Content Menu

● Understanding SMT Production Lines

● Leading Manufacturers of SMT Production Lines

>> 1. Yamaha Motor Co., Ltd.

>> 2. Juki Corporation

>> 3. Panasonic Corporation

>> 4. ASM Assembly Systems

>> 5. Mycronic AB

● Types of SMT Production Lines Available

● Key Considerations When Purchasing an SMT Production Line

● Future Trends in SMT Production Lines

>> 1. Increased Automation

>> 2. Integration of AI

>> 3. Sustainability Practices

>> 4. Flexibility in Production

>> 5. Enhanced Testing and Quality Assurance

● Where to Buy SMT Production Lines

● Conclusion

● FAQ

>> 1. What is an SMT production line?

>> 2. How do I choose the right SMT machine?

>> 3. Are there financing options available for purchasing SMT equipment?

>> 4. What maintenance is required for SMT machines?

>> 5. Can I buy used SMT equipment?

● Citations:

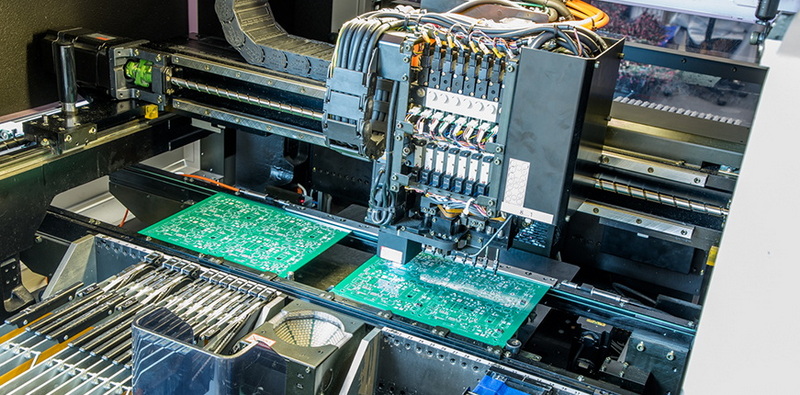

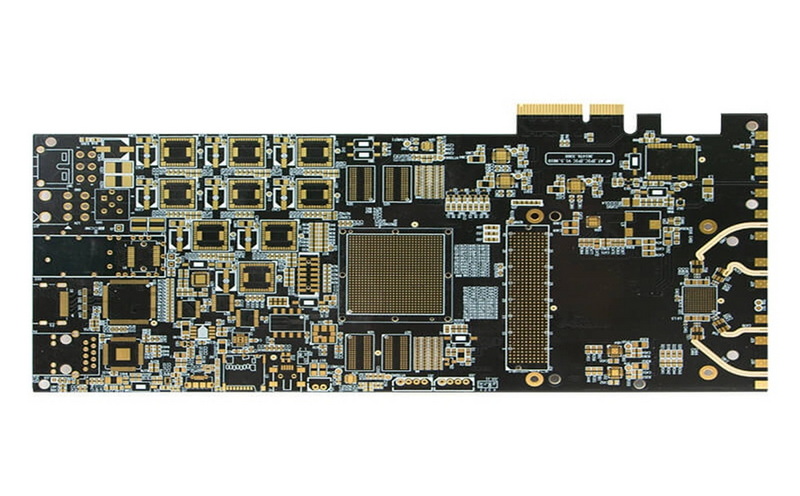

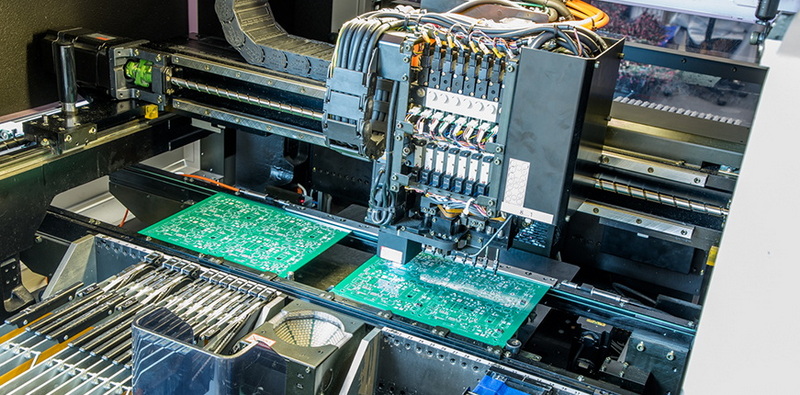

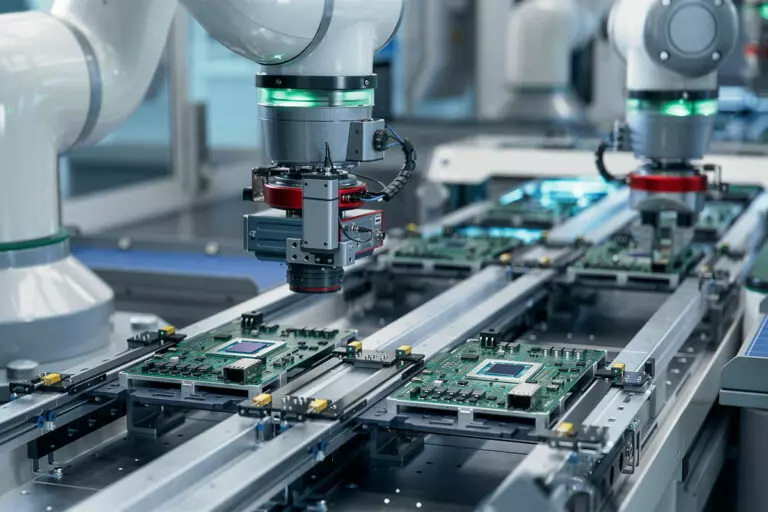

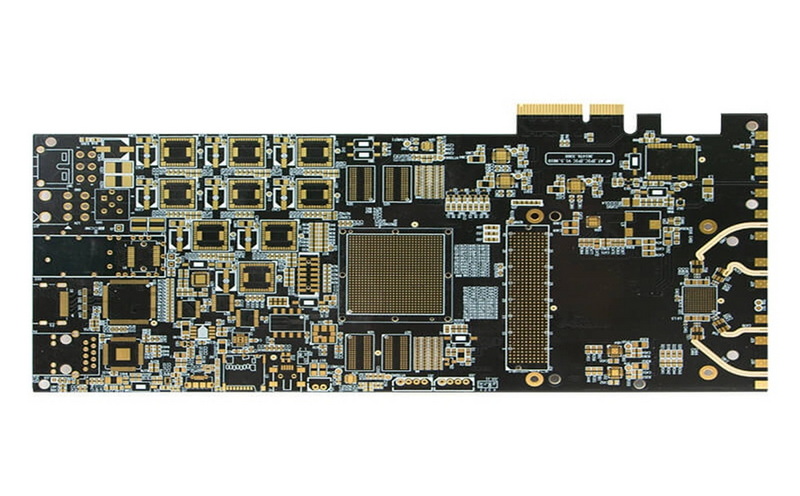

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by enabling the efficient assembly of electronic components onto printed circuit boards (PCBs). As demand for high-quality electronics continues to grow, finding the best SMT production line for sale becomes crucial for manufacturers looking to enhance their production capabilities. This article explores the leading manufacturers, types of SMT production lines available, key considerations when purchasing an SMT line, and future trends in the industry.

Understanding SMT Production Lines

SMT production lines consist of a series of machines that work together to automate the assembly of electronic components on PCBs. The main components typically include:

- Screen Printers: These machines apply solder paste to the PCB.

- Pick and Place Machines: They place surface mount components onto the PCB with high precision.

