Content Menu

● Understanding SMT Lines

● Key Benefits of SMT Lines

>> 1. Increased Production Speed

>> 2. Improved Consistency and Precision

>> 3. Cost Efficiency

>> 4. Scalability

>> 5. Compact Design Capabilities

● Applications of SMT Lines

>> Consumer Electronics

>> Automotive Industry

>> Medical Devices

>> Telecommunications

● Market Trends Driving Demand for SMT Lines

>> 1. Miniaturization of Electronic Devices

>> 2. Growth in Consumer Electronics

>> 3. Advancements in Automotive Electronics

>> 4. Expansion of IoT Applications

● Challenges Facing SMT Line Adoption

● Future Prospects of SMT Lines

● Conclusion

● FAQ

>> 1. What is an SMT line?

>> 2. Why are SMT lines important for electronics manufacturing?

>> 3. How much does an SMT line cost?

>> 4. What industries benefit from using SMT technology?

>> 5. What future trends should we expect in the SMT market?

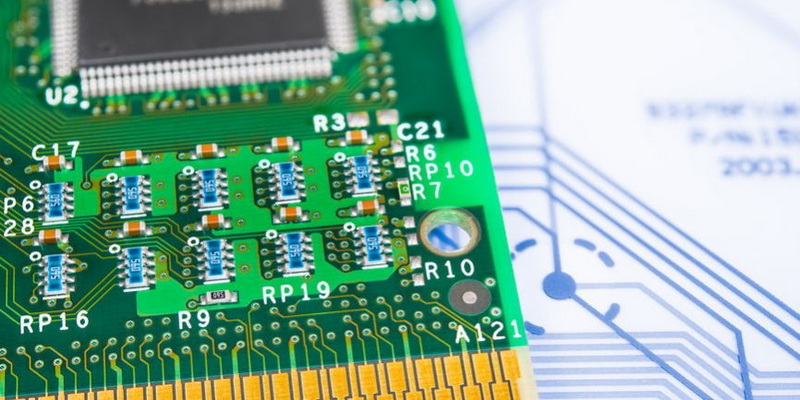

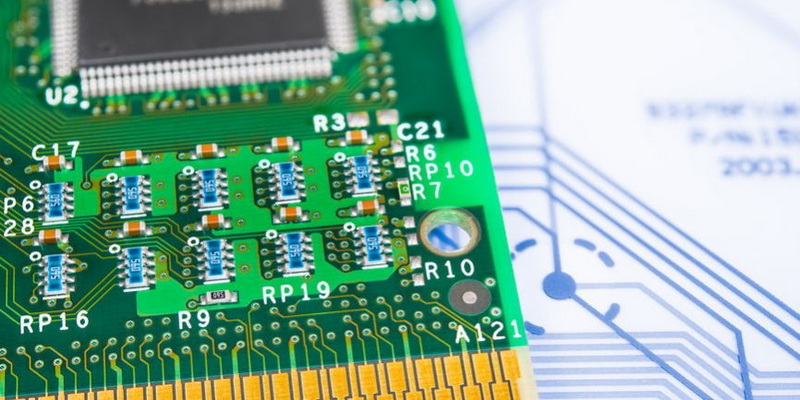

Surface Mount Technology (SMT) lines have become a cornerstone of modern electronics manufacturing, driving the production of compact, efficient, and high-performance electronic devices. As industries evolve and consumer demands shift, the need for advanced SMT lines is more pronounced than ever. This article delves into the reasons behind the growing demand for SMT lines, exploring their benefits, applications, market trends, and future prospects.

Understanding SMT Lines

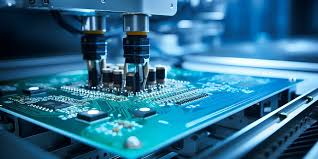

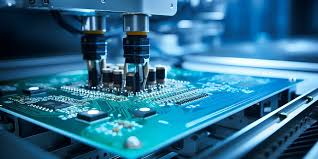

An SMT line refers to a fully automated production system designed to assemble surface mount devices (SMDs) onto printed circuit boards (PCBs). This technology has revolutionized the electronics manufacturing landscape by enabling rapid and precise assembly of components. The SMT process involves several key steps:

- Solder Paste Printing: Applying solder paste to the PCB.

- Component Placement: Automated machines place components onto the soldered areas.

- Reflow Soldering: Heating the PCB to melt the solder and secure the components.

- Inspection: Automated Optical Inspection (AOI) checks for defects.

- Testing: Functional tests ensure the assembled PCB meets specifications.

Key Benefits of SMT Lines

The increasing demand for SMT lines can be attributed to several compelling advantages:

1. Increased Production Speed

SMT lines can achieve assembly speeds exceeding 15,000 components per hour. This high throughput allows manufacturers to meet rising consumer demands swiftly and efficiently, significantly reducing time-to-market for new products. In industries where product life cycles are short, such as consumer electronics, this speed is crucial.

2. Improved Consistency and Precision

Automation in SMT lines ensures consistent component placement with precision down to 0.05mm. This level of accuracy minimizes defects and enhances product reliability, which is crucial in sectors like automotive and medical devices where quality is paramount. The use of advanced vision systems further enhances inspection capabilities, allowing for real-time adjustments during production.

