Content Menu

● Introduction to Surface Mount Technology

>> Types of Surface Mount Technology

● Industries Benefiting from Surface Mount Technology

>> Consumer Electronics

>> Automotive Industry

>> Telecommunications

>> Medical Devices

>> Industrial Automation

● Advantages of Surface Mount Technology

>> Increased Component Density

>> Improved Performance

>> Cost Efficiency

>> Enhanced Reliability

>> Flexibility in Design

● Conclusion

● Related Questions

>> 1. What are the main differences between Surface Mount Technology and Through-Hole Technology?

>> 2. How does Surface Mount Technology impact PCB design?

>> 3. What are the common applications of Surface Mount Technology?

>> 4. What are the benefits of using Surface Mount Devices?

>> 5. What future trends can we expect in Surface Mount Technology?

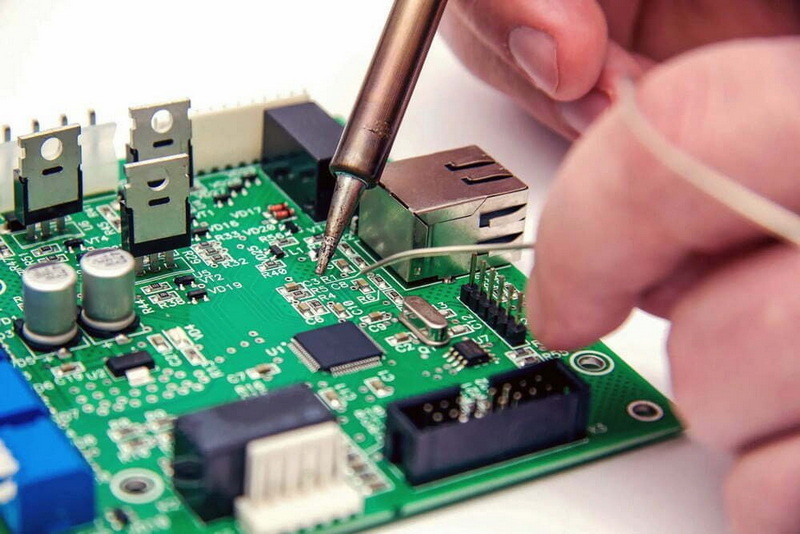

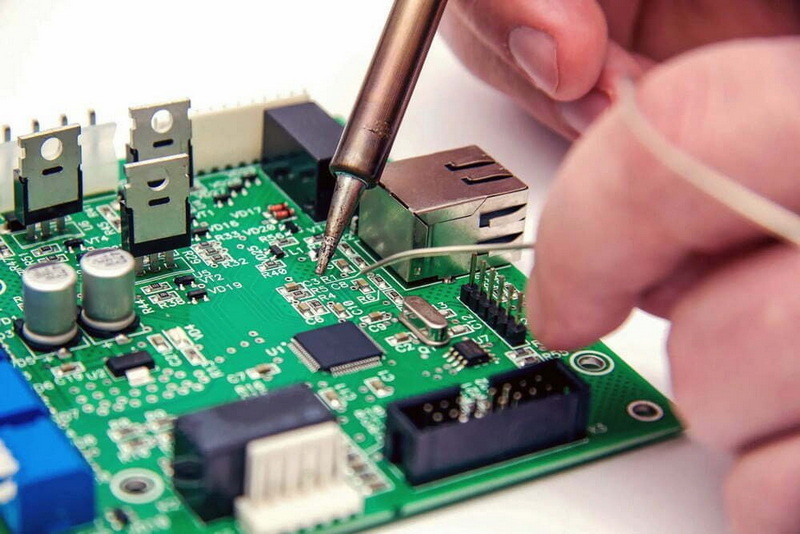

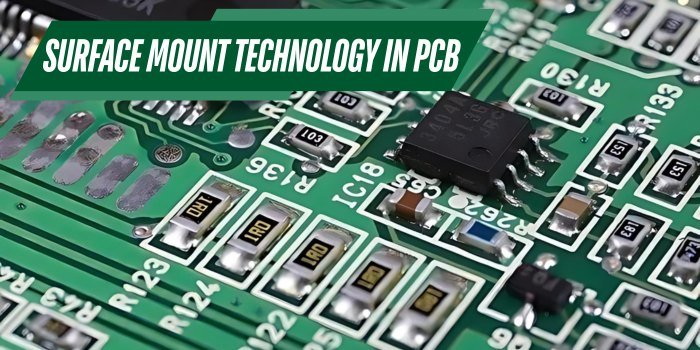

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing landscape, enabling the production of smaller, lighter, and more efficient devices. This article explores the various industries that benefit from SMT, the types of surface mount technology, and the advantages it brings to modern electronics.

Introduction to Surface Mount Technology

Surface Mount Technology is a method for mounting electronic components directly onto the surface of printed circuit boards (PCBs). Unlike traditional through-hole technology, where components are inserted into holes drilled in the PCB, SMT allows for a more compact design, which is essential in today's fast-paced technological environment. The components used in SMT, known as Surface Mount Devices (SMDs), include resistors, capacitors, transistors, and integrated circuits.

Types of Surface Mount Technology

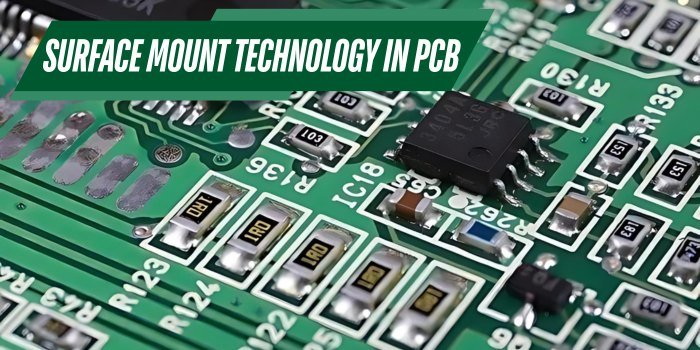

1. Chip Components: These are the most common type of SMDs, including resistors and capacitors that are small and flat.

2. Leadless Packages: These include devices like Quad Flat No-lead (QFN) and Ball Grid Array (BGA), which provide excellent electrical performance and thermal management.

3. Integrated Circuits: These are complex components that can perform multiple functions, often found in microcontrollers and processors.