- Reflow Ovens: These are used to melt the solder paste, creating a strong bond between the components and the PCB.

- Inspection Systems: Automated Optical Inspection (AOI) systems check for defects in component placement and soldering.

The efficiency and accuracy of these machines directly impact production quality and speed, making it essential to select high-quality equipment.

Leading Manufacturers of SMT Production Lines

When searching for the best SMT production line for sale, it is important to consider reputable manufacturers known for their quality and innovation. Here are some of the top manufacturers in 2023:

1. Yamaha Motor Co., Ltd.

Yamaha is renowned for its high-speed pick-and-place machines, such as the YSM series, which offer exceptional accuracy and flexibility. Their machines can handle a variety of component sizes and types, making them suitable for diverse production needs.

2. Juki Corporation

Juki is a well-established name in SMT manufacturing, known for its reliable and cost-effective solutions. Their RS series of pick-and-place machines are particularly popular among small to medium-sized enterprises due to their excellent price-to-performance ratio.

3. Panasonic Corporation

Panasonic offers a comprehensive range of SMT equipment under its Panasert brand. Their machines are recognized for their precision and speed, making them ideal for high-volume production environments.

4. ASM Assembly Systems

Known for their SIPLACE brand, ASM provides a wide array of high-speed placement solutions that cater to various production needs. Their machines are designed for both high-mix low-volume and high-volume production.

5. Mycronic AB

Mycronic specializes in advanced pick-and-place solutions that emphasize speed and flexibility. Their MY300 model is particularly noted for its compact design and ability to populate more boards in less floor space.

