Content Menu

● Understanding SMT Components

>> Types of SMT Components

● Advantages of SMT Components

>> 1. Miniaturization

>> 2. Increased Component Density

>> 3. Improved Performance

>> 4. Cost Efficiency

>> 5. Enhanced Reliability

● Applications of SMT Components

>> Consumer Electronics

>> Automotive Industry

>> Medical Devices

>> Telecommunications

● The Evolution of Surface Mount Technology

● Future Trends in SMT Technology

>> 1. Increased Automation

>> 2. Advanced Materials

>> 3. Sustainability

>> 4. Internet of Things (IoT)

● Challenges Facing the SMT Industry

● Conclusion

● FAQ

>> 1. What are the main advantages of using SMT over through-hole technology?

>> 2. What types of products commonly use SMT components?

>> 3. How do I choose between different types of SMT components?

>> 4. Are there any disadvantages associated with using SMT?

>> 5. What future trends should I be aware of regarding SMT technology?

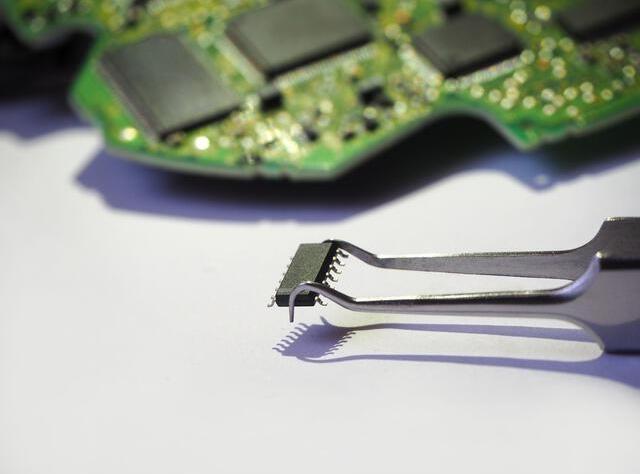

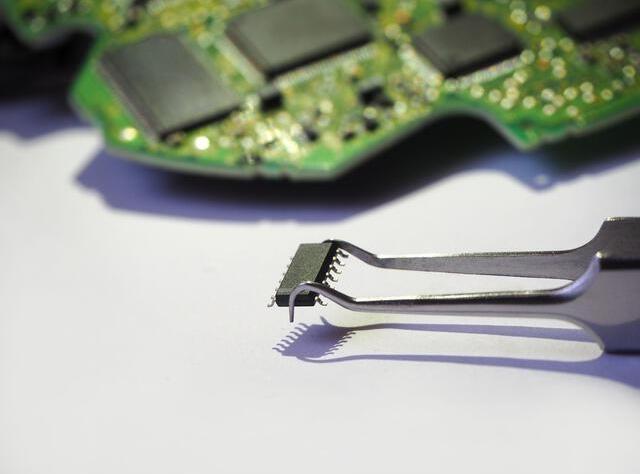

Surface Mount Technology (SMT) components have become indispensable in the realm of modern electronics. As the demand for smaller, more efficient, and more powerful electronic devices increases, SMT components have emerged as a key solution to meet these needs. This article delves into the significance of SMT components, their advantages, applications, and the future of electronics design.

Understanding SMT Components

SMT components are electronic parts that are mounted directly onto the surface of printed circuit boards (PCBs). Unlike traditional through-hole components, which require holes to be drilled into the PCB, SMT components are soldered onto pads on the surface. This technology has revolutionized the way electronic devices are designed and manufactured.

Types of SMT Components

The SMT components list includes a variety of parts essential for various applications:

- Resistors: Used to limit current flow.

- Capacitors: Store electrical energy temporarily.

- Inductors: Store energy in a magnetic field.

- Diodes: Allow current to flow in one direction only.

- Transistors: Act as switches or amplifiers.

- Integrated Circuits (ICs): Pack multiple functions into a single chip.

- Connectors: Facilitate connections between different parts of a circuit.

Advantages of SMT Components

The adoption of SMT components offers numerous benefits that contribute to their critical role in modern electronics.

