Content Menu

● Introduction

● Understanding SMT Devices

>> Key Characteristics of SMT Devices

● Advantages of Using SMT Devices

>> Space Efficiency

>> Enhanced Reliability

>> Cost-Effectiveness

>> Improved Electrical Performance

>> Flexibility in Design

● Applications of SMT Devices

>> Consumer Electronics

>> Automotive Industry

>> Medical Devices

>> Industrial Automation

● Future Trends in SMT Technology

>> Miniaturization

>> Increased Integration

>> Advanced Materials

>> Sustainability

>> Smart Technologies

● Conclusion

● FAQ

>> 1. What are the main benefits of using SMT devices?

>> 2. How do SMT devices differ from through-hole components?

>> 3. In which industries are SMT devices commonly used?

>> 4. What trends are shaping the future of SMT technology?

>> 5. Are there any challenges associated with using SMT technology?

Introduction

Surface Mount Technology (SMT) has revolutionized the electronics industry, enabling the production of compact, efficient, and reliable electronic devices. As technology continues to advance, the demand for smaller and more powerful electronic components has surged. SMT devices have become essential in meeting these demands, providing numerous advantages over traditional through-hole components. This article explores the significance of SMT devices in modern electronics, their benefits, applications, and future trends.

Understanding SMT Devices

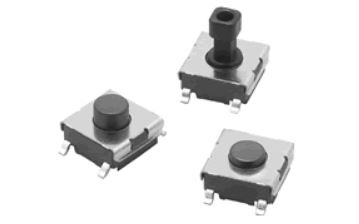

SMT devices are electronic components that are mounted directly onto the surface of printed circuit boards (PCBs). Unlike traditional components that require holes to be drilled into the PCB for mounting, SMT devices are soldered onto pads on the surface. This method allows for a more compact design, which is crucial in today's technology-driven world where space is at a premium.

Key Characteristics of SMT Devices

- Size and Weight: SMT devices are typically smaller and lighter than their through-hole counterparts. This reduction in size allows for more components to be placed on a single PCB, facilitating miniaturization of electronic products.

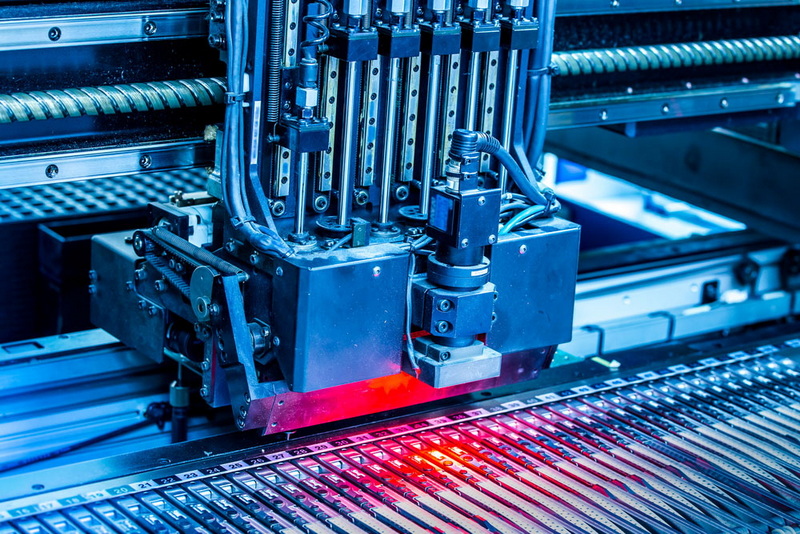

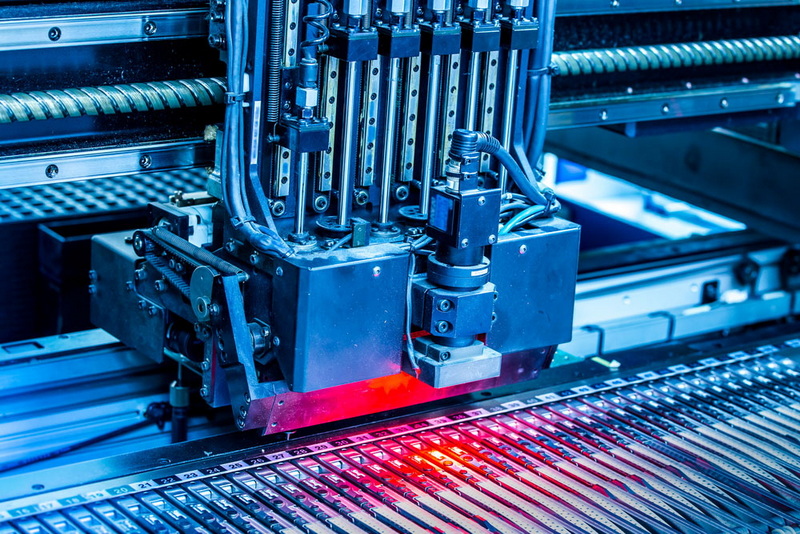

- Automated Assembly: The manufacturing process for SMT devices can be highly automated. Machines can place thousands of components per hour with precision, significantly speeding up production times and reducing labor costs.