4. Passive Components: These include inductors and capacitors that do not require a power source to operate.

Industries Benefiting from Surface Mount Technology

Consumer Electronics

The consumer electronics industry is perhaps the most significant beneficiary of SMT. Devices such as smartphones, tablets, and laptops require compact designs to accommodate advanced features while maintaining portability. SMT allows manufacturers to produce smaller devices with higher component density, leading to enhanced performance and functionality.

Automotive Industry

The automotive sector has increasingly adopted SMT for various applications, including engine control units, infotainment systems, and safety features. SMT enables the integration of more electronic components into vehicles, improving efficiency and performance. As vehicles become more reliant on electronics, the demand for SMT continues to grow.

Telecommunications

Telecommunications equipment, such as routers, switches, and base stations, relies heavily on SMT. The technology allows for the miniaturization of components, which is crucial for high-density applications. SMT also supports the rapid development of new technologies, such as 5G, by enabling faster and more efficient manufacturing processes.

Medical Devices

In the medical field, SMT is used in devices ranging from diagnostic equipment to wearable health monitors. The compact nature of SMT allows for the development of smaller, more portable medical devices that can be used in various settings, including home care. Additionally, the reliability of SMT is critical in medical applications where precision and safety are paramount.

Industrial Automation

The industrial automation sector benefits from SMT through the production of control systems, sensors, and robotics. SMT enables the creation of more sophisticated and compact control units that can operate efficiently in various environments. As industries move towards automation, the demand for SMT in this sector is expected to rise.

Advantages of Surface Mount Technology

Increased Component Density

One of the primary advantages of SMT is the ability to place more components on a PCB. This increased density allows for more complex circuits in a smaller footprint, which is essential for modern electronic devices.