1. Miniaturization

One of the most significant advantages of SMT is the ability to create smaller devices. As consumer demand for compact and portable electronics grows, manufacturers can utilize SMT components to reduce the size and weight of products without compromising performance. This miniaturization is crucial for devices like smartphones, tablets, and wearables. For instance, the latest smartphones incorporate multiple functionalities such as high-resolution cameras, advanced processors, and large batteries—all made possible through the use of compact SMT components.

2. Increased Component Density

SMT allows for a higher density of components on a PCB. With smaller sizes and the ability to place components on both sides of the board, designers can fit more functionality into a smaller area. This increased density is vital for complex devices that require numerous functionalities in limited space. For example, modern laptops can integrate powerful CPUs, GPUs, and extensive memory configurations without increasing their physical footprint due to effective component placement enabled by SMT.

3. Improved Performance

SMT components typically exhibit better electrical performance compared to their through-hole counterparts. The shorter lead lengths reduce inductance and resistance, resulting in faster signal transmission and improved overall efficiency. This enhancement is particularly important in high-frequency applications such as telecommunications and high-speed computing. In applications like 5G technology, where speed and reliability are paramount, the benefits of using SMT are clearly evident.

4. Cost Efficiency

While the initial setup costs for SMT manufacturing can be higher due to specialized equipment, the overall cost savings can be substantial. The automated processes used in SMT production reduce labor costs and increase throughput. Additionally, the ability to use smaller components can lower material costs. Many manufacturers have reported significant reductions in production time and costs after transitioning from traditional assembly methods to SMT processes.

5. Enhanced Reliability

SMT components are generally more reliable than traditional components due to their lower profile and reduced mechanical stress during operation. The soldering process used in SMT creates strong bonds between the component and PCB, enhancing durability and resistance to environmental factors such as vibration and temperature fluctuations. This reliability is crucial in applications where failure is not an option—such as aerospace or medical devices.

Applications of SMT Components

The versatility of SMT components has led to their widespread use across various industries:

Consumer Electronics

In consumer electronics, SMT components are integral to devices such as smartphones, laptops, televisions, and gaming consoles. Their compact size allows manufacturers to produce sleek designs without sacrificing functionality. The gaming industry has particularly benefited from this technology; consoles now include advanced graphics processing units (GPUs) and other complex circuitry that would be impossible without compact component design.

Automotive Industry

The automotive industry increasingly relies on SMT technology for advanced driver-assistance systems (ADAS), infotainment systems, and electric vehicle (EV) technologies. The reliability and performance of SMT components are critical for safety applications such as collision avoidance systems and automated driving features. As vehicles become more automated and interconnected through IoT technologies, the role of SMT will only expand.

Medical Devices

In medical technology, precision is paramount. SMT components are used in diagnostic equipment, monitoring devices, and implantable technologies where reliability and size constraints are crucial. Devices such as pacemakers rely on miniaturized electronics that can function effectively within limited space while maintaining high levels of performance.

Telecommunications

Telecommunications equipment benefits from the high-density capabilities of SMT components. They are used in routers, switches, and mobile communication devices where performance is essential for data transmission. As networks evolve towards higher speeds with technologies like 5G and beyond, efficient PCB designs utilizing SMT will be critical for managing increased data loads.

The Evolution of Surface Mount Technology

The journey of Surface Mount Technology began in the 1960s when it was initially referred to as "planar mounting." The first significant implementations were by IBM in small-scale computers. However, it was not until the 1980s that SMT gained widespread acceptance in PCB manufacturing due to its advantages over traditional methods.

Over the years, several stages marked its development:

- 1970s: Initial applications focused on hybrid integrated circuits.

- 1980s: Rapid miniaturization led to broader adoption across consumer electronics.

- 1990s: Most high-tech electronic assemblies transitioned to surface mount devices.

- 2000s onward: Advances in micro-assembly techniques have allowed even greater density and complexity in PCB designs.

This historical context underscores how integral SMT has become in facilitating technological advancements across various sectors.

Future Trends in SMT Technology

As technology continues to evolve, several trends are shaping the future of SMT components:

1. Increased Automation

With advancements in robotics and artificial intelligence (AI), automation in manufacturing processes will continue to rise. Automated assembly lines will enhance efficiency while reducing human error. Companies are investing heavily in smart factories where machines communicate with each other to optimize production schedules based on real-time demand forecasts.