- Performance: SMT devices often have better electrical performance due to shorter lead lengths and reduced parasitic inductance and capacitance. This leads to improved signal integrity and higher frequency performance.

Advantages of Using SMT Devices

The adoption of SMT devices offers several advantages that make them indispensable in modern electronics:

Space Efficiency

As consumer electronics become increasingly compact, the need for space-efficient components has grown. SMT devices occupy less board space compared to traditional components, allowing designers to create smaller products without sacrificing functionality.

Enhanced Reliability

SMT devices are generally more reliable than through-hole components. Their lower profile reduces mechanical stress during thermal cycling and vibration, which can lead to failures in traditional components. Additionally, the soldering process used in SMT creates a stronger bond between the component and the PCB.

Cost-Effectiveness

While the initial investment in SMT manufacturing equipment can be high, the long-term cost savings are significant. Automated assembly reduces labor costs and increases production speed. Furthermore, the ability to fit more components on a PCB can lead to savings in materials and shipping.

Improved Electrical Performance

The design of SMT devices allows for shorter connections between components, resulting in lower resistance and inductance. This improved electrical performance is particularly important for high-frequency applications such as telecommunications and computer systems.

Flexibility in Design

SMT technology provides engineers with greater flexibility in circuit design. The variety of available SMT packages allows for innovative layouts and configurations that can optimize performance while minimizing size.

Applications of SMT Devices

SMT devices are used across a wide range of industries due to their versatility and performance advantages:

Consumer Electronics

From smartphones to laptops, consumer electronics heavily rely on SMT technology. The compact size of SMT devices allows manufacturers to create sleek designs without compromising on features or performance.

Automotive Industry

The automotive sector has increasingly adopted SMT devices for various applications, including engine control units (ECUs), infotainment systems, and safety features like airbags and anti-lock braking systems (ABS). The reliability and performance of SMT devices are critical in ensuring vehicle safety and efficiency.

Medical Devices

In the medical field, precision is paramount. SMT devices are used in diagnostic equipment, monitoring systems, and implantable devices due to their reliability and compactness. The ability to integrate multiple functions into a small footprint is especially valuable in medical applications.

Industrial Automation

SMT technology plays a vital role in industrial automation systems where space constraints and reliability are crucial. Devices such as sensors, controllers, and communication modules utilize SMT technology to enhance performance while maintaining compact designs.

Future Trends in SMT Technology

As technology continues to evolve, so too does the field of surface mount technology. Several trends are shaping the future of SMT devices:

Miniaturization

The trend toward miniaturization is likely to continue as consumer demand for smaller electronic products grows. Innovations in materials science and manufacturing techniques will enable even smaller SMT packages without sacrificing performance.

Increased Integration

Future SMT devices will likely see increased integration of multiple functions into single packages. This trend will simplify designs and reduce assembly time while enhancing overall system performance.

Advanced Materials

Research into new materials will drive improvements in thermal management, electrical performance, and reliability of SMT devices. Advanced materials can help address challenges associated with high-density packaging and heat dissipation.

Sustainability

As sustainability becomes a priority across industries, there will be a push towards environmentally friendly manufacturing processes for SMT devices. This includes using recyclable materials and reducing waste during production.

Smart Technologies

The rise of smart technologies will further drive innovation in SMT design. As IoT (Internet of Things) applications expand, there will be an increasing need for compact sensors and communication modules that leverage SMT technology.

Conclusion

In conclusion, surface mount technology has become an integral part of modern electronics due to its numerous advantages over traditional component mounting methods. The ability to produce smaller, lighter, and more reliable electronic devices has made SMT essential across various industries including consumer electronics, automotive, medical devices, and industrial automation. As technology continues to advance, so too will the capabilities of SMT devices, ensuring they remain at the forefront of electronic design innovation.

FAQ

1. What are the main benefits of using SMT devices?

SMT devices offer benefits such as space efficiency, enhanced reliability, cost-effectiveness through automated assembly processes, improved electrical performance due to shorter connections, and greater flexibility in circuit design.

2. How do SMT devices differ from through-hole components?

SMT devices are mounted directly on the surface of PCBs without requiring drilled holes, making them smaller and allowing for higher component density compared to through-hole components which require insertion into holes on the PCB.

3. In which industries are SMT devices commonly used?

SMT devices are widely used across various industries including consumer electronics (smartphones, laptops), automotive (engine control units), medical (diagnostic equipment), and industrial automation (sensors).

4. What trends are shaping the future of SMT technology?

Future trends include continued miniaturization of components, increased integration of functions into single packages, advancements in materials for better performance, sustainability efforts in manufacturing processes, and innovations driven by smart technologies like IoT.

5. Are there any challenges associated with using SMT technology?

Challenges include managing thermal dissipation due to higher component density, ensuring reliable solder joints during assembly processes, handling potential issues with component placement accuracy during manufacturing, and addressing environmental concerns related to e-waste from obsolete electronic products.