Content Menu

● Understanding SMT PCB Loaders

>> Key Features of SMT PCB Loaders

● Ideal SMT PCB Loaders for Small-Batch Manufacturing

>> 1. Neoden Automatic Vacuum PCB Loader

>> 2. Hayawin SMT Loader

>> 3. CNSMT PCB Magazine Loader

● Factors to Consider When Choosing an SMT PCB Loader

>> 1. Production Volume and Flexibility

>> 2. Integration with Existing Equipment

>> 3. Maintenance and Support

>> 4. Cost-Effectiveness

>> 5. Space Constraints

● Benefits of Using SMT PCB Loaders in Small-Batch Manufacturing

>> Increased Efficiency

>> Improved Consistency

>> Enhanced Flexibility

>> Reduced Labor Costs

>> Minimized Handling Damage

● Case Study: Implementing an SMT PCB Loader in Small-Batch Production

● Future Trends in SMT PCB Loaders for Small-Batch Manufacturing

>> 1. Increased Automation and AI Integration

>> 2. Enhanced Connectivity and Data Analytics

>> 3. Greater Flexibility in PCB Handling

>> 4. Improved Energy Efficiency

>> 5. Integration of Inspection Capabilities

● Conclusion

● FAQ

>> 1. What is an SMT PCB Loader?

>> 2. How does an SMT PCB Loader benefit small-batch manufacturing?

>> 3. What features should I look for in an SMT PCB Loader for small-batch production?

>> 4. How do I determine the right SMT PCB Loader for my production needs?

>> 5. What future trends can we expect in SMT PCB Loaders for small-batch manufacturing?

● Citations:

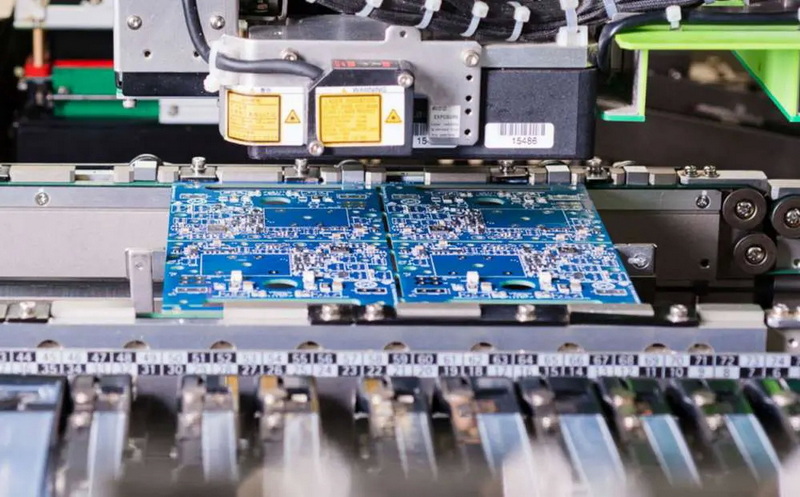

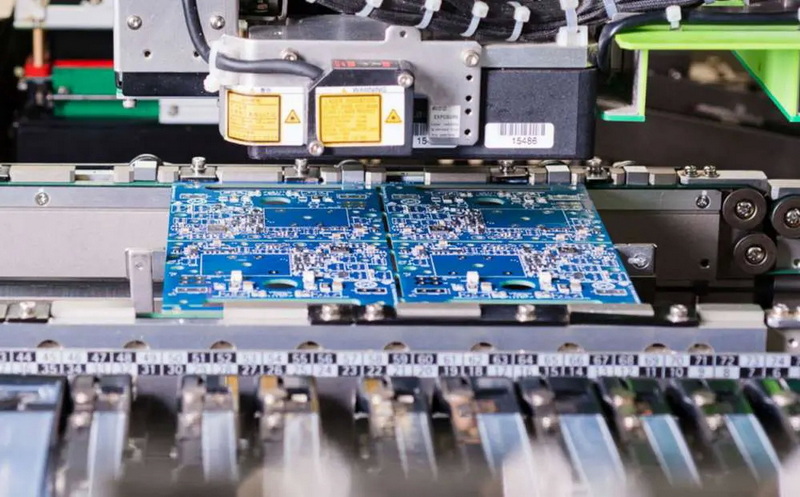

In the ever-evolving world of electronics manufacturing, small-batch production has become increasingly common. This trend has led to a growing demand for flexible and efficient equipment, particularly in the realm of Surface Mount Technology (SMT). One crucial component of the SMT process is the PCB loader, which plays a vital role in automating the production line. This article will explore the ideal SMT PCB loader for small-batch manufacturing, considering various factors such as efficiency, flexibility, and cost-effectiveness.