2. Advanced Materials

Research into new materials will lead to improved performance characteristics for SMT components. Innovations such as flexible electronics may allow for new applications in wearable technology—enabling devices that conform comfortably to human bodies while maintaining functionality.

3. Sustainability

As environmental concerns grow, manufacturers will focus on creating eco-friendly SMT components. This includes using recyclable materials and reducing waste during production processes. Additionally, there is a growing emphasis on developing lead-free soldering techniques that comply with international regulations aimed at reducing hazardous substances.

4. Internet of Things (IoT)

The rise of IoT devices will drive demand for smaller, more efficient SMT components capable of supporting connectivity features while maintaining low power consumption. As smart homes become more prevalent with interconnected appliances communicating seamlessly with each other via IoT platforms, robust yet compact electronic solutions will be essential.

Challenges Facing the SMT Industry

Despite its many advantages, the SMT industry faces several challenges:

- Heat Dissipation: As component density increases, managing heat becomes critical to prevent failures. Advanced cooling solutions must be developed alongside new designs to ensure long-term reliability.

- Complex Assembly Processes: The integration of advanced technologies like AI requires sophisticated assembly methods that can handle intricate designs without compromising quality.

- Environmental Regulations: Compliance with regulations such as RoHS mandates that manufacturers adapt their processes to use lead-free solders and environmentally friendly materials.

Addressing these challenges requires significant investment in research and development as well as ongoing training for personnel involved in manufacturing processes.

Conclusion

In conclusion, SMT components play a crucial role in modern electronics by enabling miniaturization, increasing component density, improving performance, enhancing reliability, and providing cost efficiencies. Their applications span various industries including consumer electronics, automotive technology advancements like electric vehicles or ADAS systems integration; medical device innovations ensuring patient safety; telecommunications infrastructure supporting rapid data transmission demands—all showcasing how integral these small yet powerful elements have become within our daily lives today!

As technology advances further—with trends like automation reshaping manufacturing landscapes; research breakthroughs driving material science forward; sustainability initiatives pushing eco-friendly practices; IoT proliferation requiring smarter solutions—the importance of these tiny but mighty electronic building blocks will only continue growing within our interconnected digital world!

FAQ

1. What are the main advantages of using SMT over through-hole technology?

SMT offers several advantages over through-hole technology including reduced size and weight of devices; increased component density on PCBs; improved electrical performance due to shorter lead lengths; cost efficiency through automated manufacturing processes; enhanced reliability due stronger solder joints formed during assembly processes ensuring durability against environmental factors encountered during operation cycles over time!

2. What types of products commonly use SMT components?

SMT components are widely used across various sectors including consumer electronics like smartphones/laptops; automotive applications such as advanced driver-assistance systems (ADAS); medical devices including diagnostic equipment/monitoring systems; telecommunications infrastructure supporting routers/switches facilitating seamless communication networks worldwide!

3. How do I choose between different types of SMT components?

Choosing between different types depends on specific application requirements such as size constraints; electrical specifications (like resistance/capacitance); power ratings needed under operational conditions; environmental factors influencing performance longevity over time—all while considering cost-effectiveness based upon budgetary limitations imposed during design phases prior production commencement!

4. Are there any disadvantages associated with using SMT?

While there are many advantages associated with utilizing these technologies—some challenges exist too! Potential difficulties arise during manual assembly processes due small sizes involved making handling tricky at times; heat dissipation issues may occur if not managed properly leading potential failures down line; soldering problems might arise if not executed correctly causing defects impacting overall quality assurance measures put place throughout production cycles—plus initial setup costs could be higher than traditional methods requiring careful financial planning beforehand!

5. What future trends should I be aware of regarding SMT technology?

Future trends include increased automation within manufacturing processes driven by advancements robotics/AI technologies enabling smarter factories optimizing production schedules based real-time demand forecasts; research into advanced materials improving performance characteristics leading potential new applications flexible electronics/wearable tech innovations emerging rapidly across markets worldwide—while sustainability initiatives focusing eco-friendly production practices gain traction globally ensuring compliance regulations reducing hazardous substances utilized throughout supply chains!