Content Menu

● Understanding Fine Pitch SMT Components

>> Characteristics of Fine Pitch Components

● Advantages of Using Fine Pitch SMT Components

● Applications of Fine Pitch SMT Components

>> Consumer Electronics

>> Telecommunications

>> Medical Devices

● Challenges in Fine Pitch PCB Design

● Best Practices for Fine Pitch PCB Assembly

● Future Trends in Fine Pitch Technology

● Conclusion

● FAQ

>> 1. What are fine pitch SMT components?

>> 2. Why are fine pitch components important?

>> 3. What challenges do fine pitch PCB designs face?

>> 4. How can manufacturers ensure successful assembly of fine pitch PCBs?

>> 5. In what industries are fine pitch SMT components commonly used?

● Citations:

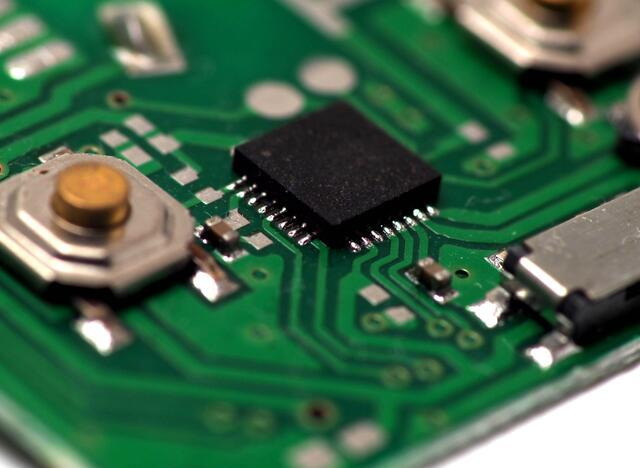

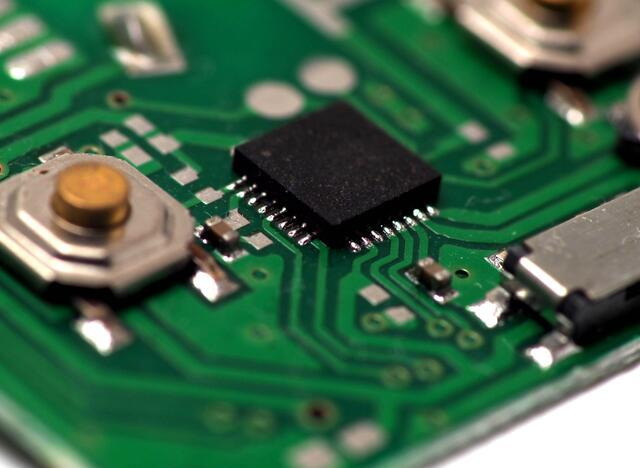

In the rapidly evolving landscape of electronics, the demand for smaller, more efficient devices has surged. This trend has led to the increased use of fine pitch SMT (Surface Mount Technology) components, which are essential for modern circuit boards. These components allow for higher density, improved performance, and greater reliability in electronic devices. This article delves into the significance of fine pitch SMT components, exploring their advantages, applications, challenges, and best practices in PCB design and assembly.

Understanding Fine Pitch SMT Components

Fine pitch SMT components refer to surface-mounted devices where the distance between leads or pads is significantly reduced, typically 0.65 mm or less. This compact design enables a higher concentration of components on a circuit board, which is crucial for modern electronics that prioritize miniaturization and functionality.

Characteristics of Fine Pitch Components

- High Density: Fine pitch components allow for a greater number of devices per square inch on a PCB.

- Compact Size: These components are smaller than traditional counterparts, making them ideal for space-constrained applications.

- Improved Performance: The close placement of components can enhance signal integrity and reduce electromagnetic interference.

Advantages of Using Fine Pitch SMT Components

1. Space Efficiency: As devices become smaller, the need for compact circuit designs increases. Fine pitch components enable designers to maximize the use of available space on PCBs.

2. Enhanced Performance: The reduced distance between components can lead to improved electrical performance by minimizing the length of signal paths and reducing parasitic capacitance and inductance.

3. Cost-Effectiveness: Although fine pitch components may have a higher initial cost due to their complexity, they can lead to overall cost savings in manufacturing by reducing the size and weight of final products.

4. Versatility in Applications: Fine pitch SMT components are used across various industries, including consumer electronics, telecommunications, automotive, and medical devices.

5. Reliability: Surface mount technology generally offers better mechanical stability compared to through-hole components, as they are less prone to vibration and shock.

Applications of Fine Pitch SMT Components

Fine pitch SMT components are integral to numerous applications:

- Consumer Electronics: Smartphones, tablets, and wearables utilize fine pitch designs to accommodate advanced features in compact formats.

Consumer Electronics

- Telecommunications: High-density PCBs are essential for routers, switches, and other networking equipment that require efficient space utilization.

Telecommunications

- Medical Devices: Compact designs in medical equipment allow for portability and ease of use without compromising functionality.

Medical Devices

- Automotive Electronics: Modern vehicles incorporate numerous electronic systems that benefit from high-density circuit boards.

Challenges in Fine Pitch PCB Design

Despite their advantages, designing PCBs with fine pitch SMT components presents several challenges:

1. Soldering Issues: The small size of fine pitch components makes them susceptible to soldering defects such as bridging or insufficient solder paste application.

2. Placement Accuracy: High precision is required during the placement process; even minor misalignments can lead to functional failures.

3. Thermal Management: With increased component density, managing heat dissipation becomes critical to prevent overheating and ensure reliability.

4. Testing Difficulties: The close proximity of components can complicate testing processes, requiring advanced inspection techniques such as X-ray imaging.

5. Manufacturing Complexity: The assembly process for fine pitch components often requires specialized equipment and skilled labor, increasing production complexity.

