and concerns[5].

Financial Stability

Assess the financial stability of potential EMS partners. A financially stable EMS provider is more likely to be a reliable long-term partner and less likely to face disruptions that could affect your supply chain[6].

The Future of EMS in PCB Assembly

As technology continues to advance, the role of EMS in PCB assembly is likely to become even more critical. Some trends shaping the future of EMS include:

Increased Automation

EMS providers are increasingly adopting advanced automation technologies, including robotics and artificial intelligence, to improve efficiency and precision in PCB assembly[6].

Industry 4.0 Integration

The integration of Industry 4.0 concepts, such as the Internet of Things (IoT) and big data analytics, is enabling EMS providers to offer more intelligent and connected manufacturing solutions[6].

Sustainability Focus

With growing environmental concerns, EMS providers are placing a greater emphasis on sustainable manufacturing practices, including the use of eco-friendly materials and energy-efficient processes[6].

Customization and Flexibility

As product lifecycles shorten and demand for customized electronics grows, EMS providers are developing more flexible manufacturing capabilities to meet these changing needs[5].

Conclusion

Choosing EMS for your PCB assembly needs offers a multitude of benefits, from cost savings and access to advanced technologies to enhanced quality control and supply chain management. By partnering with a reputable EMS provider, companies can streamline their manufacturing processes, reduce time-to-market, and focus on their core competencies.

As the electronics industry continues to evolve, the role of EMS in PCB assembly is set to become even more crucial. By leveraging the expertise and capabilities of EMS providers, companies can stay competitive in an increasingly complex and fast-paced market.

Whether you're a startup looking to bring your first product to market or an established company seeking to optimize your manufacturing processes, EMS offers a flexible, efficient, and cost-effective solution for your PCB assembly needs. By carefully selecting the right EMS partner and building a strong collaborative relationship, you can unlock the full potential of your electronic products and drive your business forward in the digital age.

FAQ

1. What is the difference between SMT and THT in PCB assembly?

Surface Mount Technology (SMT) and Through-Hole Technology (THT) are two different methods used in PCB assembly. SMT involves mounting components directly onto the surface of the PCB, allowing for higher component density and smaller board sizes. THT, on the other hand, involves inserting component leads into holes drilled in the PCB and soldering them on the opposite side. THT provides stronger mechanical bonds and is often used for larger components or those that need to withstand physical stress[2].

2. How does EMS help with supply chain management in PCB assembly?

EMS providers play a crucial role in supply chain management for PCB assembly. They often have established relationships with component suppliers and can leverage these connections to manage supply chain challenges effectively. This includes handling issues such as component shortages, obsolescence, and price fluctuations. EMS providers can also help with inventory management, forecasting, and logistics, ensuring a smooth and efficient supply chain for their clients[5].

3. What quality standards are typically followed in EMS PCB assembly?

EMS providers adhere to various quality standards in PCB assembly to ensure high-quality and reliable products. Some of the key standards include:

- IPC-A-610: A set of acceptability criteria for electronic assemblies

- ISO 9001: A standard for quality management systems

- ISO 13485: A standard specifically for medical device quality management systems

- AS9100: A quality standard for the aerospace industry

These standards help ensure that PCB assemblies meet rigorous quality and reliability requirements[6].

4. How does EMS contribute to reducing time-to-market for new electronic products?

EMS providers help reduce time-to-market for new electronic products in several ways:

1. They have optimized processes and advanced equipment that can speed up PCB assembly.

2. Many EMS providers offer design for manufacturability (DFM) services, which can help identify and resolve potential manufacturing issues early in the design process.

3. EMS companies often have prototyping capabilities, allowing for quick iterations and testing of new designs.

4. By handling the manufacturing process, EMS providers allow their clients to focus on product development and marketing, potentially speeding up the overall product launch process[3].

5. What are the environmental considerations in EMS PCB assembly?

Environmental considerations are becoming increasingly important in EMS PCB assembly. Many EMS providers are adopting sustainable practices, including:

- Using lead-free solder in compliance with RoHS regulations

- Implementing energy-efficient manufacturing processes

- Adopting proper waste management and recycling practices

- Using eco-friendly materials where possible

- Offering services for the proper disposal or recycling of electronic waste

These practices help reduce the environmental impact of PCB assembly and contribute to more sustainable electronics manufacturing[6].

Citations:

[1] https://www.pcbonline.com/blog/oem-pcb-assembly.html

[2] https://www.wevolver.com/article/what-is-electronics-manufacturing

[3] https://vinatronic.com/blog/benefits-of-outsourcing-pcb-assembly/

[4] https://essc-india.org/participant-handook/English/EMS%20Operation%20and%20Maintenance%20Manager.pdf

[5] https://asselems.com/en/the-biggest-benefits-of-outsourcing-pcb-assembly

[6] https://www.rowsum.com/electronics-manufacturing-services-explained-from-basics-to-global-trends/

[7] https://www.pcbjhy.com/blog/understanding-ems-pcb-assembly/

[8] https://www.myemssolutions.com/news/