Understanding SMT PCB Loaders

SMT PCB loaders are essential machines in the electronics assembly process. They are designed to automatically feed printed circuit boards (PCBs) into the production line, eliminating the need for manual loading and improving overall efficiency[1]. These loaders are particularly crucial for small-batch manufacturing, where quick changeovers and flexibility are paramount.

Key Features of SMT PCB Loaders

When selecting an SMT PCB loader for small-batch manufacturing, several key features should be considered:

1. Adjustable PCB Size Handling: The ability to handle various PCB sizes is crucial for small-batch production, where product specifications may change frequently[2].

2. Quick Setup and Changeover: Rapid setup and changeover times are essential to maintain efficiency in small-batch manufacturing[3].

3. Compatibility: The loader should be compatible with other equipment in the SMT line and adhere to industry standards like SMEMA[4].

4. Reliability and Precision: Consistent and accurate PCB loading is vital to prevent production errors and maintain quality[5].

5. User-Friendly Interface: An intuitive control system allows for easy operation and quick adjustments[2].

Ideal SMT PCB Loaders for Small-Batch Manufacturing

1. Neoden Automatic Vacuum PCB Loader

The Neoden Automatic Vacuum PCB Loader is an excellent choice for small-batch manufacturing. It offers a range of features that cater to the needs of flexible production:

- Adjustable PCB Handling: It can accommodate PCB sizes from 50x50mm to 460x330mm, making it suitable for a wide range of products[1].

- Efficient Loading: With a loading time of approximately 6 seconds, it ensures quick throughput[1].

- User-Friendly Control: The PLC control system and customizable touch screen panel provide easy operation[1].

- Compatibility: Standard outlet for easy connection with other equipment[1].

2. Hayawin SMT Loader

The Hayawin SMT Loader is another strong contender for small-batch manufacturing:

- Versatile PCB Handling: It uses a four-cylinder clamp frame for accurate board placement[2].

- Quick Adjustments: Hand-cranked putter cylinder width adjustment system allows for convenient and quick changes[2].

- Advanced Control: PLC central control system ensures stable performance[2].

- Safety Features: Built-in fault search function and safety testing system with abnormal sound and light alarms[2].

3. CNSMT PCB Magazine Loader

CNSMT offers a customizable PCB Magazine Loader that is well-suited for small-batch production:

- Customizable Size: While 250mm width is standard, CNSMT can customize the loader to fit larger PCB sizes[3].

- Automation Benefits: It reduces manual labor and decreases pad oxide issues[3].

- High Precision: Uses high-precision SMT handspike for accurate input[3].

- Flexible Setup: Can set the function of single-up, with max times up to 10[3].

Factors to Consider When Choosing an SMT PCB Loader

1. Production Volume and Flexibility

For small-batch manufacturing, it's crucial to choose a loader that can handle varying production volumes efficiently. Look for loaders with quick setup times and easy adjustments for different PCB sizes[4].

2. Integration with Existing Equipment

Ensure that the chosen loader can seamlessly integrate with your existing SMT line. Check for compatibility with industry standards like SMEMA interfaces[4].

3. Maintenance and Support

Consider the availability of spare parts and technical support. Loaders from reputable manufacturers like Neoden or Hayawin often come with better after-sales service[4][5].

4. Cost-Effectiveness

While initial cost is important, also consider long-term factors such as energy efficiency, maintenance costs, and potential for increased productivity[7].

5. Space Constraints

Small-batch manufacturers often operate in limited spaces. Consider the dimensions of the loader and how it fits into your production floor layout[4].