Types of SMT Production Lines Available

SMT production lines can be categorized based on their configuration and automation level:

- Fully Automatic Lines: These lines require minimal human intervention and are ideal for high-volume production. They typically include advanced features like automatic feeders and integrated inspection systems.

- Semi-Automatic Lines: These lines require some manual input but still offer significant automation benefits. They are suitable for medium-volume production where flexibility is needed.

- Manual Lines: Best suited for low-volume or prototype runs, manual lines involve more human labor but can be cost-effective for smaller operations.

Key Considerations When Purchasing an SMT Production Line

When looking to invest in an SMT production line, several factors should be considered:

- Production Volume: Assess your current and future production needs to determine whether you need a fully automatic or semi-automatic line.

- Space Requirements: Ensure that the layout of your facility can accommodate the chosen equipment without compromising workflow efficiency.

- Component Types: Different machines have varying capabilities regarding component sizes and types; ensure that your chosen line can handle your specific requirements.

- Budget: Prices for SMT lines can vary significantly based on features and capabilities. Establish a budget that aligns with your operational goals while considering potential financing options.

- Support and Maintenance: Choose a manufacturer that offers reliable customer support and maintenance services to minimize downtime during operations.

Future Trends in SMT Production Lines

The landscape of SMT technology is continuously evolving due to advancements in automation, artificial intelligence (AI), sustainability practices, and integration with emerging technologies like the Internet of Things (IoT). Here are some key trends shaping the future of SMT production lines:

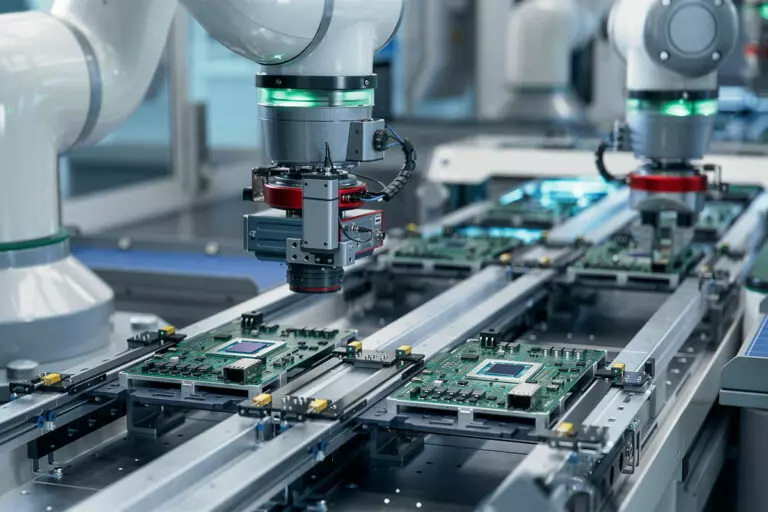

1. Increased Automation

Automation is becoming increasingly prevalent within SMT lines as manufacturers seek to reduce human error and increase efficiency. Fully automated systems that incorporate robotic arms for precise component placement, soldering, and inspection tasks are now common. This shift not only enhances productivity but also leads to higher-quality PCB assemblies with faster turnaround times[1][11].

2. Integration of AI

Artificial intelligence is set to play a significant role in optimizing SMT processes. AI algorithms can analyze vast amounts of data from manufacturing operations in real-time, enabling predictive maintenance, quality control, and process optimization[14][18]. This intelligent automation allows manufacturers to identify potential issues before they escalate, thereby improving overall product quality[14].

3. Sustainability Practices

As environmental concerns grow, sustainability has become a crucial focus in electronics manufacturing, including SMT production lines. Manufacturers are adopting eco-friendly practices such as using lead-free soldering materials and implementing energy-efficient processes[11][18]. The development of recyclable materials is gaining traction as well, contributing to a more sustainable future for the industry[11].

4. Flexibility in Production

The demand for customized electronics is on the rise, necessitating flexible manufacturing solutions capable of accommodating smaller batch sizes with greater variability in designs[1][4]. This trend drives manufacturers toward modular designs that allow quick adjustments based on changing market demands[15].

5. Enhanced Testing and Quality Assurance

As SMT components become more complex, there is an increasing need for advanced testing methods such as Automated Optical Inspection (AOI) and X-ray inspection systems[4][5]. These technologies ensure reliability by identifying defects early in the assembly process.

Where to Buy SMT Production Lines

Several avenues exist for purchasing SMT production lines:

- Direct from Manufacturers: Many leading manufacturers sell their equipment directly through their websites or sales representatives. This option often provides access to the latest models and technologies.

- Distributors: Authorized distributors can offer multiple brands, allowing you to compare options more easily. They may also provide additional services such as installation and training.