3. Cost Efficiency

While the initial investment in SMT equipment can be substantial—ranging from $500,000 for basic setups to over $5 million for advanced systems—the long-term savings through reduced labor costs and increased production efficiency often outweigh these costs. Automated processes reduce reliance on manual labor, leading to lower operational expenses. Additionally, reduced material waste during the assembly process contributes to overall cost savings.

4. Scalability

SMT lines offer flexibility that allows manufacturers to scale production up or down based on market demand. This adaptability is essential in today's fast-paced market where consumer preferences can change rapidly. Manufacturers can easily switch between different product models without significant downtime or reconfiguration.

5. Compact Design Capabilities

As electronic devices become smaller and more complex, SMT technology allows for higher component density on PCBs. This capability is vital for producing compact devices such as smartphones, wearables, and IoT gadgets. The ability to place components on both sides of a PCB further maximizes space utilization.

Applications of SMT Lines

The versatility of SMT technology enables its application across various industries:

Consumer Electronics

In consumer electronics, SMT lines are employed to manufacture a wide range of products including smartphones, tablets, laptops, and gaming consoles. The high demand for these devices drives continuous investment in advanced SMT lines capable of handling intricate designs and high volumes.

Automotive Industry

The automotive sector increasingly relies on SMT technology for manufacturing electronic control units (ECUs), sensors, and infotainment systems. As vehicles incorporate more electronics for safety and convenience features, the demand for reliable SMT lines has surged.

Medical Devices

In the medical field, precision is critical. SMT lines are used to produce devices such as pacemakers, diagnostic equipment, and imaging systems where reliability and accuracy are non-negotiable.

Telecommunications

Telecommunication equipment such as routers, switches, and base stations benefit from SMT technology due to its ability to produce high-density boards that support advanced connectivity features.

Market Trends Driving Demand for SMT Lines

The global market for SMT equipment is projected to grow significantly in the coming years. Several trends are contributing to this growth:

1. Miniaturization of Electronic Devices

The trend towards smaller devices necessitates advanced manufacturing techniques like SMT that can accommodate high-density components. As consumers increasingly favor portable electronics, manufacturers must invest in SMT lines to keep up with these demands.

2. Growth in Consumer Electronics

The rise of smart devices—such as smartphones, tablets, and smart home appliances—has led to an uptick in demand for SMT lines capable of producing these complex products efficiently. The consumer electronics segment accounted for a significant share of the SMT market in recent years.

3. Advancements in Automotive Electronics

With vehicles becoming more technologically advanced—incorporating features like advanced driver-assistance systems (ADAS)—the automotive industry is increasingly relying on SMT technology for reliable electronic components. The integration of electric vehicles (EVs) into the market further amplifies this trend due to their reliance on sophisticated electronic systems.

4. Expansion of IoT Applications

The proliferation of Internet of Things (IoT) devices requires efficient manufacturing processes that can handle a variety of small-scale electronics. SMT lines are well-suited for this purpose due to their flexibility and speed. As IoT applications expand across sectors such as healthcare, agriculture, and smart cities, the demand for capable SMT lines will continue to rise.

Challenges Facing SMT Line Adoption

Despite their numerous advantages, adopting SMT lines also comes with challenges:

- High Initial Investment: The cost associated with setting up an advanced SMT line can deter smaller manufacturers from making the leap.

- Skill Gap: Operating sophisticated SMT machinery requires skilled personnel who understand both electronics and automation technologies.

- Maintenance Costs: While automated systems reduce labor costs, they require regular maintenance and occasional upgrades that can be costly.

Future Prospects of SMT Lines

Looking ahead, several factors will continue to influence the demand for SMT lines:

- Technological Advancements: Innovations in automation, artificial intelligence (AI), and machine learning will enhance the capabilities of SMT lines, making them even more efficient and adaptable.

- Sustainability Initiatives: As environmental concerns grow, manufacturers are seeking eco-friendly practices within their production processes. SMT technology can contribute by minimizing waste and energy consumption during assembly.

- Increased Competition: As more companies enter the electronics market, maintaining a competitive edge through efficient production methods will drive further investment in advanced SMT solutions.

- Emerging Markets: Developing regions are witnessing a surge in electronics manufacturing due to lower labor costs and increasing local demand for electronic products. These markets present new opportunities for suppliers of SMT equipment.

Conclusion

The demand for SMT lines is set to continue its upward trajectory as industries adapt to changing consumer needs and technological advancements. The benefits of speed, precision, cost efficiency, scalability, and compact design capabilities make SMT lines indispensable in modern electronics manufacturing. Companies looking to thrive in this competitive landscape must consider investing in high-quality SMT solutions that align with their production goals.

FAQ

1. What is an SMT line?

An SMT line is an automated production system used to assemble surface mount devices onto printed circuit boards through various processes including solder paste printing, component placement, reflow soldering, inspection, and testing.

2. Why are SMT lines important for electronics manufacturing?

SMT lines enhance production speed and precision while reducing labor costs and improving product quality, making them essential for meeting modern consumer demands.

3. How much does an SMT line cost?

The cost of an SMT line varies widely based on its complexity and capabilities; basic setups may start around $500,000 while advanced systems can exceed $5 million.

4. What industries benefit from using SMT technology?

Industries such as consumer electronics, automotive electronics, telecommunications, healthcare devices, and industrial equipment all benefit from the efficiency and precision offered by SMT technology.

5. What future trends should we expect in the SMT market?

Future trends include increased automation through AI integration, a focus on sustainability practices within manufacturing processes, continued miniaturization of electronic components, and growth in emerging markets.