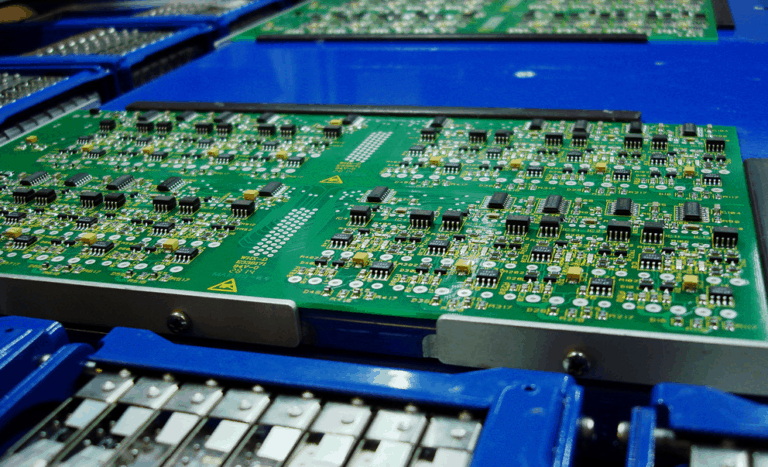

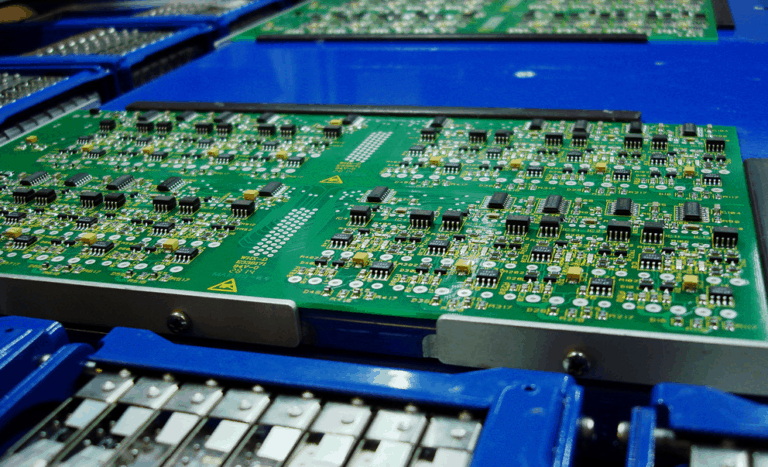

Benefits of Using SMT PCB Loaders in Small-Batch Manufacturing

Increased Efficiency

Automated PCB loading significantly reduces the time and labor required for manual loading, leading to increased production efficiency[8].

Improved Consistency

SMT PCB loaders ensure consistent and precise placement of PCBs into the production line, reducing errors and improving overall product quality[5].

Enhanced Flexibility

Modern SMT PCB loaders can handle a wide range of PCB sizes and types, making them ideal for the diverse requirements of small-batch manufacturing[1][2].

Reduced Labor Costs

By automating the PCB loading process, manufacturers can reduce labor costs and reallocate human resources to more value-added tasks[3].

Minimized Handling Damage

Automated loading reduces the risk of PCB damage that can occur during manual handling, leading to fewer defects and less waste[3].

Case Study: Implementing an SMT PCB Loader in Small-Batch Production

To illustrate the benefits of using an SMT PCB loader in small-batch manufacturing, let's consider a hypothetical case study of an electronics company, "ElectroFlex Inc."

ElectroFlex Inc. specializes in producing custom electronic devices for various industries. Their production runs typically range from 50 to 500 units per batch, with frequent changes in PCB specifications. Before implementing an SMT PCB loader, they faced several challenges:

1. Long setup times between batches

2. Inconsistent PCB placement leading to quality issues

3. High labor costs for manual loading

4. Limited production capacity due to slow manual processes

After careful consideration, ElectroFlex Inc. decided to invest in a Neoden Automatic Vacuum PCB Loader. The results were significant:

- Setup Time Reduction: Changeover time between batches decreased by 60%, allowing for more flexible production scheduling.

- Quality Improvement: Consistent and precise PCB loading reduced defects by 30%.

- Labor Efficiency: The company was able to reallocate two workers from PCB loading to more skilled tasks.

- Increased Capacity: Overall production capacity increased by 40% due to faster and more consistent loading.

- Cost Savings: Despite the initial investment, ElectroFlex Inc. saw a return on investment within 8 months through increased productivity and reduced labor costs.

This case study demonstrates how the right SMT PCB loader can significantly impact small-batch manufacturing operations, improving efficiency, quality, and flexibility.

Future Trends in SMT PCB Loaders for Small-Batch Manufacturing

As technology continues to advance, we can expect to see several trends in SMT PCB loaders that will further benefit small-batch manufacturers:

1. Increased Automation and AI Integration

Future SMT PCB loaders are likely to incorporate more advanced automation features and artificial intelligence. This could include self-adjusting mechanisms that optimize loading parameters based on PCB characteristics, further reducing setup times and improving accuracy[7].

2. Enhanced Connectivity and Data Analytics

With the rise of Industry 4.0, SMT PCB loaders will likely offer improved connectivity features, allowing for real-time monitoring and data collection. This data can be used to optimize production processes and predict maintenance needs[7].