- Used Equipment Marketplaces: For budget-conscious businesses, purchasing pre-owned equipment from reputable marketplaces can be a viable option. Ensure thorough inspections and verification of equipment condition before purchase.

Conclusion

Finding the best SMT production line for sale involves understanding your specific needs, exploring reputable manufacturers, considering various factors such as budget, space requirements, support services, and staying abreast of future trends in technology. By investing in quality equipment from established brands like Yamaha, Juki, Panasonic, ASM Assembly Systems, or Mycronic, you can enhance your manufacturing capabilities while meeting growing demands in the electronics market.

FAQ

1. What is an SMT production line?

An SMT production line is a series of automated machines used in electronics manufacturing to assemble surface mount components onto printed circuit boards (PCBs). It typically includes screen printers, pick-and-place machines, reflow ovens, and inspection systems.

2. How do I choose the right SMT machine?

Consider factors such as your production volume, component types, available space, budget constraints, and desired level of automation when selecting an SMT machine.

3. Are there financing options available for purchasing SMT equipment?

Yes, many manufacturers offer financing options or leasing agreements to help businesses acquire new equipment without upfront costs.

4. What maintenance is required for SMT machines?

Regular maintenance includes cleaning components, checking calibration settings, updating software, and replacing worn parts to ensure optimal performance.

5. Can I buy used SMT equipment?

Yes, purchasing used SMT equipment can be cost-effective; however, it's crucial to verify the condition of the machinery through inspections before finalizing any purchase agreement.

Citations:

[1] https://www.mycronic.com/product-areas/pcb-assembly/news-and-press-releases/news/ten-key-smt-trends-you-need-to-know/

[2] https://www.swfuliusmt.com/2024/07/12/understanding-smt-lines-the-backbone-of-modern-electronics-manufacturing/

[3] https://www.neodensmt.com/news/improve-smt-production-efficiency-48868013.html

[4] https://www.marketsandmarketsblog.com/future-of-surface-mount-technology-paving-the-way-for-compact-electronics.html

[5] https://nyweekly.com/tech/exploring-pcba-and-smt-in-modern-electronics-manufacturing/

[6] https://www.viasion.com/blog/smt-assembly-and-its-advantages/

[7] https://www.adoptsmt.com/en/efficiency-enhancement-in-smt-manufacturing/

[8] https://emsginc.com/resources/the-evolution-of-surface-mount-technology/

[9] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[10] https://www.smtneoden.com/news/how-to-effectively-improve-the-production-efficiency-of-pcb-smt-machine/

[11] https://www.smtfactory.com/Future-Trends-in-SMT-Lines-Innovations-Shaping-The-Electronics-Manufacturing-Industry-id44863586.html

[12] https://www.wevolver.com/article/smt-process

[13] https://www.tronstol.com/how-to-optimize-smt-mounter-machine-equipment.html

[14] https://www.rhsmt.com/news/smt-industrys-future-trends-the-impact-of-ai-and-automation/

[15] https://www.pcbcart.com/article/content/smt-assembly-development-trend.html

[16] https://www.smtfactory.com/Exploring-SMT-Line-Cost-Factors-and-Savings-id43117676.html

[17] https://www.smtfactory.com/Perfecting-Your-SMT-Line-Layout-for-Efficiency-id47017676.html

[18] https://www.globenewswire.com/news-release/2024/10/14/2962707/28124/en/Surface-Mount-Technology-Equipment-SMT-Market-to-Surge-to-8-32-Billion-by-2028-Global-Long-term-Forecast-to-2033.html

[19] https://m.smt11.com/blog/SMT-Field/SMT-Process-Status-and-Future-Development-Trends-2023.html

[20] https://www.allsmt.com/SMT-line-concept-assembly-manufacturing-production-Assembly

[21] https://www.raypcb.com/line-efficiency/

[22] https://smt.fuji.co.jp/en/topics/2858

[23] https://www.linkedin.com/pulse/advantages-smt-manufacturing-practical-cost-effective-nyn3c

[24] https://quality-line.com/smt-quality/

[25] https://smttoday.com/2024/07/29/smt-component-market-trends-and-win-sources-strategic-responses/

[26] https://www.pcbjhy.com/blog/pros-and-cons-of-smt-pcb-assembly/

[27] https://www.smthelp.com/methods-and-measures-to-improve-the-production-efficiency-of-smt-production-line

[28] https://www.renishaw.com/resourcecentre/download/feature-article-why-future-smt-placement-needs-absolute-encoder-feedback--84260?userLanguage=tw

[29] https://www.zjyingxing.com/info/what-is-the-future-of-smt-machine-82208106.html