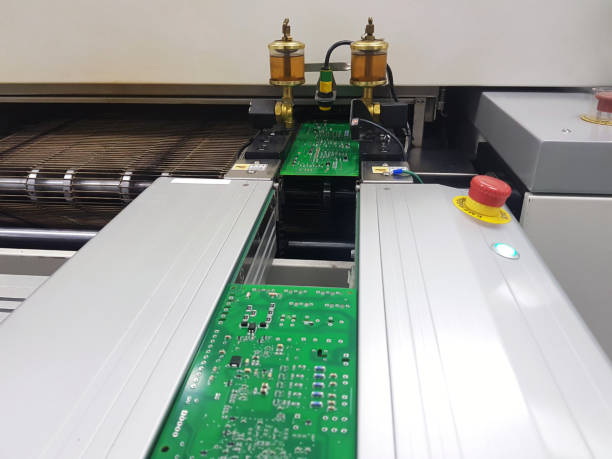

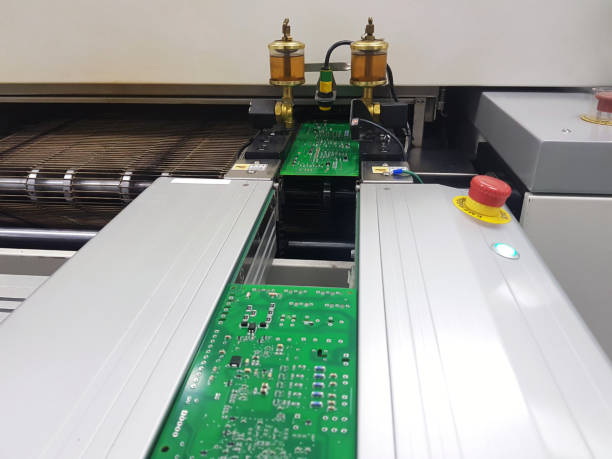

Best Practices for Fine Pitch PCB Assembly

To overcome these challenges, manufacturers can adopt several best practices:

- Use Advanced Stencil Designs: Custom stencil apertures can improve solder paste application by ensuring adequate coverage on small pads.

- Implement Vision Systems: Automated placement machines equipped with vision systems enhance accuracy by compensating for any alignment errors during component placement.

- Optimize Thermal Management Solutions: Incorporating thermal vias and heat sinks can help manage heat effectively in densely packed boards.

- Conduct Thorough Testing Procedures: Employing advanced testing methods ensures that all aspects of the assembly meet quality standards before deployment.

Future Trends in Fine Pitch Technology

As technology continues to advance, several trends are emerging that will shape the future of fine pitch SMT components:

1. Increased Integration: There is a growing trend towards integrating multiple functions into single packages (System-in-Package or SiP), which will further drive the need for fine pitch designs.

2. Advancements in Materials: New materials that offer better thermal conductivity and electrical performance will enhance the capabilities of fine pitch components.

3. Miniaturization Techniques: Continued miniaturization in electronics will push manufacturers to develop even finer pitch technologies while maintaining reliability.

4. Automation and AI in Assembly Processes: The integration of artificial intelligence in manufacturing processes will improve quality control and efficiency in assembling fine pitch PCBs.

5. Sustainability Initiatives: As environmental concerns grow, there will be an increasing focus on sustainable practices in PCB manufacturing, including the use of eco-friendly materials and processes.

Conclusion

Fine pitch SMT components play a pivotal role in the design and functionality of modern circuit boards. Their ability to facilitate high-density designs while enhancing performance makes them indispensable in today's electronics landscape. As technology continues to advance, understanding the importance and application of these components will be crucial for engineers and manufacturers alike. Embracing best practices and staying abreast of future trends will ensure that companies remain competitive in this fast-paced industry.

FAQ

1. What are fine pitch SMT components?

Fine pitch SMT components are surface-mounted devices with lead spacings typically 0.65 mm or smaller, allowing for high-density placements on printed circuit boards.

2. Why are fine pitch components important?

They enable compact designs that maximize space efficiency while improving electrical performance in various electronic applications.

3. What challenges do fine pitch PCB designs face?

Challenges include soldering issues, placement accuracy requirements, thermal management concerns, testing difficulties due to component proximity, and increased manufacturing complexity.

4. How can manufacturers ensure successful assembly of fine pitch PCBs?

By using advanced stencil designs, implementing vision systems for accurate placement, optimizing thermal management solutions, and conducting thorough testing procedures.

5. In what industries are fine pitch SMT components commonly used?

They are widely used in consumer electronics, telecommunications, medical devices, automotive electronics, and many other sectors requiring compact circuit designs.

Citations:

[1] https://www.pcbonline.com/blog/fine-pitch-pcb-assembly.html

[2] https://geospacemfg.com/blog/smt-assembly-technology/

[3] https://www.ourpcb.com/fine-pitch.html

[4] https://pl.hayawin.com/resources/what-is-smt-assembly-the-advantages-and-applications-of-smt.html

[5] https://madpcb.com/glossary/fine-pitch/

[6] https://www.hayawin.com/resources/what-is-smt-assembly-the-advantages-and-applications-of-smt-64f6e8bd90b55.html

[7] https://www.raypcb.com/pcb-pitch/

[8] https://www.intel.sg/content/dam/www/public/us/en/documents/packaging-databooks/packaging-chapter-07-databook.pdf

[9] https://www.ipc.org/system/files/technical_resource/E18&S07-1.pdf

[10] https://www.sfcircuits.com/pcb-production-capabilities/pcb-assembly/fine-pitch-pcb-assembly

[11] https://piektraining.com/en/faq-items/what-do-they-mean-by-fine-pitch-components/