3. Greater Flexibility in PCB Handling

As electronic devices continue to diversify, SMT PCB loaders will need to handle an even wider range of PCB sizes and types. Future models may offer more advanced adjustability features to accommodate this diversity[1][2].

4. Improved Energy Efficiency

With a growing focus on sustainability, future SMT PCB loaders are likely to incorporate more energy-efficient technologies, reducing operational costs and environmental impact[7].

5. Integration of Inspection Capabilities

Some SMT PCB loaders may incorporate basic inspection capabilities, allowing for early detection of PCB defects before they enter the production line. This could significantly reduce waste and improve overall quality[5].

Conclusion

Choosing the right SMT PCB loader is crucial for small-batch manufacturers looking to optimize their production processes. The ideal loader should offer flexibility in PCB handling, quick setup and changeover times, compatibility with existing equipment, and user-friendly operation. Options like the Neoden Automatic Vacuum PCB Loader, Hayawin SMT Loader, and CNSMT PCB Magazine Loader offer compelling features for small-batch production.

When selecting an SMT PCB loader, manufacturers should consider factors such as production volume, integration with existing equipment, maintenance and support, cost-effectiveness, and space constraints. The benefits of implementing an SMT PCB loader in small-batch manufacturing are significant, including increased efficiency, improved consistency, enhanced flexibility, reduced labor costs, and minimized handling damage.

As technology continues to advance, we can expect SMT PCB loaders to become even more sophisticated, with increased automation, enhanced connectivity, greater flexibility, improved energy efficiency, and potentially integrated inspection capabilities. These advancements will further support the needs of small-batch manufacturers in an increasingly dynamic and competitive electronics industry.

By carefully evaluating their specific needs and considering the features of available SMT PCB loaders, small-batch manufacturers can significantly improve their production processes, leading to increased competitiveness and profitability in the ever-evolving electronics market.

FAQ

1. What is an SMT PCB Loader?

An SMT PCB Loader is an automated machine used in electronics manufacturing to feed printed circuit boards (PCBs) into the production line. It's a crucial component in Surface Mount Technology (SMT) assembly processes, designed to improve efficiency and consistency in PCB handling[1][2].

2. How does an SMT PCB Loader benefit small-batch manufacturing?

SMT PCB Loaders offer several benefits for small-batch manufacturing:

- Increased efficiency through automated loading

- Improved consistency and reduced errors

- Enhanced flexibility to handle various PCB sizes

- Reduced labor costs

- Minimized risk of PCB damage during handling[3][8]

3. What features should I look for in an SMT PCB Loader for small-batch production?

Key features to consider include:

- Adjustable PCB size handling

- Quick setup and changeover times

- Compatibility with existing equipment (e.g., SMEMA compliance)

- User-friendly interface

- Reliability and precision in PCB placement[1][2][4]

4. How do I determine the right SMT PCB Loader for my production needs?

To choose the right SMT PCB Loader, consider:

- Your typical production volume and batch sizes

- The range of PCB sizes you work with

- Your available floor space

- Integration requirements with your existing SMT line

- Your budget for initial investment and ongoing maintenance[4][7]

5. What future trends can we expect in SMT PCB Loaders for small-batch manufacturing?

Future trends in SMT PCB Loaders may include:

- Increased automation and AI integration for self-optimization

- Enhanced connectivity for real-time monitoring and data analytics

- Greater flexibility in PCB handling to accommodate diverse product types

- Improved energy efficiency

- Potential integration of basic inspection capabilities[7]

Citations:

[1] https://www.neodensmt.com/other-products/smt-automatic-vacuum-pcb-loader.html

[2] https://www.hayawin.com/product-list-loader.html

[3] https://cnsmtline.com/pcb-magazine-loader/

[4] https://www.neodensmt.com/other-products/automatic-smt-pcb-loader.html

[5] https://www.charmhigh-tech.com/sale-14482662-automatic-pcb-loader-k1-250-smt-magazine-loader-for-smt-production-line.html

[6] https://shenzhenshengdian.en.made-in-china.com/product/SFOaZxvKiycl/China-Professional-PCB-Magazine-Loader-Unloader-SMT-Magazine-PCB-Loader-for-SMT-Production-Line.html

[7] https://www.smtfactory.com/I-C-T-Cost-effective-SMT-PCB-Assembly-Production-Line-with-High-Speed-pd40859564.html

[8] https://www.smtworldwide.com/pf/chi-pcb-loader/

[9] https://www.alibaba.com/product-detail/Low-Cost-Small-SMT-Production-Line_1600408463378.html