Improved Performance

SMT components typically have shorter leads, which reduces the distance electrical signals must travel. This leads to improved performance, including faster signal transmission and reduced electromagnetic interference.

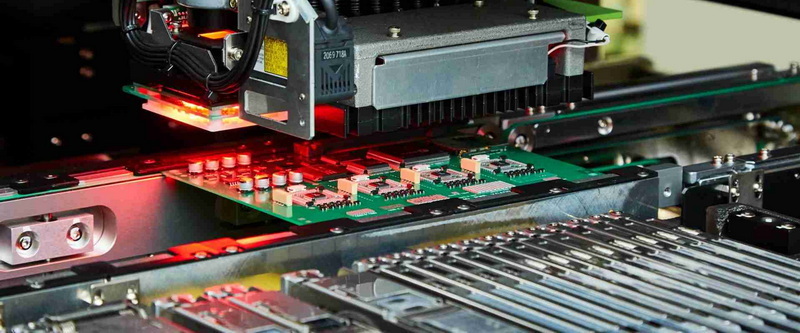

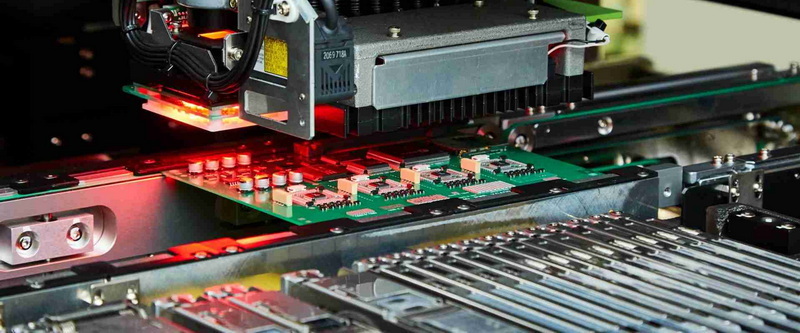

Cost Efficiency

While the initial setup for SMT can be higher due to the need for specialized equipment, the overall cost of production can be lower. SMT allows for faster assembly times and reduced material costs, making it a cost-effective solution for manufacturers.

Enhanced Reliability

SMT connections are generally more reliable than through-hole connections. The solder joints created during the SMT process are less prone to mechanical stress and environmental factors, leading to longer-lasting products.

Flexibility in Design

SMT provides designers with greater flexibility in PCB layout. The ability to place components on both sides of the board and the reduced size of components allows for innovative designs that were not possible with traditional methods.

Conclusion

Surface Mount Technology has transformed the electronics manufacturing industry, providing significant benefits across various sectors. From consumer electronics to automotive and medical devices, SMT enables the production of smaller, more efficient, and reliable products. As technology continues to evolve, the importance of SMT will only increase, driving innovation and shaping the future of electronics.

Related Questions

1. What are the main differences between Surface Mount Technology and Through-Hole Technology?

Surface Mount Technology (SMT) mounts components directly onto the surface of PCBs, while Through-Hole Technology requires components to be inserted into holes. SMT allows for higher component density and smaller designs, whereas Through-Hole is often used for larger components and provides better mechanical support.

2. How does Surface Mount Technology impact PCB design?

SMT allows for more compact and efficient PCB designs by enabling the placement of components on both sides of the board. This flexibility can lead to innovative designs and improved performance in electronic devices.

3. What are the common applications of Surface Mount Technology?

Common applications of SMT include consumer electronics (smartphones, tablets), automotive systems (engine control units), telecommunications equipment (routers, switches), medical devices (diagnostic tools), and industrial automation (control systems, sensors).

4. What are the benefits of using Surface Mount Devices?

The benefits of using Surface Mount Devices include increased component density, improved performance, cost efficiency, enhanced reliability, and greater design flexibility.

5. What future trends can we expect in Surface Mount Technology?

Future trends in SMT may include advancements in automation for assembly processes, the development of even smaller and more efficient components, and increased integration of smart technologies in various applications.